Type MR108

6

Installation

!

WARNING

Personal injury or system damage

may result if this regulator is installed,

without appropriate overpressure

protection, where service conditions

could exceed the limits given in the

nameplate. Refer to Overpressure

Protection section for recommendations

on how to prevent service conditions

from exceeding those limits.

Additionally, physical damage to the

regulator may result in personal injury

or property damage due to escaping of

accumulated gas. To avoid such injury

and damage, install the regulator in a

safe location.

All vents should be kept open to permit

Protect openings against entrance of

rain, snow, insects or any other foreign

material that may plug the vent or vent

line. On outdoor installations, point the

spring case vent downward to allow

condensate to drain.

Under enclosed conditions or indoors,

escaping gas may accumulate and be

an explosion hazard. In these cases,

the vent should be piped away from the

regulator to the outdoors.

Note

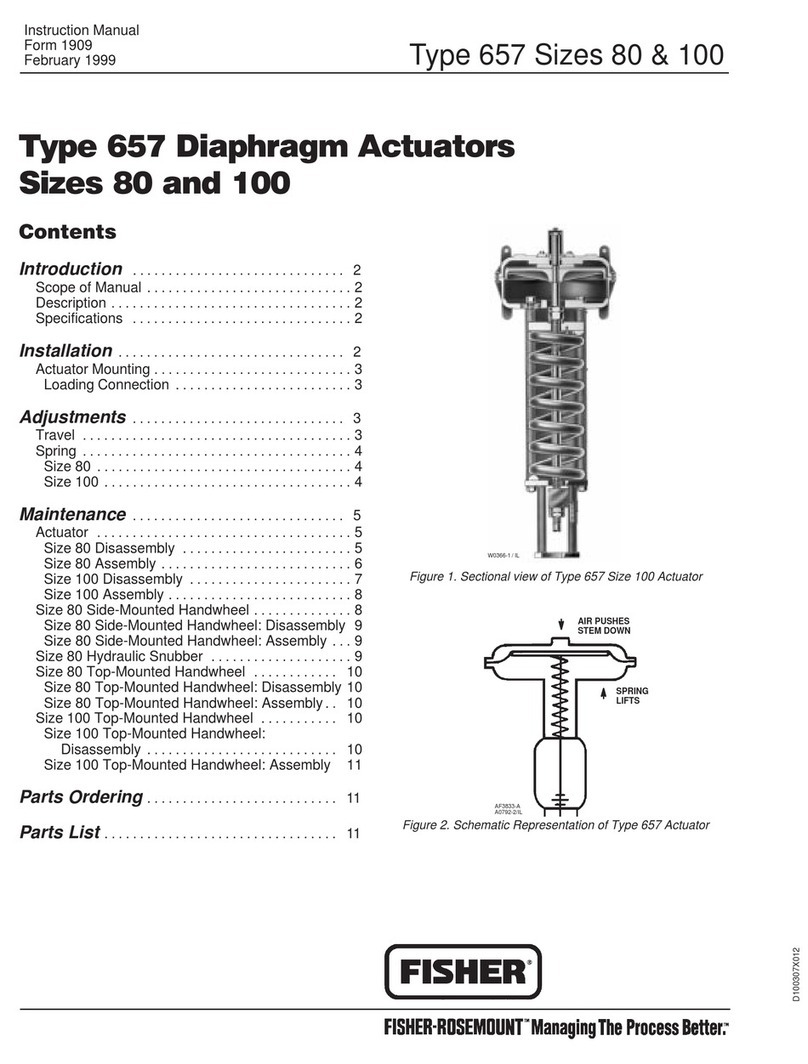

To avoid premature wear of internal

parts, it is recommended that the

actuator be oriented up or down in liquid

General Installation Instructions

!

WARNING

bleed valve may result in regulator

damage, personal injury and property

damage. To avoid such injury and

damage, make certain the bleed valve (if

used) is properly closed after venting air.

Always open bleed valves slowly. These

weepage will occur when the valves

are opened. Operating personnel must

protect themselves from exposure to

Note

A linear cage is recommended for

is a concern but it will limit the overall

capacity of the regulator.

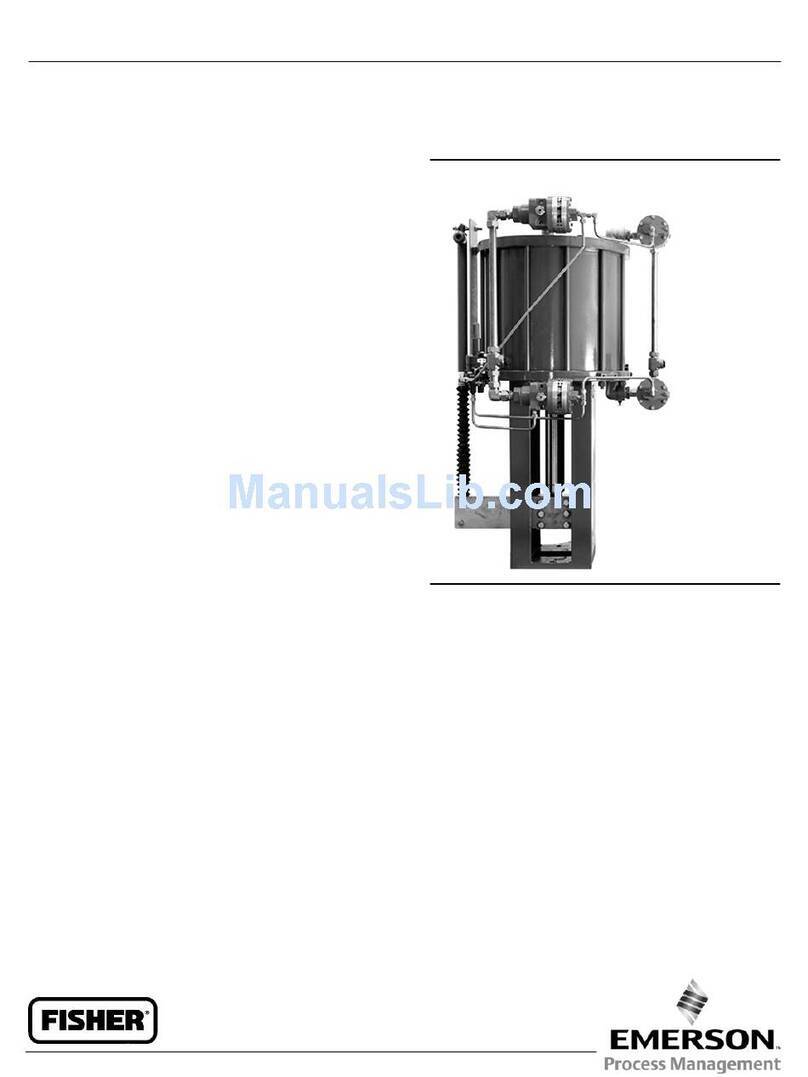

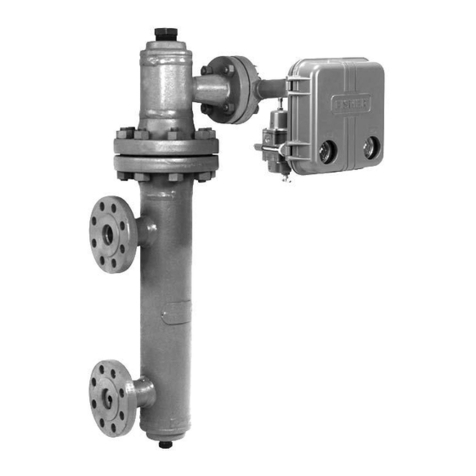

Vertical installation with the actuator installed directly

above or below the main valve is recommended but for

optimal performance, the actuator should be installed

below the main valve. The use of a bleed valve is

recommended for liquid installations that require the

high pressure actuator to be mounted above the main

valve. The unit will operate in horizontal installations

with the actuator on the side, however, this could result

in premature wear of parts. Make sure that ow will

be in the same direction as that indicated by the body

arrow. Orientation of the two vents should always be

down. Vents may be rotated after regulator installation

so that the vent screens are down.

Before installing the regulator:

• Check for damage which might have occurred

during shipment.

• Check for and remove any dirt or foreign material

which may have accumulated in the regulator body.

• Blow out any debris, dirt or copper sulfate in the

tubing and the pipeline.

• Apply pipe compound to the external threads of

the pipe before installing the regulator.

• Make sure gas ow through the regulator is in the

same direction as the arrow on the body. “Inlet”

and “Outlet” connections are clearly marked.

Note

For proper regulator control and