11

Safety instructions

Safety instructions - performance of trials

Wear your personal protective equipment

in accordance with the hazard category

of the media to be processed. Otherwise

there is a risk from:

- splashing and evaporation of liquids

- ejection of parts

- release of toxic or combustable gases.

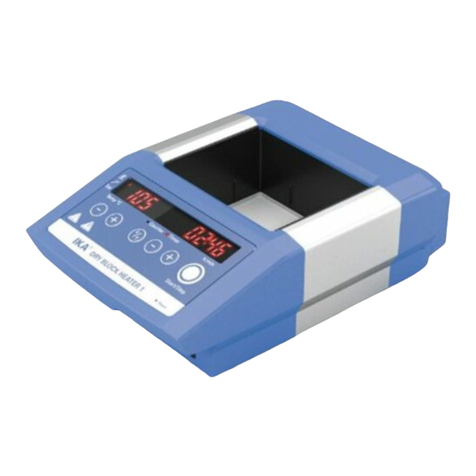

• Immerse external temperature sensors (PT 1000 ...) at least 20

mm deep into the medium or insert the sensor into the hole

provided for the purpose in the temperature control block.

• The PT 1000 external temperature sensor must always be in-

serted in the block / media when connected.

• Do not heat liquid media except with the block. Never pour

liquid media directly on to the heating plate!

• Safe operation is only guaranteed with the accessories de-

scribed in the ”Accessories” chapter.

• Always disconnect the plug before fitting accessories.

• Accessories must be securely attached to the device and can-

not come off by themselves. The centre of gravity of the as-

sembly must lie within the surface on which it is set up.

• Refer to the operating instructions for the accessories.

Safety instructions - power supply/ switching off the device

The appliance can only be disconnected

from the mains supply by pulling out the

mains plug or the connector plug.

• The device will automatically restart in mode B following any

interruption to the power supply.

For protection of the equipment

• The appliance may only be opened by experts.

• Do not cover the device, even partially e.g. with metallic plates

or film. This results in overheating.

• Ensure that the base plate is kept clean.

• Protect the appliance and accessories from bumps and impacts.

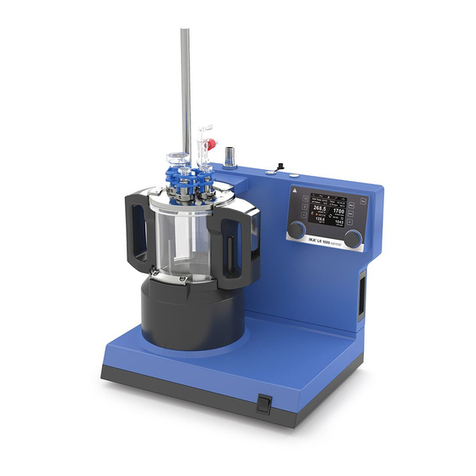

• Observe the minimum distances between the devices, be-

tween the device and the wall and above the assembly (min.

800 mm), see Fig. 2.

General safety instructions

•Read the operating instructions in full before starting

up and follow the safety instructions.

•Keep the operating instructions in a place where they can be

accessed by everyone.

•Ensure that only trained staff work with the appliance.

•Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations

•Socket must be earthed (protective ground contact).

•Before starting the device for the first time, ensure that the

connector cable is suitable for the type of socket used and that

a safe protective earth connection is assured.

Risk of burns! Exercise caution when

touching the housing parts and the heat-

ing plate.

The heating plate can reach tem-

peratures in excess of 120 °C. Pay attention to the residual heat

after switching off.

The device may not be transported

unless it is cold!

Safety instructions - device arrangement

Do not operate the appliance in explo-

sive atmospheres, with hazardous sub-

stances or under water.

•Set up the appliance in a spacious area on an even, stable,

clean, non-slip, dry and fireproof surface.

•The feet of the appliance must be clean and undamaged.

•The voltage stated on the type plate must correspond to the

mains voltage.

•The socket for the mains cord must be easily accessible.

•The power supply cable and cables to the external sensors must

not be allowed to come into contact with the hot mounting

plate.

•Check the appliance and accessories beforehand for damage

each time you use them. Do not use damaged components.

Safety instructions - permissible media

Caution! Only media whose flashpoint

lies above the safety temperature limit of

130 °C may be processed or heated with

this device.

Beware of hazards due to:

- flammable materials

- combustible media with a low boiling temperature

- glass breakage

- incorrect container size

- overfilling of media (in a beaker)

- unsafe condition of container.

• Process pathogenic materials only in closed vessels under a

suitable extractor hood. Please contact IKA®if you have any

questions.

Only process media that will not react

dangerously to the extra energy produced

through processing. This also applies to any

extra energy produced in other ways, e.g. through light irradiation.

• Bear in mind the possibility of contamination that might lead

to undesirable chemical reactions.

Fig. 2

DANGER

DANGER

WARNING

WARNING

DANGER

WARNING

WARNING