MachineCleanout(1)

CVAC3 9/24/2018

If the machine is slow or stops flushing, but the motor

and air still operate, please follow these procedures.

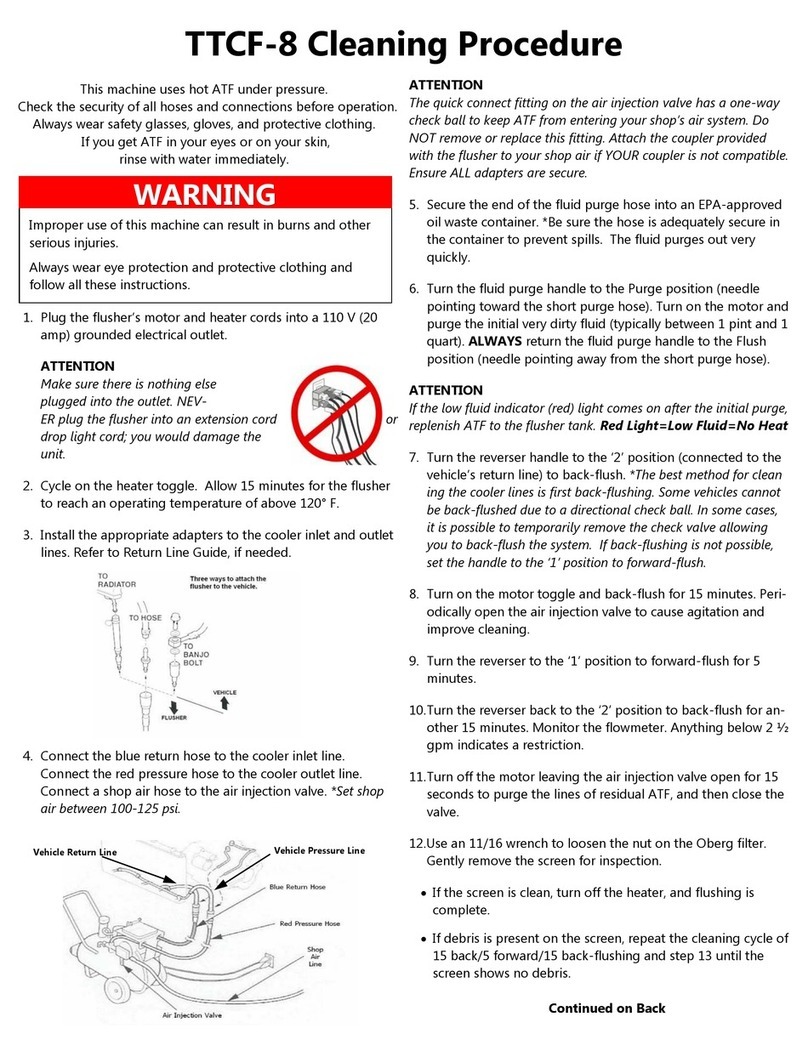

Clean the filter(s): Cleaning the filters should be

done as a normal part of machine maintenance to

prevent problems from occurring.

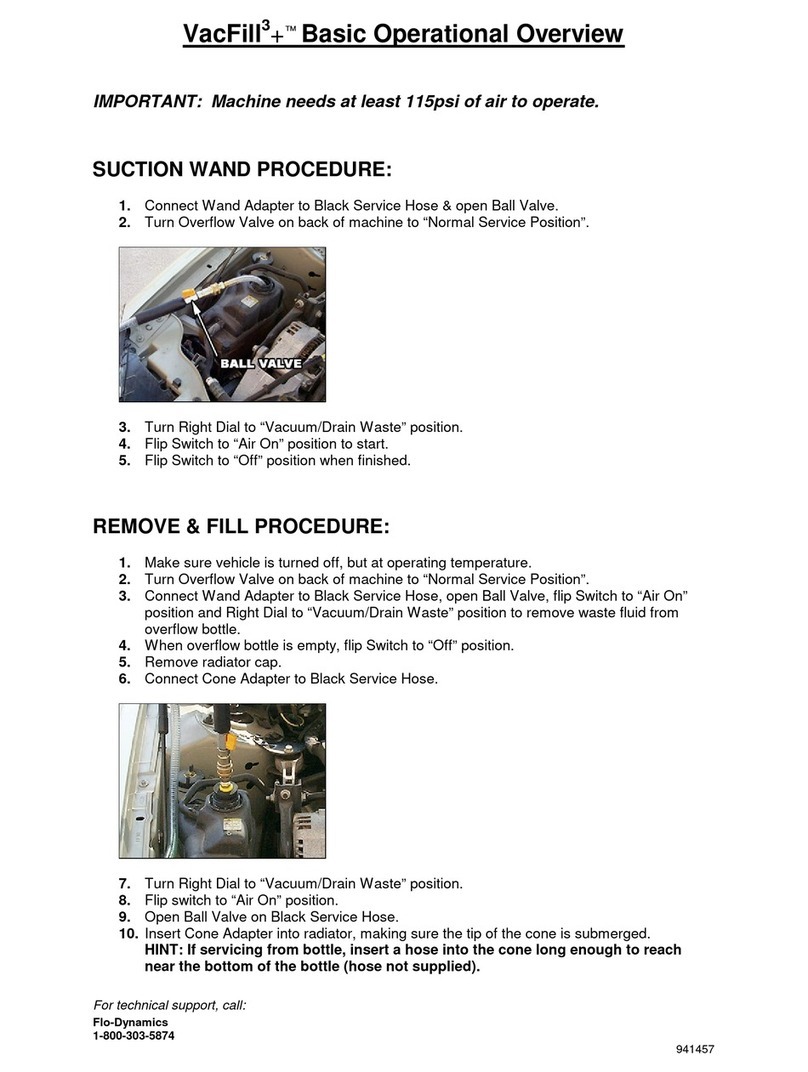

1. Locate the external filter at the end of the black

service hose where it attaches to the machine.

Figure 1-3

2. Unscrew the cup portion from the filter housing.

3. This filter screen can be cleaned with tap water

and then blown out with compressed air. The screen

is permanently glued to the cup section of the filter

housing; do not attempt to remove it.

4. Replace the cup taking care not to pinch the

gasket.

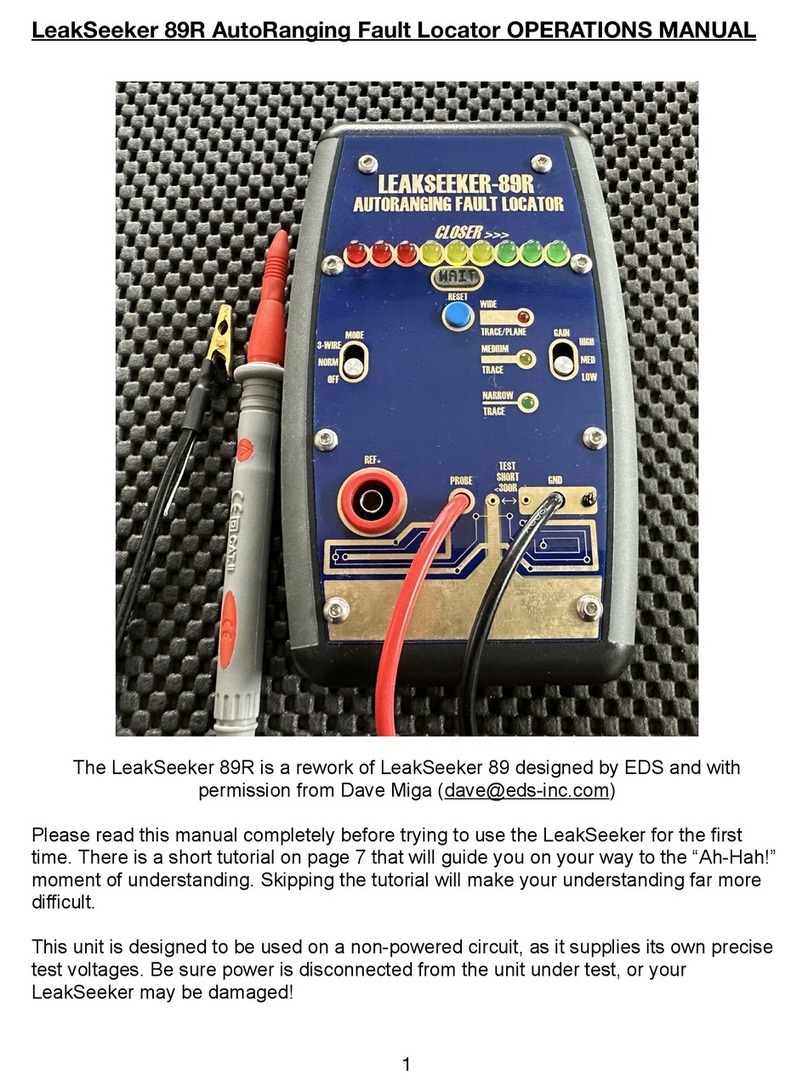

Some of the older machines may also have an internal

filter (Figure 1-4) that can be cleaned or removed

(current production machines do not use an internal

filter).

To access and clean the internal filter:

1. Remove the rear bottom service panel behind the

machine and see if there is a filter attached to the

pump. It may be either a silver Y shaped filter, or a

black canister type. The silver version can be

opened and the screen cleaned; the black one may

be back flushed in the direction opposite the flow

arrow.

2. Clean either type with water or cleaner solvent

and blow out with compressed air.

7

FIGURE 1-3

FIGURE 1-4 Internal Filter

External Filter

Cup & Screen

Housing