FISNAR DC100 MAX User manual

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 2 - DC100 MAX Rev 4

Table of Contents

Overview 4

Product Safety Statements 5

Specifications 7

Accessories 7

External Controls 8

Display Screen 11

Keypad Controls 12

Machine Setup 15

Dispense Setup 16

Dispense Modes 18

•Purge Mode

18

•Teach Mode

19

•Timed Mode

20

•Time+ Mode

22

•Cycle Mode

24

Function Menu 26

•Program Number

28

•Glue Alarm

29

•Pressure Alarm

31

•Vacuum Alarm

33

•Auto Purge

35

•Add Time+

37

•Cycle Delay

38

•Dispense Count

39

•Dispense Limit

40

•Dispense Time

42

•Sequence

43

•Shot Actuation

47

•Power Button

48

•Language

49

•Calibration

50

•Machine Reset

51

•Total Cycles

52

•Used Time

53

•Machine Copy

54

•RS232 Port

55

•Pressure Unit

56

•Vacuum Unit

57

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 3 - DC100 MAX Rev 4

Table of Contents

•Dispense Cancel

58

•Change Password

59

•Operator Lockout

60

Foot Switch Connector 61

I/O Connector 62

•Schematic

62

•

Output Signals

63

•

Input Signals

64

•Output Signal Definition

65

•Input Signal Definition

66

•

Input / Output Signal Testing

68

RS232 Connector 70

•Barcode Scanner

70

•RS232 External Control

71

Spare Parts List 72

Technical Drawing 74

Appendix 75

•Appendix 1

75

•Appendix 2

76

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 4 - DC100 MAX Rev 4

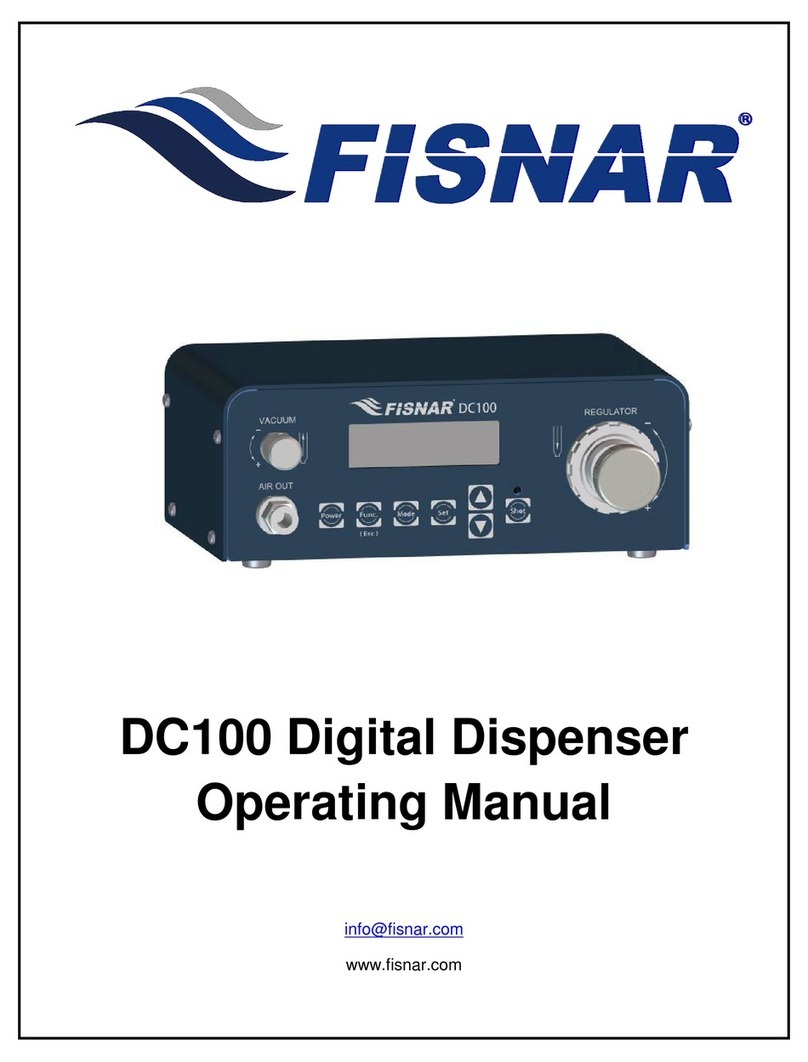

OVERVIEW

Model DC100 MAX Digital Dispenser

The DC100 MAX is a versatile, high precision dispenser designed to achieve exceptional levels

of process stability in critical dispense

applications: from microdot deposits and precise

beads, to potting and encapsulation. The advanced user-friendly dispense software features

a wide range of intelligent functions, allowing the user to maximize accuracy, control and

monitoring of their dispensing process.

Programmable alarms can be set to notify the user when fluid material life has ended, or when

fluctuations in the dispensing pressure have occurred. The sequence function enables the

dispense time to be changed at pre-set time intervals or shots. This ensu

res consistent

dispense results from the start to finish of the process, due to fluid viscosity changes or

reduction in the syringe fluid level being accounted for.

•Digital dispensing parameters, precision regulator, vacuum control and high flow solenoid ensure

high accuracy repeatable dispense results.

•16 programmable memory slots

•5 dispense modes (Purge, Teach, Timed, Time+, Cycle)

•Multilingual Display, digitally displaying dispense time, pressure and vacuum

•13 channel I/O circuit for external program change, dispense actuation, machine status and alarm

monitoring & signaling.

•I/O test mode

•Momentary or Latching shot actuation signal

•RS232 port for external control, monitoring and programming of dispense parameters

•Internal pressure and vacuum calibration function

•Operator lockout function prevents dispense programs and functions from being modified

•Pressure and Vacuum alarm for maintaining consistent dispense parameters

•

Auto-purge cycle and glue alarm prevents premature curing when dispensing 2K fluid materials

•

Option to attach barcode scanner for touch-free program selection and dispense actuation

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 5 - DC100 MAX Rev 4

Do not operate the machine in excess of its maximum ratings / settings.

Make sure that the input air supply is clean and dry. A 5 micron air filter/regulator

(560567) is recommended to ensure the input air supply is clean and dry.

If corrosive or flammable fluids are being used, a syringe barrel adapter head

assembly with inline filter must be used, to help prevent the fluids from being

sucked back into the machine.

The fluid being dispensed may be toxic and / or hazardous. Refer to the Material

Safety Data Sheet for proper handling and safety precautions.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Do not expose the machine directly to sunlight.

Avoid cleaning the machine with aggressive solvents – neutral detergents are

preferred.

Do not overfill the barrel and/or lay the barrel on its side. This will prevent fluids

from flowing back into the machine – refer to figures A& Bbelow.

DC100 MAX Malfunction

If the machine malfunctions, shut down the machine immediately. This can be

done by either pressing the power button on the front of the machine or

disconnecting the power cord.

Always use a piston with the barrel to prevent fluids from flowing back into the

machine

When dispensing low viscosity fluids that require the vacuum be aware not to

increase to a point where fluids begin to run back into the air line potentially

reaching the control box. The vacuum should not be set too high or it will cause

material to creep backwards.

SAFETY

General Precautions

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 6 - DC100 MAX Rev 4

Inappropriate Use

If the machine is used in a way other than described in this manual, it may cause damage

to self or property.

Do not use any components with the machine other than Fisnar authorized

components.

Do not use incompatible materials.

Do not make any modifications to the machine.

All repairs must be done using Fisnar specified spare parts.

Do not operate the machine in excess of its maximum ratings / settings.

Fire Prevention

Refer to the following instructions to avoid any fire or explosion.

Access your surroundings and the location of the nearest fire extinguisher and

Emergency Exit.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Immediately disconnect power if any sparking or smoke appears.

Do not expose the machine directly to sunlight.

Maintenance

The DC100 MAX is generally a maintenance free machine. However, to ensure smooth

operation please follow the below instructions.

Only use non-woven cleaners on the machine.

Avoid cleaning the machine with aggressive solvents – neutral detergents are

preferred.

Ensure that compressed air supply to the machine is clean and moisture free.

Do not lay the barrel on its side. This will prevent fluids from flowing back into

the machine.

SAFETY

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 7 - DC100 MAX Rev 4

ACCESSORIES

Item

Description

Quantity

5601890

Power Adaptor (Input: 100 – 240 VAC / Output: 24 VDC)

1

5601888

Foot Pedal

1

561851

Air Inlet Hose Assembly 1

5601969

FSX Syringe Barrel Stand

1

5779K712

Push To Connect Tube Fitting 1/4" Stem OD X 5/32" Tube OD

1

Note: Consumable kit (part # QK-CSK) & needle sample kit (part # QK-NSK) available to purchase separately.

Part # QK-CSK Part # QK-NSK

SPECIFICATIONS

Dimensions (W x D x H): 7.56” x 5.04” x 3.00” (192 x 128 x 76 mm)

Weight: 2.31 lbs. (1.05 kg)

Input AC to Power Supply: 100 – 240 VAC, 50 / 60 Hz

Output DC from Power Supply: 24 VDC – 0.75 Amp

Cycle Rate: Up to 600 cycles / min

Relative Humidity: 20 – 90% (No Condensation)

Operating Temperature: 50 – 104℉ (10 – 40℃)

Timer: 0.008 – 999.9 seconds

Air Input: 100 psi (7 bar) max

Air Output: 1 – 100 psi (0.07 – 7 bar)

Standards:

CE & UKCA Approved, EMC Compliant.

RoHS Compliant

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 8 - DC100 MAX Rev 4

EXTERNAL CONTROLS

Item Illustration Item Illustration Item Illustration

1 Vacuum Control 7 Scroll Buttons 13 Air In Port

2 Air Out Port 8 Shot Button 14 Foot Switch Connector

3 Power Button 9 Display 15 Fuse

4 Function / Escape

Button

10 Air Pressure

Regulator 16 Exhaust Port

5 Mode Button 11 Power Input Connector 17 RS232 Connector

6 Set Button 12 I/O Connector 18 Grounding Point

1

2

3

4

5

6

7

9

8

16

REAR

14

11

12

13

15

FRONT

10

17

18

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 9 - DC100 MAX Rev 4

EXTERNAL CONTROLS

1. Suck Back Control

Keeps a negative air pressure in the syringe barrel when not

dispensing. Required to prevent low viscosity fluids dripping from the

dispense tip in between dispense cycles.

2. Air Out Port The syringe barrel adapter head assembly is connected here.

3. Display Screen

Shows the current program number, dispense mode, parameter

values and active function alarms of the machine.

For further information, please refer to display screen overview.

4. Pressure Regulator

Adjusts the amount of pressure being used to dispense fluid from the

syringe barrel. To reach the desired pressure, turn the knob

counterclockwise to a point below the required pressure, and then turn

the knob clockwise to reach the required pressure.

The regulator can be locked into position by tightening the jam nut

behind the knob against the regulator body on the front panel of the

machine.

1

2

3

4

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 10 - DC100 MAX Rev 4

EXTERNAL CONTROLS

1. Foot Switch

Connector

The foot pedal switch is connected here. Alternatively, it can be used

for connecting to an external device (e.g. Fisnar dispense robot) that

will send the dispense start signal to the machine.

2 Fuse The machine fuse is located here.

3. Power Input

Connector Power input cable from the external power supply is connected here.

4. I/O Connector

Where the external machine I/O input signals and output signals are

connected.

A courtesy 24V + output is also included on the I/O Connector

5. RS232 Connector

Used for externally programming and controlling the machine.

Alternatively, a barcode scanner can be plugged into this connector.

6. Grounding Point

A wire from an external earth ground

source within the workplace

environment can be connected here

to ensure the machine is

permanently and safely grounded.

7. Air In Port External Compressed air 70-100 psi (5-7 bar) is connected here,

using the supplied ¼” OD air inlet hose.

8. Exhaust

When the suck-back control is in use, air will be exhausted from this

port in between dispense cycles.

A muffler (560024-DCHF) can be fitted into the exhaust outlet port to

reduce the emitted noise of the exhausted air.

8

1

3

4

7

2

5

6

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 11 - DC100 MAX Rev 4

DISPLAY SCREEN

1. Program Number Displays the currently selected program number. Up to sixteen (16)

individual programs can be saved to the machine for future recall.

2. Dispense Mode

Displays the current mode the saving program is in. There are five (5)

dispense modes available: PURGE, TEACH, TIMED,

TIME+ and

CYCLE.

3. Function Alarms

Displays which feature(s) are currently turned ON. I.E. Dispense Limit

(L), Glue Alarm (G), Pressure Alarm (P), Vacuum Alarm (V) and Auto

Purge (A).

4. Parameter Values Displays the values of the machine parameters (i.e. dispensing time,

pressure and/or vacuum).

1

2

3

4

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 12 - DC100 MAX Rev 4

KEYPAD CONTROLS

1. Power On / Off Press the button to switch the machine ON or OFF.

2. Function Menu Press the button to enter into the function menu.

3. Dispense Mode Press the button to select the dispense mode that the program

will operate in (i.e. PURGE, TEACH, TIMED, TIME+, CYCLE).

4.

Set Dispense Time

/ Function Menu

Navigate

Press the button to set the dispense time. Use the or

buttons to change the individual numeric value. The digit displaying

the “_” below it, is the one that will be adjusted.

Continue to press the button to scroll through the digit positions,

adjusting the numerical values as required.

When the button is pressed after the first digit from the left is

displaying “_” below it, the “_” will move to below the decimal place.

1

2

3

4

5

6

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 13 - DC100 MAX Rev 4

Use the or

buttons to move the decimal place into the

correct needed position.

The button can continue to be pressed to cycle through the digit

and decimal place positions in a continuous scrolling cycle.

When the dispense time has been correctly set, press and hold the

button for approximately two (2) seconds to save the dispense

time and exit back to the home screen.

When in the function menu, the button is used to enter into the

function setting and then used to scroll through the different parameter

values within the function setting.

5. Parameter Display

Press the or

button to scroll through the different

parameter display screens.

Dispense Time

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 14 - DC100 MAX Rev 4

Dispense Time and Vacuum

Dispense Time and Pressure

Dispense Limit, Glue Alarm and Auto Purge

6. Dispense Shot Press the button to actuate the machine and begin dispensing

fluid.

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 15 - DC100 MAX Rev 4

MACHINE SETUP

1. Connect the air hose from a compressed air supply source 70-100 psi (5-7 bar) to the “Air

In” port on the back of the machine.

2. Insert the foot pedal connector plug into the “Foot Switch" connector on the back of the

machine.

3. Attach the appropriate country type plug adapter onto the power supply and then connect

the electrical power cord to the port on the back of the machine.

4. Connect the end of the adapter head assembly with the green colored push to connect fitting,

to the “Air Out” port on the front of the machine.

1

2

3

4

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 16 - DC100 MAX Rev 4

DISPENSE SETUP

Attach the syringe barrel adapter head assembly to the syringe barrel (with piston fitted inside) as shown

below. See FIG. 1 (A – C).

FIG. 1: Dispense Setup

Do not overfill the syringe barrel and/or lay the syringe barrel on its side. This will

prevent fluids from flowing back into the machine – refer to figures A& Bbelow.

Place the filled syringe barrel in the supplied syringe barrel stand (5601969) when

not being used.

1.

Connect the syringe barrel adapter head assembly to the “Air Out” port on the front of the

machine. Fisnar adapter head assemblies are fitted with a green colored push to connect

fitting (5606038) that can be inserted directly into the “Air Out” port on the front of the

machine.

2.

If a syringe barrel adapter head assembly with 5/32” OD tubing is being

used with the

machine that has a bayonet fitting attached to the end of it, make sure to cut the bayonet

fitting off from the tubing first. Then install the included push to connect air adapter fitting

(5779K712) onto the tubing and insert it into the “Air Out” port on the front of the machine.

If a syringe barrel adapter head assembly with 1/4” OD tubing is being

used with the

machine, cut the bayonet fitting off from the tubing and insert it directly into the “Air Out” port.

A

B

C

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 17 - DC100 MAX Rev 4

3.

When not being used, the syringe barrel

should be placed in the syringe barrel stand

provided. This will prevent the dispense tip from being accidentally damaged or having fluid

inside the syringe barrel flow back into the machine if it is placed horizontally on the work

surface.

The bottle it is placed into, allows any fluid that drips from the dispense tip to be safely

captured. The dispense tip is also protected in the bottle from any foreign contaminants or

environmental lighting that may affect the properties of the fluid within it.

4.

Purge trays are provided with the syringe stand to allow for a small amount of fluid to be

purged into a clean and contained location. This is also helpful when a new dispense tip is

attached to the syringe barrel or when checking for accurate fluid material flow. This is helpful

for ensuring optimum dispense results.

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 18 - DC100 MAX Rev 4

DISPENSE MODES

PURGE MODE

1.

Press the button until “PURGE” mode is displayed.

PURGE mode allows the operator to actuate the machine on demand whenever

the dispense signal is activated (i.e. foot pedal is pressed).

2.

Press the foot pedal or the button to actuate the machine

and begin

dispensing fluid. Release the foot pedal or button to stop dispensing fluid.

The machine will count up from zero (0) seconds

the amount of time you are

dispensing fluid while the foot pedal or button is pressed.

The TIME shown on the digital display after the foot pedal or button has

been released, will reset to zero (0) seconds every time the machine is actuated.

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 19 - DC100 MAX Rev 4

DISPENSE MODES

TEACH MODE

1.

Press the button until “TEACH” mode is displayed.

TEACH mode allows the operator to calculate the correct dispense time needed

for the application process. This is useful when carrying out a potting process.

2.

Press the foot pedal or the

button to actuate the machine and begin

dispensing fluid. Release the foot pedal or button to stop dispensing fluid.

The TIME shown will increase cumulatively every time the machine is actuated.

If or when needed, press and hold the button to reset the timer to zero (0).

3.

The time shown on the screen will be the total cumulative time the machine has

been actuated for.

Once the correct dispense time is obtained, press the button to switch to

TIMED, TIME+ or CYCLE mode to save the value.

DC100 MAX Digital Dispenser Operating Manual

© 2023 Fisnar - 20 - DC100 MAX Rev 4

DISPENSE MODES

TIMED MODE

1.

Press the button until “TIMED” mode is displayed.

TIMED mode allows the operator to dispense fluid for a set period, regardless of

how long the foot pedal is pressed.

2.

Press the button to set the dispense time. Use the or buttons to

change the individual numeric value. The digit displaying the “_” below it, is the

one that will be adjusted.

Continue to press the button to scroll through the digit positions, adjusting

the numerical values as required.

When the button is pressed after the first digit from the left is displaying “_”

below it, the “_” will move to below the decimal place. Use the or

buttons to move the decimal place into the correct needed position.

Table of contents

Other FISNAR Dispenser manuals

Popular Dispenser manuals by other brands

Kingston Technology

Kingston Technology SKID-DOO KFC110 instructions

Hydro

Hydro Chem 918 quick start guide

Franke

Franke EXOS629X Installation and operating instructions

Cornelius

Cornelius 2230 C4-100 manual

Cornelius

Cornelius IntelliBlue R134 Kuwait Series operating instructions

Silkpaint

Silkpaint AirPen manual