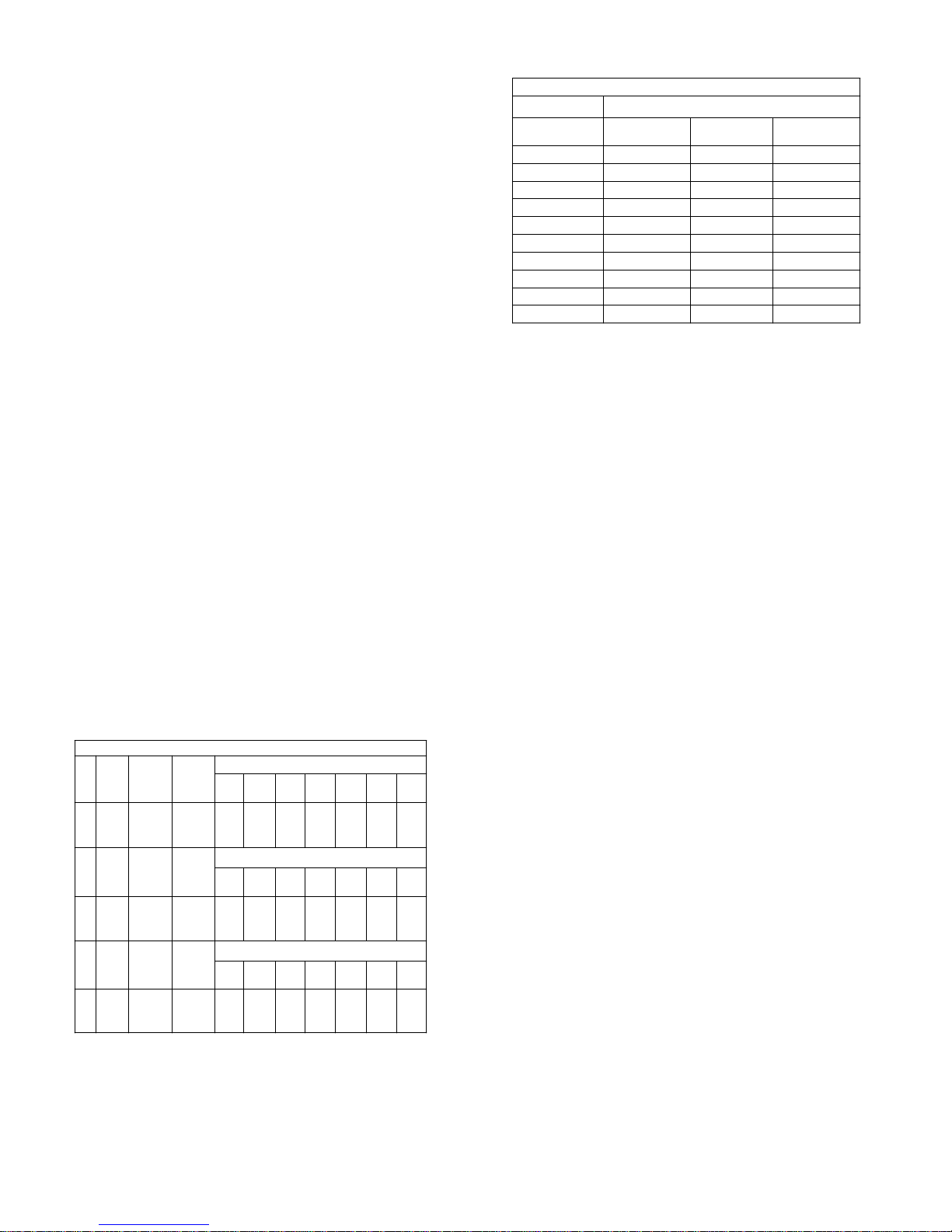

Gallons Per 100 Sq. Ft. - Based on Water

Gallons Per 1000 Sq. Ft. - Based on Water

Gallons Per Acre - Based on Water

Capacity

Pressure

Spray

Tip

Height

2

No.

40

50

18"

30

20

(psi)

.076

.068

.059

.048

MPH

.136.20

.23 .152

.17

.14

(GPM)

.118

.096

MPH

1

.034.045

.051 .038

.039

.032

MPH

3 2

.030

.024

MPH

4

Capacity

Capacity

Rate Chart for 8002 Spray Tip

50

Height

Spray

2

Tip

No.

20

18"

50

30

40

Pressure

(psi)

Height

Spray

No.

2

Tip

(psi)

18"

20

40

30

Pressure

16.622.233.266.4.23

.76

.68

.59

.48

MPH

.96.14

.23

.20

.17

1.52

1.36

1.18

(GPM)

MPH

1

.24.32

.51

.45

.39

.38

.30

.34

MPH

3 2

MPH

4

29.6

25.6

20.9

MPH

1

(GPM)

.14

.20

.17

41.8

59.2

51.2

MPH

4

3 2

19.8

17.2

14.0

MPH

10.5

14.9

12.9

MPH

.015

.014

.012

.010

MPH

10

.018.027

.031 .020

.024

.019

MPH

5

.016

.013

MPH

7.5

6.68.813.3

.15

.14

.12

.10

MPH

10

.13.19

.31

.27

.24

.20

.16

.18

MPH

5

MPH

7.5

5.9

5.1

4.2

MPH

10

7.5 5

8.4

11.9

10.3

MPH

5.6

7.9

6.9

MPH

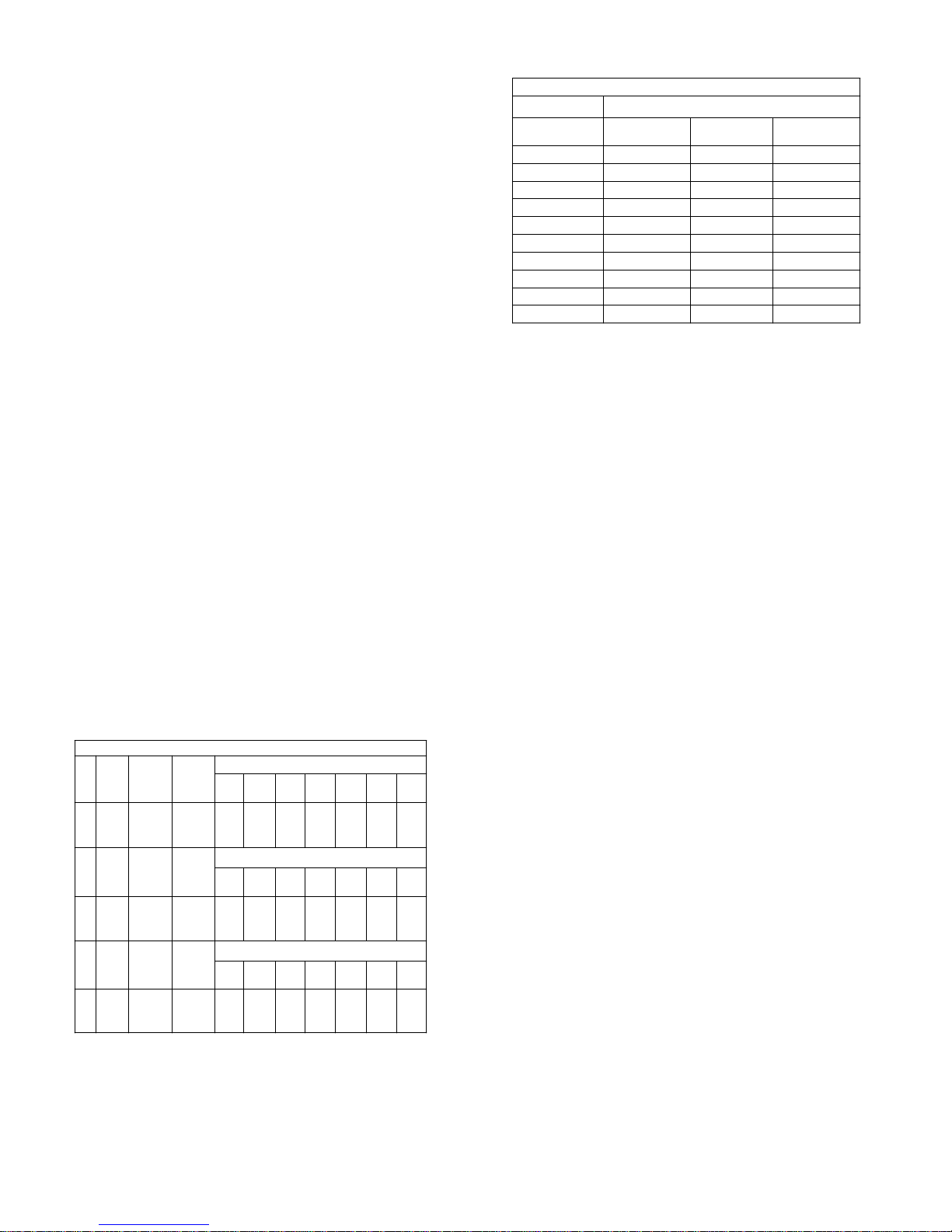

Time Required in seconds to travel a distance of:

17 344.0

5.0

6.0

7.0

9.0

8.0

10.0

7.6

6.8

9.7

8.5

14

11

15

14

19

17

23

27

100 Ft.

68 sec.

2.0

3.0

1.0

(Miles per Hour)

Speed in M.P.H.

Speed Chart

136 sec.

34

23 45

68

200 Ft.

51

23

20

26

29

41

34

205 sec.

300 Ft.

102

68

Page 2

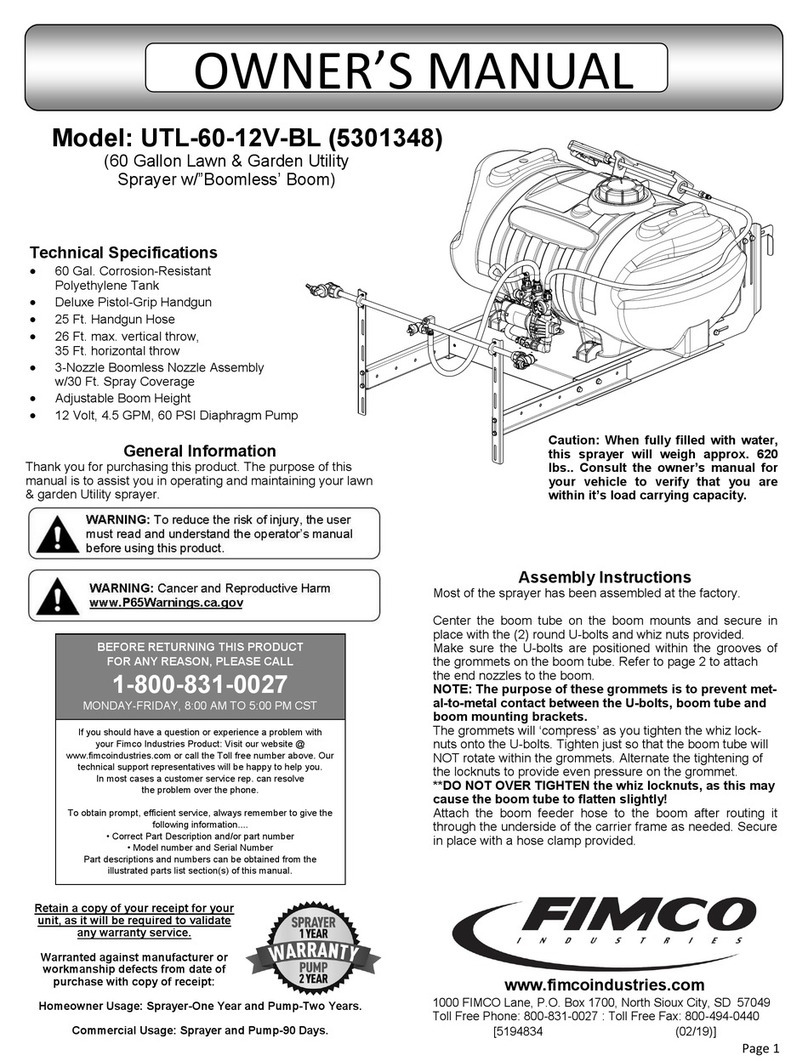

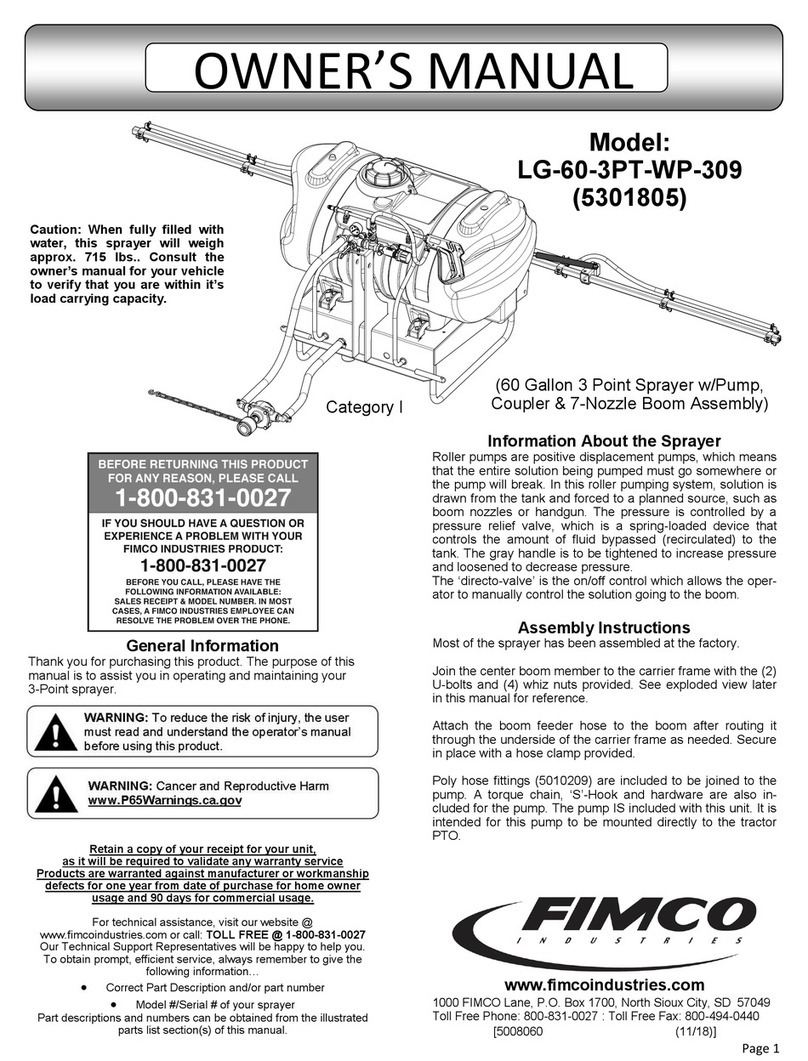

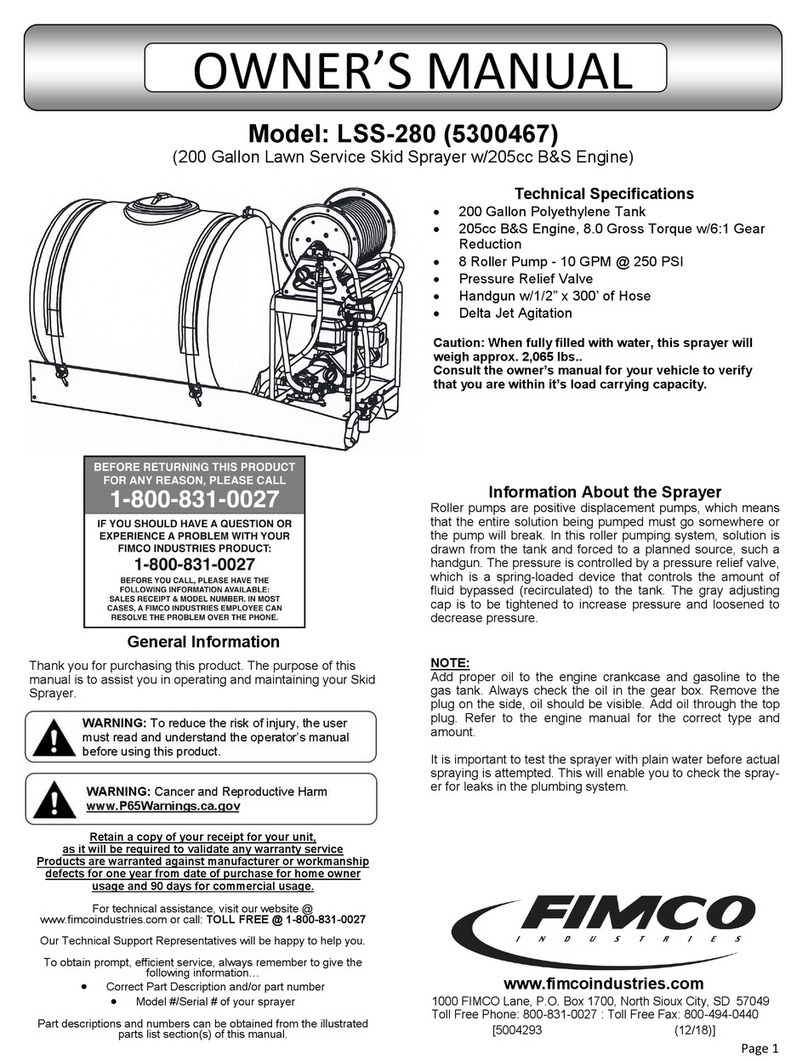

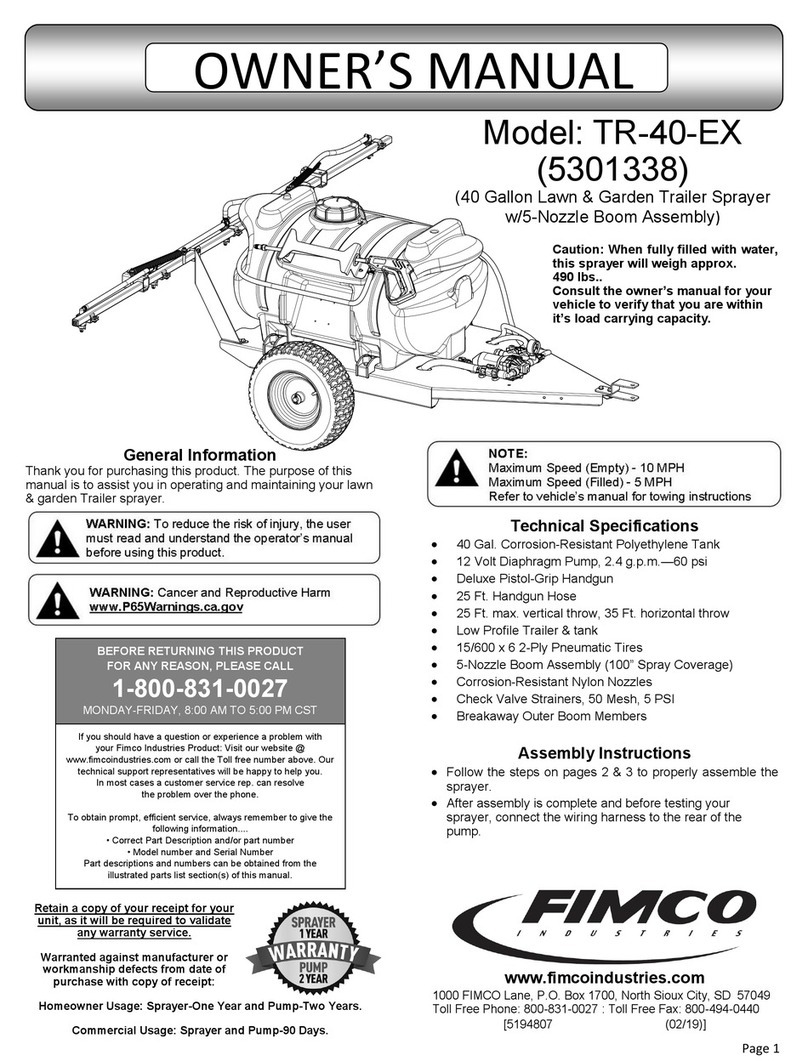

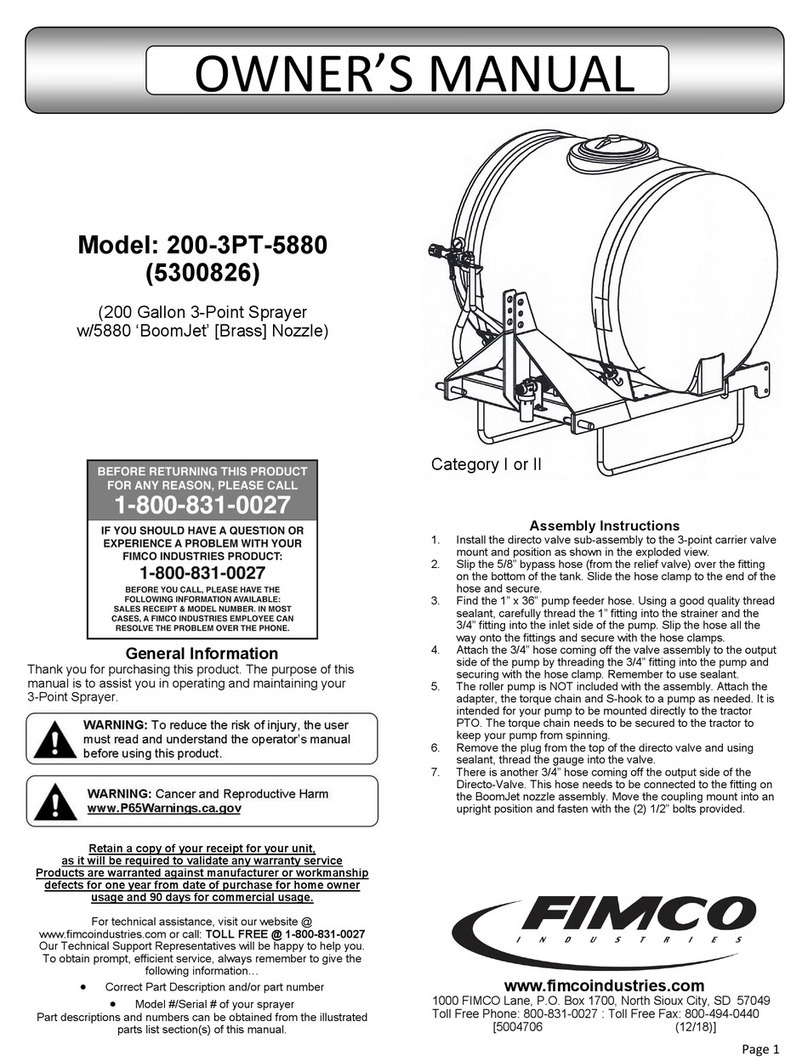

The performance of any agricultural chemical depends upon

the proper application

The tips supplied as standard with the sprayer can be used for

a wide variety of spraying applications. Other tip sizes are

available for different coverages. The speed and pressure

charts shown indicate the rates can be changed considerably

by changing speed and pressure. The nozzles on the boom will

spray a 100" wide swath. The proper nozzle height is 17" to 20"

above the object being sprayed.

Check the spray patterns. Each nozzle should overlap the next

nozzle approximately 30%.

The pumping system draws solution from the tank,

through the strainer/filter, and to the pump. The pump forces

the solution under pressure to the handgun and/or boom

nozzles.

Open the handgun by squeezing the handle lever.

•

Rotating the adjustable nozzle tip on the handgun will

•

change the tip pattern from a straight stream to a cone

pattern (finer mist).

Conditions of weather and terrain must be considered when

setting the sprayer. Do not spray on windy days. Protective

clothing must be worn in some cases.

Be sure to read the chemical label(s) correctly!

WARNING:

Some chemicals will damage the pump valves if

allowed to soak untreated for a length of time. ALWAYS

thoroughly flush the pump with water after use. DO NOT allow

chemicals to sit in the pump for extended times of idleness.

Follow the chemical manufacturer's instructions on disposal of

all waste water from the sprayer.

When you are ready to spray, mix chemicals as follows. Add

the proper amount of water to the tank. Run the sprayer while

adding chemical to the water. Do NOT spray through the boom

at this time. This will allow the solution to return (or 'bypass') to

the tank. The movement of solution through the bypass will aid

in mixing the water and chemicals. You should now be ready to

spray.

Operation & Calibration

- Four things must be considered before spraying with the boom:

How much chemical must be mixed in the tank?

1.

Rate of spray? (Gallons per Acre to be sprayed)

2.

What Pressure (p.s.i.) will be used?

3.

Speed Traveled (m.p.h.) while spraying?

4.

- Refer to your chemical's label to determine the chemical mixture.

- See the tip chart to determine the pressure to be used. The chart

will also show the speed used when spraying.

- If the towing vehicle does not have a speedometer, speed can

be determined as per the directions.

Determining the proper speed of the pulling vehicle can be done

by marking off 100, 200, & 300 feet. The speed chart indicates the

number of seconds it takes to travel the distances. Set the throttle

and with a running start, travel the distances. Adjust the throttle

until you travel the distances in the number of seconds indicated

by the speed chart. Once you have reached the throttle setting

needed, mark the throttle location so you can stop and go again,

returning to the same speed.

Add water and proper amount of chemical to the tank and drive to

the starting place for spraying.

Once you know how much you are going to spray, then determine

(from the tip chart) the spraying pressure (PSI), and the spraying

speed (MPH). The pressure can be set by running the sprayer

with the boom nozzles 'on', and then adjusting the relief valve until

the gauge reads the desired pressure. Notice that the pressure

will go up when the boom line is shut off. This is normal, and the

pressure will return as before when you open the boom line.

When selecting pressure from the tip chart, it is a good idea to try

for the 20 or 30 p.s.i. range as this allows an excellent nozzle

pattern. Spraying at 10 p.s.i. begins to break up the pattern, and

at 40 p.s.i. you may notice some drift.