Flo-Dynamics®TSD450™ II. Features & Specifications

Operations Manual Printed in the U.S.A. for Flo-Dynamics ® 9

II. FEATURES & SPECIFICATIONS

2.01 FEATURES

Mechanical Features

• Accurate sensor technology allows optimum fluid level to be maintained in

vehicle’s transmission.

• Two in-line 22-micron absolute fluid filters capture microscopic particles and

contaminants.

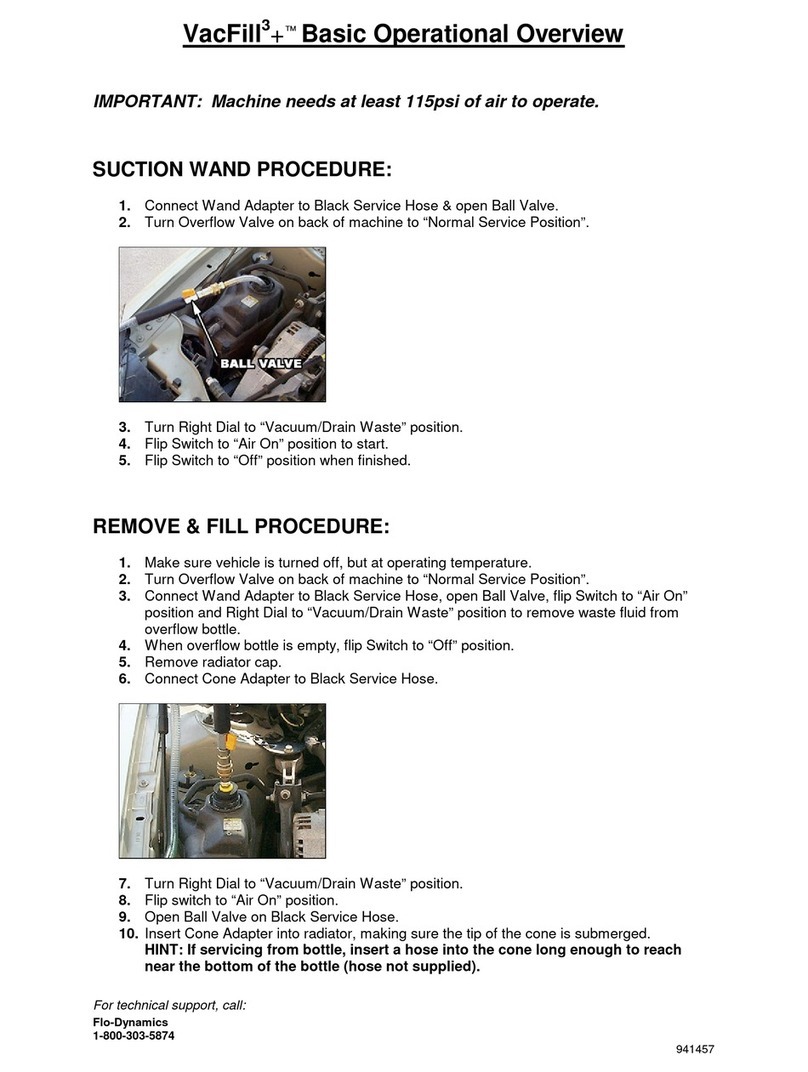

• Numbered quick-disconnect hoses with adapters save time in identifying the proper

hoses for the application

• Easy to use adapters allow quick hookup to virtually any automobile make and model,

saving time and money.

• Clear service hoses give visual confirmation of new and used fluid movements.

• Ergonomically correct working height means greater productivity, less stress and strain.

• Durable roto-cast polyethylene body and tanks prevent vehicle damage. The unit is also

lightweight and durable, for easier handling and longer life.

• Large 5-inch locking caster wheels make machine easy to maneuver.

• Easy-access service panel provides hassle-free operations for greater efficiency.

Electronic Features

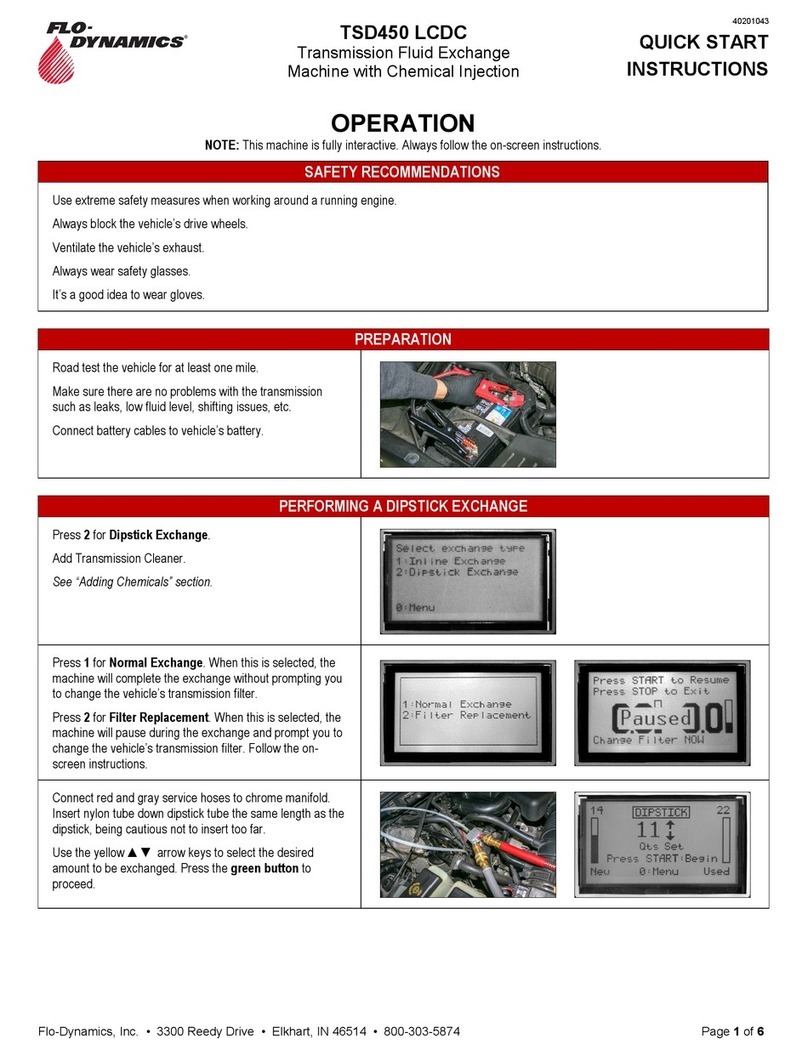

• Self-contained battery cables hook up to the vehicle’s 12-volt battery

• Automatic monitoring of fluid in new and used fluid tanks assures safe operation

• Accurate sensor technology

• LCD counter display with cumulative ATF options

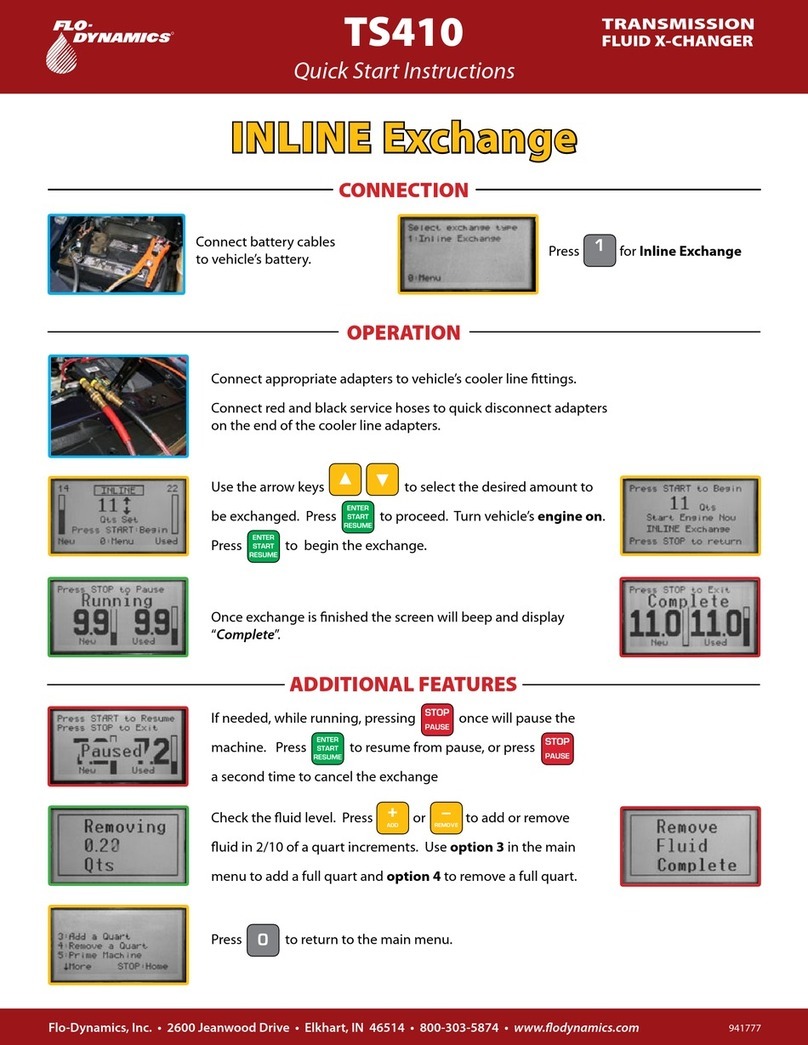

• Ability to exchange anywhere from 1 to 20 quarts in 1 quart intervals

• Fluid measurements can be changed from quarts to liters

• Drain used fluid tank (no need to tip machine upside-down)

• Drain new fluid tank

• Ability to pause machine during exchange to change transmission filter

• Battery backup allows machine to resume where it left off should it lose power

• Add new fluid to transmission in 2/10 quart increments (approx. 1/8” on the dipstick)

• Remove fluid from transmission in 2/10 quart increments (approx. 1/8” on the dipstick)

• Cycle valves feature allows you to electronically clean out valves

• Totalizer check (indicates lifetime use)

• Interactive menu:

- “Auto Prime” feature automatically primes the system

- Indicate new fluid volume

- Indicate used fluid capacity

- Read battery voltage

Chemical Injection Features

• 0.9 GPM diaphragm chemical injection pump

• Easy access, front console mounted, 16 oz. delivery bottle, removable for easy cleaning

• Delivers chemical in less than a minute

• Chemical injection is fully integrated into inline exchange routine

• Chemical injection functionality as a standalone menu option

• Adjusts final fluid level to offset added chemicals