Page 9

Mul-Lid Direcons

1. Open ll cap and place garden hose into tank. Fill tank to desired gallon marker, if marker is

above the boom of calibraon container, stop before water reaches calibraon container. This is

done to help chemical mix beer and keep foaming of chemical to a minimum later.

2. Remove Mul-Lid and use calibraon container to measure the correct amount of chemical for

the water being used.

3. Pour chemical into tank and ghten Mul-Lid back onto tank. If desired amount of water was

added in step 1, you are done. Be sure to press rmly on ll cap to seal with Mul-Lid. If desired

amount of water was not met in step 1, proceed to step 4.

4. Open ll cap and place garden hose into tank. Add water to the desired gallon marker. Close

ll cap, pressing rmly to seal cap to Mul-Lid.

NOTE: If water and chemical has not mixed properly, use the pressure adjustment control on the manifold to recirculate the

mixture through tank.

Long Range Pro Series Handgun

• No Drip Shut O • Easy Pull Trigger Handle • Chemical Resistant Construcon

• 38’ Horizontal Throw & 27’ Vercal Throw

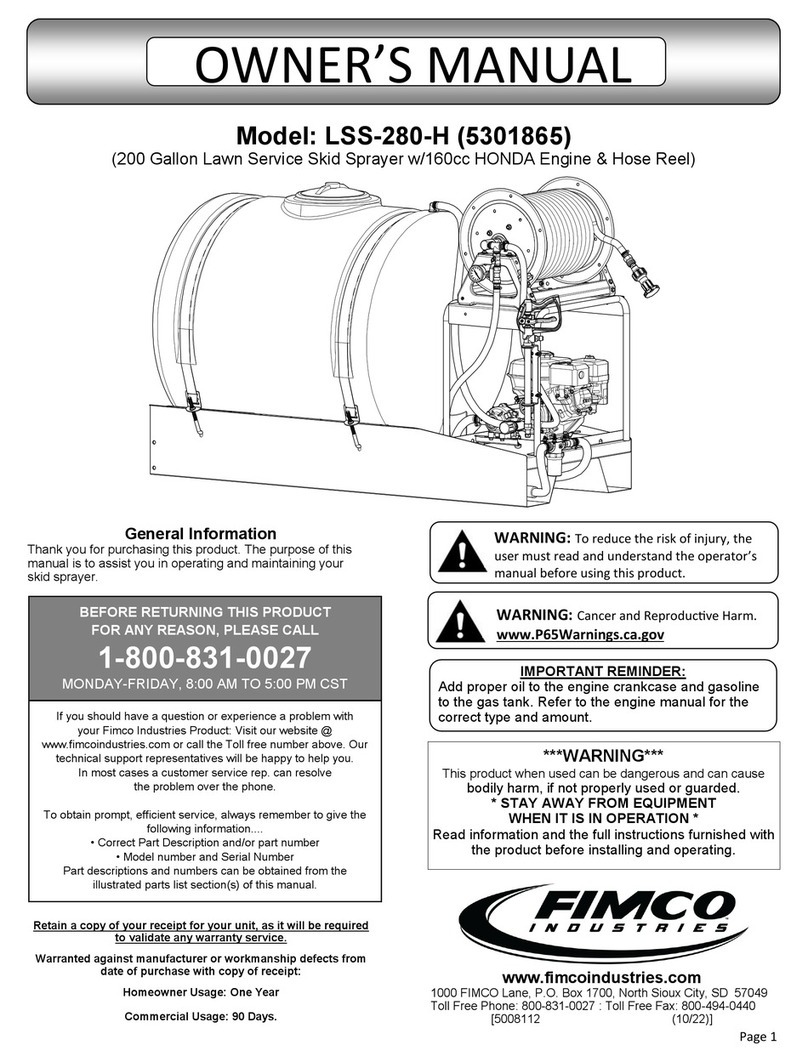

To adjust the spray paern, the nut needs to be adjusted (Ref. A). Spinning it o, towards the lever,

will make a cone paern and spinning it on, away from the lever, will make a stream. The lever (Ref.

B), is the lock that can be used to lock the lever when pulled, holding the valve open. Squeezing the

trigger, will release the lock.

Before Troubleshoong or Aempng to Service the Pump:

Review Troubleshoong Chart: Do Not aempt to repair unl steps below are followed.

Personal Protecve Gear: Wear protecve gear when servicing pump.

Disconnect Power: Disconnect the power to the pump and relieve the pressure from the system.

Empty and Flush pump system with water, never aempt to service the pump unl it has been emped and ushed.

Perform Repairs: Follow direcons provided in the troubleshoong secon to repair the pump.

Test: Always test the pump for leaks with plain water aer any repairs before using.

Sprayer and Pump FAQs:

Why does the pump not run all the me?

This is an on-demand pump and only runs when a discharge is open (spray gun, bypass, boom (if applicable) or a leak in system.

Why does the pump surge while using the spray gun?

Low ow/high pressure may cause the pump to surge (or cycle). Typically the spray wand is adjusted at too ne of a mist, to

overcome, adjust the nozzle for a higher ow.

How do I adjust the pressure?

Pressure can only be adjusted by opening the pressure adjust (bypass) valve to allow some of your water or soluon to return

to the tank (if equipped).

Pump quit and will not run, what do I need to do?

Squeeze trigger on spray gun to ensure that the system isn’t just pressurized up with discharges closed.

Check electrical connecons, ensure switch is on. Check fuses. Check for proper voltage. Check pressure switch.

Low ow or no ow at all, what do I need to check for?

Check for a clogged intake hose and/or intake strainer. Check for proper voltage.

You will need to occasionally check your intake strainer to ensure that it is clean of any debris.

What is causing the fuse to blow each me I turn the pump on?

Check for excessive voltage. Improper adjustment of the pressure switch. Damaged or defecve wire harness or defecve

pressure switch.

Warning:

Ensure the wiring harness does not become pinched or damaged in any way. This may damage the pump or cause the wiring

harness to overheat, resulng in a melt down or re.