TTCF-8 Cleaning Procedure

This machine uses hot ATF under pressure.

Check the security of all hoses and connections before operation.

Always wear safety glasses, gloves, and protective clothing.

If you get ATF in your eyes or on your skin,

rinse with water immediately.

1. Plug the flusher’s motor and heater cords into a 110 V (20

amp) grounded electrical outlet.

ATTENTION

Make sure there is nothing else

plugged into the outlet. NEV-

ER plug the flusher into an extension cord or

drop light cord; you would damage the

unit.

2. Cycle on the heater toggle. Allow 15 minutes for the flusher

to reach an operating temperature of above 120° F.

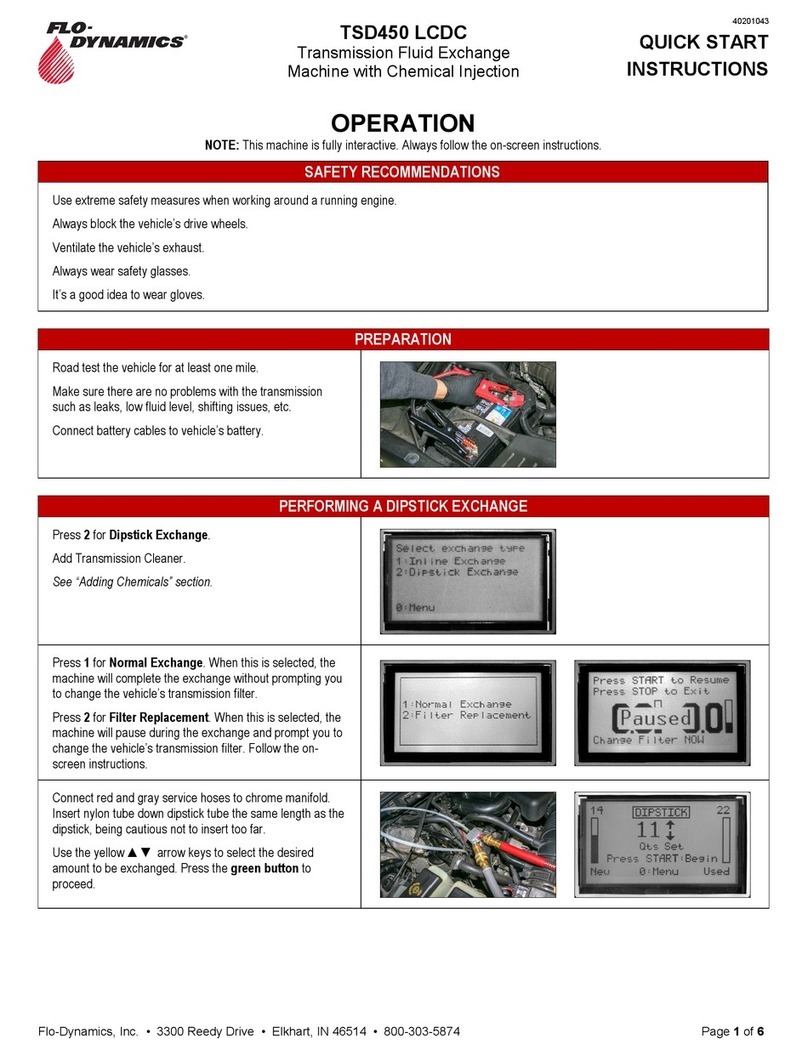

3. Install the appropriate adapters to the cooler inlet and outlet

lines. Refer to Return Line Guide, if needed.

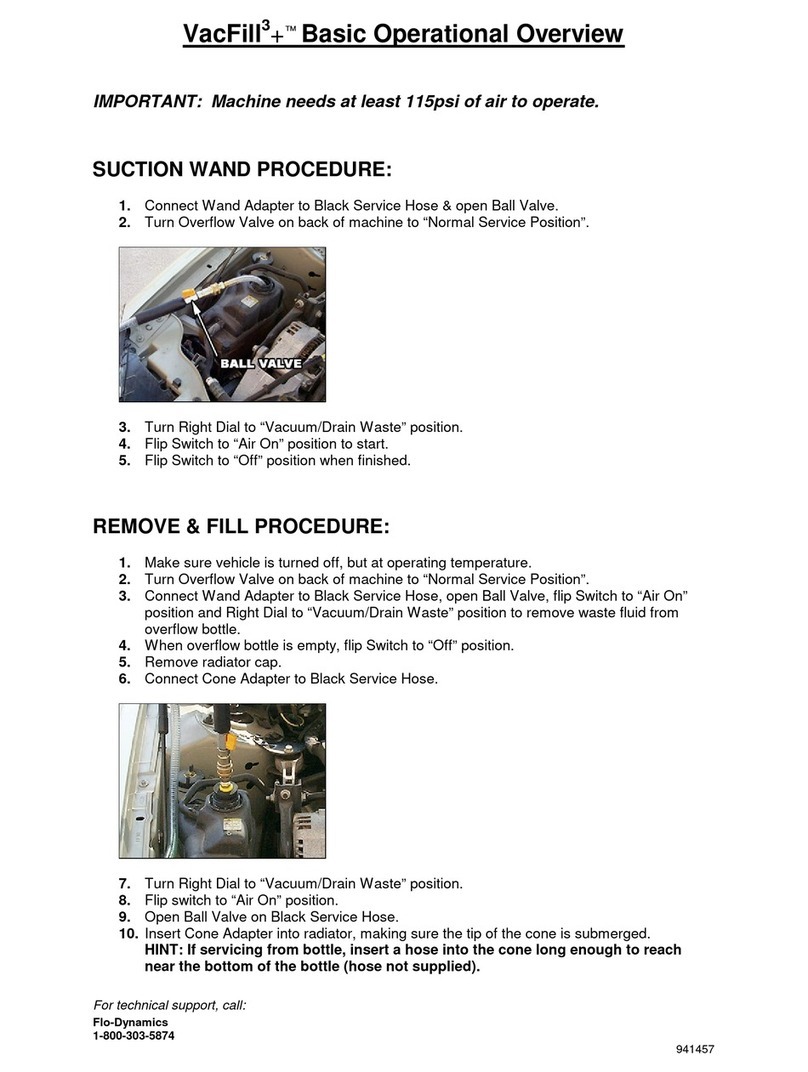

4. Connect the blue return hose to the cooler inlet line.

Connect the red pressure hose to the cooler outlet line.

Connect a shop air hose to the air injection valve. *Set shop

air between 100-125 psi.

ATTENTION

The quick connect fitting on the air injection valve has a one-way

check ball to keep ATF from entering your shop’s air system. Do

NOT remove or replace this fitting. Attach the coupler provided

with the flusher to your shop air if YOUR coupler is not compatible.

Ensure ALL adapters are secure.

5. Secure the end of the fluid purge hose into an EPA-approved

oil waste container. *Be sure the hose is adequately secure in

the container to prevent spills. The fluid purges out very

quickly.

6. Turn the fluid purge handle to the Purge position (needle

pointing toward the short purge hose). Turn on the motor and

purge the initial very dirty fluid (typically between 1 pint and 1

quart). ALWAYS return the fluid purge handle to the Flush

position (needle pointing away from the short purge hose).

ATTENTION

If the low fluid indicator (red) light comes on after the initial purge,

replenish ATF to the flusher tank. Red Light=Low Fluid=No Heat

7. Turn the reverser handle to the ‘2’ position (connected to the

vehicle’s return line) to back-flush. *The best method for clean

ing the cooler lines is first back-flushing. Some vehicles cannot

be back-flushed due to a directional check ball. In some cases,

it is possible to temporarily remove the check valve allowing

you to back-flush the system. If back-flushing is not possible,

set the handle to the ‘1’ position to forward-flush.

8. Turn on the motor toggle and back-flush for 15 minutes. Peri-

odically open the air injection valve to cause agitation and

improve cleaning.

9. Turn the reverser to the ‘1’ position to forward-flush for 5

minutes.

10.Turn the reverser back to the ‘2’ position to back-flush for an-

other 15 minutes. Monitor the flowmeter. Anything below 2 ½

gpm indicates a restriction.

11.Turn off the motor leaving the air injection valve open for 15

seconds to purge the lines of residual ATF, and then close the

valve.

12.Use an 11/16 wrench to loosen the nut on the Oberg filter.

Gently remove the screen for inspection.

If the screen is clean, turn off the heater, and flushing is

complete.

If debris is present on the screen, repeat the cleaning cycle of

15 back/5 forward/15 back-flushing and step 13 until the

screen shows no debris.

Continued on Back

Improper use of this machine can result in burns and other

serious injuries.

Always wear eye protection and protective clothing and

follow all these instructions.

WARNING

WARNING

WARNING

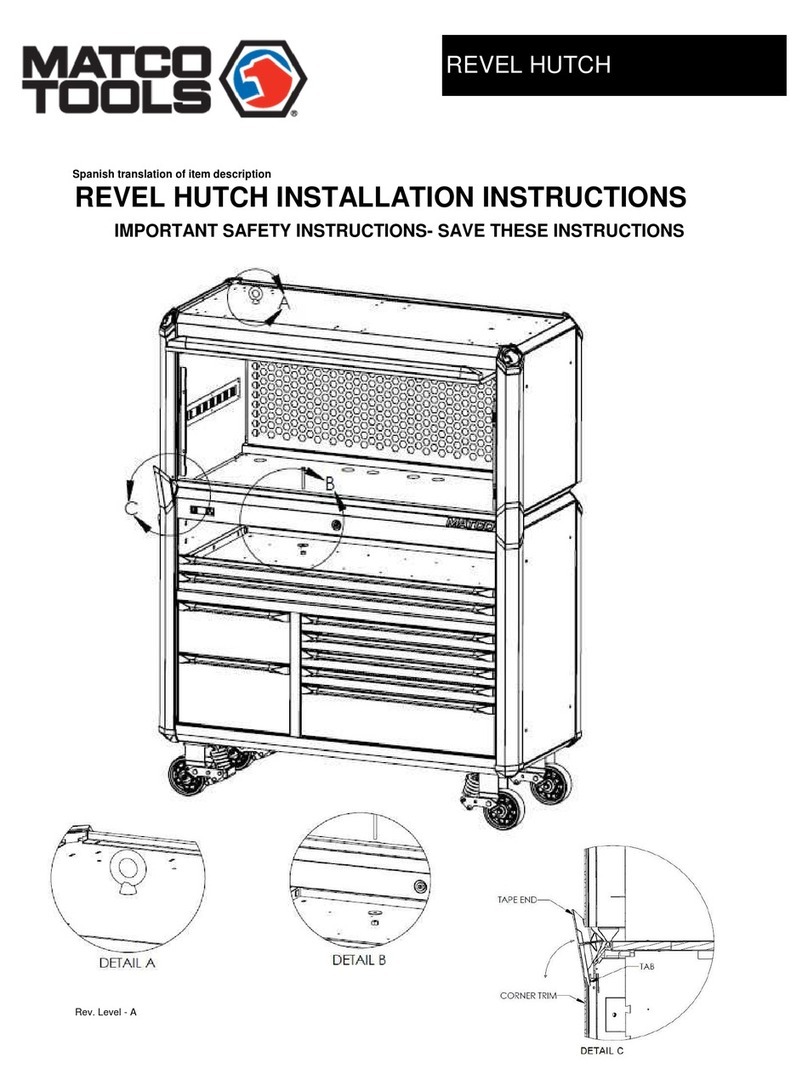

Vehicle Pressure Line

Vehicle Return Line