Instruction Manual CertoClav Connect 19.05.2017

9

4 Forbidden substances for autoclaving

Never use the autoclave to sterilize any of the following hazardous materials or substances with alkali

content. Sterilization of such objects can cause explosion, corrosion of the working chamber or chamber

piping, and deterioration of gaskets.

Explosive substances

Nitroglycol, nitroglycerin, nitrocellulose, and other explosive nitric esters.

Trinitrobenzene, trinitrotoluene, picric acid, and other explosive nitro compounds.

Peracetic acid, methyl ethyl ketone peroxide, benzoyl peroxide, and other organic peroxides.

Ignitable substances

Metallic lithium, potassium, sodium, yellow phosphorous, phosphorus sulfide, and red phosphorus.

Celluloids, calcium carbide (carbide), lime phosphide, and magnesium powder.

Aluminum powder, magnesium powder, and metallic powders other than aluminum powder.

Sodium dithionite (or sodium hydrosulfite).

Oxidizing agents

Potassium chlorate, sodium chlorate, ammonium chlorate, and other chlorates.

Potassium perchlorate, sodium perchlorate, ammonium perchlorate, and other perchlorates.

Potassium peroxide, sodium peroxide, barium peroxide, and other inorganic peroxides.

Potassium nitrate, sodium nitrate, ammonium nitrate, and other nitrates.

Sodium chlorite and other chlorites.

Calcium hypochlorite and other hypochlorites.

Flammable substances

Ethyl ether, gasoline, acetaldehyde, propylene oxide, carbon disulfide, and other substances whose

flash points range from -30 to 0C.

Methanol, ethanol, xylene, benzyl acetate (or amyl acetate), and other substances whose flash points

range from 0 to 30C.

Kerosene, gas oil, turpenine oil, isopentyl alcohol (or isoamyl alcohol), acetic acid, and other substances

whose flash points range from 30 to 65C.

Flammable gas (hydrogen, acetylene, ethylene, methane, ethane, propane, butane, and

othersubstances that are gases at a temperature of 60C at 0.2 bar absolute pressure.)

If liquid with salt water and much salinity of salt agar etc has been spilled in the chamber, remove all

water in the chamber and wipe up all water around the lid gasket.

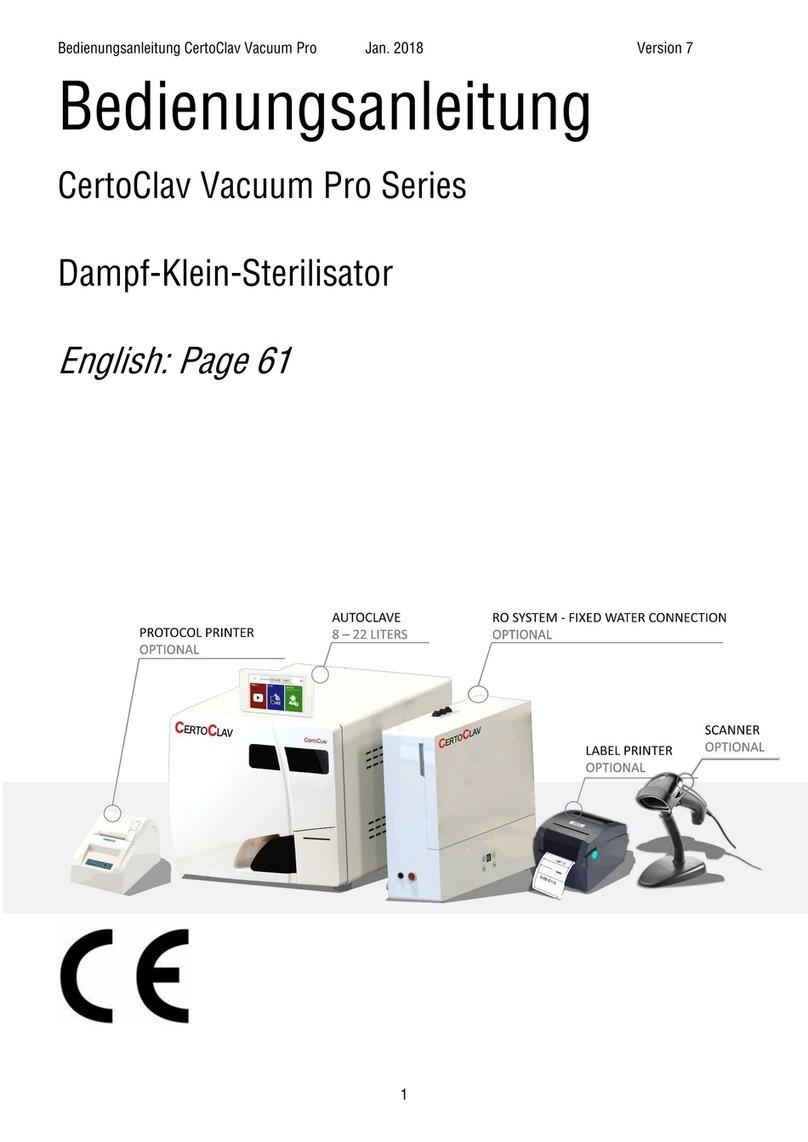

5 Introduction

This autoclave is an automatic vacuum steam sterilizer. The autoclave can perform all kinds of cycles

known from class B, class S and class N autoclaves. The autoclave sterilizes liquids in bottles, hollow

bodies of type A and B, porous materials, textiles, double wrapped, single wrapped and unpacked solid

instruments. In material testing mode, the cycles can be performed fully automatically without user

interaction. The autoclave has an 7” touch interface and a digital built in front panel LCD screen. 4

independent temperature sensors, a flexible media temperature sensor, a high precision pressure

sensor, vacuum pump made-in-Germany, safety valves, electrical locker, safety switches and two

independent microcontrollers ensure safe operation and automatic monitoring of the autoclave. The