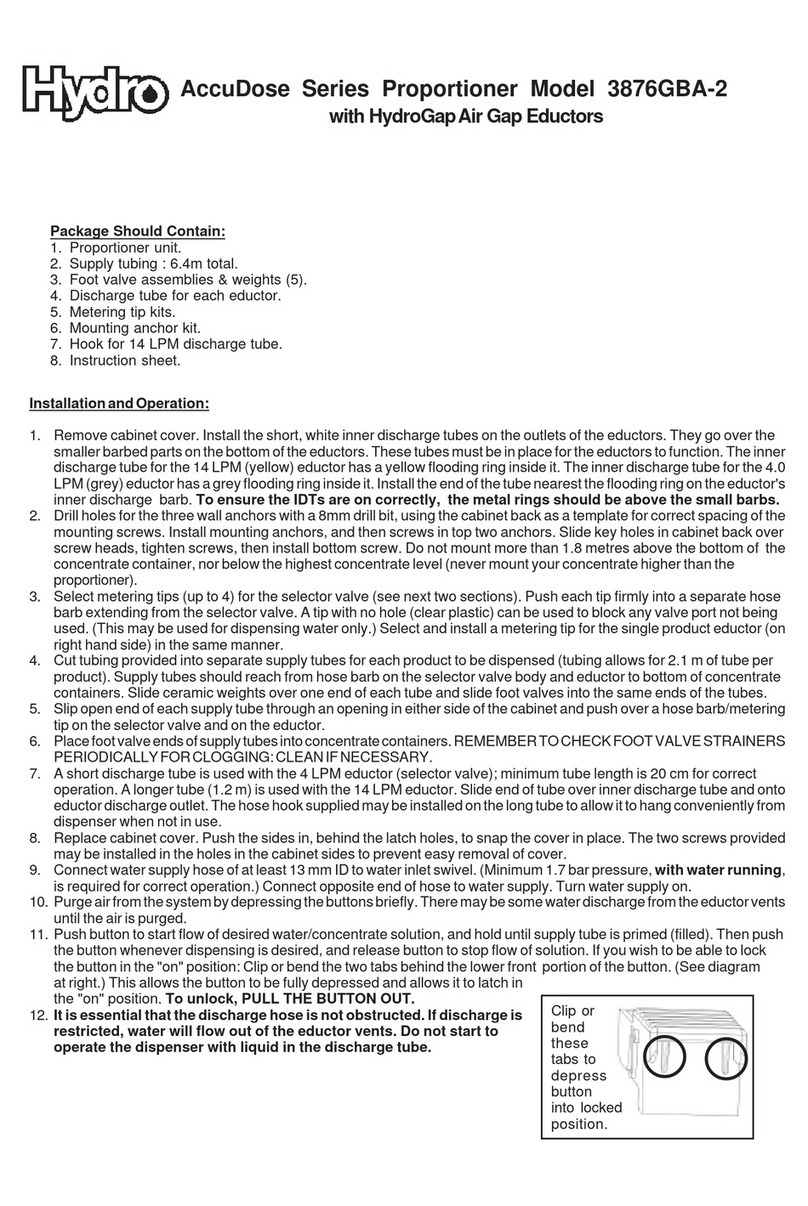

Troubleshooting Guide:

Problem Cause Solution

1. No discharge a. No water a. Open water supply

b. Excessive water pressure b. Install regulator if pressure

exceeds 85 PSI

c. Eductor clogged c. Clean* or replace

2. No concentrate draw a. Clogged check valve a. Clean or replace

b. Metering tip clogged b. Rinse in hot water or replace:

DO NOT REAM CLEAN!

c. Eductor clogged c. Clean or replace

d. Clogged water inlet d. Clean screen

e. Clogged foot strainer e. Clean or replace

f. Low water pressure and/or f. Minimum 25 PSI and 4 GPM

volume flow required to operate unit

g. Concentrate container empty g. Replace with full container

h. Check valve not screwed into h. Tighten, but DO NOT OVER

eductor firmly TIGHTEN!

3. Excess concentrate draw a. Metering tip not in place a. Press correct tip firmly into barb

(Or wrong metering tip)

4. Water flow won't shut off a. Ball valve defective a. Replace

5. Leaks at plastic tube a. Compression nut loose a. Tighten nut 1/2 turn

6. Low or no water flow a. Inlet screen clogged a. Clean or replace

b. Supply source inadequate b. 4 GPM flow necessary to unit.

Move unit or replumb incoming

line.

c. Scaled eductor or fittings c. Clean* or replace

7. Backflow into concentrate a. Eductor check valve inoperable a. Clean or replace check valve

* In hard water areas, scale (mineral deposits) may form at the discharge of the eductor. This scale may be

removed by soaking the eductor in a descaling (deliming) solution or by running the descalant through the

system.Whenremovingan eductorfor soaking,firmly graspthe eductorand unthreadthe adapterslocated

above and below the eductor. Replace in the same manner.

10084408

REV. A 1/04

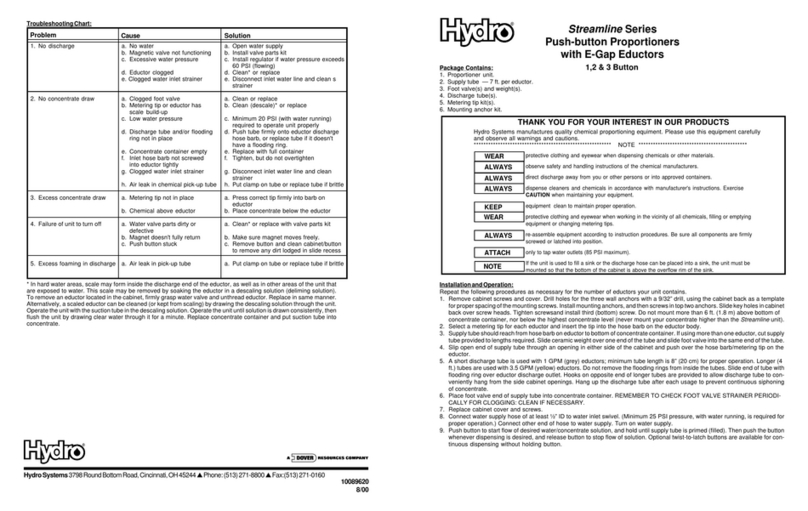

THANK YOU FOR YOUR INTEREST IN OUR PRODUCTS

protective clothing and eyewear when dispensing chemicals or other materials.

observe safety and handling instructions of the chemical manufacturers.

direct discharge away from you or other persons or into approved containers.

dispense cleaners and chemicals in accordance with manufacturer's instructions. Exercise

CAUTION when maintaining your equipment.

equipment after each use in accordance with instruction sheet.

protective clothing and eyewear when working in the vicinity of all chemicals, filling or emptying

equipment or changing metering tips.

re-assemble equipment according to instruction procedures. Be sure all components are firmly

screwed or latched into position.

only to tap water outlets (85 PSI maximum).

WEAR

ALWAYS

ALWAYS

ALWAYS

CLEAN

WEAR

ALWAYS

ATTACH

Hydro Systems manufactures quality proportioning and dispensing equipment. Please use this equipment carefully and

observe all warnings and cautions.

************************************************************ NOTE ********************************************************

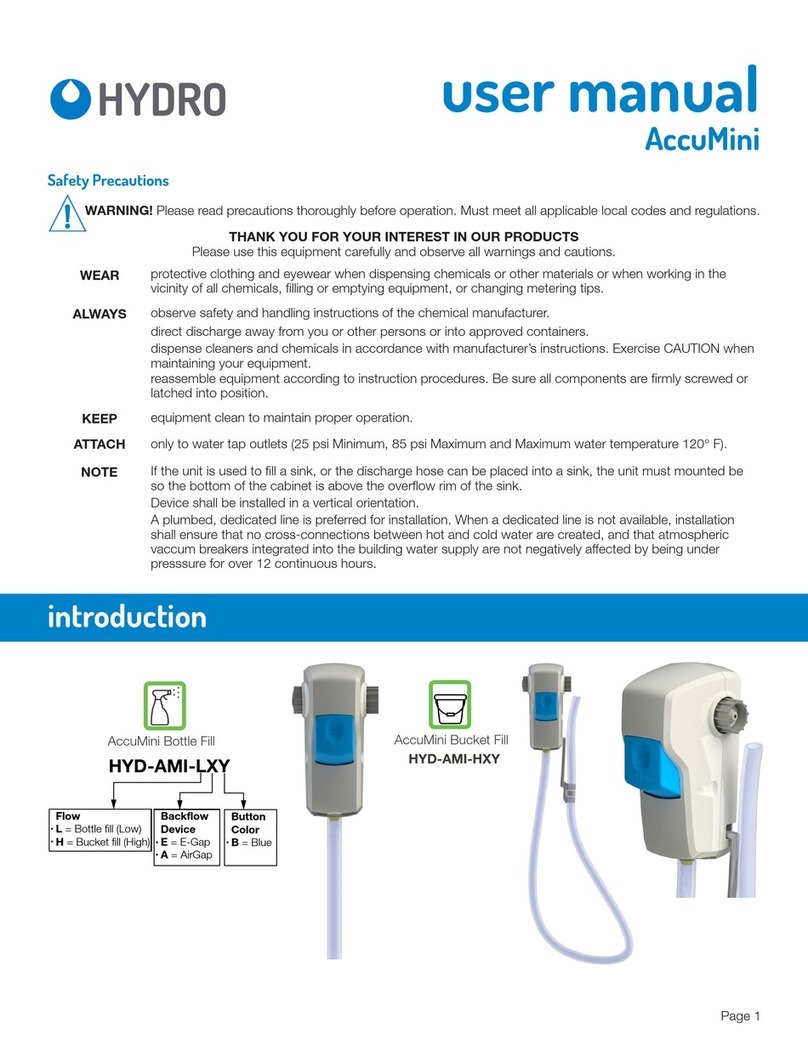

Wall mounted, high volume washing or foaming proportioner with one product eductor.

HydroChem Model 918

Multifunction Proportioning and Dispensing System

Package includes:

-- complete unit mounted on stainless steel front plate

-- (1) 7-foot vinyl product suction tube with foot strainer

-- (1) metering tip kit

-- (4) screws and (4) wall anchors for wall mounting (use 9/32" drill)

-- parts list and product structure diagram

Instructions for Operation:

1. Attach unit to wall using hardware provided.

2. Select metering tip (see section on metering tip selection) and press firmly into hose barb provided at the side

of the eductor. Install product suction tube on hose barb. The strainer end of the suction tube can be dropped

directly into the concentrate container.

3. Connectwater inlethose with 3/4" malegarden thread to femaleswivel at top leftside of unit. Tightento avoid

leaking.

4. Connect discharge hose to male 3/4" discharge provided at bottom of unit. Hose of 1/2" ID is recommended

if the hose length will be 50 feet or less. Use 3/4" ID hose if the total length of the hose will exceed 50 feet.

5. Turn on water supply to unit. Minimum 25 PSI water pressure is required to operate the unit.

6. Turn on product valve to begin proportioning and dispensing. Shut off the valve and turn on rinse (right) lever

for full volume rinse. Note: You may only use either the product or the rinse feature - only one valve may be in

use at a time.

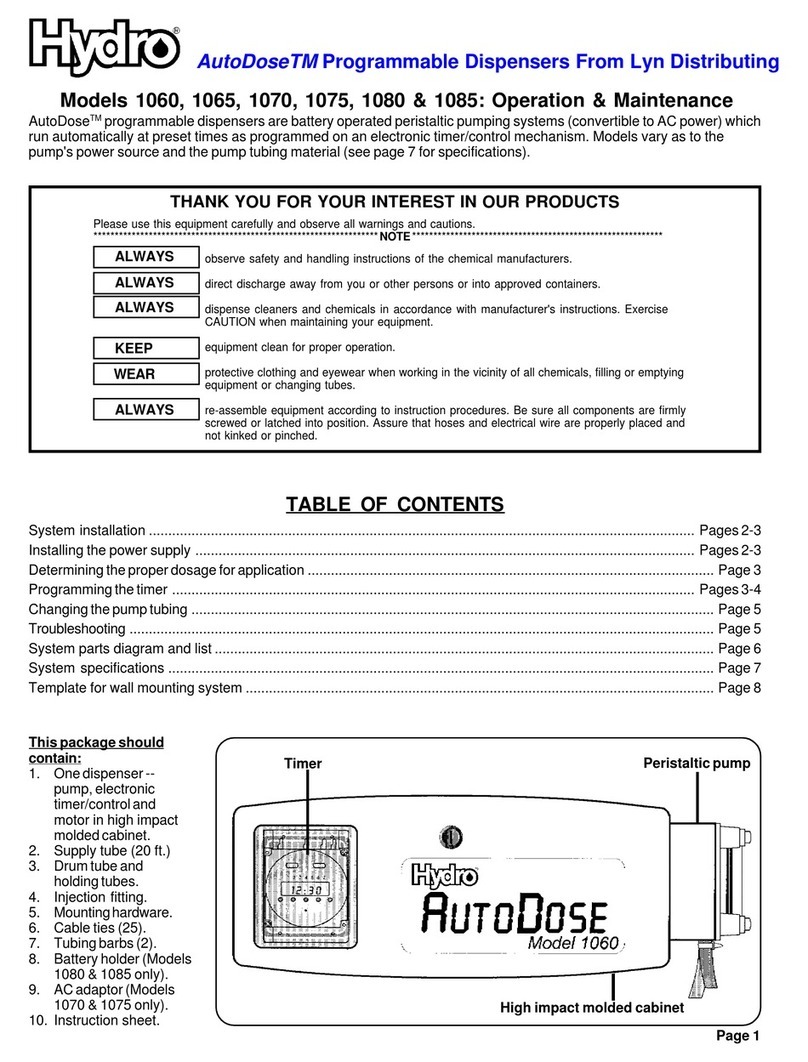

Metering Tip Selection:

The final concentration of the dispensed solution is related to several factors in the application, such as viscosity

oftheproduct,lengthanddiameterofthedischargehose,waterpressure,waterflowrate,watertemperature,hose

end attachments used, etc. A chart is provided on the next page which can be used as a guideline for selecting a

metering tip when proportioning water-thin concentrates. Test the actually achieved dilution using the Measure-

ment of Concentration procedure discussed on the next page. If product viscosity is greater than that of water,

choose a tip with a larger orifice than that which would deliver the desired water-to-product ratio for a water-thin

product. Test the actually achieved ratio using the Measurement of Concentration procedure on the next page.

Continue to choose and test tips until the desired dilution is achieved. A clear, undrilled tip is supplied to permit

drilling an orifice size not listed, if necessary.