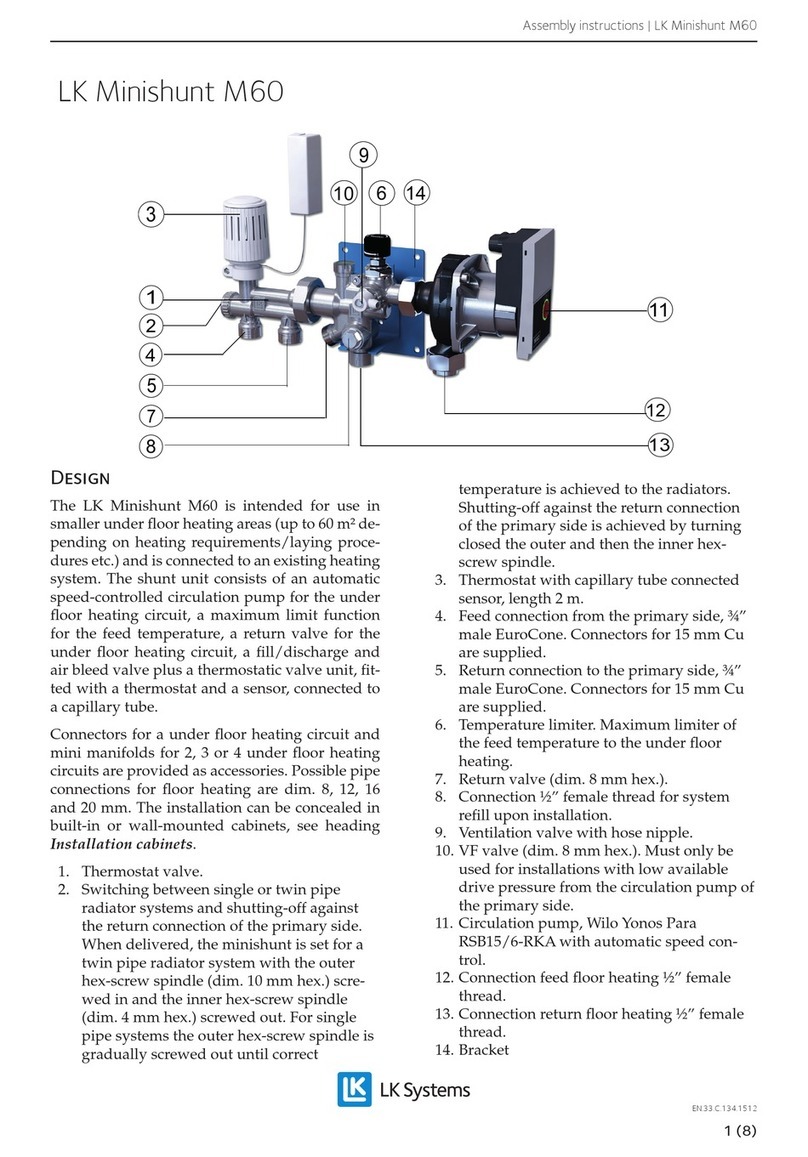

4) Laying the cable.

A hole is provided at the side of the box to feed out the cable. Do not take the cable off the

drum before laying as it will twist and make the installation difficult..

Connection is only required at one

end. The first 3metres is black

cable that can be cut as required.

The orange cable is the heated

part that must never be cut or

shortened.

As shown loop the cables to the

required marked spacings and

secure to the floor as you go

using the fixing tape supplied.

Towards completion it may be

necessary to slightly readjust the

cable spacings to the available

area. This will not be a problem

as long as the cables remain at

least 50mm apart and do not

cross or touch each other.

Never bury or try to hide the

cable. If necessary, start again.

If you have ordered the wrong size of kit contact your supplier.

Now and referring to the tables on page 1 test the cable circuit for continuity

(resistance) using an ohmeter. Avoid traffic over the laid area until floor tiling is

complete.

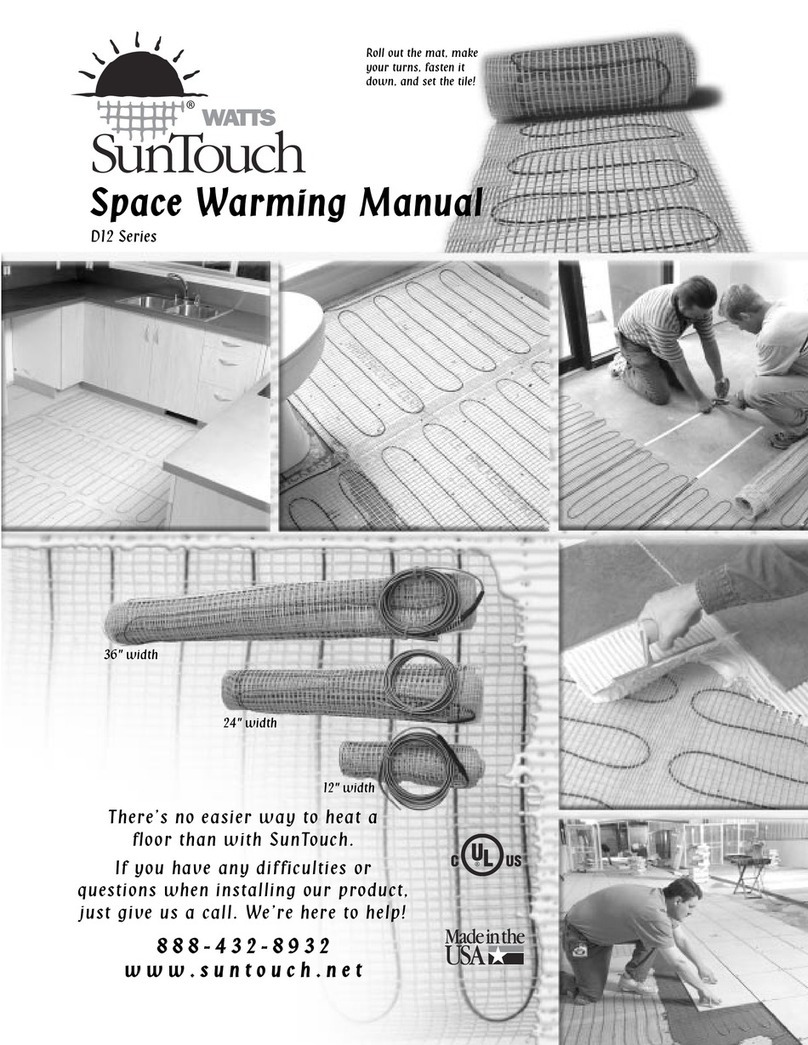

5). Install the Thermostat and Floor Probe.

Follow the instructions provided with the thermostat and the floor probe. For the floor probe

you will need to cut a channel for the protective spiral hose. (This may have been done at an

earlier stage as suggested). Fix the hose into position and shorten to the required length.

Feed the floor probe into the hose and block off the end. The floor probe is then attached to

the thermostat.

The thermostat should be installed in the room that is to be heated. For bathrooms the

thermostat must be placed outside the bathroom but as close to the installation as possible.

If necessary the heating cable cold tail and thermostat can be extended by up to 50 metres

using cable supplied by Flexel International Limited.

Figure 4.