First Sales UVPC-12 User manual

First Sales, LLC

12630 US Highway 33 N

Churubusco, IN 46723

Phone (260) 693-1972 Fax (260) 693-0602

UVPC-12 and UVPC-20 Instructions 190726.docx

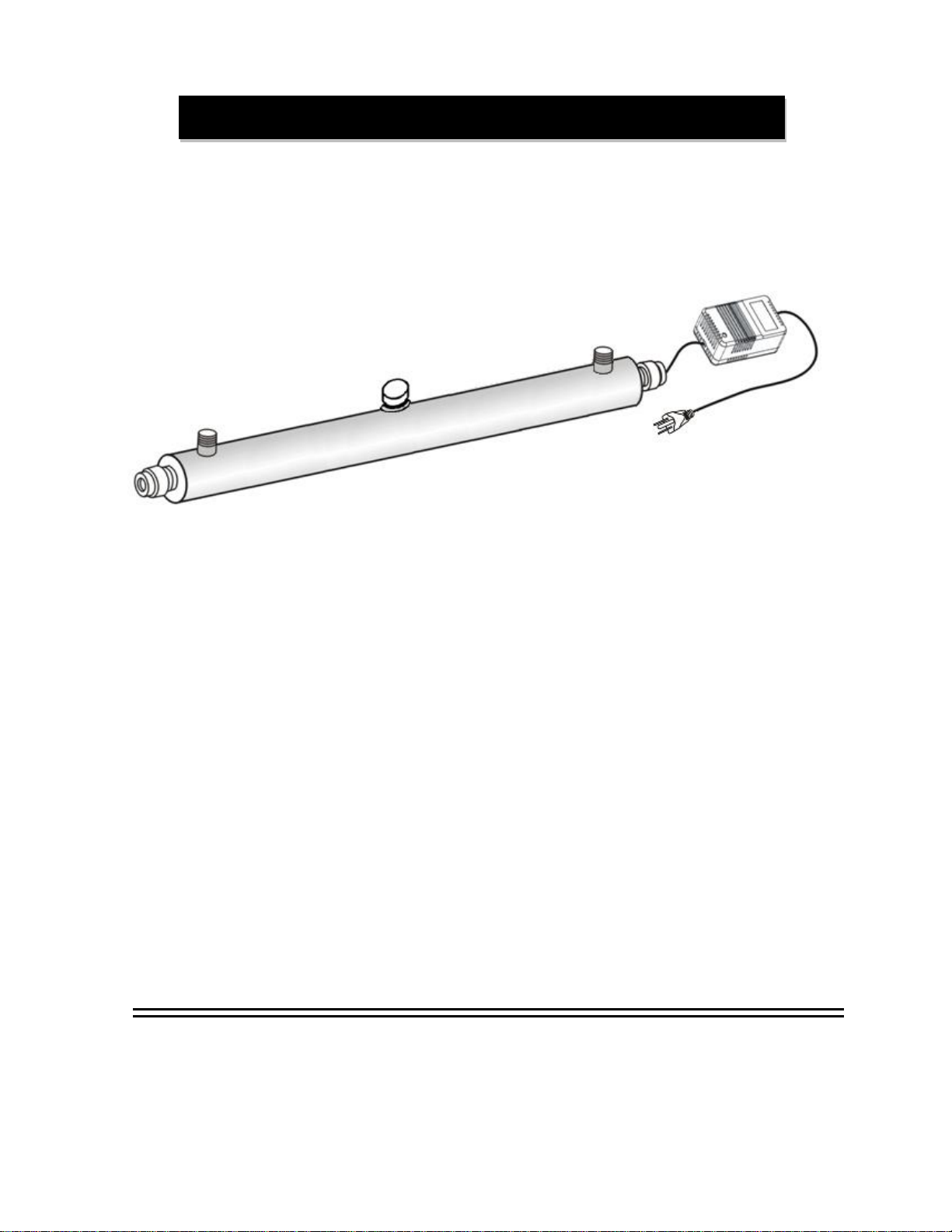

ULTRA VIOLET LIGHT

WATER STERILIZER

Please read these instructions completely before installing this unit.

UVPC-12 and UVPC-20

1

Never plug in UVlamp when itis outside the stainless steel chamber.

1. Water mayneed to be treated prior to entering the sterilizer. Water must be free of color and turbidity.

Turbidityand color will shield bacteria from the UV rays. A 5 micron sediment cartridge filter is

recommended to precede the UV. Water hardness should be 5 grains per gallon or less and the iron

concentration below0.3 ppm. Ideally, it should be soft and iron free.

2. All water treatment equipment (except reverse osmosis systems) should be installed before the

sterilizer.

3. A non-switched, 115 volt GFI protected electrical outlet is needed near the unit.

4. It is recommended that the unit be installed horizontally with adequate room on one side to remove the

quartz sleeve and bulb (approximately 37”).

5. Install only in an area that will maintain an ambient temperature between 36°F and 104°F.

6. Maximum operating pressure is 100 psi.

7. Connect to plumbing system while complying to all state and local regulations.

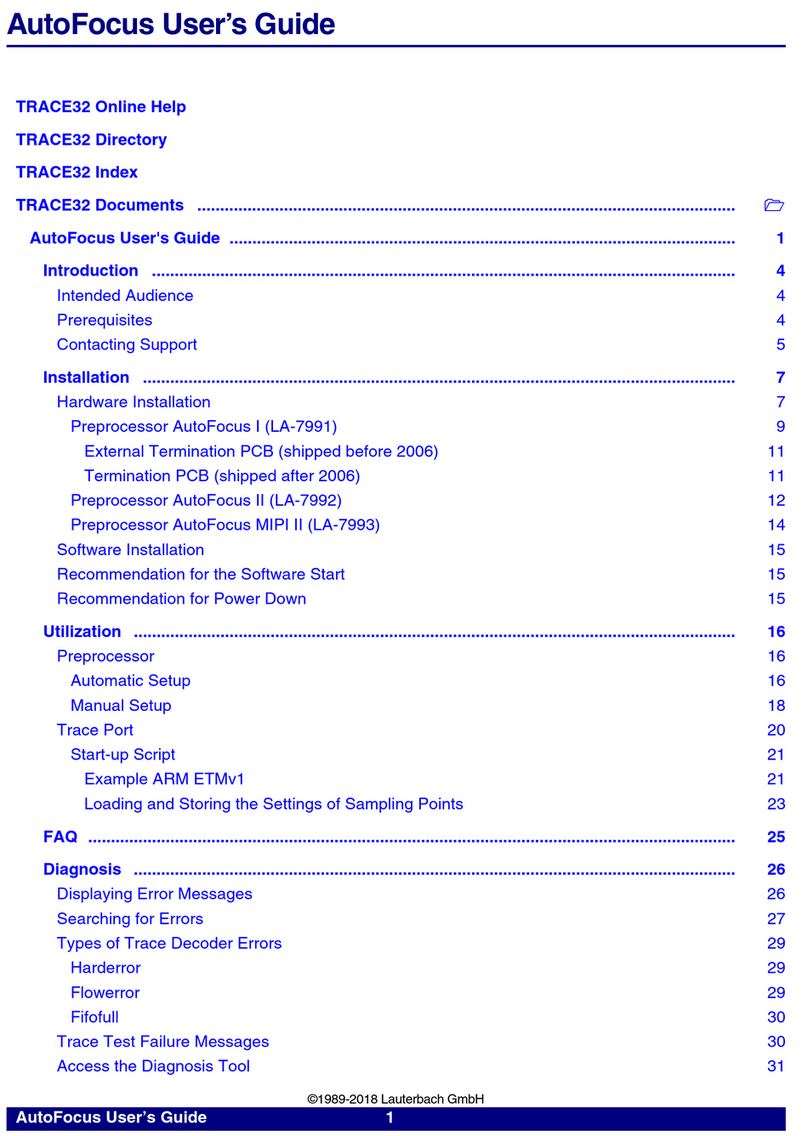

ITEM #

PART #

DESCRIPTION

1

UVPC-PG135

Water Proof Cord Strain Relief

2

UVPC-A02

Aluminum Nut

3

UVPC-4P80

Lamp Socket and Wire

4

UVPC-LAMP

Germicidal Lamp, 12 gpm, 9,000 hour

UVPC-LAMP-20

Germicidal Lamp, 20 gpm, 9,000 hour

5

UVPC-OR

O-Ring

6

UVPC-QS

QuartzSleeve

7

UVPC-ST635890

Stainless Steel Chamber, UVPC-12

UVPC-B6

Stainless Steel Chamber, UVPC-20

8

UVPC-1002

Mounting Clip for UVPC-12

UVPC-CLIP-20

Mounting Clip for UVPC-20

9

UVPC-BALL

Ballast, 115v, 12 gpm unit

UVPC-BALL-20

Ballast, 115v, 20 gpm unit

10

UVPC-GLO PLUG

UV Lamp indicator (Glow Plug)

Not

Shown

CV7A106D-12

External Flow Control, UVPC-12

CV7A106D

External Flow Control, UVPC-20

Pre-installation Instructions

Components

FIGURE 1

2

WARNING: NEVER PLUG IN UV LAMP WHEN IT IS OUTSIDE THE STAINLESS STEEL

CHAMBER. NEVER LOOK DIRECTLY AT ILLUMINATED UV LAMP

CAUTION: QUARTZ SLEEVE AND LAMP ARE EXTREMELY FRAGILE AND EASILY

DAMAGED…BE VERY CAREFUL WHEN HANDLING, INSTALLING AND REPLACING

THE SLEEVE AND LAMP. ALWAYS REPLACE THE QUARTZ SLEEVE WHEN

REPLACING THE LAMP.

1. Using mounting clips provided, mount the stainless steel chamber (Item 7) inthe desired

location. It isrecommended that the chamber be mounted horizontally to prevent dropping

the quartz sleeve and UV lamp during assembly. Ensure there is a minimum of 37” on one

side of the stainless steel chamber for installation and future replacement of the quartz

sleeve and UV lamp.

2. Install the flow control (12 gpm, UVPC-12 or 20 gpm, UVPC-20) on the connection that you

have designated asthe inlet of the unit. The unit itself is not directional regarding flow.

3. Connect inlet (with flow control) and outlet of the stainless steel chamber to the plumbing.

4. Avoid touching the sides ofthequartz sleeve and lamp. Handle only the ends. Gloves are

recommended to prevent getting oil from your hands on thequartz sleeve and UV lamp.

5. Remove aluminum nuts from both ends of the stainless steel chamber (Item 2).

6. Carefully insert the quartz sleeve (Item 6) into one end of the stainless steel chamber (Item

7) so that it exits the other end. Make sure equal lengths of quarts sleeve protrude from

each end.

7. Place an o-ring (item 5) on each end of the quartz sleeve where it enters the stainless steel

chamber.

8. Replace the aluminum nuts (item 2) on each end of the chamber. The nut without the plastic

end cover is for the end with the electrical cord. The nuts should be only hand tight.

9. Carefully slide the lamp through aluminum nut on one end of the chamber.

10. Ensure the power cord is NOT plugged in and connect the lamp to the lamp socket on the

wiring harness.

11. Screw the water proof cord strain relief (Item 1) into the aluminum nut.

12. Turn on water supply and check for leaks. Repair if necessary.

13. Plug the ballast (Item 9) into GFI (ground fault interrupt) protected electrical outlet.

14. Run water through the unit for 5 minutes prior touse.

15. If your unit has a maintenance timing device, attach the timer to the chamber. Strap and

screws are provided. Push the reset buttonto start the timer. The timer indicates when

lamp and quartzsleeve replacement is required.

If the plumbing system has been previously exposed to water that is known to have

bacterial contamination, the entire plumbing system will require disinfection once the

UV light is installed and in operation.

Installation

3

Replace the quartz sleeve and germicidal lamp annually.

1. Disconnect electrical power.

2. Turn off water supply and relieve pressurefrom system.

3. Unscrew power cord strain relief and slide the lamp out to disconnect the wiring.

4. Carefully remove lamp from chamber.

5. Unscrew both aluminum nuts and carefully remove the quartz sleeve. Retain the existing

O-rings for re-use or replace with new O-rings (item 5).

6. See installation procedure to install new quartz sleeve and lamp.

7. If timing device is used, press and hold buttonto reset timer.

Dimensions

UVPC-12

UVPC-20

(A) Distance Between Inlet and Outlet

31.5”

31.5”

(B) Chamber Diameter

2.5”

4.8”

(C) Total Height

4.3”

5.6”

(D) Overall Length

37”

38”

Maximum Flow Rate

12 GPM

20 GPM

Minimum UV Dose @ maximum flow rate

(at end of recommended bulb life)

16+ mJ/cm2

30+ mJ/cm2

UVWavelength 254 nanometers (nm)

UV Lamp Life 9,000 hours (1 year)

FeedWater Quality

Hardness <5 gpg

Iron <0.3 ppm

Manganese <0.05 ppm

Turbidity <5 NTU

Color None

Maintenance

Specifications

4

This UV system is guaranteed against any manufacturing defects that are due to faulty material

or workmanship during the warranty period. This warranty does not include damage to the

product resulting from accident, neglect, misuse, misapplication, alteration, installation or

operation contrary to printed instructions, or damage caused by freezing, fire, flood, or Acts of

God. For a period of two years from the original date of installation, or 30 months from

manufacture, whichever occurs first, we will repair or replace, at our discretion, any part found to

be defective. Purchaser is responsible for any shipping cost to our facility and any local labor

charges.

Stainless Steel Chamber

Aluminum Nuts

Ballast

Lamp Socket and Lead Wire

Strain Relief Fitting

GENERAL CONDITIONS –Should a defect or malfunction occur, contact the dealer that you

purchased the product from. If you are unable to contact the dealer, contact First Sales, LLC. @

(260)693-1972. We will require a full description of the problem, model number, date of

purchase, and selling dealer’s business name and address.

We assume no warranty liability in connection with this UV system other than specified herein.

This warranty is in lieu of all other warranties, expressed or implied, including warranties of

fitness for a particular purpose. We do not authorize any person or representative to assume for

us any other obligations on the sale of this UV system.

Two Year Limited Warranty

This manual suits for next models

1

Table of contents