10

7

9

8

10

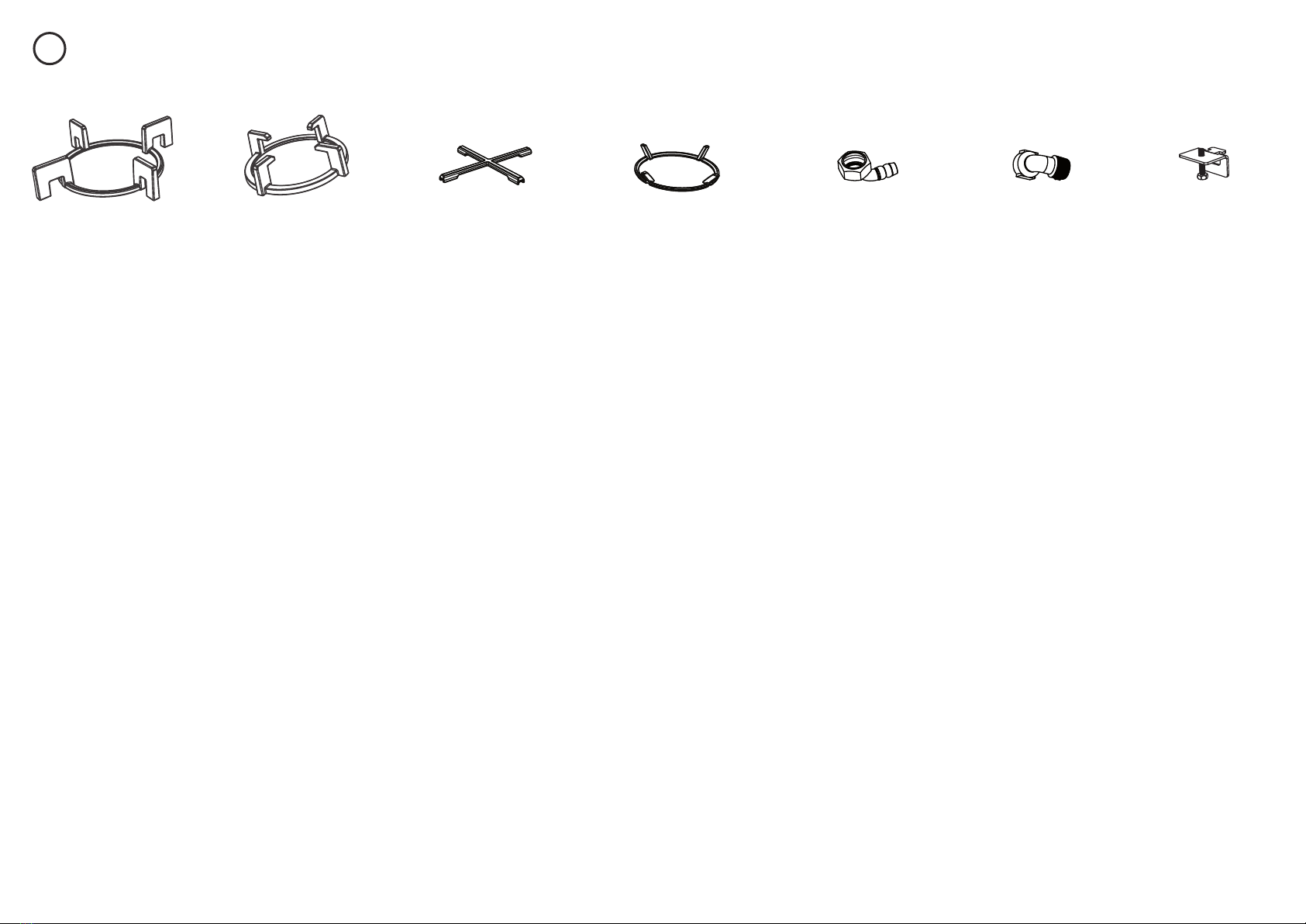

DISCARD PACKAGING

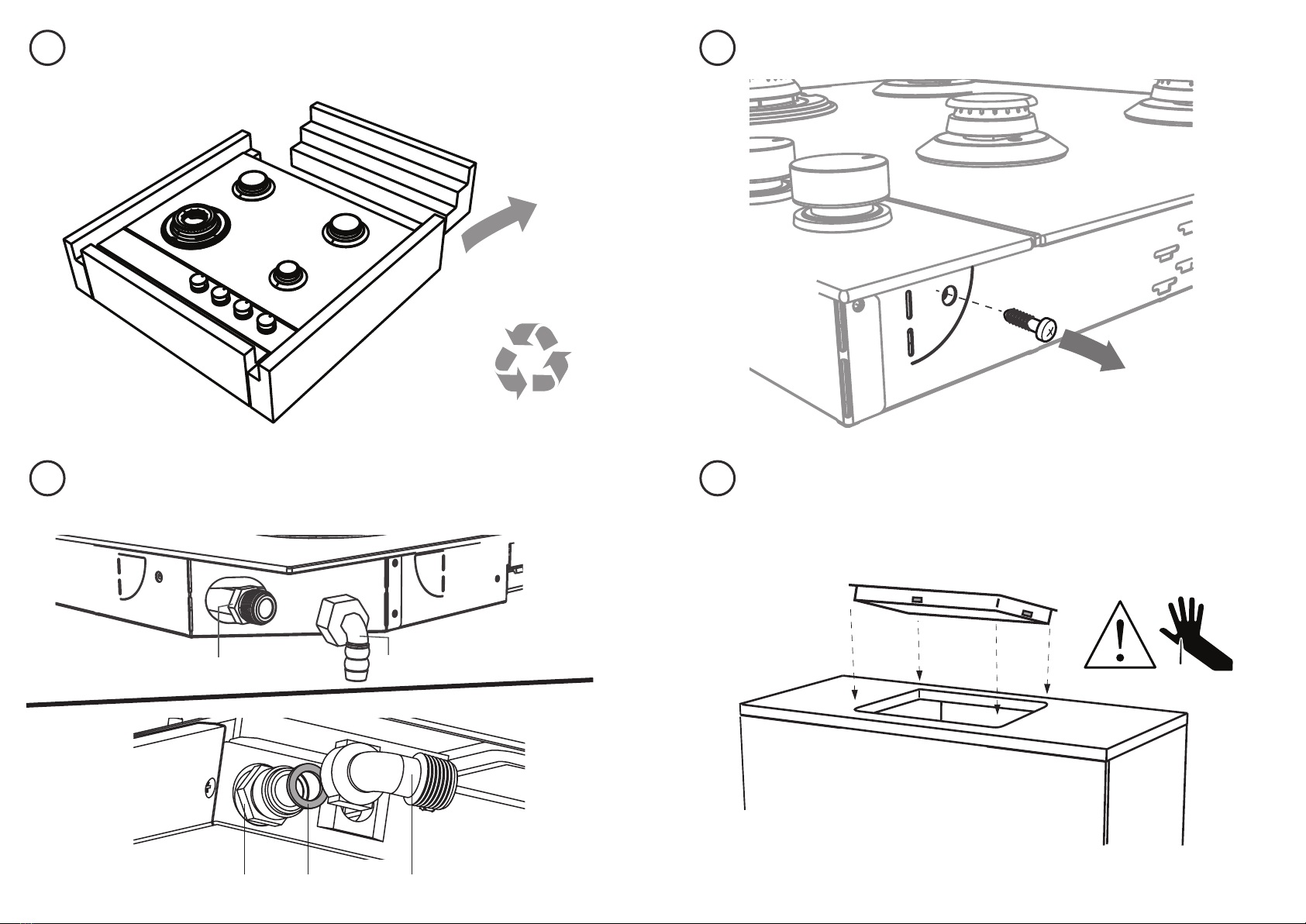

FIT THE ELBOW AND WASHER

REMOVE THE TWO TRANSIT SCREWS

LOWER GENTLY INTO THE CUTOUT

GAS

ON

GAS

ON

PTFE

⁄”NPT

500 mm

50 mm

1

2

500 mm

25 mm

25 mm

500 mm

NG

NG LPG

LPG

20-50 mm

½“ BSP ½“ BSP

x 4

1

1

2

2

16-20mm 20-30mm

Fibre washer

Floating nut Elbow (½”BSP external thread)

LPG test point adaptor (if using LPG)

min

S

A

R

min

A

F

S

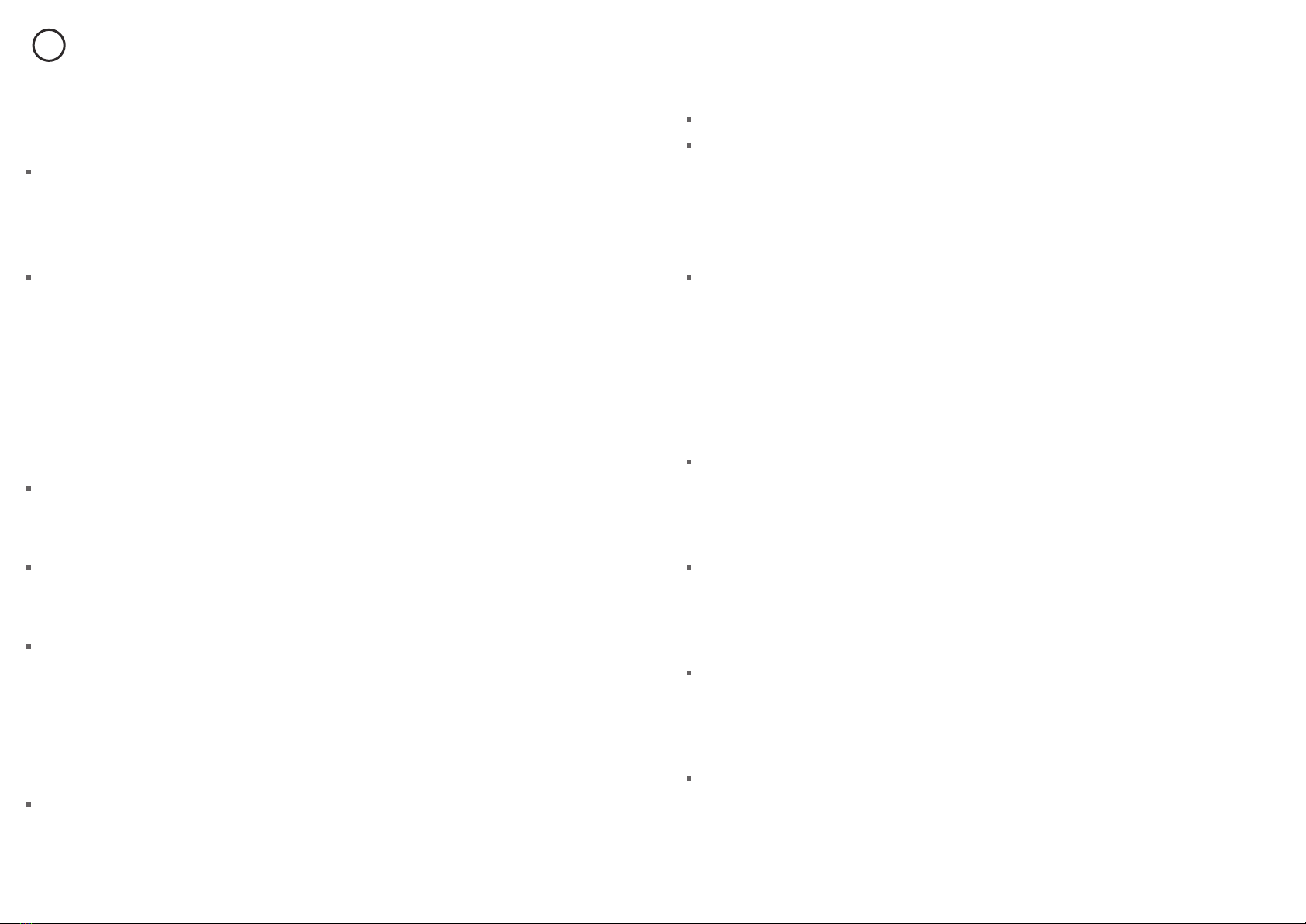

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

Foam Tape

Adhesive side

Fibre washer

Floating nut Elbow (½”BSP external thread)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½”(ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG Models

check all connections

Make sure to t the supplied

washer and test point adaptor.

Make sure the supply pressure

is regulated to 2.75 kPa, with

the two semi-rapid burners

operating at highest setting.

Washer Washer

yellow tiplifting o

good ame

Arrow

x 4

x 4

30-40mm 40mm+

Recycle responsibly

GAS

ON

GAS

ON

PTFE

⁄”NPT

500 mm

50 mm

1

2

500 mm

25 mm

25 mm

500 mm

NG

NG LPG

LPG

20-50 mm

½“ BSP ½“ BSP

x 4

1

1

2

2

16-20mm 20-30mm

Fibre washer

Floating nut Elbow (½”BSP external thread)

LPG test point adaptor (if using LPG)

min

S

A

R

min

A

F

S

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

Foam Tape

Adhesive side

Fibre washer

Floating nut Elbow (½”BSP external thread)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½”(ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG Models

check all connections

Make sure to t the supplied

washer and test point adaptor.

Make sure the supply pressure

is regulated to 2.75 kPa, with

the two semi-rapid burners

operating at highest setting.

Washer Washer

yellow tiplifting o

good ame

Arrow

x 4

x 4

30-40mm 40mm+

Repeat on the other side

GAS

ON

GAS

ON

PTFE

⁄”NPT

500 mm

50 mm

1

2

500 mm

25 mm

25 mm

500 mm

NG

NG LPG

LPG

20-50 mm

½“ BSP ½“ BSP

x 4

1

1

2

2

16-20mm 20-30mm

Fibre washer

Floating nut Elbow (½”BSP external thread)

LPG test point adaptor (if using LPG)

min

S

A

R

min

A

F

S

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

Foam Tape

Adhesive side

Fibre washer

Floating nut Elbow (½”BSP external thread)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½”(ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG Models

check all connections

Make sure to t the supplied

washer and test point adaptor.

Make sure the supply pressure

is regulated to 2.75 kPa, with

the two semi-rapid burners

operating at highest setting.

Washer Washer

yellow tiplifting o

good ame

Arrow

x 4

x 4

30-40mm 40mm+

Floating nut Elbow (1/2” BSP thread) & Washer

GAS

ON

GAS

ON

PTFE

⁄”NPT

500 mm

50 mm

1

2

500 mm

25 mm

25 mm

500 mm

NG

NG LPG

LPG

20-50 mm

½“ BSP ½“ BSP

x 4

1

1

2

2

16-20mm 20-30mm

Fibre washer

Floating nut Elbow (½”BSP external thread)

LPG test point adaptor (if using LPG)

min

S

A

R

min

A

F

S

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

Foam Tape

Adhesive side

Fibre washer

Floating nut Elbow (½”BSP external thread)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½”(ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG Models

check all connections

Make sure to t the supplied

washer and test point adaptor.

Make sure the supply pressure

is regulated to 2.75 kPa, with

the two semi-rapid burners

operating at highest setting.

Washer Washer

yellow tiplifting o

good ame

Arrow

x 4

x 4

30-40mm 40mm+

Model may vary from illustrations shown

Floating nut Fibre washer Elbow (1/2” BSP external thread)

HONG KONG

SINGAPORE

GAS

ON

GAS

ON

PTFE

⁄”NPT

500 mm

50 mm

1

2

500 mm

25 mm

25 mm

500 mm

NG

NG LPG

LPG

20-50 mm

½“ BSP ½“ BSP

x 4

1

1

2

2

16-20mm 20-30mm

Fibre washer

Floating nut Elbow (½”BSP external thread)

LPG test point adaptor (if using LPG)

min

S

A

R

min

A

F

S

REAR CLAMPS FRONT CLAMPS

40 mm

40 mm

30 mm

30 mm

30 mm

30 mm

Foam Tape

Adhesive side

Fibre washer

Floating nut Elbow (½”BSP external thread)

NG Models

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 3 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½”(ISO 71) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG Models

check all connections

Make sure to t the supplied

washer and test point adaptor.

Make sure the supply pressure

is regulated to 2.75 kPa, with

the two semi-rapid burners

operating at highest setting.

Washer Washer

yellow tiplifting o

good ame

Arrow

x 4

x 4

30-40mm 40mm+