Fike FlamQuench II User manual

SOLUTIONS

Fire Protection

Explosion Protection

Overpressure Protection

Pressure Activation

INSTALLATION AND MAINTENANCE INSTRUCTIONS

FlamQuench II™

VENTING WITH FLAME AND PARTICLE

RETENTION - PASSIVE EXPLOSION

PROTECTION

Doc. 8.8520.00.5

Rev. April, 2019

COPYRIGHT INFORMATION

© Copyright 2017, Fike Corporation. All rights reserved. Printed in Europe.

This document may not be reproduced, in whole or in part, by any means without the prior written consent of Fike. All

Fike documentation and hardware are copyrighted with all rights reserved.

TRADEMARKS

Fikeis a registered trademark of Fike. All other trademarks, trade names or company names referenced herein are

the property of their respective owners.

ERRORS AND OMISSIONS

While every precaution has been taken during the preparation of this document to ensure the accuracy of its content,

Fike assumes no responsibility whatsoever for errors or omissions.

Fike reserves the right to change product designs or specifications without obligation and without further notice in

accordance with our policy of continuing product and system improvement.

READER QUESTIONS AND RESPONSES

If you have any questions regarding the information contained in this document, or if you have any other enquiries

regarding Fike products, please call Fike Europe Product Support at 0032 14 21 00 31.

Fike encourages input from our distributors and end users on how we can improve this manual and even the product

itself. Please direct all calls of this nature to Fike Europe Product Support at 0032 14 21 00 31. Any communication

received becomes the property of Fike.

TERMS AND CONDITIONS OF SALE

Because of the many and varied circumstances and extreme conditions under which Fike’s products are used, and

because Fike has no control over this actual use, Fike makes no warranties based on the contents of this document.

FIKE MAKES NO IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A SPECIFIC PURPOSE. Refer to

www.fike.com/terms-conditions for Fike’s full TERMS AND CONDITIONS OF SALE.

TERMS OF USE

Do not alter, modify, copy, or otherwise misappropriate any Fike product, whether in whole or in part. Fike assumes

no responsibility for any losses incurred by you or third parties arising from such alteration, modification, copy or

otherwise misappropriation of Fike products.

Do not use any Fike products for any application for which it is not intended. Fike shall not be in any way liable for any

damages or losses incurred by you or third parties arising from the use of any Fike product for which the product is not

intended by Fike.

You should install and use the Fike products described in this document within the range specified by Fike, especially

with respect to the product application, maximum ratings, operating supply voltage range, installation and other

product characteristics. Fike shall have no liability for malfunctions or damages arising out of the use of Fike products

beyond such specified ranges.

You should install and use the Fike products described in this document in compliance with all applicable laws,

standards, and regulations in the country of installation. Fike assumes no liability for damages or losses occurring as a

result of your noncompliance with regionally applicable laws and regulations.

It is the responsibility of the buyer or distributor of Fike products, who distributes, disposes of, or otherwise places the

product with a third party, to notify such third party in advance of the contents and conditions set forth in this

document. Fike assumes no responsibility for any losses incurred by you or third parties as a result of unauthorised

use of Fike products.

QUALITY NOTICE

Fike has maintained ISO 9001 certification since 1996. Prior to shipment, we thoroughly test our products and review

our documentation to assure the highest quality in all respects.

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 1

REVISION HISTORY

ORIGINAL RELEASE DATE: ..........................................................................................................................................June, 2017

REVISION /DESCRIPTION OF CHANGE REVISION DATE

4 / Change 5m hearing protection to 10 X D hearing protection January 2018

PAGE / 2

Doc. P/N 8.8520.00.5

Rev. April, 2019

TABLE OF CONTENTS

Section Page No.

1. INTRODUCTION ...........................................................................................................................................................3

2. GENERAL INFORMATION.............................................................................................................................................3

2.1. Description.........................................................................................................................................................3

2.2. Service Qualifications.........................................................................................................................................3

2.3. External Effects ..................................................................................................................................................3

2.4. FlamQuench II Safety .........................................................................................................................................4

2.5. FlamQuench Installation Procedure ..................................................................................................................4

2.6. FlamQuench Removal Procedure ......................................................................................................................5

2.7. Identification of FlamQuench II .........................................................................................................................5

3. INSTALLATION .............................................................................................................................................................5

4. SUPPORT CONSIDERATIONS........................................................................................................................................6

5. REFURBISHMENT INSTRUCTIONS................................................................................................................................6

5.1. Filter Handling Warning.....................................................................................................................................6

5.2. Filter Replacement.............................................................................................................................................6

5.2.1. Remove Filter (fig. 4 & 5)...............................................................................................................................6

5.2.2. Installation of Filter(s) (fig. 6) ........................................................................................................................6

5.3. Refurbish Kits.....................................................................................................................................................7

5.4. Tools Needed for Refurbishment (not included as part of kit)..........................................................................7

6. SCHEDULED MAINTENANCE........................................................................................................................................8

6.1. Every Three (3) Months .....................................................................................................................................8

7. MAINTENANCE AFTER EACH FLAMQUENCH II ACTIVATION .......................................................................................8

8. EXPLOSION VENT REQUIREMENTS..............................................................................................................................8

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 3

1. INTRODUCTION

This document is intended to provide information to assist with the installation, use, maintenance and replacement of

the Fike FlamQuench II.

Fike Corporation has designed and manufactures the FlamQuench II in two versions: an imperial size unit specified

according to NA standards, available in size 8” through 40”; and a metric version specified and built for the CE market,

available in size DN200 through DN1000.

2. GENERAL INFORMATION

2.1. Description

The Fike FlamQuench II is designed to allow for indoor explosion venting with flame arresting and particulate

retention. It consists of various layers of high temperature stainless steel that retain burned and unburned dust and

absorb heat produced during the explosion.

2.2. Service Qualifications

The information contained in this document is provided for reference purposes only. For further product information

or ordering replacement parts, please contact your local Fike Branch Office or Representative (details of which can be

found on the back page) or:

Fike Product Support by calling 816-229-3405 (fax: 816-229-0314) or

Fike Europe Product Support at +32 14 21 00 31 (fax: +32 14 21 07 43)

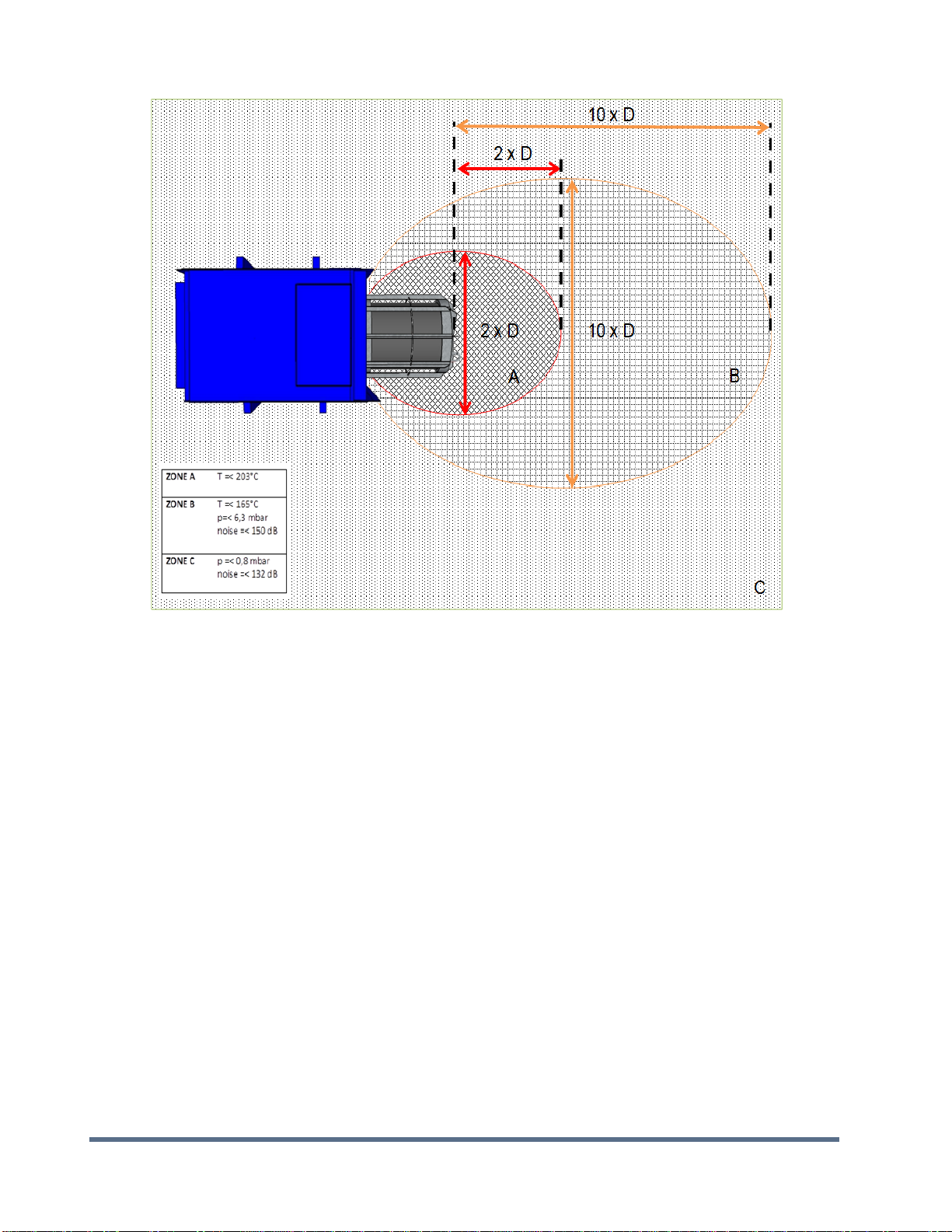

2.3. External Effects

Tests conducted with FlamQuench devices indicated that

Maximum surface temperature at the flame arrestor mesh was 203°C.

a manikin located at 1 m from the device was not blown over and no visual burn damage to polypropylene

coverall (melting point 160- 165°C).

External noise measurements at 1 m and 5 m from the device resulted peak SPL 150 dB at 1 m and at 5 m

peak SPL 132 dB.

a dust cover slightly increased to noise levels but did not increase the Pred.

External pressures –at 1m and 5 m from the device resulted in peak values of 6.3 mbar and 0.8 mbar

respectively.

Refer to figure below for guidance on safety perimeter surrounding the flameless venting device.

PAGE / 4

Doc. P/N 8.8520.00.5

Rev. April, 2019

The FQ devices reduce the noise level compared to an open vent by ~10 dB(A). Fike recommends that the user

provide appropriate hearing protection for workers who may be in the vicinity (within 10 x D) of the vent device. Local

regulations may prevail.

2.4. FlamQuench II Safety

WARNING: Any damage to the Filter may cause the FlamQuench II to malfunction, which may result in a dust

explosion in the surrounding area.

2.5. FlamQuench Installation Procedure

WARNING: When installing do not damage filter. Any damage to filter may compromise the function of the

FlamQuench II.

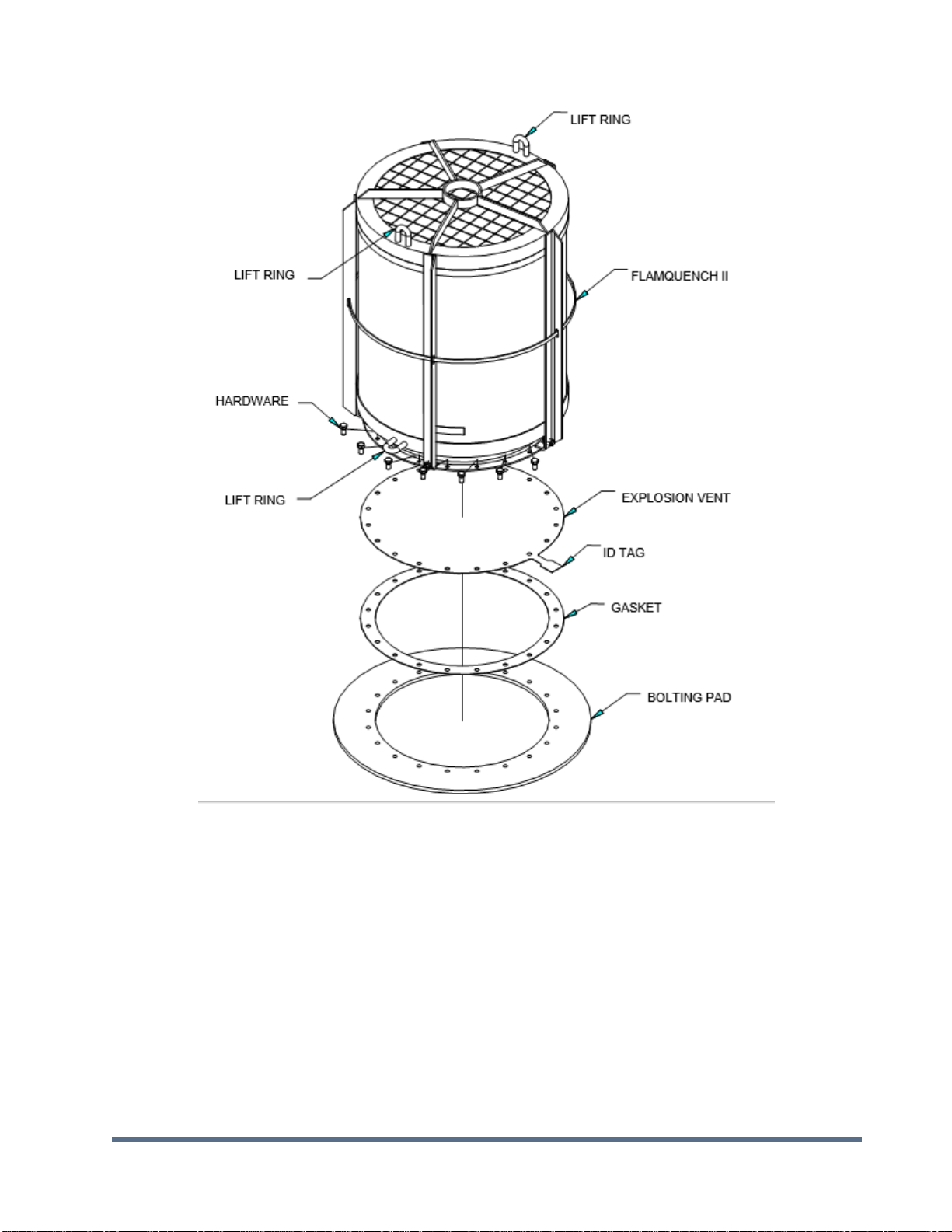

Refer to Figure 1 (page 9) for assembly diagram.

1. All system components shall be installed and the electrical and control systems thoroughly checked by a

qualified technician before proceeding with installation.

2. Use provided lift ring(s) when installing FlamQuench II. The rings are located on the top and bottom

weldments. Do not attempt to lift FlamQuench II by any other method.

3. Carefully clean gasket, explosion vent, and bolting pad surface (frame or flangering).

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 5

4. Place gasket onto bolting pad (AFM30/34 or similar is the recommended gasket material. Sealant may be

used, type may vary depending on process requirements). Be sure to line up holes.

5. Place the explosion vent onto gasket with ID tag lettering facing up. Align holes.

Note: Explosion vent may be placed onto the FlamQuench II first. However you must wait until the sealant has dried

before continuing the installation. Follow the instructions on sealant for drying time.

WARNING: TAKE EXTREME CAUTION NOT TO DAMAGE EXPLOSION VENT WHEN INSTALLING FlamQuench II.

DAMAGE TO THE EXPLOSION VENT WILL CAUSE IT TO MALFUNCTION.

6. Carefully place FlamQuench II on top of explosion vent making sure holes are lined up before placing all the

weight on the explosion vent.

7. Fasten the FlamQuench II to the bolting pad using either 18-8 or 304 stainless steel hardware. Torque to 35-

40 foot pounds (48-54 N-m).

8. Connect Burst Indicator. (See Installation Instructions on connecting BI)

Note: Cables attached to lifting rings can be used to help support the FlamQuench II. Do not attempt to support the

FlamQuench II using any other method other than the lift rings

2.6. FlamQuench Removal Procedure

Caution: Before removing FlamQuench II, carefully check the surface temperature. Make sure it is not too hot to

handle.

Do not disassemble the FlamQuench II when mounted to a vessel.

1. Shut down process if not already shut down.

2. Remove hardware holding FlamQuench II to vessel.

3. Use only the provided lift rings for lifting.

4. Follow instructions in Section 5 for refurbishment.

2.7. Identification of FlamQuench II

For the purpose of identifying the FlamQuench II and ordering replacement parts and refurbishment kits the

FlamQuench II has been permanently tagged. The FlamQuench II has separate ID tags for each component. See

Figures 4 & 5 for ID tag locations. The ID tags contain the following information: Size, Part Number and Lot Number.

The explosion vent will be marked separately.

3. INSTALLATION

Keep a minimum distance of 2 feet (0.7 meters) between the FlamQuench II and any equipment or walls to

allow for proper venting.

FlamQuench II may be installed anywhere between vertical and horizontal. See Figure 2. Fike Corporation

shall evaluate any deviation from this orientation.

PAGE / 6

Doc. P/N 8.8520.00.5

Rev. April, 2019

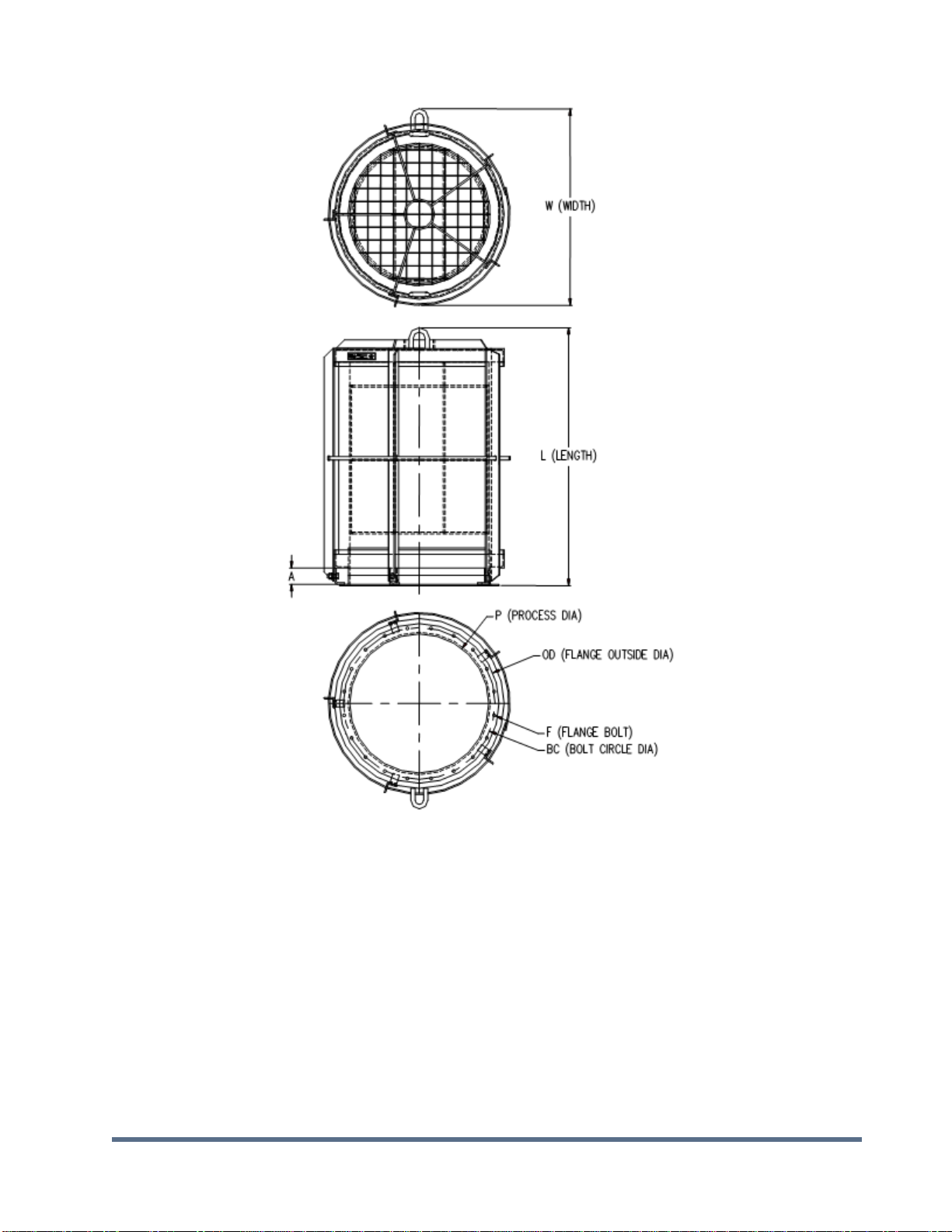

The FlamQuench II requires sufficient support based on the FlamQuench II weight and reaction force created

during activation. Refer to Table 2 or Table 3 and Figure 3 for FlamQuench II physical specifications.

4. SUPPORT CONSIDERATIONS

The FlamQuench II should be supported to prevent damage to the vessel it is protecting. If the vessel is sufficiently

sturdy, the flange connection may be used to support the FlamQuench II. Weight and angle must be considered when

evaluating vessel strength for mounting. If the vessel wall is not sufficient to support the FlamQuench II, additional

reinforcement should be provided.

Where lighter weight vessels are used, the FlamQuench II should be supported independently. This may be

accomplished by attaching cables to the lifting rings on the top and side of the FlamQuench II.Refer to Figure 2.

5. REFURBISHMENT INSTRUCTIONS

5.1. Filter Handling Warning

WARNING: To prevent possible injury (cuts & scrapes), wear leather gloves when handling the filters.

5.2. Filter Replacement

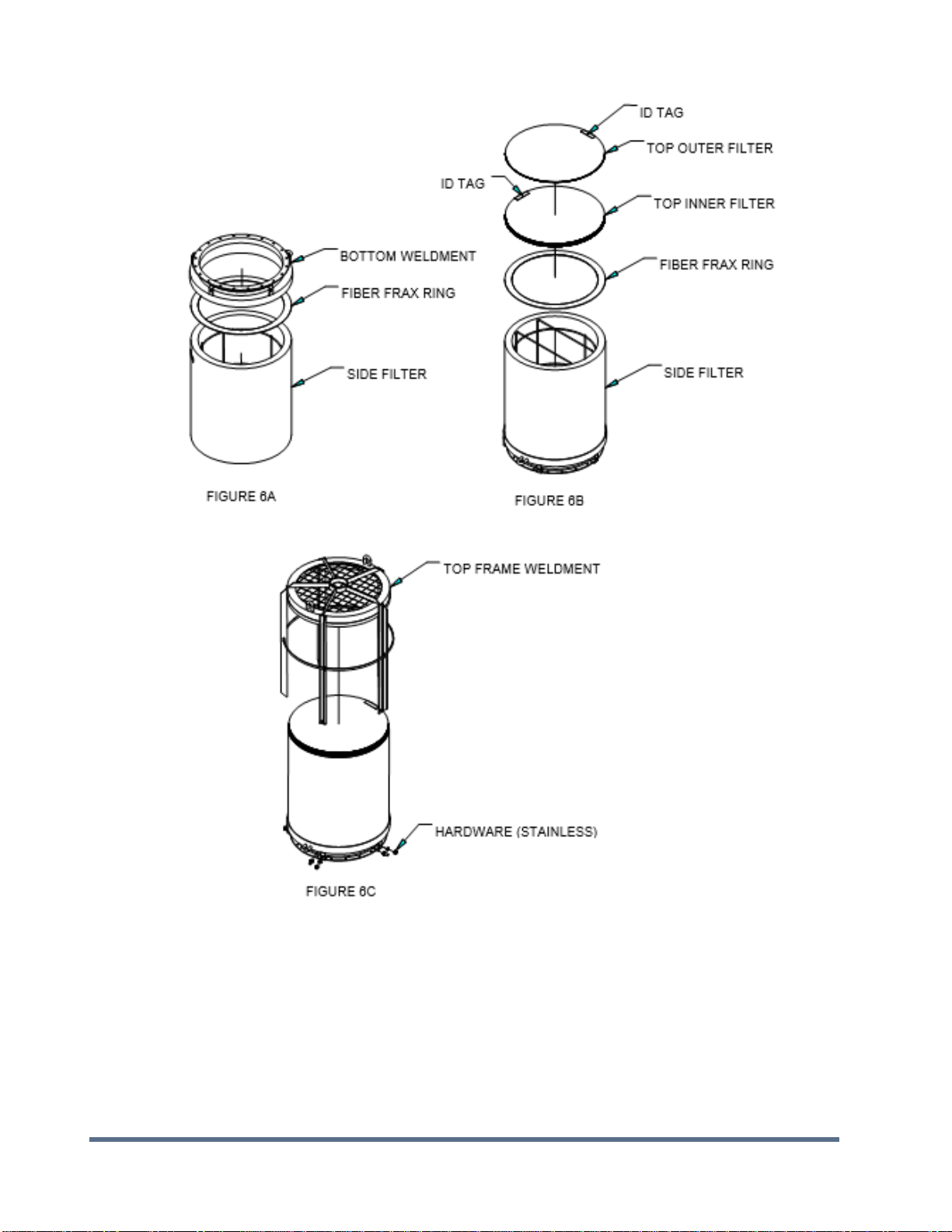

5.2.1. Remove Filter (fig. 4 & 5)

1. Follow removal procedures in Section 2.6.

2. Remove nuts, bolts and washers and discard.

3. Use supplied lift rings to remove Top Frame Weldment. Be sure to remove lower bands on larger

FlamQuench II.

4. Remove Top and Side Filters and dispose of properly.

5. Remove Fiber Frax rings and discard in a safe manner.

5.2.2. Installation of Filter(s) (fig. 6)

CAUTION: BEFORE INSTALLING NEW FILTER, THOUROUGLY INSPECT FRAME FOR STRESS FRACTURES. IF FRACTURES

ARE FOUND, REPLACE ENTIRE FRAME.

1. Place Fiber Frax ring into Bottom Weldment. Be careful not to tear ring.

2. Carefully install Side Filter into Bottom Weldment, ID tag down. If Filter is damaged in any way, it may

compromise the function of the filter. For easier installation turn assembly upside down to install filter. See

Figure 6A. Be sure to note location of ID tag (Refer to Figure 4 or 5).

3. Place Fiber Frax ring on top of Side Filter. See Figure 6B.

4. FlamQuench II sizes 8” – 20” (DN200 – DN500) skip to Step 9.

5. FlamQuench II sizes 24” – 40” (DN600 – DN1000) install Center Ring Support Weldment. (Refer to Figure 5)

6. Place Fiber Frax ring on top of Center Ring Support Weldment.

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 7

7. Carefully install Side Filter into Center Ring Support Weldment

8. Place Fiber Frax ring on top of Side Filter.

9. Lay the Inner Top Filter on top of the Fiber Frax (ID tag up). Be sure to center this part on top of the Filter.

See Figure 6B. Be sure to note location of ID tag.

10. Lay the Outer Top Filter on top of the Inner Top Filter (ID tag up). Be sure to center. See Figure 6B . Be sure to

note location of ID tag.

11. Carefully lower Top Frame Weldment onto filter assembly. Align holes in top weldment with holes in bottom

weldment. In order to line-up holes the assembly needs to be compressed using 3 bar clamps. Place the bar

clamps equaly spaced around the diameter. Slowly tighten each bar clamp until the holes line-up. See Figure

6C .

12. Install new hardware provided. DO NOT USE OLD HARDWARE! Torque all hardware to 35 ft-lbs (48 N-m).

13. Refurbishment complete. Refer to Section 2.5 for installation.

5.3. Refurbish Kits

Each Refurbish Kit contains the following components:

Hardware (nuts, bolts, washers)

Top Inner Filter

Top Outer Filter

Side Filter (s)

Fiber Frax Rings

FlamQuench II Installation and Operation Manual (E06-045)

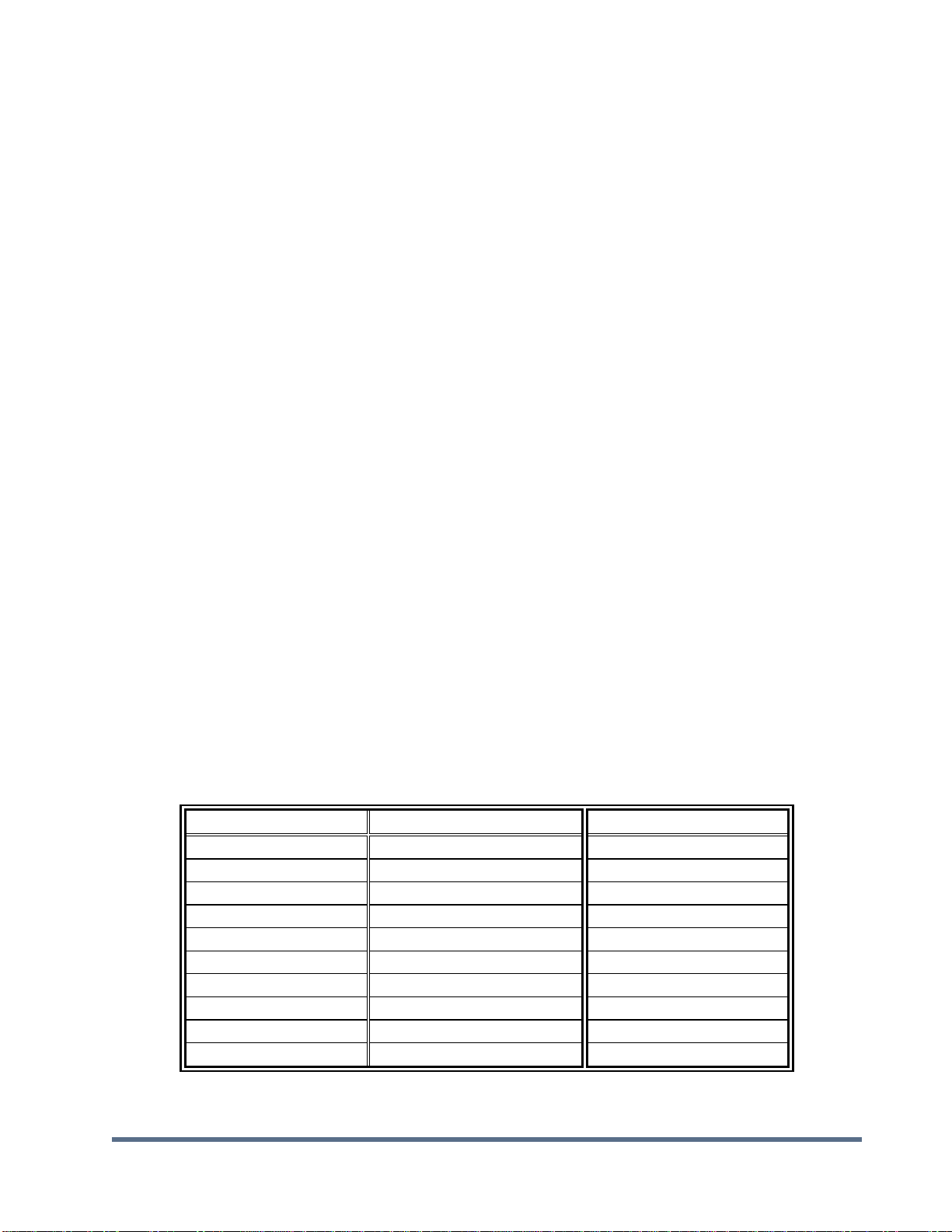

Table 1 - Refurbish Kits

FlamQuench II Size

Kit Part Number –English

Kit Part Number –Metric

8” (DN200)

E85-039-08

91002020-S

12” (DN300)

E85-039-12

91002120-S

14” (DN350)

E85-039-14

91002220-S

16” (DN400)

E85-039-16

91002320-S

20” (DN500)

E85-039-20

91002420-S

24” (DN600)

E85-039-24

91002520-S 2

30” (DN750)

E85-039-30

91002620-S 2

DN800

Not Available

91002720-S 1 2

36” (DN900)

E85-039-36

91002720-S 1 2

40” (DN1000)

E85-039-40

91002820-S 2

Note 1: DN800 and DN900 FlamQuench II both use the same filter elements.

5.4. Tools Needed for Refurbishment (not included as part of kit)

PAGE / 8

Doc. P/N 8.8520.00.5

Rev. April, 2019

Torque wrench

Bar clamps

p/n 91009000: bar clamps for FQII reload kit DN 200 to DN600

p/n 91009100: bar clamps for FQII reload kit DN750 to DN1000

6. SCHEDULED MAINTENANCE

All system components should be thoroughly inspected by factory trained personnel. Following are specific

requirements. Additional maintenance may be required depending on process and environmental conditions.

6.1. Every Three (3) Months

Visually inspect the system.

Keep filter free of dust. Use soft brush or vacuum to remove dust from filter.

Check for loose hardware.

The explosion vent is maintenance free.

7. MAINTENANCE AFTER EACH FLAMQUENCH II ACTIVATION

Replacement is required after every activation. This includes replacing filters and hardware (See Section 5).

8. EXPLOSION VENT REQUIREMENTS

The following round Explosion Vents have been approved for use in conjunction with the FlamQuench II.

HI-CV

HI-CV-S

Burst Indicators are required on all explosion vents when used with a FlamQuench II.

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 9

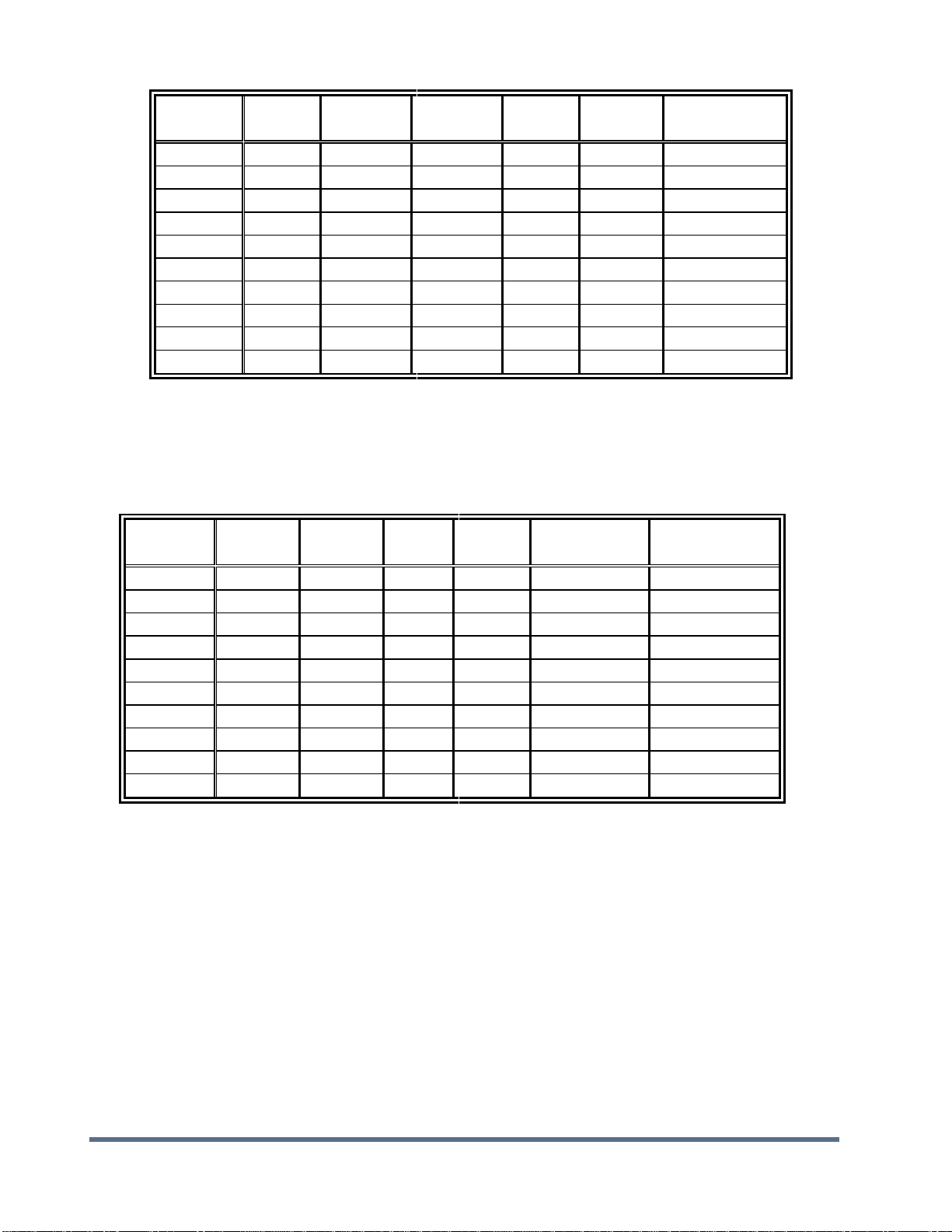

Table 2 - FlamQuench II (fig. 3)

FQ II

SIZE

P

OD

BC

F

BOLT

QTY

TORQUE

(FT-LBS.)

8”

8 1/8

10 5/8

9 ½

3/8

8

30

12”

12 3/16

15 3/16

13 13/16

7/16

12

30

14”

14 3/16

17 3/16

15 13/16

7/16

12

30

16”

16 ¼

19 ¼

18 1/8

7/16

16

30

20”

20 ¼

23 ¼

22 1/8

7/16

20

30

24”

24 ¼

27 ¼

26 1/8

7/16

20

30

30”

30 ¼

34 ¼

32 ½

9/16

28

50

36”

26 ¼

40 ¼

38 ½

9/16

32

50

40”

40 ¼

44 ¼

42 ½

9/16

36

50

NOTE: Flange stud torque values are based on using 1/8" Garlock 3600 gasket material and lightly oiled and freely

running threads.

FQ II

SIZE

L

W

A

WT

LBS.

GASKET

INSIDE DIA

GASKET

OUTSIDE DIA

8”

23 ½

13

1 ¾

44

8 1/8

10 5/8

12”

26 ¼

19

1 ¾

80

12 3/16

15 3/16

14”

31 ½

22 ¼

2 ½

113

14 3/16

17 3/16

16”

35 ½

25

2 ½

168

16 ¼

19 ¼

20”

37 ½

28 ½

2 ½

199

20 ¼

23 ¼

24”

57 ¾

32 ½

2 ½

402

24 ¼

27 ¼

30”

86 ¼

38 ¾

2 ½

635

30 ¼

34 ¼

36”

88 ¼

46 ¼

2 ½

804

26 ¼

40 ¼

40”

88 ¼

49 ¾

2 ½

965

40 ¼

44 ¼

NOTE: All specifications are subject to change and should be used for reference only.

PAGE / 10

Doc. P/N 8.8520.00.5

Rev. April, 2019

FQ II

SIZE

P

OD

BC

F

BOLT

QTY

TORQUE

(N-m)

DN200

208

268

242

10

8

40

Dn300

310

390

355

12

12

33/80**

DN350

342

422

387

12

12

33/80**

DN400

393

483

443

12

16

33/80**

DN500

494

584

544

12

20

33/80**

DN600

596

686

646

12

20

33/80**

DN750

743

843

798

12

28

33/80**

DN800

799

899

854

12

28

33/80**

DN900

900

1000

935

12

32

33/80**

DN1000

1002

1102

1057

12

36

33/80**

NOTE: Flange stud torque values are based on using 1/8" Garlock 3600 gasket material and lightly oiled and freely

running threads.

** For burst pressures less or equal to 100 mbar at 22°C. Use 33 N-m, otherwise 80 N-m.

FQ II

SIZE

L

W

A

WT

KG.

GASKET

INSIDE DIA

GASKET

OUTSIDE DIA

DN200

597

330

44

20

208

268

Dn300

664

485

44

36

310

390

DN350

800

564

63

51

342

422

DN400

900

636

63

76

393

483

DN500

954

727

63

90

494

584

DN600

1465

828

63

182

596

686

DN750

2189

982

63

288

743

843

DN800

2238

1173

63

365

799

899

DN900

2238

1173

63

365

900

1000

DN1000

2242

1264

63

438

1002

1102

NOTE: All specifications are subject to change and should be used for reference only.

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 11

Figure 1- Installation Diagram

PAGE / 12

Doc. P/N 8.8520.00.5

Rev. April, 2019

Figure 2 - Installation Orientation

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 13

Figure 3 - FQ II Specification 8" - 40" (DN200 - DN1000) sizes

Ref. table 2 and 3

PAGE / 14

Doc. P/N 8.8520.00.5

Rev. April, 2019

Figure 4 - FQ II Assembly 8" - 20" (DN200 - DN500)

Doc. P/N 8.8520.00.5

Rev. April, 2019

PAGE / 15

Figure 5 - FQ II Assembly 24" - 40" (DN600 - DN1000)

PAGE / 16

Doc. P/N 8.8520.00.5

Rev. April, 2019

Figure 6 - Filter Installation

Notes:

CONTACT US

Fike Europe

Toekomstlaan 52

2200 Herentals, België

Tel: +32 14 210031

www.Fike.com

For a list of contact information for Fike offices around the

world, visit the Global Locations section of Fike.com

Table of contents

Other Fike Protection Device manuals

Popular Protection Device manuals by other brands

Stahl

Stahl Series 9160 operating instructions

Segen Solar

Segen Solar ACDB-250A-2000A-8-1-1 installation manual

Kindermann

Kindermann 4003 000 001 DSH42 Mounting instructions

ABB

ABB Relion 670 series Product guide

Ametek

Ametek Surgex SA Series User manual & installation guide

Microelettrica Scientifica

Microelettrica Scientifica MC2-30M Operation manual