ACE95 Series

7

Monthly Maintenance

1.Visually inspect the unit to ensure tight connec-

tions, tight seals, and safe operation.

2. Observe the blanketing pressure.

3. Inspect the inlet pressure for the proper pressure

range(stamped on the valvenameplate).

Annual Maintenance

1.Visually inspect the unit to ensure tight connec-

tions, tight seals, and safe operation.

2. Observe the blanketing pressure.

3. Inspect the inlet pressure for the proper pressure

range(stamped on the valvenameplate).

4.Visually inspect valve for any external wear.

5. If there is evidence of leakage or unstable internal

motion, a rebuild with seal replacement and

relubricationmaybe in order.

Disassembly and Assembly

Before removing the valve from the line,

ensure that it is isolated from the gas

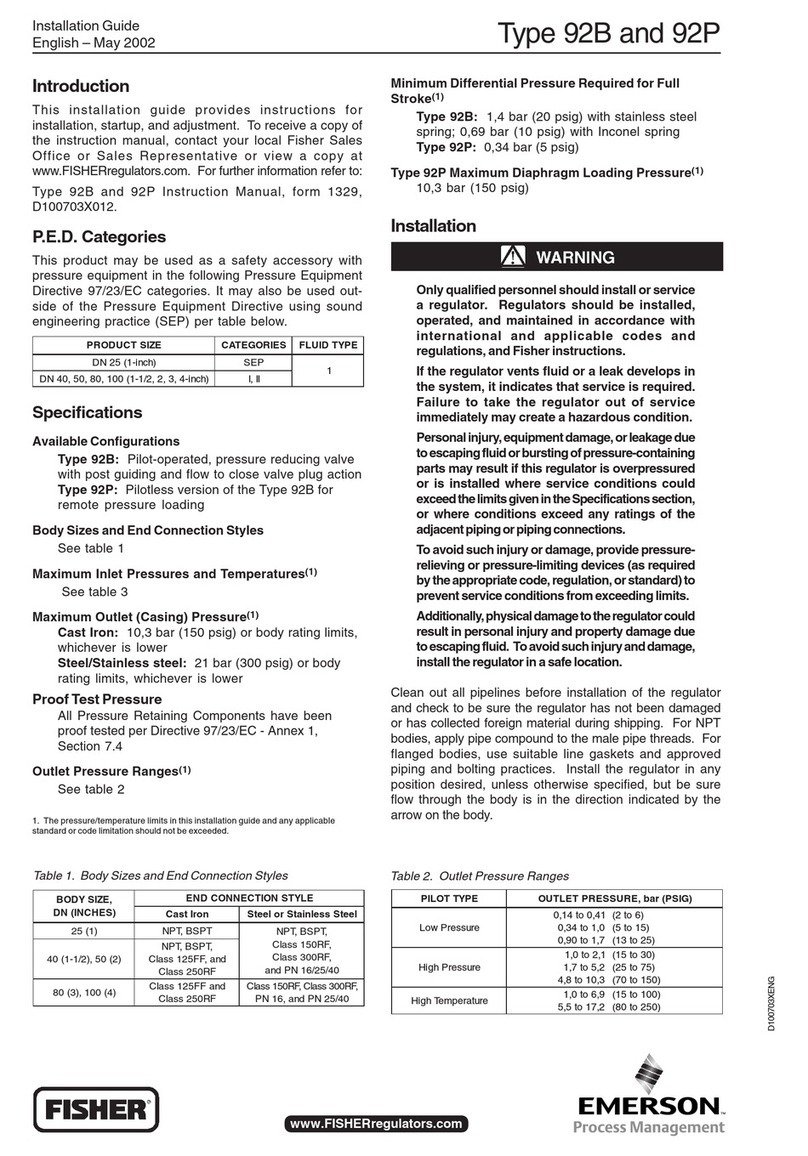

YLPPUSTELNILAUTCA ,EVLAVOTERUSSERP )rab(GISP

ERUSSERPTROPCITSONGAID

TOLIPNEHW)rab(GISP NEPOOTSTRATS EVLAVNIAMNEHW)rab(GISP NEPOOTSTRATS SIEVLAVNIAMNEHW)rab(GISP NEPOYLLUF

)rab7,1(52)rab6,1(42)rab6,0(9)rab1,0(2

)rab1,2(03)rab0,2(92)rab9,0(31)rab4,0(6

)rab4,2(53)rab3,2(43)rab1,1(61)rab6,0(9

)rab8,2(04)rab7,2(93)rab4,1(02)rab9,0(31

)rab1,3(54)rab0,3(44)rab7,1(42)rab2,1(71

)rab5,3(05)rab4,3(94)rab9,1(82)rab5,1(12

YLPPUSTELNILAUTCA ,EVLAVOTERUSSERP )rab(GISP

ERUSSERPTROPCITSONGAID

TOLIPNEHW)rab(GISP NEPOOTSTRATS EVLAVNIAMNEHW)rab(GISP NEPOOTSTRATS SIEVLAVNIAMNEHW)rab(GISP NEPOYLLUF

)rab6,3(15)rab5,3(05)rab0,2(92)rab3,0(5

)rab1,4(06)rab0,4(95)rab5,2(63)rab8,0(21

)rab8,4(07)rab7,4(96)rab0,3(34)rab3,1(91

)rab5,5(08)rab4,5(97)rab6,3(15)rab9,1(72

)rab2,6(09)rab1,6(98)rab0,4(95)rab3,2(43

)rab9,6(001)rab8,6(99)rab6,4(66)rab9,2(24

)rab6,7(011)rab5,7(901)rab1,5(47)rab5,3(05

)rab3,8(021)rab2,8(911)rab6,5(18)rab9,3(75

Table 3.Type ACE95 DiagnosticsTable: Cv 1through 4, Inlet Pressure Range Spring25 to 50 psig (1,7 to3,5 bar)

Table 4.Type ACE95 DiagnosticsTable:Cv 1through 4, Inlet PressureRange Spring 51 to 120 psig (3,5 to 8,3 bar)

supply pressure and that all pressure has

been released from the valve. (The drain

on the inlet filter is convenient to bleed

off gas.) All tank connections must be

closed or sealed in accordance with your

plant’s operating and safety procedures. If

installed, electrical connections to the

explosion proof switch must be deacti-

vated before opening the enclosure or

disconnecting the wiring (in accordance

with codes and safety practices).

It is recommended that all seals and diaphragms be

replaced as a matter of good practice whenever a valve

is disassembled and re-assembled.Parts kits are

availablethrough either your Fisher SalesRepresenta-

tive or the Fisher Sales Office.

If you are performing disassembly or assembly opera-

tions on a Type ACE95Sr valve, refer to the Parts List

and see figure 8.If you are working on aType ACE95

valve, refer to the Parts List and see figure 9.

Note

Have your model number,serial number,

inlet pressure and set pressure range, Cv

value, and tank vent/relief setting avail-

able when ordering parts.Valve informa-

tion is on the nameplate (on the upper

actuatorcase).