3

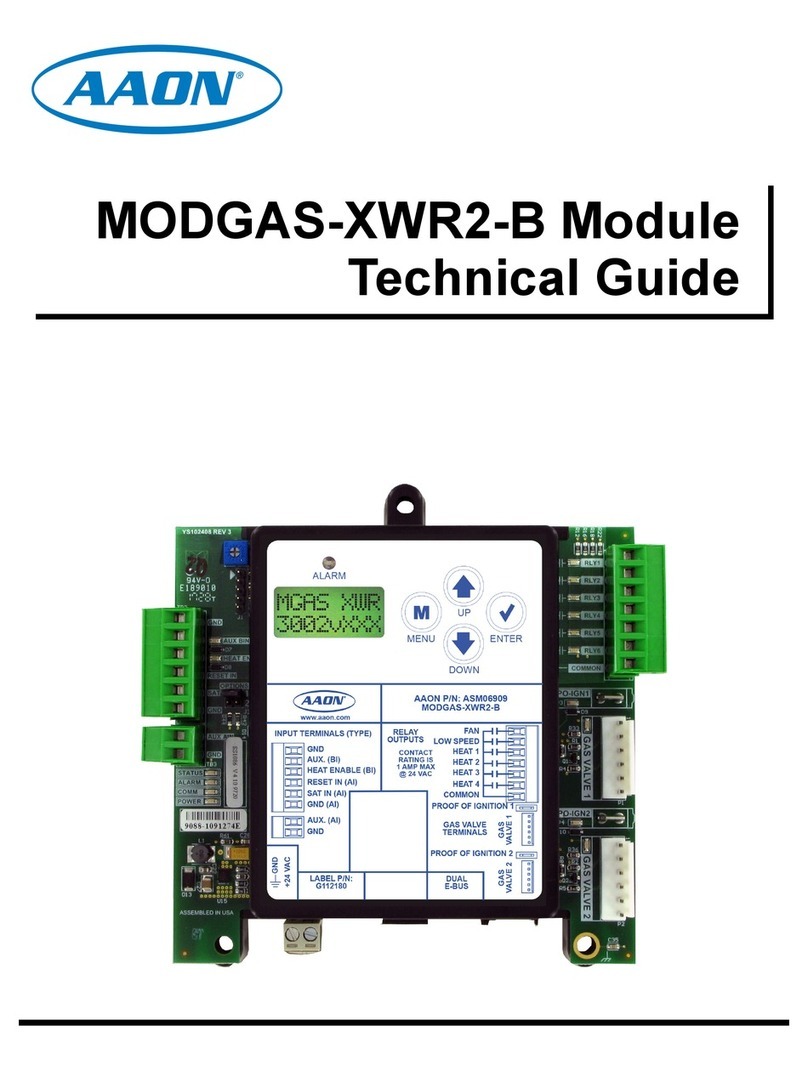

MODGAS-XWR2 Technical Guide

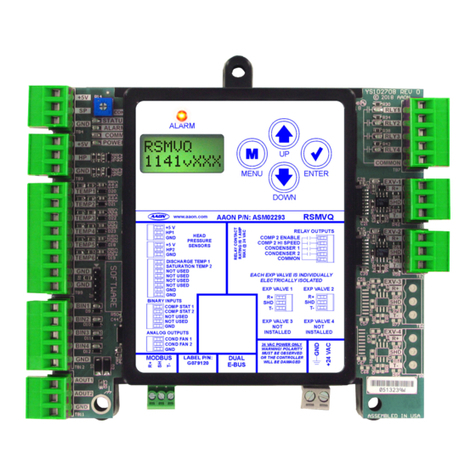

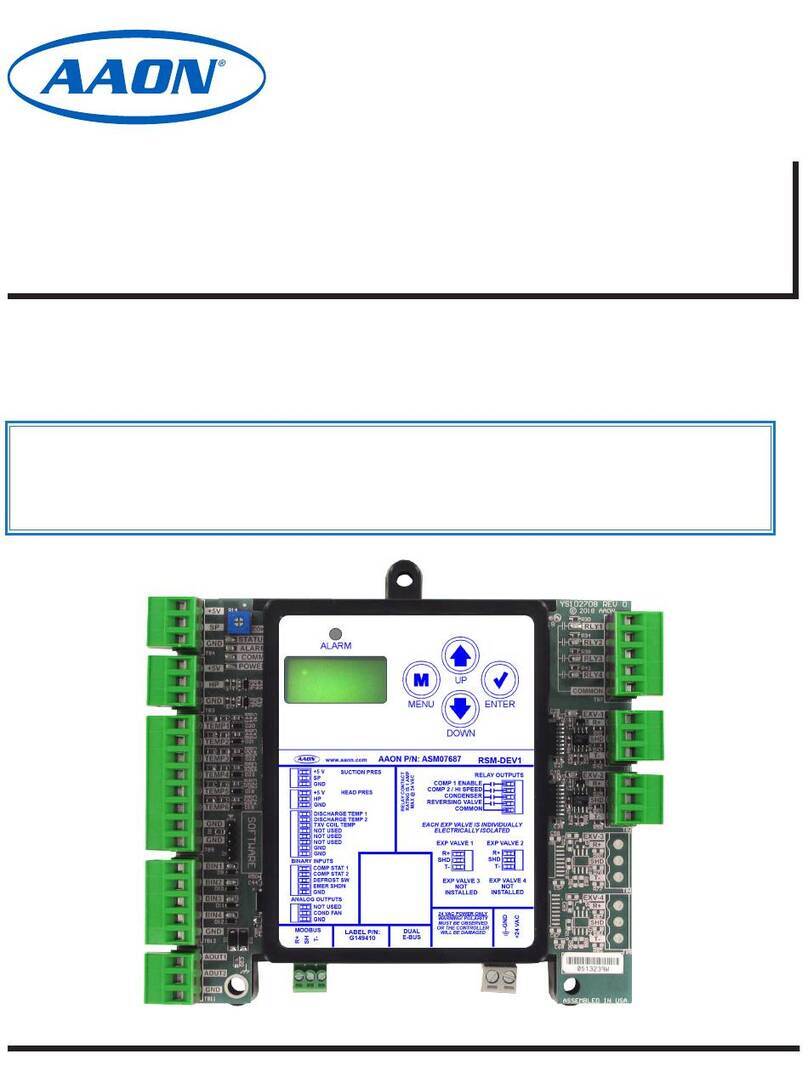

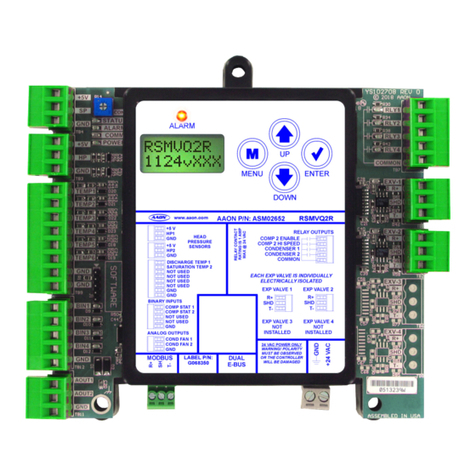

OVERVIEW....................................................................................................................... 5

General Information ................................................................................................................................................ 5

Dimensions ............................................................................................................................................................. 6

WIRING ............................................................................................................................ 7

Important Wiring Considerations............................................................................................................................. 7

STAND-ALONE WIRING .................................................................................................. 8

One Modulating Valve, One Ignitor, One Stage (1V1IGN1S) ................................................................................. 8

Two Modulating Valves, Two Ignitors, Two Stages (2V2IGN2S)............................................................................. 9

Two Modulating Valves, One Ignitor, One Stage (2V1IGN1S)...............................................................................11

Two Modulating Valves, Two Ignitors, One Stage (2V2IGN1S) ............................................................................ 13

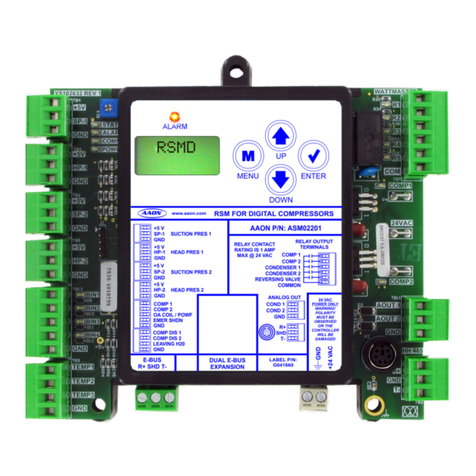

12 Relay E-BUS Expansion Module ..................................................................................................................... 14

COMMUNICATIONS WIRING ........................................................................................ 15

One Modulating Valve, One Ignitor, One Stage (1V1IGN1S) ............................................................................... 15

Two Modulating Valves, Two Ignitors, One Stage (2V2IGN1S) ............................................................................ 16

Two Modulating Valves, Two Ignitors, Two Stages (2V2IGN2S)........................................................................... 17

Two Modulating Valves, One Ignitor, One Stage (2V1IGN1S).............................................................................. 19

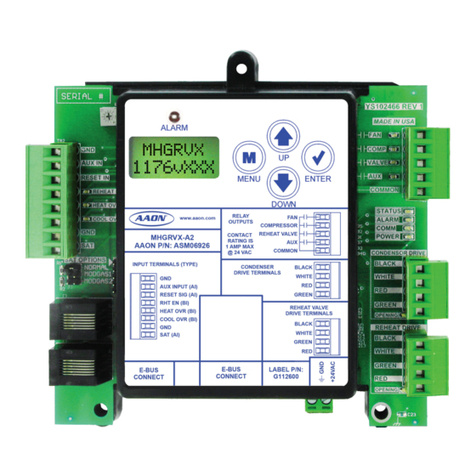

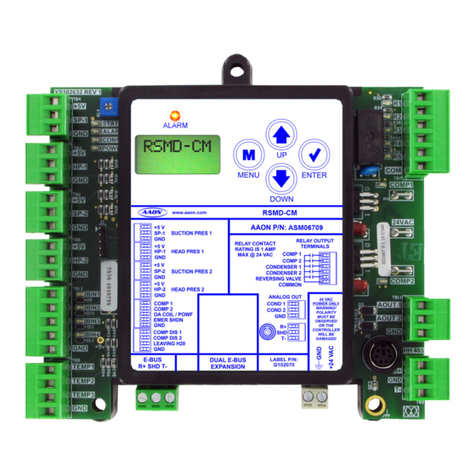

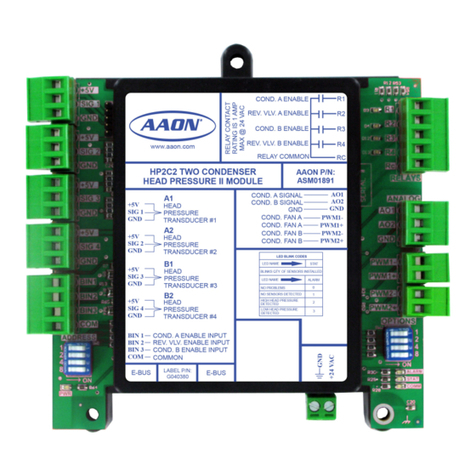

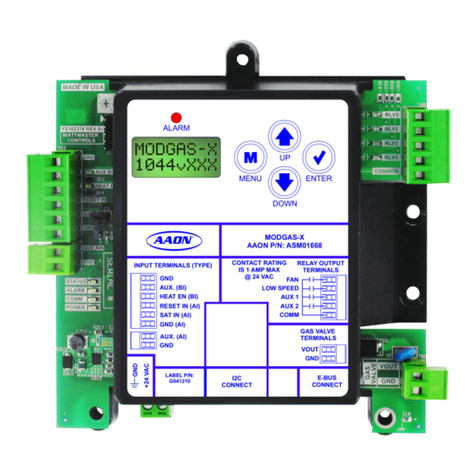

INPUTS AND OUTPUTS................................................................................................ 21

Inputs and Outputs................................................................................................................................................ 21

SEQUENCE OF OPERATION......................................................................................... 23

Operating Modes and Min Mode........................................................................................................................... 23

Heating Mode........................................................................................................................................................ 24

Valve Failure, Force Mode and Master vs. Normal............................................................................................... 25

LCD SCREENS ............................................................................................................... 26

Navigation Keys .................................................................................................................................................... 26

Main Screens Map ................................................................................................................................................ 27

Main Screens ........................................................................................................................................................ 28

Alarms Menu and Slave Alarms............................................................................................................................ 30

Setpoint Screens................................................................................................................................................... 31

Force Valves Screens ........................................................................................................................................... 32

Protected and Conguration Screens ................................................................................................................... 33

Conguration Screens .......................................................................................................................................... 34

TROUBLESHOOTING .................................................................................................... 35

LED Diagnostics ................................................................................................................................................... 35

Alarms................................................................................................................................................................... 37

SAT Sensor Testing............................................................................................................................................... 38

APPENDIX A: SAT SENSOR.......................................................................................... 40

Installation............................................................................................................................................................. 40

SAT Sensor Wiring Guide and Jumper Settings ................................................................................................... 41

APPENDIX B: MODGAS-XWR REPLACEMENT ............................................................ 42

MODGAS-XWR2 Replacement of MODGAS-XWR.............................................................................................. 42

TABLE OF CONTENTS