Maintenance Manual Edward Forged Steel Valves FCD EVENIM2001-04-AQ – 10/15

8

Reassembly

Valves of the screwed bonnet/ cover type construction are sealed at the

bonnet by flat, soft metal gaskets and “O” Rings. Screwed-in seats are

also sealed by “O” Rings. Such seals require smooth clean surfaces on

body, bonnet or seat. Bolted bonnet valves, such as Figure 848 type,

are sealed with spiral-wound gaskets. In all valves, new gaskets (and

“O” Rings) are recommended for reassembly. Bonnet gaskets (and “O”

Rings) are inexpensive and available out of factory stock.

Valves with screwed bonnet/ cover joints require the bonnet threads to be

well lubricated and tightened to develop sufficient gasket compression.

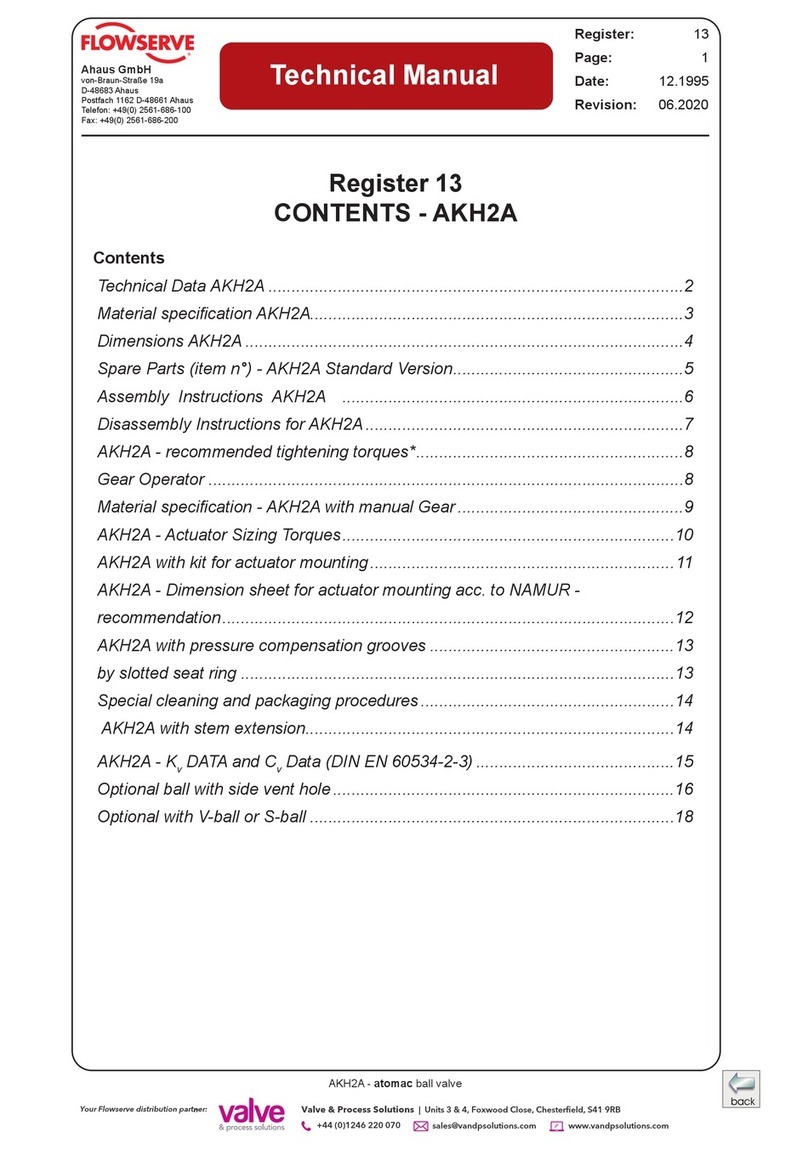

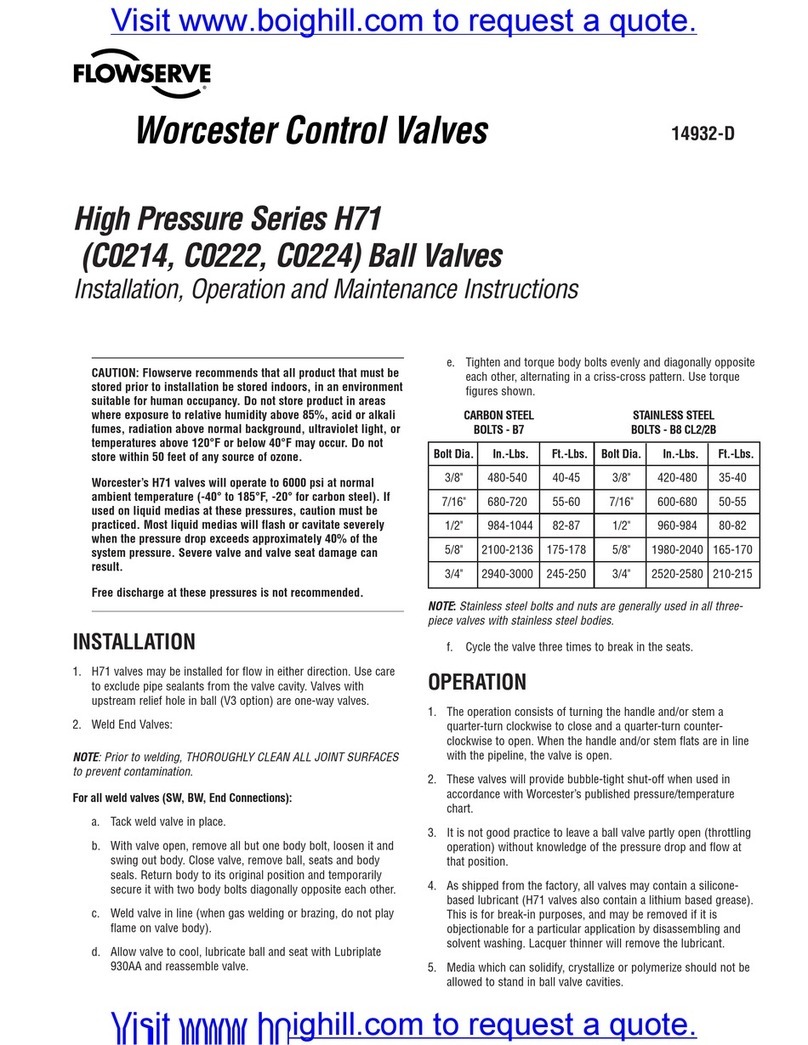

Bolted Bonnet/Cover Torques

A torque wrench should be used for tightening the bonnet, which is

used to preload the spiral-wound gaskets.

The following procedure is recommended:

1. Guard against leakage by having these capscrews tight at all times.

2. Capscrews should be tightened to the torque shown below.

Bolt diameter, Inches

3 / 8 7 / 16 1 / 2 9 / 16 5 / 8 3 / 4 7/ 8 11-1/ 8 1-1/ 4

Torque, Ft. Lbs.

18 30 45 68 90 150 240 370 585 750

Step #1

Snug to approximately 10% of full recommended torque.

Sequence: 1-2-3

Step #2

Torque to approximately 75% of full recommended torque.

Sequence: 4-3-2

Step #3

Torque to full recommended torque. Sequence: 1-2-3-4

NOTE: The steps for tightening cover capscrews is for the purpose of

pulling the cover down evenly. If this objective can be achieved without

following this suggested method precisely, then some variation from

this method is permissible.

Seat Ring & Bonnet/Cover Torques

Valve Size Figure Number Seat Ring Torque Bonnet/ Cover

Torque

1/ 4, 3 / 8, 1 / 2 158 ,160 75 40

3 / 4 158 ,160 100-120 60

1158 ,160 240-260 125

1-1/ 4, 1-1/ 2 158 ,160 320-340 150

2158,160, 5158,

5160, 9160 400-420 300

Welding Flowserve-Edward Valves into Piping Welding is outside the

scope of this manual, but Flowserve recommends you consult the

appropriate welding procedure in ASME/ ANSI B31, or whatever other

codes apply to your system. When welding Flowserve-Edward valves

into piping, make sure there is no foreign material on the seat joint, then

close the valve tightly to avoid distorting the seats.

After welding, open the valve and flush the line to clean out all foreign

matter.

Lubrication

In order to obtain full service life, valves require periodic lubrication of

the stem threads. Exposed threads should be wiped clean of old grease

and accumulated dirt and fresh lubricant applied. This is most effective-

ly done with the valve in the closed position.

For valves that see frequent operation, such as motor-actuated, the

lubricant should be replenished every three months. If extreme service

conditions dictate, a more frequent relube schedule is recommended.

Motor-actuated valves have a lubricant fitting at the yoke flange.

The recommended lubricant for all stem threads, bonnet, packing nut

and bolt threads is Rykon EP #2, manufactured by the American Oil

Company. This is an extreme pressure, extreme temperature lubricant

of high quality. For valves that are operated infrequently, relubrication

should be at least once a year.