Siemens RC 195 User manual

Other Siemens Controllers manuals

Siemens

Siemens SCALANCE M800 User manual

Siemens

Siemens SSA955 User manual

Siemens

Siemens SINUMERIK 840D sl Parts list manual

Siemens

Siemens SINUMERIK 808D User manual

Siemens

Siemens 6MD85 User manual

Siemens

Siemens SIMATIC NET MOBIC T8 User manual

Siemens

Siemens 8MR2170 User manual

Siemens

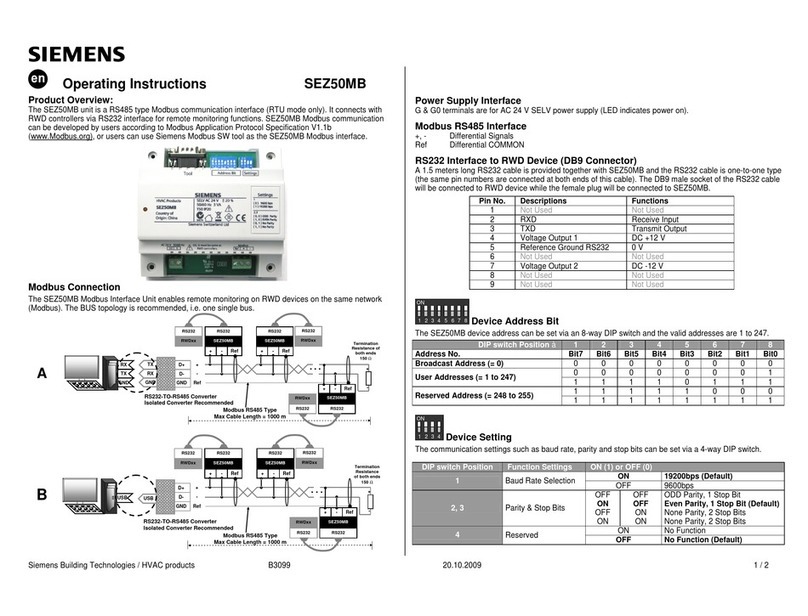

Siemens SEZ50MB User manual

Siemens

Siemens OpenAir GCA Series Owner's manual

Siemens

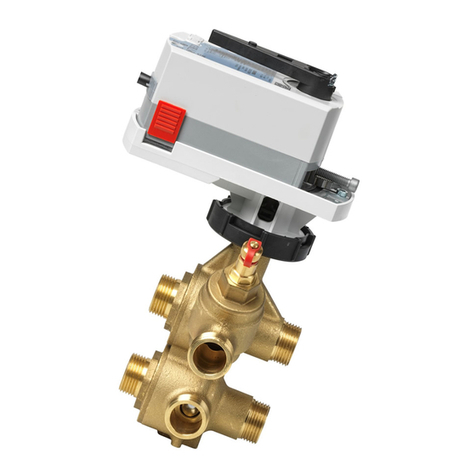

Siemens Powermite 599 MT Series Owner's manual

Siemens

Siemens SSD31 Series User manual

Siemens

Siemens SLX-ASC-PFCU User manual

Siemens

Siemens instabus JB 527C23 User manual

Siemens

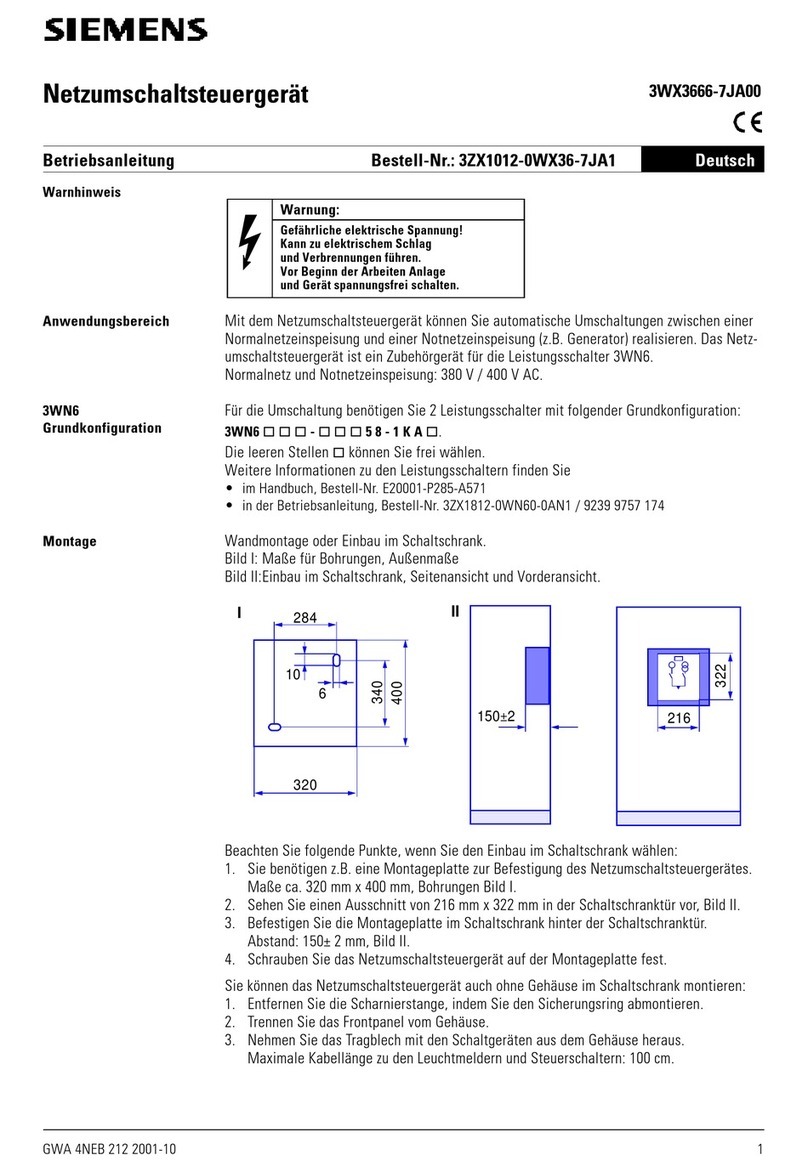

Siemens 3WX3666-7JA00 User manual

Siemens

Siemens RWF40.000A97 User manual

Siemens

Siemens SIMATIC S7-200 User manual

Siemens

Siemens SINUMERIK ONE PPU 1740 Series Technical Document

Siemens

Siemens RAJA+ Operating instructions

Siemens

Siemens VWPG51 Q Series User manual

Siemens

Siemens RVD230 Operator's manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions