Finkbeiner EHB702 User manual

Operation Manual

(translation of original document)

EHB702

Before installation, commissioning and operation of the lift this docu-

mentation needs to be regarded imperatively!

Keep this documentation at site of the lift.

EC – DECLARATION OF CONFORMITY

Manufacturer: Walter Finkbeiner GmbH

Alte Poststrasse 9 - 11

D-72250 Freudenstadt

Machine: Electro- hydraulic mobile lifting system for commercial vehicles

Type:

EHB 702

including accessory

Serial number/ year of

manufacture: _____________________________________________/__________

Herewith the manufacturer confirms that above named machine is compliant to the following directives:

2006/42/EG Machinery directive

2006/95/EG Low voltage directive

2004/108/EG Electromagnetic Compatibility (EMC) directive

Source of information for the harmonised directives:

DIN EN 1493:1998/A1:2008 Car lifts

DIN EN 60204-1:2006 Safety of machinery

DIN EN 61000-3 Electro-magnetic compatibility

DIN EN ISO 14121:2007 Safety of machinery – risk evaluation

Authorised representative for documentation:

Günther Obmann

Alte Poststrasse 9/11

D-72250 Freudenstadt

Signatory:

Günther Obmann, operations manager

Freudenstadt, den 29.12.2009

Walter Finkbeiner GmbH

ppa. Obmann

Content

Walter Finkbeiner GmbH

Alte Poststrasse 9 - 11

72250 Freudenstadt / Germany

www.finkbeiner.eu

4 / 56

PB-BA-EHB702-102GB

22.02.2011

0 Table of content

0

Table of content........................................................................................................................ 4

1

General...................................................................................................................................... 6

1.1

Delivery of the equipment................................................................................................... 6

1.2

Warranty and liability.......................................................................................................... 6

1.3

Environment protection....................................................................................................... 6

1.4

Disposal.............................................................................................................................. 6

1.5

Origin, property rights......................................................................................................... 6

1.5.1

Made in Germany............................................................................................................... 6

1.5.2

© Copyright Walter Finkbeiner GmbH................................................................................ 7

1.5.3

Trade mark ® ..................................................................................................................... 7

1.5.4

Patent rights ....................................................................................................................... 7

1.5.5

Technical changes.............................................................................................................. 7

2

Safety......................................................................................................................................... 8

2.1

Risk information.................................................................................................................. 8

2.2

Intended use....................................................................................................................... 9

2.3

Operation duties ................................................................................................................. 9

2.4

General safety notes .......................................................................................................... 10

3

Technics.................................................................................................................................... 12

3.1

Master data sheet............................................................................................................... 12

3.2

Safety equipment................................................................................................................ 13

3.3

Dimensions EHB702 .......................................................................................................... 14

3.4

Dimensions EHB702 version „Hymer“................................................................................ 15

4

Labels on the lift....................................................................................................................... 16

5

Commissioning ........................................................................................................................ 19

5.1

Loading with fork lift truck................................................................................................... 19

5.2

Loading with crane.............................................................................................................. 19

5.3

Unloading from container ................................................................................................... 19

5.4

Electrical connection........................................................................................................... 20

6

Detailed operation instructions .............................................................................................. 21

6.1

Moving of columns.............................................................................................................. 21

6.1.1

Wheel jack, spring-loaded (standard) ................................................................................ 21

6.1.2

Hydraulic travelling device (option)..................................................................................... 22

6.2

Installation........................................................................................................................... 23

6.3

Cable connection................................................................................................................ 24

6.4

Load support....................................................................................................................... 24

6.4.1

Wheel fork.......................................................................................................................... 26

6.5

Operation............................................................................................................................ 27

6.6

Lifting and lowering............................................................................................................. 28

7

Cleaning .................................................................................................................................... 29

8

Inspection and maintenance................................................................................................... 30

8.1

Inspection and maintenance by the operator ..................................................................... 30

8.1.1

Daily inspection................................................................................................................... 30

8.1.2

Monthly inspection.............................................................................................................. 30

8.1.3

Annual inspections ............................................................................................................. 31

8.1.4

Oil change .......................................................................................................................... 32

8.2

Inspection and maintenance by customer service ............................................................. 32

9

Failures...................................................................................................................................... 33

9.1

Prevention of possible failures............................................................................................ 33

9.2

Behaviour during failures.................................................................................................... 33

9.3

Possible failures and fault repair ........................................................................................ 34

9.3.1

Locating defective column.................................................................................................. 35

9.3.1.1

Check of master column..................................................................................................... 35

9.3.2

Fault repair on the defective column .................................................................................. 36

9.4

Emergency lowering – lowering during failure.................................................................... 37

Content

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

5 / 56

PB-BA-EHB702-102GB

22.02.2011

10

Spare parts lists and circuit diagrams ................................................................................... 39

10.1

Overview mechanical parts with spare parts list................................................................. 39

10.2

Overview hydraulics with spare parts list............................................................................ 41

10.3

Overview electrics .............................................................................................................. 42

10.3.1

Electrical circuit diagram master column............................................................................ 44

10.3.2

Spare parts list master column........................................................................................... 45

10.3.3

Electrical circuit diagram slave column .............................................................................. 46

Spare parts list slave column........................................................................................................... 47

11

Accessory.................................................................................................................................. 48

11.1

Remote control / Fine- operation........................................................................................ 48

12

Inspection log........................................................................................................................... 49

12.1

Information on inspection log.............................................................................................. 49

12.2

Checklist on technical inspection........................................................................................ 49

12.3

Inspection results before first commissioning by the competent person............................ 50

12.4

Inspection results on a regular verification......................................................................... 51

General

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

6 / 56

PB-BA-EHB702-102GB

22.02.2011

1 General

FINKBEINER products are based on decade-long experience in the manufacture of vehicle lifts. The

most modern procedures in areas such as construction, production and quality assurance ensure the

highest reliability and longevity.

1.1 Delivery of the equipment

Before the equipment leaves our plant, it is subjected to careful inspection to ensure that it reaches

you in perfect condition and with complete equipment according to your order.

To prevent later reclamations we ask the customer to carefully check the condition and completeness

of the delivered equipment.

1.2 Warranty and liability

Our “General Sales and Delivery Conditions“ basically apply. Warranty and liability claims for personal

or material damage are specifically excluded, if they arise one or more of the following causes:

•Improper use of the lift.

•Improper assembly, commissioning, operation, maintenance and repair of the lift.

•Operation of the lift with defective safety equipment or improperly attached or non-functional safety

and protective equipment.

•Non-compliance to the notes in this operation manual regarding transport, storage, assembly,

commissioning, operation and inspection of the lift.

•Arbitrary constructional changes to the lift.

•Arbitrary changes of parameter settings (e.g. pressure control valve).

•Insufficient supervision of wearing parts.

•Non-use of original spare parts of the manufacturer.

•Catastrophic incidences caused by force majeure.

1.3 Environment protection

The lift is operated with hydraulic oil. In case of a defect the oil may leak out. Regard the oil does not

get into the hydrologic cycle.

The operator of the lift is responsible for the compliance with the legal local environment regulations at

disposal of waste such as packing material and oil.

1.4 Disposal

The operator of the lift is responsible for the complete removal and disposal of the lift in compliance

with all local legislation and regulations.

1.5 Origin, property rights

1.5.1 Made in Germany

The lift’s country of origin is the Federal Republic of Germany.

General

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

7 / 56

PB-BA-EHB702-102GB

22.02.2011

1.5.2 © Copyright Walter Finkbeiner GmbH

This operation manual or extracts thereof may only be copied, translated or made accessible to third

parties with the express written permission of the manufacturer.

1.5.3 Trade mark ®

Is a international registered trademark.

1.5.4 Patent rights

International patent rights have been registered and accorded to FINKBEINER lifts.

1.5.5 Technical changes

Technical changes to the images and technical information reserved for progress purposes.

Safety

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

8 / 56

PB-BA-EHB702-102GB

22.02.2011

2 Safety

2.1 Risk information

DANGER

Highest hazard level. Indicates a hazardous situation which will result in death or

severe physical injury if not observed.

WARNING

Second hazard level. Indicates a possibly hazardous situation which could result in

death or severe physical injury if not observed.

CAUTION

Third hazard level. Indicates a possible situation which could result in light physical

injury or damage to material assets if not observed.

Environment information

Information

Explanations, tips and background information.

Call to action

Safety

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

9 / 56

PB-BA-EHB702-102GB

22.02.2011

2.2 Intended use

•The lift exclusively serves to lift vehicles by the vehicle frame or by the wheels depending on the

applied equipment.

•The lift is suitable for work under the lifted load.

•The lift is not designed for personal transportation.

•The lift is not designed for permanent outside use, in moist surroundings or in washing areas.

Please observe the protection type applicable to moisture and dust; see master data.

•Observe the admissible temperature range for operation of the lift; see master data.

•The lift is not designed for application under corrosive or aggressive environmental influences.

•The lift is not designed for application within explosion-hazardous areas.

•The rules and regulations applicable to the installation site must be observed in addition to the

safety instruction contained in the operation manual.

A further use or one over and above the described purposes is not considered as intended.

2.3 Operation duties

•The lift may only be operated in safe, perfect and reliable condition.

•Damages of the lift to be prevented respectively to be removed immediately.

•Recurring maintenance or inspection periods must be complied with.

•Service and repair on the lift must be conducted by an authorized expert only.

•Spare parts must comply with technical requirements specified by the manufacturer; this is only

guaranteed for original parts.

•Operation only by adult and authorized persons instructed in the handling of the lift.

•Operation only by persons who are familiar with the operation of the lift and who have read and

understood the operation manual.

•The safety- and hazard-conscious work by personnel must be monitored at occasional intervals.

•All safety and information plates on the lift must be maintained in readable condition.

•The operator may only authorize suitable persons with repairs to the lift. Suitable persons are per-

sons who are able to professionally remove faults due to their professional knowledge, experience,

training and their technical skills. They must be familiar with the operation manual of the lift and the

applicable safety regulations and requirements of the respective operating country.

Safety

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

10 / 56

PB-BA-EHB702-102GB

22.02.2011

2.4 General safety notes

DANGER

Personal injury or damage to material assets at misuse.

Carefully read and observe this operation manual!

DANGER

Personal injury when entering the danger zone of the lift.

•The operation person must not stand underneath the load during movement or

within the danger zone of the lift and has to observe sufficient safety clearance to-

wards the moving parts of the lift.

DANGER

Personal injury at unauthorised entering the danger zone of the lift.

•The operation person has to observe that no persons are staying within the dan-

ger zone of the lift.

DANGER

Personal injury at unauthorised use of the lift.

•After termination of the lifting or lowering process the main switch needs to be

switched-off and secured against unauthorised use.

•At failures of the lift immediately take the lift out of operation and secure it against

re-commissioning.

DANGER

Personal injury by non-compliance of escape routes.

•The specified local regulations on escape routes have to be observed for com-

missioning and operation of the lift.

DANGER

Unattended operation of the lift can result in severe accidents.

•The operation person has to supervise constantly the lift and the lifted load and

has to stop the operation immediately if anything is working not correctly.

Safety

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

11 / 56

PB-BA-EHB702-102GB

22.02.2011

DANGER

Excessive wind speeds can cause the lifted vehicle to fall.

•The lift may be used outdoors only when the wind speeds are below the admis-

sible data (see chart below).

•If wind freshens up immediately lower the lifted vehicle to the ground.

Type of vehicle Weight of veh. Maximal admissible wind speed

Cars, vans, light commercial

vehicles

1 - 10t

14m/s = 6 Beaufort

Buses

10 - 15t

20m/s = 8 Beaufort

Trucks and heavy duty vehicles

> 15t

24m/s = 9 Beaufort

WARNING

Hazard of injury by falling or squeezing.

•Do not climb onto the lift or the lifted vehicle.

•Conveyance of persons on the lift or in the lifted vehicle is prohibited.

WARNING

Hazard of material damage by insufficient space conditions.

•Maintain sufficient safety distances between the lift and walls, ceilings or other

fixed boundaries.

•The operation person has to ensure that no obstacles are within the danger zone

of the lift.

WARNING

Unsafe positioning of the lift can cause crashing of the lifted vehicle.

•

The lift may be used on an even and sufficiently stable floor only.

CAUTION

Hazard of injury.

•Wear suitable protective clothing according to the applicable safety regulations.

Technics

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

12 / 56

PB-BA-EHB702-102GB

22.02.2011

3 Technics

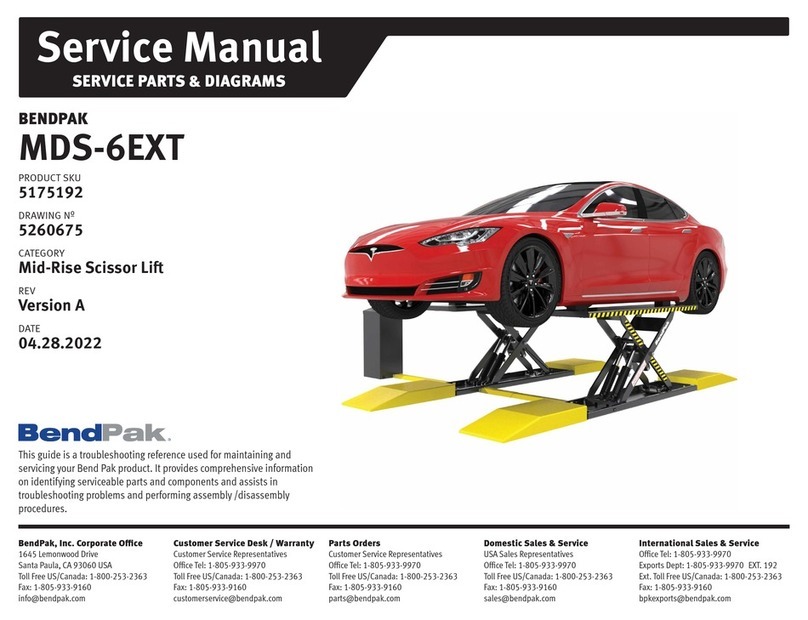

3.1 Master data sheet

Description of machine: Electro-hydraulic column lift equipment to lift vehicles at the

wheels or at the chassis; synchronisation with safety shut-off,

additional safety by mechanical locking device at each column.

Lift type: EHB702V11

Capacity per column: 2,5 t

Load support:

Wheel fork adjustable for wheel sizes 3.50R13 – 14.5R20,

resp.diameter 340 – 1100 mm

Length of fork: 350 mm

Version „Hymer“

Lifting height: 1700 mm (effective)

Lifting-/ lowering time: appr. 90 sec.

Operation:

Up/ Down at every column

Operation modes: Common / Single

Cable connection: Cable connection from column to column, length of cables 10 m.

Power supply cable with plug, 10 m, at master column.

Control: Synchronisation in cycle steps, system deviation max. 3 mm.

Supervision of all operation functions.

Drive: Electro-hydraulic

Motor 0.75 kW per column

Connection: 400 V / 3 Ph+PE / 50 Hz, 16 A

Control voltage: 24 V

Operating pressure

at nominal load: 160 bar

Pressure relief valve adjusted to 165 bar

Weight: 420 kg per column

Protection class: IP 65

Admissible temperature range: -5°bis 50°C

Admissible ground inclination: 1°

Noise level: < 70 dB(A)

Hydraulic oil: HLP ISO-VG 32

Surface treatment: Powder coating

Technics

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

13 / 56

PB-BA-EHB702-102GB

22.02.2011

3.2 Safety equipment

•Relay controlled synchronisation with cycle steps.

•Supervision of synchronisation which stops movement if system deviation limit is exceeded.

•Lockable main switch at master column: protection from unauthorised use.

•Emergency Stop at each column: Immediate Stop of movement.

•Dead-man’s control: when releasing the operation buttons the corresponding movement stops.

•Thermo switch inside motor: protection from overheating of motor.

•Hydraulic check valve: protection from unintended lowering.

•Pressure relief valve: protection from exceed pressure.

•Mechanical lock: additional protection from unintended lowering.

•Rear wheel jack: brake to prevent column to roll away.

Technics

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

14 / 56

PB-BA-EHB702-102GB

22.02.2011

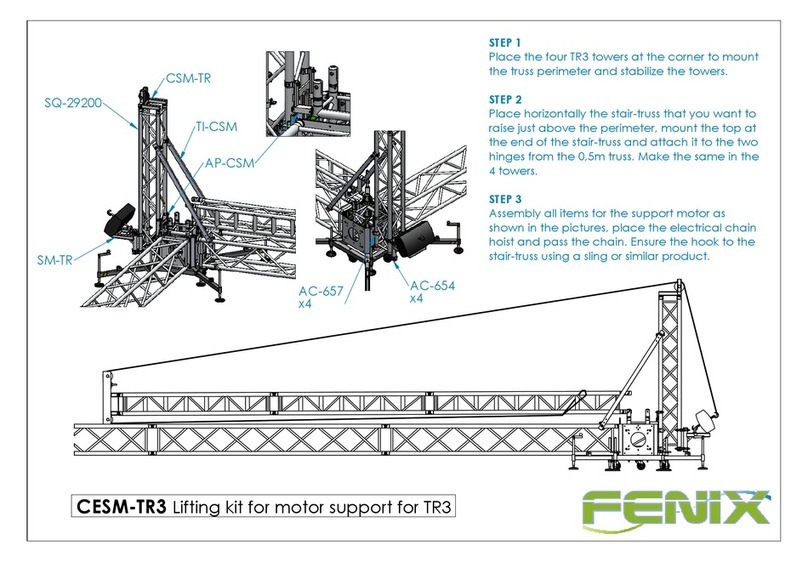

3.3 Dimensions EHB702

Technik

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

15 / 56

PB-BA-EHB702-102GB

22.02.2011

3.4 Dimensions EHB702 version „Hymer“

Labels

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

16 / 56

PB-BA-EHB702-102GB

22.02.2011

4 Labels on the lift

Manufacturer nameplate

Alte Poststrasse 9

- 11

D

-72250 Freudenstadt

www.

finkbeiner.eu

Typ:

Type:

EHB702 Serien-Nr.:

Serial-No.:

Baujahr:

Year: Tragkraft:

Capacity:

Druck:

Pressure: Gewicht:

Weight:

Motoranschluss:

Operat. Voltage:

Steuerspannung:

Control Voltage:

Made in Germany

High voltage warning

Wheel fork

Oil level

Capacity

2,5 t

Labels

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

17 / 56

PB-BA-EHB702-102GB

22.02.2011

Control box master column Control box slave column

Security advices

Labels

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

18 / 56

PB-BA-EHB702-102GB

22.02.2011

Short operation instructions

Short operation instructions – Mobile Column Lift EHB / GAB

Installation

•Locate columns on a level and sufficient load-bearing surface.

•Plug together columns by interconnect cables from column to column in a circuit around

the vehicle.

Operation

•Operation only by adult and authorised persons instructed in the handling of the lift.

•Plug-in power supply plug into prescribed mains (clockwise phase sequence!).

•Switch-on main switch, press START-button.

•Press UP respective DOWN.

Load support

•Do not exceed admissible capacity of the lift.

•Attach columns at the wheels respective pick-up points specified by vehicle manufacturer; always

two columns at one common axle.

•Check safe lifting of the vehicle immediately after load pick-up.

To regard during operation

•The operating person must not stand underneath the load during operation and has to observe

sufficient safety clearance towards the moving parts of the lift.

•The operating person has to pay attention that the movement area of the lift is free from any

obstacles and that no persons stay therein.

•The operating person has to supervise constantly the lift and the lifted load and has to stop

operation immediately if anything is working not correctly.

•Do not ride on the lifted vehicle or on the load attachments.

•Do not climb up the lift or the lifted vehicle.

•After operation the main switch has to be switched-off and locked against unauthorised use.

•Regard Operation Manual of the lift.

Commissioning

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

19 / 56

PB-BA-EHB702-102GB

22.02.2011

5 Commissioning

ENVIRONMENT INFORMATION

Environmental hazard through hydraulic oil leakages.

•Do not tilt the lift, oil can leak out.

•Remove packing material according to regulations.

5.1 Loading with fork lift truck

WARNING

Damaged packing wood or material can result in crashing of the lift.

Before loading check if package unit is free of damage.

•Column package to be lifted only at the points marked by arrows; the inside distance of the fork

tines should be minimum 500 mm.

5.2 Loading with crane

•Columns may be loaded individually only.

•Lift the column on the front top steel plate by chain.

•When using a carrying strap avoid damage of strap by sharp edges.

5.3 Unloading from container

•The columns are shipped in vertical position and are connected by wooden or steel beams.

•Remove packing material before unloading.

•Move columns individually out of the container

.

Commissioning

Walter Finkbeiner GmbH

Alte Poststrasse 9/11

72250 Freudenstadt / Germany

www.finkbeiner.eu

20 / 56

PB-BA-EHB702-102GB

22.02.2011

5.4 Electrical connection

•If lift has been delivered without power supply plug (country-specific) mount appropriate plug to

power supply cable.

WARNING

Hazard of material damage by wrong operation voltage.

•Take care that lift is connected to the prescribed power supply (see manufac-

turer nameplate).

•Connect power supply plug into appropriate mains.

•Clockwise phase sequence required. Turning direction if incorrect can be changed as follows:

Unplug lift from mains, open plug and change phase connections L1 and L2. Close plug correctly

again.

•If the lift is used at some other location or at use of an electrical extension cable the phase se-

quence may be incorrect and needs to be checked again.

Table of contents

Other Finkbeiner Lifting System manuals