37-5

Disassembling the Body

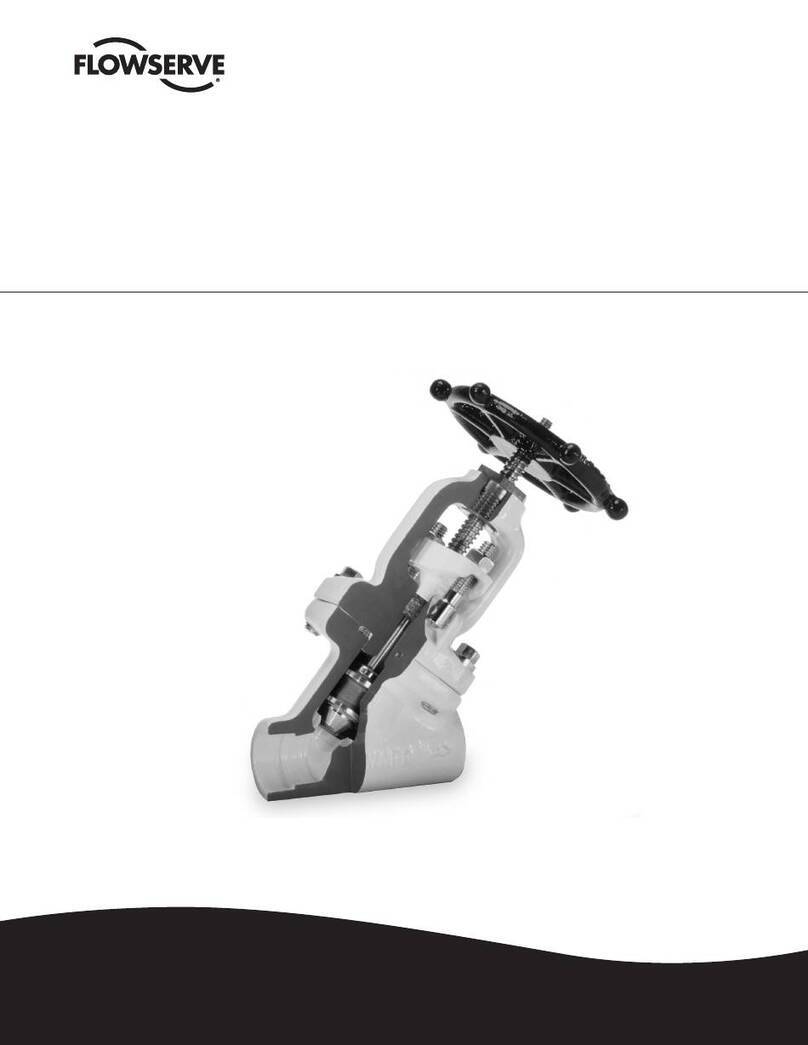

To disassemble the Valdisk 150 body, refer to Figures

1 and 3 and proceed as follows:

1. Lay the valve body on a flat surface with the seat

surface up. Carefully insert a flat screwdriver into

the groove behind the seat retainer and pry the

retainer out of the body. The seat insert will now

easily lift out of the body.

2. Turn the body over so its backside is up and mark

the location of the thin end of the taper pin on the

disc. (This mark will be used during reassembly.)

Grindoffthetackweldholdingthetaperpininplace.

Drive the taper pin out of its slot using a punch and

hammer.

3. Placethevalvebodyintoavisewiththeshaftpoint-

ing up. Use brass jaws or wood blocks to prevent

damage to the body surfaces.

4. Removethetwo packingboxnutsandgland flange

from off the shaft.

5. Pull the shaft out of the body, noting that the disc

may fall out of body. Use caution to prevent it from

striking any hard objects or personnel. Next, re-

movethepackingfollower,packingsetandpacking

retainer.

6. The disc can now be removed from the body, fol-

lowed by the thrust and shaft bearings.

Reassembling the Body

To reassemble the Valdisk 150 body sub-assembly,

refer to Figures 1, 2, and 3 and proceed as follows:

1. Clean or replace all parts. The O-ring and packing

setshouldbereplacedeachtimethevalveisdisas-

sembled.

2. Check the disc seating surface to make sure it is

smooth and free of excessive wear, scoring and

scratches.

CAUTION: Damaged or dirty seat surfaces can

cause excessive seat wear and high torque re-

quirements. Damaged discs should be re-

placed.

3. Inspect the shaft for scratches or galled surfaces.

Formaximum performance, Valdisk 150shafts are

machinedtoaverysmoothfinish. Ifdamageexists,

replacetheshaftorcontactthefactoryrepresentative.

NOTE: Disc and shaft are interchangeable. Re-

placingthediscdoesnotrequirereplacingtheshaft

and vice versa.

4. Placethe valve body in a vise with shaft bore point-

ing up. Brass jaws or wood blocks are recom-

mended to prevent damage to the valve surfaces

while being held in the vise.

5. Placeoneshaftbearingintothelowerbearingbore,

followed by a thrust bearing.

6. Place the disc into the body from the backside with

the taper pin slot on top. Do not dislodge the thrust

bearing.

7. Insert the second thrust bearing between the disc

andthevalvebody. Alignbothbearingswiththedisc.

8. Insert the shaft into the body with the taper pin slot

end first. Slowly insert it through the body, upper

thrust bearing, disc, lower thrust bearing and into

the shaft bearing.

9. Inserta new taperpinintotheslot in the back of the

disc and in the shaft. Refer to the mark on the disc

made during disassembly and make sure the pin

does not go beyond it. Be certain the pin is flat

against the disc. Set in place with a punch and

hammer.

10. Place the remaining shaft bearings* over the shaft

andinto the bearing bore. (*Refer to the valve’s bill

of materials for the number of shaft bearings re-

quired.) Next, place the packing retainer, followed

by the packing set into the packing bore. (See Fig-

ure2. Teflonpackingchevronspointawayfromthe

disc.) Be careful to not damage the packing rings

while inserting them over the shaft.

11. The packing follower is next inserted into the pack-

ing bore with machined lip end up.

12. If the packing box studs were removed, re-install

them using anti-seize lubricant. Tighten until they

bottomout. Placeawasher overeachstudandse-

cure in place with a jam nut tightened until snug

(valve sizes 1 thru 6-inch).

13. Place the gland flange over the shaft and onto the

studsbeingcertaintherockerknobisfacingtoward

thedisc. Placethepackingboxnuts ontothe pack-

ing box studs and tighten finger tight plus 1/2to one

fullturn with Teflonpacking. (Ropepacking should

betorquedto14foot-poundsor19newton-meters.)

14. Installtheseatassemblyintothevalvebodybyfirst

insertingseatgasketintoouterseatretainergroove.

Next, remove the body from the vise and lay it on a

flat surface with the seat side up. Proceed as fol-

lows.

Softor metalseat design- Laytheseatinsertinto

thevalvebody. Next,inserttheseatretainerintothe

body seat counter bore. Use a rubber mallet or

press to press the seat retainer into the body.

Fire-safe seat design - Place one Grafoil gasket

into the retainer ring groove. Place two additional

Grafoil gaskets on either side of the seat insert.

Place the metal seat on top of the seat/gasket as-

sembly and then place the entire assembly into the

retainer ring in the body. Next, insert the seat re-

tainerintothebodyseatcounterbore. Usearubber

mallet or press to press the seat retainer into the

body.