FFC AUTORAKE LAF6866 Owner's manual

Farmers’ Factory Company

AUTORAKE ®

OWNER'S & OPERATOR'S MANUAL

Models covered:

LAF6866,

LAF6876

OWNER'S & OPERATOR'S MANUAL

FFC PART # MR15595

FARMERS’ FACTORY COMPANY

100 EAST LEE ROAD

LEE, IL 60530

1-800-747-2132

06-23-00

TABLE OF CONTENTS

Introduction, General Information, Serial Number…………………………………………….1

Owner and Operator Safety Information..............................…..................................….2-5

Definitions of Safety Terms and Symbols, Accident Prevention....………..………2

Safety Instructions..................……....................................................................3-4

Safety Signs...............................……...….............................................................5

Power Unit Specifications, Mounting, Hydraulic

Connection………………..…....................6 Operation

............................................................……......................................................7-8

Maintenance ......................……...........................................................…………….............8

Service

..….........................................………...........…...…..............................................…9 Parts

Illustration.................................……..................................................……................10

Parts List..................................................……..............................................................11-

12 Specifications

.................……..........…..............................................................................13 Warranty

...........................................…..........…….....................................….............….....i

INTRODUCTION

Congratulations on your purchase of a new Farmers’ Factory Company AutoRake®. This product has been

designed and built to remove small rocks (less than 6” maximum dimension) and debris from loose soil and the sifting of

the surface layer of that soil. You or any other person who will be assembling, operating, maintaining, or working with this

product are required to read and completely understand the information and instructions contained in this manual. If

anyone does not fully understand every part of this manual, please obtain further assistance by contacting the dealer from

which this product was purchased or by contacting FFC at the telephone number or address listed on the cover of this

manual. Keep this manual available for reference whenever this product is being handled or used. Provide this manual

to any new owners and/or operators.

This manual covers model(s) LAF6866 and LAF6876. The difference between the models is the width of the

product, details of which are covered on the parts list and specifications page(s).

GENERAL INFORMATION

The purpose of this manual is to assist in assembling, mounting, operating, and maintaining your AutoRake®.

Read this manual carefully to obtain valuable information and instructions that will help you achieve years of safe and

dependable service.

The illustrations and data used in this manual were current at the time of printing, but due to possible engineering

and/or production changes, this product may vary slightly in detail. FFC reserves the right to redesign and/or change

components as may be necessary without notification to anyone.

Throughout this manual, references may be made to:

Power Unit The engine-driven machine to which this product must be attached.

Right, Left, Front, Rear Directions that are determined in relation to the operator of the equipment when

seated in the normal operating position.

IMPORTANT Precautions that must be followed to prevent damage to equipment.

NOTICE Precautions that must be followed to prevent substandard performance.

SERIAL NUMBER LOCATION

Always refer to the model and serial number when ordering parts or requesting information from your dealer. The

serial number plate for this product is located on the top left side of the bucket portion of your AutoRake®.

Reference Information

Model Number _______________________ Loader Make ____________________________

Serial Number _______________________ Loader Model ____________________________

Date Purchased _______________________ Loader Serial # ____________________________

1

DEFINITION OF SAFETY TERMS AND SYMBOLS

Throughout this manual, the terms DANGER, WARNING, and CAUTION are used to indicate the degree of

hazard to personnel if proper safety procedures are not followed. These words will be used in conjunction with the Safety

Alert Symbol: a dark triangle containing a white exclamation mark.

The Safety Alert Symbol means:

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

DANGER Indicates an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury;

OR

mayalso be used to alert against unsafe practices that may result in personal injury.

ACCIDENTS CAN BE PREVENTED WITH

YOUR HELP !

No accident prevention program can be successful

without the wholehearted cooperation of the person who

is directly responsible for the operation of the equipment.

To read equipment accident reports from all over the

country is to be convinced that a large number of

accidents can be prevented only by operators who

consistently anticipate the results of their actions and

thus prevent accidents from ever occurring. No power-

driven equipment, whether it is on the highway, in a farm

field, or in an industrial plant, can be any safer than is

allowed by the person who is at the controls.

If accidents are to be prevented (and accidents can be

prevented), that prevention will come from equipment

operators who accept their complete responsibility.

The designer, the manufacturer, and the safety engineer

all help create a safe product, but the operator of that

product can wipe out their combined efforts with a single

careless act.

The best safety device is a careful operator. FFC and

your dealer ask that YOU be that careful, responsible

equipment operator.

YOU ARE THE KEY TO SAFETY BECAUSE:

YOU are responsible for the SAFE operation and

maintenance of YOUR AutoRake®.

YOU are responsible to familiarize yourself, and anyone

else who will assemble, operate, maintain, or work

around this product, with the SAFETY information

contained in this manual.

YOU are responsible to read ALL information contained

in this manual to any operators or maintenance person-

nel who are not fully able to read the written English

language. Whether YOU read the manual as written or

translate it into another language, YOU must make cer-

tain that all operators and maintenance personnel have

a complete understanding of the full and exact contents

of this manual. Translations of this manual into other

languages are available by submitting an order to FFC.

YOU can reduce the risk of injury or death by following

all safety precautions and by using good safety

practices.

2

SAFETY INSTRUCTIONS

WORK SAFELY - A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST ACCIDENTS !!

SECTION 1

WARNING

Obey all the safety instructions listed in

this section and throughout this manual.

Failure to obey instructions in this

section could result in death or serious

injury.

BEFORE ATTEMPTING ANY TYPE OF ASSEMBLY,

OPERATION, MAINTENANCE, OR OTHER WORK ON

OR NEAR THIS PRODUCT:

•READ AND COMPLETELY UNDERSTAND THIS

MANUAL.

•READ AND COMPLETELY UNDERSTAND THE

MANUALS PROVIDED WITH YOUR power unit,

loader, and quick-attach.

•Read and understand all safety signs on this product

and on your power unit, loader, and quick-attach.

•Know all your controls and know how to quickly stop

all power unit movement, the AutoRake®movement,

and the engine in case of an emergency.

•Know and obey all applicable government rules,

O.S.H.A. regulations, local laws and other

professional guidelines for your operation.

•Make sure that anyone who will be assembling,

mounting, maintaining, repairing, removing, and/or

storing this product:

•has been instructed in the safe operation of this

product and of the power unit, loader, and quick-

attach to which this product is attached.

•is physically and mentally capable of the safe

operation of this type of equipment.

•is not under the influence of drugs or alcohol.

•is carefully supervised from a safe distance,

especially if such person is inexperienced.

•wears appropriate protective equipment (i.e.

hardhat, safety glasses, work gloves, protective

shoes, respirator, ear protection, etc.).

•does not wear loose fitting clothing, loose or

uncovered hair, or any accessories (jewelry,

necktie, scarf, wrist watch, etc.) that can catch in

moving parts.

•has annually reviewed all safety instructions.

•Know and follow good work practices when

assembling, mounting, maintaining, repairing,

removing, and storing this product:

•Work on a level surface in a well-lit area.

•Keep the area clean and dry.

•Use properly grounded electrical outlets & tools.

•Use the right tool for the job at hand.

•Make sure that your tools are in good condition

for performing the desired function.

•When using tools, wear the protective

equipment specified by the tool manufacturer.

(i.e. hardhat, safety glasses, work gloves,

protective shoes, etc.)

WHEN YOUR POWER UNIT IS USED DURING ANY

TYPE OF ASSEMBLY, OPERATION, MAINTENANCE,

OR OTHER WORK ON OR NEAR THIS PRODUCT:

•Before leaving the operator’s station or before

beginning any type of work on this product, lower

this product to the ground, apply your power unit’s

parking brake, stop the engine, remove the starter

key, wait for all moving parts to stop, and then

relieve all pressure in the hydraulic lines. Refer to

your power unit’s operator’s manual for instructions

on how to relieve hydraulic pressure in lines.

•Know your loader’s safe lifting and operating

capacity and the weight of this product. See the

specifications in this manual for the weight of this

product and refer to your power unit’s and your

loader’s operator’s manuals for safe operating limits.

Lift capacity may be reduced if using a quick-attach.

•Never allow anyone, except the operator, to be

around the power unit or this product when either is

in motion. Do not startup unless others are clear of

the work area.

•Do not allow riders on this product or the power unit.

•Do not stand or climb on this product when raised.

•Never lift the lowest portion of the attachment plate

higher than 5’-0” above the ground.

•Do not place any part of your body under any part of

this product unless this product is securely resting

on adequate blocking or on the ground.

•Do not use blocking made of concrete blocks, logs,

buckets, barrels or any other material that could

suddenly collapse or shift positions. Do not use

wood or steel blocking that shows any signs of

material decay. Do not use blocking that is warped,

twisted, or tapered.

•Never operate controls from the ground. Operate

the controls only from the operator’s station.

•Never leave equipment unattended with the engine

running or with this product raised on the loader.

•Be aware of the added weight and width of this

product. Reduce travel speeds accordingly,

especially when traveling over rough ground.

•Keep this product close to the ground and under

control when transporting.

3

SAFETY INSTRUCTIONS

WORK SAFELY - A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST ACCIDENTS !!

SECTION 1 (CONTINUED)

WARNING

Obey all the safety instructions listed in

this section and throughout this manual.

Failure to obey instructions in this

section could result in death or serious

injury.

WHEN DEALING WITH HYDRAULICS DURING ANY

TYPE OF ASSEMBLY, OPERATION, MAINTENANCE,

OR OTHER WORK ON OR NEAR THIS PRODUCT:

•Hydraulic fluid under pressure can penetrate the

skin and cause serious injury or death. Hydraulic

leaks under pressure may not be visible!

•If any fluid penetrates the skin, GET IMMEDIATE

MEDICAL ATTENTION!!

•Wear safety glasses, protective clothing, and use a

sound piece of cardboard or wood when searching

for hydraulic leaks. DO NOT USE YOUR HANDS!

•Before connecting or disconnecting hydraulic hoses,

read your power unit’s operator’s manual for detailed

instructions on connecting and disconnecting

hydraulic attachments.

•Make certain that all parts meet the specifications for

this product when installing or replacing hydraulic

hoses or fittings.

•After connecting hydraulic lines:

•Slowly and carefully raise the loader and cycle

the rollback / dump cylinders to check hose

clearances and to check for any interference.

•Operate the hydraulics on this product to check

hose clearances and to check for any

interference.

•Make certain that the hoses cannot interfere

with or actuate the quick-attach mechanism.

•Make certain that hoses will not be pinched, or

get tangled, in any equipment.

•Do not lock the auxiliary hydraulics of your power

unit in the “ON” position.

•Refer to your power unit’s operator’s manual and

this manual for procedures and intervals, then

inspect and maintain the entire hydraulic system to

insure that the fluid remains clean, that all devices

function properly, and that there are no fluid leaks.

WHEN MOUNTING THIS PRODUCT TO YOUR

POWER UNIT:

•Refer to the operator’s manuals of your power unit,

your loader, and your quick-attach for special or

detailed mounting instructions.

•This product should fit onto the quick-attach or

loader arms of your power unit the same as the

original products that were designed by your loader /

quick-attach manufacturer.

•If this product does not fit properly, contact FFC

before operating.

•Never place your finger into the mounting plate or

loader holes. A slight movement of the power unit or

this product could cause serious injury.

BEFORE EACH USE, THOROUGHLY INSPECT THIS

PRODUCT AND:

•Make certain that all safety signs are in place and

legible. Refer to the safety sign page in this manual

for the placement of safety signs for this product.

•Replace all damaged or excessively worn parts and

hardware only with genuine FFC parts or with

properly rated fasteners, hydraulic hoses, or fittings.

•Make certain that all locking pins, latches, and

connection devices are properly installed and

secured.

•Make certain that all protective guards, canopies,

doors, etc. are in place and secure.

WHEN OPERATING THIS PRODUCT IN

ACCORDANCE WITH DESIGN INTENTIONS:

•Keep everyone at least nine feet away from the unit

when operating.

WHEN ADJUSTING, SERVICING OR REPAIRING

THIS PRODUCT:

•Make no modifications to your AutoRake®.

•When making repairs, use only genuine FFC parts

or, for fasteners, hydraulic hoses, or hydraulic

fittings, use only properly rated parts.

•Replacement parts, for parts with safety signs

attached, must also have safety signs attached.

SECTION 2

CAUTION

Obey all the safety instructions listed in

this section and throughout this manual.

Failure to obey instructions in this

section may result in personal injury.

•Do not use the top of this product as a step. Under

certain conditions, this area can be slippery.

4

SAFETY SIGN LOCATIONS

ITEM QTY. PART # - DESCRIPTION

1 1 RDL3141-Read Manual

2 1 RDL3129-Hydraulics

3 2 RDL3100-Stand Clear

4 1 RDL3101-Roll Over Hazard

5 1 RDL3102-Shields

6 2 RDL3178-No Step

INSTRUCTIONS

•Keep all safety signs clean and legible.

•Replace all missing, illegible, or damaged

safety signs.

•Replacement parts for parts with safety

signs attached must also have safety

signs attached.

•Safety signs are available, free of charge,

from your dealer or from FFC.

PLACEMENT OR REPLACEMENT OF SAFETY SIGNS

1. Clean the area of application with non-flammable

solvent, and then wash the same area with soap

and water.

2. Allow the surface to fully dry.

3. Remove the backing from the safety sign, exposing

the adhesive surface.

4. Apply the safety sign to the position shown in the

diagram above and smooth out any bubbles.

ITEM 1

ITEM 2 ITEM 3 ITEM 4

ITEM 5 ITEM6

5

POWER UNIT SPECIFICATIONS

IMPORTANT Exceeding any of the maximum recommended power unit specifications

CAN result in damage to this product and

WILL

void all FFC warranties.

DESCRIPTION SPECIFICATIONS

Rated net Engine Horsepower of Power Unit 110 maximum

Weight of Power Unit without Autorake 10,000 lbs. maximum

Hydraulic Pressure Output 4,000 psi. maximum

Rear Ballast As required to maintain full power unit stability.

(Note the Shipping Weight on page 13, then see the operator’s

manual(s) for your power unit, loader, and quick-attach for

ballasting needs.)

AUTORAKE®MOUNTING

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE®MOUNTING

1. Place this product on a firm, level surface that is large enough to safely accommodate this product, your power unit

and all workers involved in the mounting process.

2. Refer to the operator’s manual(s) for your power unit, loader, and quick-attach and follow the mounting instructions

contained therein.

3. Carefully raise the loader and cycle the rollback/dump cylinders to check clearances and to verify that all mounting

procedures have been successfully completed.

4. IMPORTANTLubricate all grease fittings before connecting this product to your power unit’s hydraulic

system. Refer to AUTORAKE®MAINTENANCE on page 8 and follow the instructions.

AUTORAKE®HYDRAULIC CONNECTION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE®HYDRAULIC CONNECTION

1. Disconnect the hydraulic hose quick couplers from one another and attach the quick couplers to your power unit as

per the instructions in your power unit’s operator’s manual.

2. Carefully raise the loader and cycle the rollback/dump cylinders to check hose clearances and to check for any

interference. Operate the hydraulic cylinder(s) on this product to make the same checks.

3. Cycle the hydraulic cylinder(s) on this product several times from fully retracted to fully extended until all air has been

completely removed from the cylinder(s).

NOTICE: When shipped, the hydraulic cylinder(s) on this product contained air or an air-fluid mixture. Also,

there are orifices beneath the port(s) in the hydraulic cylinder barrel(s) that will restrict the exit of that air. Failure

to remove all the air from the hydraulic cylinder(s) can cause uneven, jerky cylinder movement when the

hydraulic controls are being operated and unwanted cylinder movement when those controls are not being

operated.

WARNING

Do not lock the auxiliary hydraulics of your power unit in the “ON” position.

Failure to obey this warning could result in death or serious injury.

6

AUTORAKE®OPERATION

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE®OPERATION

WARNING

Failure to obey the following procedures could result in death or serious injury.

•Never lift this product above (a.) the operator’s eye level or (b.) to a height where visibility is

obstructed, whichever is lower.

•Do not roll back this product so far that the load falls off toward or on the operator.

•Do not lock the auxiliary hydraulics of your power unit in the “ON” position.

•Keep everyone at least nine feet away from the unit when operating.

CAUTION

Failure to obey the following procedures may result in personal injury.

•Do not use the top of this product as a step. Under certain conditions, this area can be slippery.

IMPORTANT Attempting to pick up large rocks, large tree branches, etc.

CAN result in damage to this product and

WILL

void all FFC warranties.

IMPORTANT Using this product to till compacted soil

CAN result in damage to this product and

WILL

void all FFC warranties.

Before using this product on an area, make sure that:

•the area is free of all boulders larger than 6” in diameter, all logs and large tree branches, all wire, all lumber, and any

other item that is too large for the bucket or could get wrapped around the rake chain, and

•the soil is relatively loose and any compacted areas have been tilled with another piece of equipment to a depth of 2”

or deeper.

RAKING

Keeping in mind that all raking must be done while moving backward, position your power unit and this product on the

area to be raked. To begin raking:

1. activate the auxiliary hydraulics for operating the rake chain,

(If the rake chain does not move but the hydraulic cylinder begins to retract, then activate the auxiliary hydraulics

in the opposite direction to get the rake chain to operate.)

2. lower the loader arms completely and set the loader arm control in the float position,

3. tilt this product forward until the weight of the rake portion is resting on the depth adjustment plates, and

4. move your power unit slowly backward.

To achieve the best possible results, please keep in mind that:

•If the rake is throwing too much soil into the bucket, then the depth adjustment plates should be placed in a lower hole

on the main housing.

•If the rake is slipping over items that should be collected, then the depth adjustment plates should be placed in a

higher hole on the main housing.

•Multiple passes may be needed to achieve the desired results depending on what those results are and what the

initial conditions are.

•The wide variety of soil types, moisture conditions, compaction levels, foliage densities, and rock and debris

quantities that can be encountered mean that the operator may need to make adjustments based upon the operator’s

experience.

IMPORTANT Opening the main housing and using the bucket for standard bucket operations

CAN result in damage to this product and

WILL

void all FFC warranties.

7

AUTORAKE®OPERATION (Continued)

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE®OPERATION

DUMPING

1. Shut off the auxiliary hydraulics.

2. Move to the dump site and park on firm, level ground.

3. Activate the auxiliary hydraulics in the direction opposite of what was used to operate the rake chain. This will retract

the hydraulic cylinder and open the main housing.

4. Raise this product about four feet above the ground.

5. Dump the bucket and reverse the process so that you are ready to resume raking.

AUTORAKE®MAINTENANCE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE®MAINTENANCE

BEFORE EACH USE

•Make sure that all nuts and bolts are in place and properly tightened.

•Make sure that all other fasteners are in place and are performing their specified function.

•Make sure that all hydraulic fittings are tightened and that there are no leaks in any fittings or hoses.

•Make sure that all safety signs are in place, are clean, and are legible.

(SEE THE SAFETY SIGN SECTION ON PAGE 5.)

•Replace any damaged parts and excessively worn parts. Replace the rake chain when the raking action has been

reduced to an inefficient level.

AFTER EVERY 10 HOURS OF USE

•Grease 11 fittings: one on each of the six bearings (one on each end of the two idler shafts and one on each end of

thedriveshaft),

two on each of the two swing arms where the main housing pivots on the bucket, and

one on the barrel end of the hydraulic cylinder.

AFTER EVERY 30 HOURS OF USE

•Check the drive chain and the rake chain tension and adjust if necessary. (See AUTO-RAKE SERVICE on page 9)

•The proper tension on the drive chain results in the longest run of chain having a 3/8” to 1/2” midpoint deflection.

•The proper tension on the rake chain results in the top run of chain (i.e. from the front idler shaft to the drive shaft)

having a 3/4” to 1” midpoint deflection. (Note: For this chain, the combined up and down midpoint deflection of 1-

1/2” to 2” may be easier to measure.)

•Check the rake chain travel to make sure that the chain is centered on the idlers. Adjust the front idler if centering is

necessary.

AFTER EVERY 250 HOURS OF USE

•Check the drive chain, the drive and driven sprockets, the drive shaft, and the idler shafts for excessive wear and

replace if necessary.

IMPORTANT Using heat to straighten bent rake chain teeth

CAN result in damage to this product and

WILL

void all FFC warranties.

•Check for bent rake chain teeth and cold straighten those teeth.

BEFORE EXTENDED STORAGE (More than 2 month)

•Oil the drive chain and all 3 rake chains.

8

AUTORAKE®SERVICE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE®SERVICE

1. Park your power unit on a level surface with this product properly attached.

2. Place your power unit’s transmission in “Park” and engage the parking brake.

3. Lower this product onto a level surface.

4. Shut off your power unit’s engine, remove the starter key, wait for all moving parts to come to a stop, and relieve all

pressure in the hydraulic lines.

DRIVE CHAIN ADJUSTMENT

5. Remove four bolts from the drive chain shield. (Two from the top-front face and two from the bottom-rear face.)

6. Remove the shield by pulling straight out to the left.

7. Loosen the nut on the idler sprocket and push the sprocket toward the chain until the opposite chain run (i.e. the

longest) has a midpoint defection of 3/8” to 1/2”.

8. Retighten the idler sprocket nut to 304 ft. lbs., + or - 22 ft. lbs.

9. Recheck the chain deflection and repeat steps 7 and 8 if the deflection is not within the above specified range.

10. Replace the drive chain shield and bolts. Tighten the bolts to 20 ft. lbs., + or - 2.0 ft. lbs.

RAKE CHAIN ADJUSTMENT

5. Loosen the four nuts that secure the bearing on one end of the front idler shaft. Repeat this process for the other end

of the front idler shaft.

6. For each of the two front idler shaft bearings, loosen the jam nut on the 5/8” dia. x 6” long tightener bolt.

7. Tighten the tightener bolts until a midpoint deflection of 3/4” to 1” between the idler shaft and the drive shaft has been

achieved for each of the roller chain portions of the rake chain. (By utilizing a tape measure and a long, slender hook

device, the combined up and down midpoint deflection of 1-1/2” to 2” may be easier to measure.)

8. Retighten the four nuts on each of the two bearings to 84 ft. lbs., + or - 6.0 ft. lbs. and retighten the jam nut on the two

tightener bolts to 169 ft. lbs., + or - 12 ft. lbs.

9. Recheck the chain deflection for compliance with the above specifications and check the chain travel to make sure

that the chain is centered on the idlers. Repeat steps 5 to 8 until both the specified deflection and desired line of

travel has been attained.

9

PARTS ILLUSTRATION

10

AUTORAKE®PARTS LIST

LAF6866 LAF6876

ITEM QTY. 66” 76” DESCRIPTION

1 1 LAF4216 Hydraulic Cylinder: 2” Dia. Piston x 8-1/2” Stroke x 1” Dia. Rod

With(2)#6MaleO-RingPorts

2 1 LAF4243 Hydraulic Hose Protector: 1-7/8” Dia. x 7’-9” Long

3 1 LAF4245 Hydraulic Hose Protector: 1-7/8” Dia. x 2-10” Long

4 1 LAF4082 Hydraulic Hose Protector: 1-7/8” Dia. x 2-2” Long

5 1 LAF4533 Hydraulic Control Block

6 2 LAF4252 Hydraulic Plug: Socket Head, Male #6 O-Ring Boss

7 1 LAF4528 Hydraulic Check Valve Cartridge: Male #10 O-Ring Boss

8 1 LAF4528 Hydraulic Relief Valve: Male #10 O-Ring Boss

9 1 LAF4278 Hydraulic Elbow: 90 Degree, Male #10 O-Ring Boss To Male #10 JIC

10 1 Contact FFC To Obtain The Correct Hydraulic Hose Quick Coupler: #10 Female O-Ring Boss,

Couplers (And Possibly Adapters). With Male Connection

11 1 Contact FFC To Obtain The Correct Hydraulic Hose Quick Coupler: #10 Female O-Ring Boss

Couplers (And Possibly Adapters). With Female Connection

12 2 LAF4360 Hydraulic Hose: 1/2” I.D. x 2’-6” Long W/ (1) #10 Female JIC & (1) #10

MaleO-RingBossFittings

13 1 LAF4307 Hydraulic Hose: 3/8” I.D. x 3’-8” Long W/ (2) #6 Female JIC Fittings

14 1 LAF4311 Hydraulic Hose: 3/8” I.D. x 2’-10” Long W/ (2) #6 Female JIC Fittings

15 2 LAF4514 Hydraulic Hose: 1/2” I.D. x 7’-9” Long W/ (1) #10 Female JIC & (1) #10

MaleO-RingBossFittings

16 2 LAF4406 Hydraulic Adapter: Male #6 O-Ring Boss To Male #6 JIC

17 3 LAF4414 Hydraulic Adapter: Male #10 O-Ring Boss To Male #10 JIC

18 1 LAF4417 Hydraulic Elbow: 90 Degree, Female #10 JIC To Male #10 JIC

20 1 LAF4584 Hydraulic Motor: 2 Bolt Flange With 1-1/4” Dia. Keyed Shaft

And 7/8” Dia. x 14 TPI Female O-Ring Boss Ports

21 2 LAF6801 Swing Arm

22 4 LAF6802 Swing Arm Pivot Bushing

23 4 LAF6803 Depth Adjustment Plate

24 1 LAF6804 Connecting Link: #80 Single Pitch

25 7 LAF6805 Washer: 13/32” I.D. x 1-27/32” O.D. x 1/4” Thick (Shaft End)

26 5 LAF6806 Shaft End Shield

27 1 LAF6807 Drive Chain Shield

28 2 LAF6808 Flange Mount Bearing: 1-7/16” I.D., 4 Bolt

29 4 LAF6809 Flange Mount Bearing: 1-7/16” I.D., 2 Bolt

30 2 LAF6810 Bearing Backplate

31 1 LAF6811 Drive Sprocket: 13 Tooth #80 With 1-1/4” Keyed Bore

32 1 LAF6812 Driven Sprocket: 13 Tooth #80 With 1-7/16” Keyed Bore

33 1 LAF6813 Idler Sprocket: 12 Tooth #80 With 3/4” I.D. Bearing

34 1 LAF6814 Roller Chain: #80 x 37 Links

35 1 LAF6815 Offset Connecting Link: #80

36 1 LAF9965 Washer: 41/64” I.D. x 2” O.D. x 5/16” Thick (Spring Retainer)

37 1 LAF6817 Spring: 1-3/4”O.D. x 4” Long, Coil Compression

38 2 LAF6818 Cylinder Rod Support Block Pivot Bushing

39 1 LAF6819 Cylinder Rod Support Block

40 1 LAF6820 Cylinder Rod Guide Tube

41 2 LAF6821 Cylinder Rod Wiper: 1” I.D.

42 2 LAF6822 Washer: 17/32” I.D. x 2-1/4” O.D. x 1/4” Thick (Guide Tube Retainer)

43 1 LAF6823 Cylinder Cross Tube Sleeve

NOTE: All parts are the same as the LAF6876 except for those parts numbered under the other models.

11

AUTORAKE®PARTS LIST (Continued)

LAF6866 LAF6876

ITEM QTY. 66” 76” DESCRIPTION

44 3 LAF6824 Connecting Link: #80 Double Pitch

45 1 LAF6867 LAF6877 Bucket Weldment

46 1 LAF6868 LAF6878 Main Housing

47 2 LAF6869 LAF6879 Rake Chain Shaft: Idler

48 1 LAF6870 LAF6880 Rake Chain Shaft: Drive

49 1 LAF6871 LAF6881 Rake Chain Weldment

50 4 RHW1203 Hex Head Cap Screw: 3/8” Dia. x 3/4” Long, Grade 5

51 7 RHW1205 Hex Head Cap Screw: 3/8” Dia. x 1” Long, Grade 5

52 2 RHW1218 Hex Head Cap Screw: 3/8” Dia. x 3-3/4” Long, Grade 5

53 2 RHW1403 Hex Head Cap Screw: 1/2” Dia. x 1” Long, Grade 5

54 2 RHW1406 Hex Head Cap Screw: 1/2” Dia. x 1-3/4” Long, Grade 5

55 2 RHW1666 Hex Head Cap Screw: 5/8” Dia. x 6” Long, Grade 5, Full Threads

56 4 RHW1707 Hex Head Cap Screw: 3/4” Dia. x 2-1/2” Long, Grade 5

57 1 RHW1715 Hex Head Cap Screw: 3/4” Dia. x 5” Long, Grade 5

58 8 RHW2406 Carriage Bolt: 1/2” Dia. x 1-3/4” Long, Grade 5

59 1 RHW2709 Carriage Bolt: 3/4” Dia. x 3” Long, Grade 5

60 4 RHW5262 Washer: 3/8” Dia. USS

61 2 RHW5462 Washer: 1/2” Dia. USS

62 16 RHW5732 Washer: 3/4” Dia. SAE

63 1 RHW5932 Washer: 1” Dia. SAE

64 6 RHW6202 Lock Washer: 3/8” Dia. Medium Split

65 18 RHW6402 Lock Washer: 1/2” Dia. Medium Split

66 2 RHW7201 Hex Nut: 3/8” Dia. With 16 Threads Per Inch

67 16 RHW7401 Hex Nut: 1/2” Dia. With 13 Threads Per Inch

68 8 RHW7403 Locknut: 1/2” Dia. Center Dent

69 2 RHW7601 Hex Nut: 5/8” Dia. With 11 Threads Per Inch

70 11 RHW8090 Grease Zerk: 1/4” Dia. With 28 TPI, Self-Tapping

71 1 RHW8115 Square Key: 5/16” x 5/16” x 1-1/4” Long (Drive)

72 1 RHW8116 Square Key: 3/8” x 3/8” x 2” Long (Driven)

73 12 RHW8226 Set Screw: 5/16” Dia. x 24 TPI x 1/4” Long, Socket Head

74 2 RHW8236 Socket Head Cap Screw: 1/2” Dia. x 1-1/2” Long, Grade 5

75 6 RHW8604 Locknut: 3/4” Dia. Flanged

76 1 RHW8605 Locknut: 5/8” Dia. With 18 Threads Per Inch, Top Lock

77 12 RHW2405 Carriage Bolt: 1/2” Dia. x 1-1/2” Long, Grade 5

78 2 LAF4298 Hydraulic Elbow: 90 Degree, Male #6 O-Ring to Male #6 JIC

79 2 RHW5970 Machinery Bushing – 2.25 OD. X 1.50 ID X 10 GA.

80 4 LAF9526 Spacer – 1.88 OD. X 0.25 Wall X 0.50

81 1 LAF4524 Hydraulic Orifice: 0.078 ID

82 1 LAF4527 Hydraulic Orifice: 0.142 ID

12

NUMBERS FROM HYDRAULIC CYLINDER ILLUSTRATION

1 1 LAF4105 Barrel: 2” I.D. x 8-1/2” Stroke With Internal Cross Tube End

2 1 LAF4106 Shaft: 1” Dia. With Turned Down 5/8-18 Threaded End

3 1 LAF4107 Head: 1” I.D., Nominal

4 1 LAF4108 Piston: 2” O.D. x 5/8” I.D., Nominal

5 1 RHW8605 Nut: 5/8” Dia., 18 TPI, Top Lock

6 1 LAF4109 Seal Kit (Includes All Seals, O-Rings, Etc.)

7 1 RHW8090 Grease Zerk: 1/4” Dia. With 28 TPI, Self-Tapping

NOTE: All parts are the same as the LAF6876 except for those parts numbered under the other models.

HYDRAULIC CYLINDER

ILLUSTRATION

AUTORAKE®SPECIFICATIONS

Model Overall Overall Overall Working No. of Bucket Shipping

Number Width Height Depth Width Teeth Capacity* Weight

LAF6866 74” 40” 64” 63.5” 432 13 cu. ft. 1,092 lbs.

LAF6876 84” 40” 64” 73.5” 504 15 cu. ft. 1,200 lbs.

All replacement hydraulic hoses and fittings must have a minimum rated working pressure of 4,000 psi.

TORQUE SPECIFICATION FOR STANDARD MACHINE HARDWARE

Bolt SAE Grade Torque Bolt SAE Grade Torque

Size Bolt Ft./Lbs Size Bolt Ft./Lbs

0.31-24 5 19 0.63-11 5 150

0.38-16 5 30 0.63-18 5 180

0.50-13 5 75 0.75-10 5 260

13

This manual suits for next models

1

Table of contents

Other FFC Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Krone

Krone EasyCut 2801 CV operating instructions

AGI

AGI A114 Assembly and operators manual

Checchi & Magli

Checchi & Magli UNITRIUM Use and maintenance manual

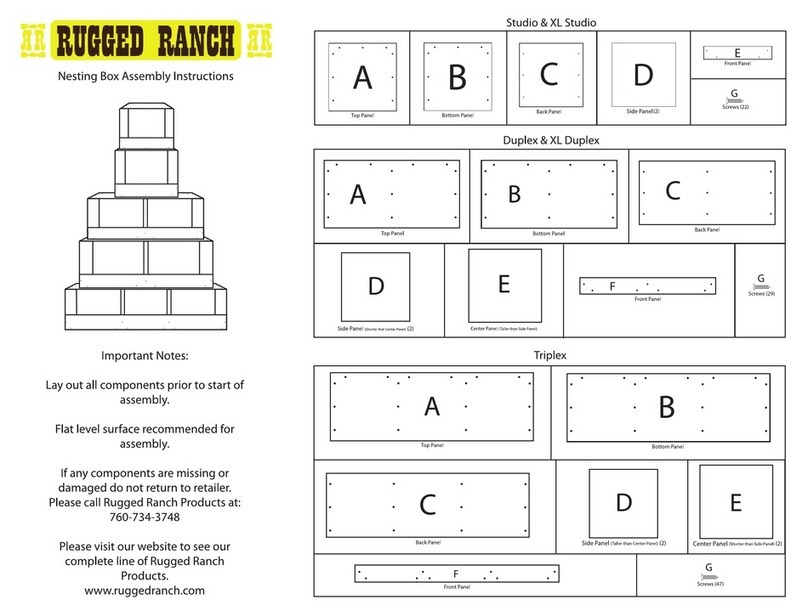

RUGGED RANCH

RUGGED RANCH Nesting Box Assembling instructions

Cima

Cima S520 Instructions for use and maintenance

AGI

AGI Westeel EasyFlow2 100 Series Assembly & installation manual