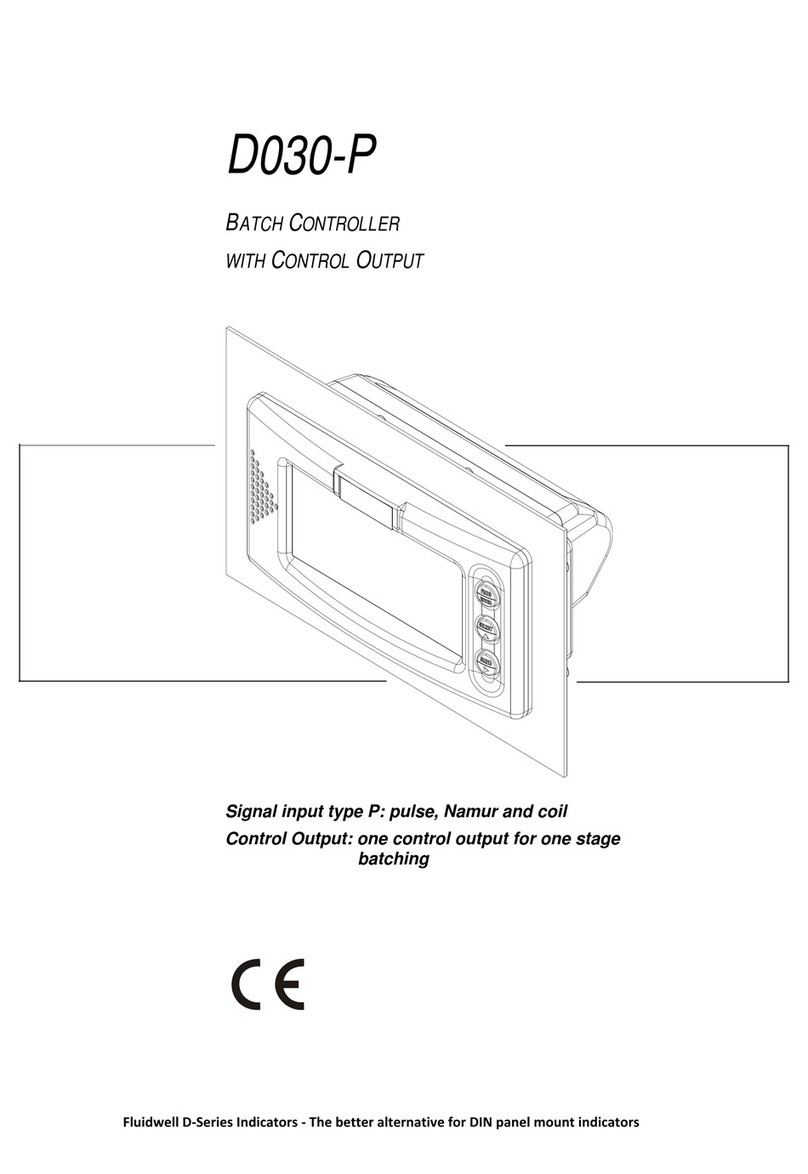

FW_F133P_v1702_02_EN

CONTENTS MANUAL

Safety instructions.................................................................................................................................3

Disposal of electronic waste..................................................................................................................3

Safety rules and precautionary measures.............................................................................................3

About the manual..................................................................................................................................4

Warranty and technical support ............................................................................................................4

Contents manual...................................................................................................................................5

1. Introduction.......................................................................................................................6

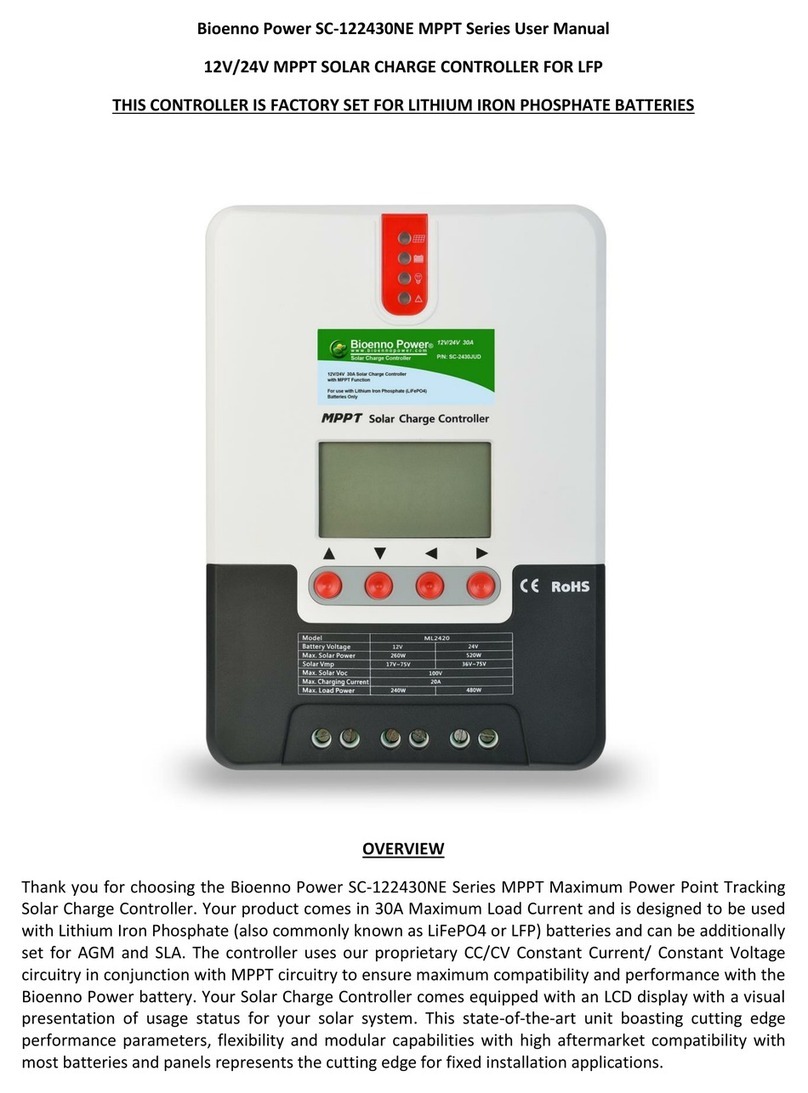

1.1. System description ......................................................................................................6

2. Operational .......................................................................................................................7

2.1. General........................................................................................................................7

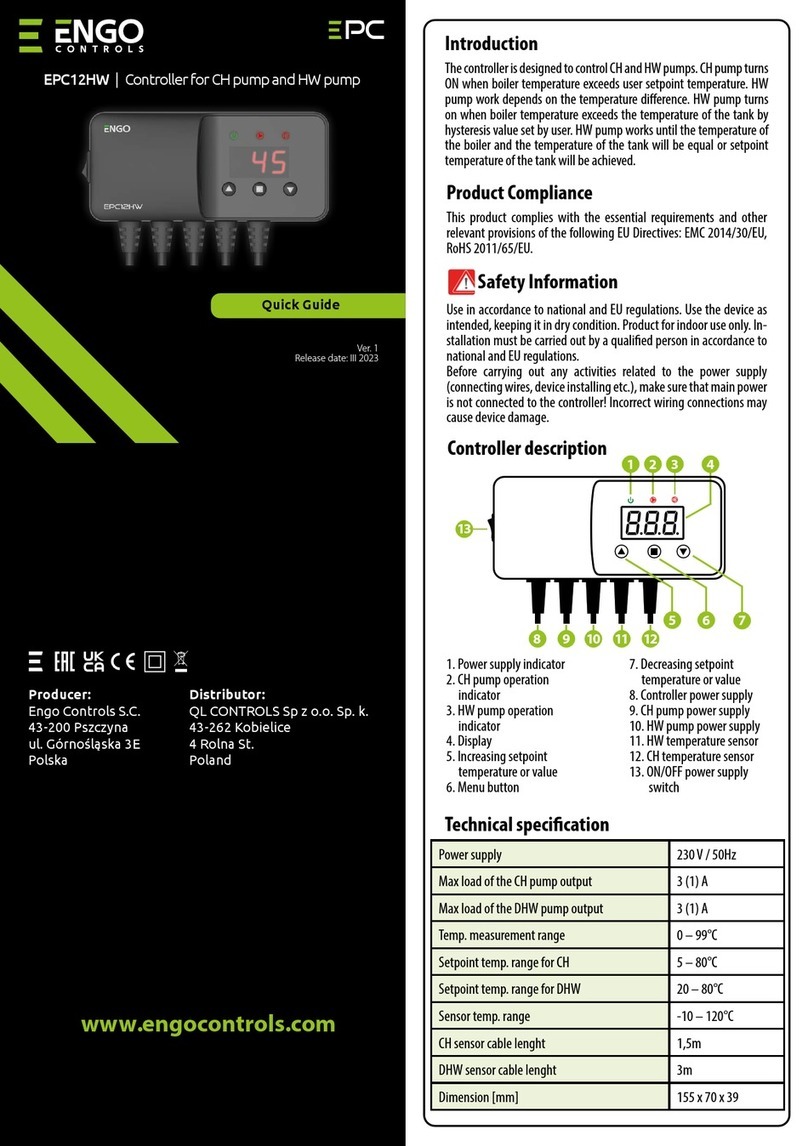

2.2. Control panel ...............................................................................................................7

2.3. Operator information and functions.............................................................................7

2.4. dispenser functional diagram.......................................................................................9

3. Configuration...................................................................................................................10

3.1. How to program the F133-P......................................................................................10

3.1.1. Setup menu - Settings...............................................................................................12

3.1.2. Explanation of Setup menu 1 - Total.........................................................................13

3.1.3. Explanation of Setup menu 2 - Flow rate ..................................................................13

3.1.3. Explanation of Setup menu 3 - Display.....................................................................14

3.1.4. Explanation of Setup menu 4 - Power management.................................................14

3.1.5. Explanation of Setup menu 5 - Flowmeter ................................................................15

3.1.6. Explanation of Setup menu 6 - Control .....................................................................15

3.1.7. Explanation of Setup menu 7 - Status.......................................................................16

3.1.8. Explanation of Setup menu 8 - Communication (option)...........................................16

3.1.9. Explanation of Setup menu 9 - Others ......................................................................17

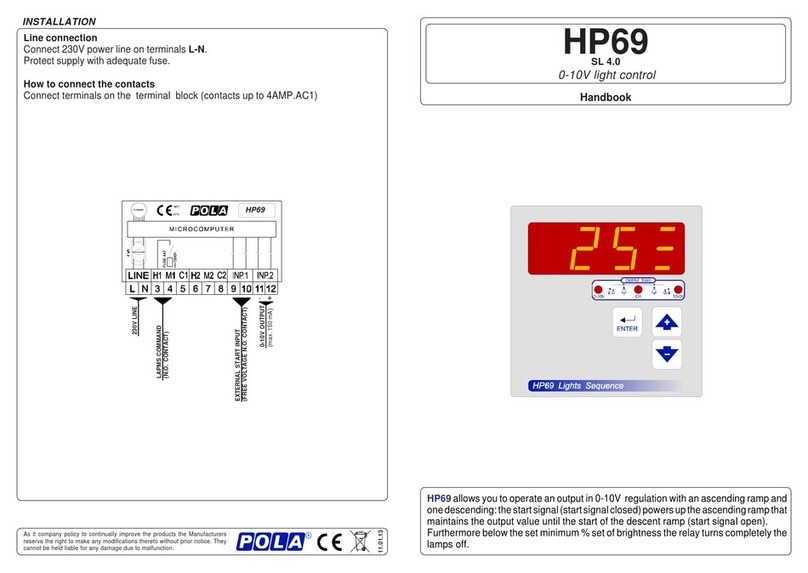

4. Installation.......................................................................................................................17

4.1. General directions......................................................................................................17

4.2. Installation / surrounding conditions..........................................................................17

4.3. Dimensions- Enclosure..............................................................................................18

4.4. Installing the hardware ..............................................................................................20

4.4.1. General installation guidelines...................................................................................20

4.4.2. Aluminum enclosure - Field mounted........................................................................21

4.4.3. Aluminum enclosure - Panel mounted.......................................................................21

4.4.4. Plastic (GRP) enclosure ............................................................................................22

4.4.3. Terminal connectors..................................................................................................23

5. Intrinsically safe applications ..........................................................................................30

5.2. Terminal connectors Intrinsically safe applications ...................................................31

5.3. Configuration examples Intrinsically Safe applications .............................................33

5.4 Battery replacement instructions ...............................................................................35

5.4.1. Safety instructions .....................................................................................................35

5.4.2. Replace the battery ...................................................................................................35

5.4.3. Disposal of batteries..................................................................................................35

6. Maintenance ...................................................................................................................36

6.1. General directions......................................................................................................36

6.2. Repair........................................................................................................................36

6.3. Repair policy..............................................................................................................36

Appendix A: Technical specification....................................................................................................37

Appendix B: Problem solving ..............................................................................................................40

Appendix C: Communication variables ...............................................................................................41

APPENDIX D: Declaration of Conformity............................................................................................44

Index of this manual............................................................................................................................45

List of figures in this manual................................................................................................................46