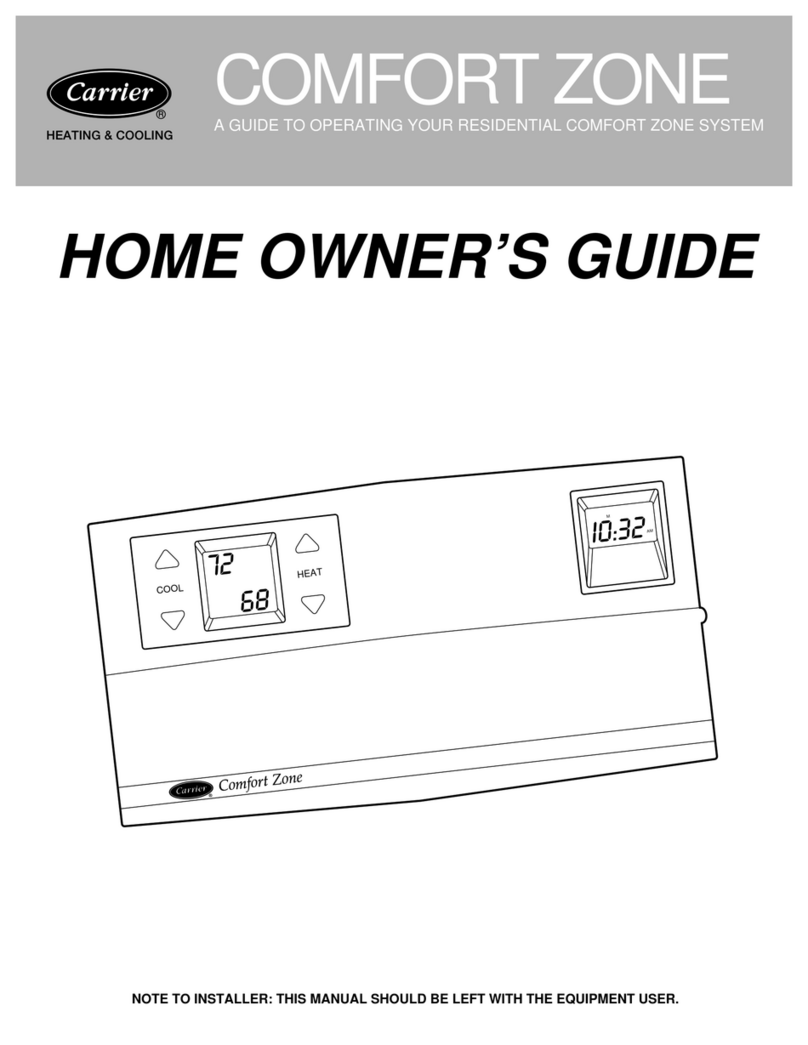

Fluidwell D030-P Series User manual

Fluidwell D-Series Indicators - The better alternative for DIN panel mount indicators

D030-P

BATCH CONTROLLER

WITH CONTROL OUTPUT

Signal input type P: pulse, Namur and coil

Control Output: one control output for one stage

batching

User manual D030-P Batch Controller

ii FW-D030-P-MAN-EN-V0102_02

Health and Safety Information

This instruction manual supplements the requirements of nationally accepted codes of

practice. All installations must comply with the relevant sections of these codes and/or

other comparable codes that applies in the region the D030-P is installed in.

In addition, particular industries or end users may have specific requirements relating to

the safety of their installations. These requirements must also be met.

Disposal

Caution:

The D030-P must only be installed, operated and maintained by competent personnel

that received proper training on regular basis, including instructions on the various

types of protection and installation practices, relevant rules and regulations, and the

general principles of area classification.

At the end of its life this product must be disposed of according to local regulations

regarding waste electronic equipment. If a battery is present in this product it must be

disposed of separately. The separate collection and recycling of your waste equipment

will help to conserve natural resources and ensure that it is recycled in a manner that

protects the environment.

FW-D030-P-MAN-EN-V0102_02 iii

Read Me First!

About This Guide

This manual describes all standard features and instructions related to the D030-P Batch

Controller.

This manual is intended for all personnel involved in the operation, configuration,

installation and troubleshooting of the D030-P Batch Controller.

Information in this manual is subject to change without prior notice. Fluidwell bv is not

responsible for mistakes in this material or for incidental damage caused as a direct or

indirect result of the delivery, performance or use of this material.

© All rights reserved. No parts of this publication may be reproduced or used in any

form or by any means without written permission of your supplier.

Prerequisites

All personnel working with the D030-P Batch Controller are assumed to fully understand,

be capable of and act according to the information provided in this manual.

All personnel working with the D030-P are further assumed to be authorized and

properly trained for the task at hand.

About Functions and Type Codes

Not all D030-P types share the same functions. Depending on the type codes on your

particular D030-P, some functions described in this manual may –or may not– be

available.

For details see this manual.

Conventions

The following conventions may have been used to emphasize information:

Note:

This version (FW-D030-P-MAN-EN-V0102_02) is written with a focus on software

version 03.03.01. For other versions contact your supplier.

Warning:

This icon warns about actions that, when not performed correctly, may lead to product

damage, personal injury or even death.

Warning:

Danger of electrical shock: this icon warns about actions that include the risk of

electrical shock, resulting in product damage, personal injury or even death.

Such actions are best performed with power removed or made inaccessible.

Caution:

This icon warns about actions or procedures that may lead to incorrect functioning of

the D030-P when not applied correctly.

Note:

This icon indicates a hint or provides important background information about the

consequences of the described procedure or action.

Example:

This icon indicates a solution for a hypothetic situation, intended to help you interpret

the related concept information.

User manual D030-P Batch Controller

iv FW-D030-P-MAN-EN-V0102_02

How To Read This Manual

This guide consists of the following main sections:

Power up, Power down and Storage of the D030-P

Your D030-P was shipped to you in a cardboard box and may be equipped with battery

power. During transport the unit was switched off (shelf mode).

• If your D030-P is equipped with a battery you can press START twice to power it up.

• To power your D030-P down you must perform the following steps:

a Press and hold PROG for 7 seconds. (See "Password Protection" on page 19 when

password protected.)

b Setup is indicated. Use to go to Setup Menu 4 — "Power Management"

c Next press twice to go to 42 "Battery Mode" and press PROG

dYouenter menu 42. Select shelf and press PROG to switch the unit off.

Storage and Hot Spare Configuration

When storing or transporting the D030-P, put the unit back in shelf mode and store it

at room temperature, in a dry place and in the original box.

Caution:

• Before operating, configuring, opening or installing the D030-P you are expected to

have read and understood all relevant sections in this manual.

• Before operation the D030-P MUST be installed in compliance with the installation

instructions as described in "Installation Instructions" on page 8.

chapter 1: "Introduction" on page 1 Provides an introduction and technical overview of the

D030-P Batch Controller.

chapter 2: "Specifications of the D030-P" on page 4 Provides an overview of the D030-P specifications.

chapter 3: "Installation Instructions" on page 8 Providesmechanicalandelectricalinstallationinstructions.

chapter 4: "Configuring the D030-P" on page 18 Provides an overview of configuration commands and

programming sequence of the D030-P.

chapter 5: "Operating the D030-P" on page 27 Provides operating instructions for the daily use of the

D030-P.

chapter 6: "Maintenance" on page 31 Provides maintenance instructions.

Note:

Before storing you may want to consider configuring a spare unit with identical settings

as an active unit in the field. This way you have created a “hot spare” which can be

taken from shelf and field mounted within minutes by electrical engineers.

SETUP

SETUP

v

FW-D03FW-D030-P-MAN-EN-V0102_02 v

Contents

Read Me First! iii

About This Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Prerequisites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

About Functions and Type Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

How To Read This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Power up, Power down and Storage of the D030-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Storage and Hot Spare Configuration. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . iv

1 Introduction 1

System Description of the D030-P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Functions and Features . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . 1

Field Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Standard Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

The D030-P Display Functions. . . . . . . . . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . 2

Configuration of the D030-P. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

EEPROM Memory . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. 2

Options of the D030-P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Available D030-P configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Specifications of the D030-P 4

General specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Panel Mount Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Approvals and compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power supply . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . 4

Sensor excitation . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . 5

Terminal connections . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . 5

Data protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Flowmeter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control output. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . 6

Operational. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operator functions . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . 6

Preset and Total. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Accumulated total. . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . 6

3 Installation Instructions 8

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical installation – general. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview of Terminal Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

External Power Supply wiring. . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . 10

Backlight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

I/O wiring options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Active / Passive output, Type OH. . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . 16

Passive output, Type OT . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . 17

Relay Contact Output, Type OR. . . . . . . . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . 17

User manual D030-P Batch Controller

1–CONTENTS

vi FW-D030-P-MAN-EN-V0102_02

4 Configuring the D030-P 18

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

The D030-P Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

The D030-P Key Functions . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . 18

Quick Reference Menu . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . 19

Password Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9

Modes of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Overview of Setup Functions and Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

The D030-P Setup Functions Explained . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overrun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Power Management . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .25

Flowmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Operating the D030-P 27

The D030-P button and display functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

The D030-P Display Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

The D030-P Key Functions . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . 27

Operator functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

To enter a batch quantity. . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . .28

Batch maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Starting up the batch process . . . . . . . . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . 28

Interrupting and ending the batch process. . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . 29

Display total and accumulated total. . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . 29

Clear total . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Display accumulated total . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . .29

Operator alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Low-battery alarm . . . . . . . . . . .. . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . .. . 30

Alarm 01-03. . . . . . . . . . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . 30

6 Maintenance 31

General directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Battery life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Replacing the battery. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .. . . . . . 31

Preventive maintenance checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setup Configuration Examples 33

Troubleshooting the D030-P 35

FW-D030-P-MAN-EN-V0102_02 1

1

CHAPTER

Introduction

System Description of the D030-P

Functions and Features

The Batch Controller model D030-P is a microprocessor controlled device for batching and filling

of small batch sizes up to medium large quantities as well as displaying total and accumulated

total .

The D030-P has been designed with a focus on:

• Ultra-low power consumption, to allow for battery operation of up to five years.

• Front panel mounting solution based on IP66/67 (Nema4X), suitable for harsh industrial

surroundings.

• Very easy and user-friendly installation and programming through an easy menu-driven

structure. Know one, know them all!

• Ability to process all type of signals.

• One control output for controlling a pump or valve.

Field Input

The “P” in D030-P indicates a pulse flowmeter input. Other versions are available to process (0)4-

20mA “A” or 0-10V “U” flowmeter signals.

•The D030-P can read one passive or active flowmeter with a passive, active, Namur or sine

wave (coil) pulse output.

•To power the flowmeter, several options are available.

Standard Outputs

The following output is available for the D030-P:

• Control output: This passive transistor output controls the valve or pump for the batch

process.

Control output

Figure 1: Typical application of the D030-P

User manual D030-P Batch Controller

1–INTRODUCTION

2FW-D030-P-MAN-EN-V0102_02

The D030-P Display Functions

The D030-P has a large transflective LCD with a number of symbols and digits to display

measuring units, status information, trend indication and keyword messages.

Configuration of the D030-P

"Available D030-P configurations" on page 3 shows that this unit is available in various hardware

configurations to support a wide range of applications. Other models of this type have other

configurations. Contact your reseller for details.

The configuration mode of the D030-P allows you to configure and shape your D030-P towards

your specific requirements. The configuration mode supports all available hardware

configurations of the D030-P and includes several important features such as K-factor,

measurement units, signal settings, etc.

All setting as are stored in EEPROM memory and will not be lost in case of power breakdown or in

the event of an empty battery.

EEPROM Memory

The D030-P contains EEPROM memory that does not loose its data upon power loss.

All configuration settings remain stored in case of a power failure or deactivation of the unit (e.g.

during transport or storage).

Options of the D030-P

The following section describes the configuration options this particular D030-P may have been

equipped with. Other models of this type have other options. Contact your reseller for details.

Figure 2: The display functions of the D030-P

Indication of large

display readout Measuring units large display

readout

Large display trending

(increase or decrease) Numerical 17mm large display

readout

low battery indicator (replace

when steady) D030-P status indicators

indication of small

display readout Alphanumerical small display

readout

RUN

LOW BATTERY

SET-UP PAUSE

ALARM

PROGRAM

READY

Note:

You may optimize battery-life time (type PB only) by optimizing the power-

management functions as described in "Power Management" on page 25.

User manual D030-P Batch Controller

INTRODUCTION – 1

FW-D030-P-MAN-EN-V0102_02 3

Available D030-P configurations

Your D030-P model is available in a number of hardwired configuration options.

A product label on the backside of the unit identifies which configuration options are included in

your D030-P.

The following table identifies the options that may apply to your D030-P.

Note:

A combination of configuration options is not always possible: some options rule others

out and some options require others to be included. Consult the product label on your

D030-P enclosure to see which options are included on your particular unit.

Standard confuguration: D030-P-HB-OT-PX-ZX

Coding information D030-_ -HB -O_ -P_ -Z_

flowmeter input signal(s)

PPulse (coil, NAMUR, npn, pnp, reed switch)

Front Panel mount enclosure - IP66/67 (NEMA4X)

HB Aluminum DIN 43700 / IEC 61554 front panel

Control output

OH Active and passive transistor output - requires PD (DC). (PD (AC) and PM are pending).

OR Highly isolated mechanical relay output - requires PD (DC). (PD (AC) and PM are pending

OT Passive transistor output - standard configuration.

Power supply

PB Long life lithium battery

PD 24V DC/AC + sensor supply.

PM 115 - 230V AC + sensor supply.

PX Basic power supply 8 - 30V DC

Other options

ZB Backligh, Bi-colort green/amber

ZF Extra high sensitive coil input: 10mV p-p

ZG Very high sensitive coil input: 5mV p-p

ZX No options

The bold marked text contains the standard configuration.

CHAPTER

4FW-D030-P-MAN-EN-V0102_02

2

Specifications of the D030-P

General specifications

Display

Type High intensity reflective numeric and alphanumeric LCD, UV-

resistant.

Digits Seven 17mm (0.67") and eleven 8mm (0.31")digits.

Various symbols and measuring units.

Refresh rate User definable: fast - 1 sec - 3 sec - 15 sec - 30 sec - off.

Option ZB Transflective LCD with bi-color LED backlight; green / amber.

Intensity and color can be adjusted in the configuration menu.

High contrast readings in full sunlight and darkness.

Panel Mount Enclosure

General Die-cast ALU (aluminum) enclosure with Polycarbonate

window and silicone.

UV stabilized and flame retardant material. GRP back cover.

Control Keys Three industrial micro switch keys. UV-stabilized silicone

keypad

Painting UV-resistant 2-component industrial paint

Dimensions 144 x 72 x 71.4mm (5.67" x 2.83" x 2.81") – LxHxD

Weight 325 gr.

Classification IP66, IP67 (NEMA4x) at the front-side

Panel cutout 138 x 68mm (5.43" x 2.68") – LxH

Panel thickness Max. 6mm (¼")

Type HB Die-cast ALU panel-mount enclosure according: DIN 43700 /

IEC 61554

Temperature

Operating -40°C to +80°C (-40°F to +176°F) ambient

Approvals and compliances

EMC compatibility Compliant ref: EN 61326 (1997), EN 61010-1 (1993).

Power supply

Type PB 3,6V Lithium battery life-time depends upon settings and

configuration – up to 5 years.

Type PD 24V AC / DC + 10%. Power consumption max. 5 Watt.

Type PM 115-230V AC + 10%. Power consumption max. 15 Watt.

Type PX 8-30V DC. Power consumption max. 0.3 Watt.

Type ZB 20 - 30V DC. Power consumption max. 1 Watt.

With type PD - PM: Internally powered

User manual D030-P Batch Controller

SPECIFICATIONS OF THE D030-P – 2

FW-D030-P-MAN-EN-V0102_02 5

Sensor excitation

Sensor exitation specifications relate to the power supply

type.

Type PB / PX 3V DC for pulse signals and 1.2V DC for coil pick-up.

Type PD / PM Dipswitch adjustable sensor supply:

8.2V DC. Iout max 35mA @ 20°C

12V DC. Iout max 50mA @ 20°C

24V DC. Iout max 75mA @ 20°C (this voltage can vary

depending on the input supply voltage).

Terminal connections

Type Removable plug-in terminal strip.

Wire max. 1.5mm2and 2.5mm2solid / stranded.

Screw thread M3

Tightening torque 0.5-0.6 Nm

Data protection

Memory type EEPROM; data retention >10 years

Automatic backup of settings upon change & running totals

every minute

Access restriction Via configurable 4 digit numerical pass code

Inputs

Flowmeter

Type P Coil/sine wave (minimum 20mVpp or 80mVpp - sensitivity

selectable), NPN/PNP, open collector, reed-switch, Namur,

active pulse signals 8 - 12 and 24V

Frequency Min. 0 Hz – max. 7 kHz for total and flowrate (max. frequency

depends on signal type and internal low-pass filter).

Reed switch with low-pass filter: max. frequency 120 Hz.

K-Factor 0.00001 - 9,999,999 with variable decimal position.

Low-pass filter Available for all pulse signals.

Option ZF: coil sensitivity 10mVpp.

Option ZG: coil sensitivity 5mVpp.

Note:

To prevent battery drainage only use for pulse

sensors with a very low power consumption such as

coils (sine wave) and reed-switches.

User manual D030-P Batch Controller

2–SPECIFICATIONS OF THE D030-P

6FW-D030-P-MAN-EN-V0102_02

Outputs

Control output

Output type Control output according the batch process.

Type OH Active 24V DC transistor output; Requires PM/PD. Max load

75mA

Passive transistor output - not isolated; Requires PM/PD. Max.

24V DC - 300mA.

Type OR Isolated electro-mechanical relay (NO/NC); max. resistive

load: 2A@230Vac / 30V DC. Pilot duty rating: 0,5A @ 230Vac.

Requires PM/PD (DC).

Note: In case of inductive load, use RC snubbers.

Type OT Passive transistor output (NPN) - not isolated; Max. 50V DC -

300mA.

Operational

Operator functions

Displayed functions • Preset value - can be entered by the operator

• Total and accumulated total

• Batched quantity or remaining quantity

• key-word messages

Preset and Total

Units L, m3, GAL, USGAL, kg, lb, bbl - no units

Digits 7 digits

Displayed decimals configurable 0 — 3

Accumulated total

Units / Decimals Identical to selection for "Total".

Digits 11 digits

Note:

Total can be reset to zero by pressing the STOP key

twice.

Note:

Accumulated total can not be reset to zero.

User manual D030-P Batch Controller

SPECIFICATIONS OF THE D030-P – 2

FW-D030-P-MAN-EN-V0102_02 7

This page is left blanc intentionally.

3

8FW-D030-P-MAN-EN-V0102_02

CHAPTER

Installation Instructions

Mechanical Installation

To extend life of your unit:

• Mount the D030-P on a solid base to avoid vibrations.

• Provide sufficient slack on cables to prevent stress on cable entries.

• Make sure the seal is mounted properly between the housing and the panel.

• The IP66, IP67 (NEMA4X) classification is valid for the front enclosure only.

• Do not expose the casing to strongly varying (weather) conditions, not even when rated IP67.

Note:

This section describes various hardware configurations of the D030-P. Your particular

model of the D030-P may not support all configuration options described.

Figure 3: Mechanical mounting precautions

Figure 4: Panel cut-out dimensions

@@Panel cut-out dimensions D-series

68mm (2.68")

138 mm (5.43")

10.2 mm (0.4”)

72 (2.83”)

144 mm (5.67”)

55,3mm (2.18”)

15,6mm (0.61”)

User manual D030-P Batch Controller

INSTALLATION INSTRUCTIONS – 3

FW-D030-P-MAN-EN-V0102_02 9

Electrical installation – general

Overview of Terminal Connectors

To gain access to the connectors open the panel containing the D030-P. You now see the battery

cover with the battery and the connectors at the back side of the display unit as shown below.

The actual number and size of connectors depends on your particular model.

Figure 5: Connector location D030-P

flowmeter and Power

A 6-pole Classic COMBICON connector connects the

flowmeter and (optional) power supply.

Pulse Output

A 3-pole Classic COMBICON connector connects the

optional Pulse output.

Mains Power Supply

A3-poleClassicCOMBICON connector connects the mains

power supply.(110/230V) (PM)

Figure 6: Pin layout options of main connector(s) –availability depends on model ID

AC power

supply

(option)

control out Voltage

switch

8.2/12/24V

input sensor

supply DC power

supply

Analog out /

HART

(option)

R1 R2 R3 S1 S2 S3 S4 P3 P4 A1 A2

⊥+↑+↓ ⊥ +↑⊥+↑

OH: PNP / NPN P: reed / NPN PX: 8-30Vdc

COM

⊥NO NC ⊥-↑3.0V↓8.2/12/

24V↓

OR: make-and-

break relay

P: PNP

Note:: OH and OR require a

PM/PD Power Supply. ⊥-↑3.0V↓8.2/12/

24V↓

P: NAMUR

⊥+↑3.0V↓8.2/12/

24V↓

P: active pulse

P0 P1 P2

∼∼

PD:24V AC

L1 N

PM: 115-

230V AC

User manual D030-P Batch Controller

3–INSTALLATION INSTRUCTIONS

10 FW-D030-P-MAN-EN-V0102_02

Connector Types and Wiring Sizes

The following connector types are fitted. Wires are connected using a flat head screw driver:

Classic COMBICON

A screw connector with 5.08mm pitch, suitable for 0.2—2.5mm2 or AWG

24—12 wire. Max. torque 0.5Nm.

Power Supply Wiring

Below section describes the available power supply types for the D030-P. Which types are

available in your particular D030-P depends on the ordering code.

Battery equipped models switch their internal battery off when an external supply is active.

The following power supply options are available:

• Battery powered. see "Battery powered type PB" on page 10 for details.

• Externaly powered, see ""External Power Supply wiring" on page 10" for details.

Battery powered type PB

Type PB is internally battery powered and does not require any external wiring.

When power supply PX is available (see below) the internal battery is switched off. This extends

battery life and guarantees higher availability during power outages.

• A healthy battery has a life expectancy of several years, depending on its use and

configuration settings. For details see "Battery life" on page 31.

• When installing verify that the battery is in good working condition by running the power-up

sequence on page iv of this manual. If the battery needs to be replaced follow the battery

replacement instructions delivered with the new battery.

External Power Supply wiring

The D030-P can be equipped with a power supply, type PX or PD.

• For type PX or PD DC your D030-P must be equipped with a 6 pole connector.

Type PD can also power your flowmeter in the field, see "Power wiring type PD" on page 11 for

details.

Figure 7: Voltage switch positions

8.2V 12V 24V

A

B

A

B

A

B

A

B

A

or

B

A

B

Note:

• Type PX < 16V does not foresee in the (optional) backlight power; see "Backlight" on

page 12.

• The internal battery is on standby, when external power is supplied. Note that the

internal battery cannot be used to power a flowmeter with 8.2V (pin S4)!

Caution:

The D030-P and it’s field devices are functionally isolated to a maximum of 500V!

User manual D030-P Batch Controller

INSTALLATION INSTRUCTIONS – 3

FW-D030-P-MAN-EN-V0102_02 11

Power wiring type PX

Connect the “-”, GND or “0V” wire of your external power supply to pin P3. Connect the “+” wire

to pin P4.

With power wiring type PX pin S4 offers 8.2V to power a device in the field

Power wiring type PD

Figure 8: Power wiring type PX

D030-P

P4

8-30Vdc

P3

With power wiring type PD / PM pin S4 offers a limited sensor supply (8.2/12/24V) to power the

flowmeter in the field.

Figure 9: Power wiring type PD DC / AC – with flowmeter supply

D030-P

P4

24Vdc ±10%

P3

S4 Power supply to flowmeter,seeFigure

7: "Voltage switch positions" for settings

P2

24Vac 50/60Hz

P1

0V

+

++

-

+

0V

++

-

~

~

ground - yellow /green

P0

User manual D030-P Batch Controller

3–INSTALLATION INSTRUCTIONS

12 FW-D030-P-MAN-EN-V0102_02

Power wiring type PM

Type PM is a galvanically isolated highpower switching power supply, converting 115–230Vac

mains (50/60Hz) to power the D030-P,the backlight (option) and provides up to 24V sensor

supply to the field.

Backlight

For those applications where readability during day and night is an issue, a bi-color backlight is

available. The background color can be set to green or amber and the intensity can be adjusted

in the configuration menu, see 32 "Backlight" on page 24

Backlight requires a power supply of at least 16V and is internally powered by options PD, PM or

PX above 16V.

Warning

•HIGH VOLTAGE! Danger of electrical shock: remove power from the supply lines

before connecting.

Warning

• Never connect 24V AC and DC together on the same unit, this will damage the unit.

Figure 10: Power wiring type PM

D030-P

S4 Supplies up to 24Vdc@75mA sensor

power, see Figure 7: "Voltage switch

positions" for settings

P3/

S1

P2

115–230Vac 50/60Hz

+

0V

N

P1

L1

P0 ground - yellow /green

User manual D030-P Batch Controller

INSTALLATION INSTRUCTIONS – 3

FW-D030-P-MAN-EN-V0102_02 13

I/O wiring options

Batch Controller Input Wiring Options Type P

Below flowmeter signal types can be connected to the D030-P.

The screen of the signal wire must be connected to the common ground if not earthed at the

sensor itself.

The maximum input frequency is approximately 10 kHz (depending on the type of signal). The

input signal type has to be selected with the correct SETUP-function (see "Signal" on page 25).

Explanation of symbol ‘cable shielding’

Low pass filter

A low-pass filter is an electronic filter that passes low-frequency signals and attenuates (reduces

the amplitude of) signals with frequencies higher than the cutoff frequency.

Sine-wave (Coil) Signal

The D030-P can be connected to flowmeters with a coil output signal.

Two sensitivity levels can be selected with setup menu 51 "Signal":

• COIL LO: sensitivity about 120mVp-p.

• COIL HI: default sensitivity about 20mVp-p.

(with type ZF COIL HI sensitivity is increased to 10mVp-p and with type ZG to 5mV p-p.)

cable shielding

Figure 11: Coil signal input

D030-P +1.2Vdc S3 Input sensitivity selectable

via setup menu 51 "Signal"

S2

S1

~

~

User manual D030-P Batch Controller

3–INSTALLATION INSTRUCTIONS

14 FW-D030-P-MAN-EN-V0102_02

Pulse-signal NPN / NPN-LP

The D030-P is suitable for use with flowmeters which have a NPN output signal.

For reliable pulse detection, the pulse amplitude has to go below 1.2V. Signal setting NPN-LP

employs a low-pass signal noise filter, which limits the maximum input frequency. See "Low pass

filter" on page 13.

Pulse-signal PNP / PNP-LP

The D030-P is suitable for use with flowmeters which have a PNP output signal.

3.0V is offered as a pull-up voltage which has to be switched by the PNP sensor. Optionally an

8.2/12/24V pull-up voltage can be wired, when powered with a power supply type PD/PM.

For a reliable pulse detection, the pulse amplitude has to go above 1.2V. Signal setting PNP-LP

employs a low-pass signal noise filter, which limits the maximum input frequency. See "Low pass

filter" on page 13.

For a signal detection level of 50% of the supply voltage: please refer to "Flowmeter Pickup

Signal Types Supported" on page 33

Figure 12: NPN pulse signal input

D030-P +3.0Vdc LP = Optional Low-Pass filter. For configuration details see Setup

menu 51 "Signal".

S2

S1

*

100kΩ

Figure 13: PNP pulse signal input

D030-P LP = Optional Low-Pass filter. For

configuration details see Setup menu 51

"Signal"

8.2/12/

24Vdc S4

Choose between sensor power from 3.2Vdc

or 8.2Vdc terminal

3.0Vdc S3

S2

S1

or

820

Ω

Table of contents

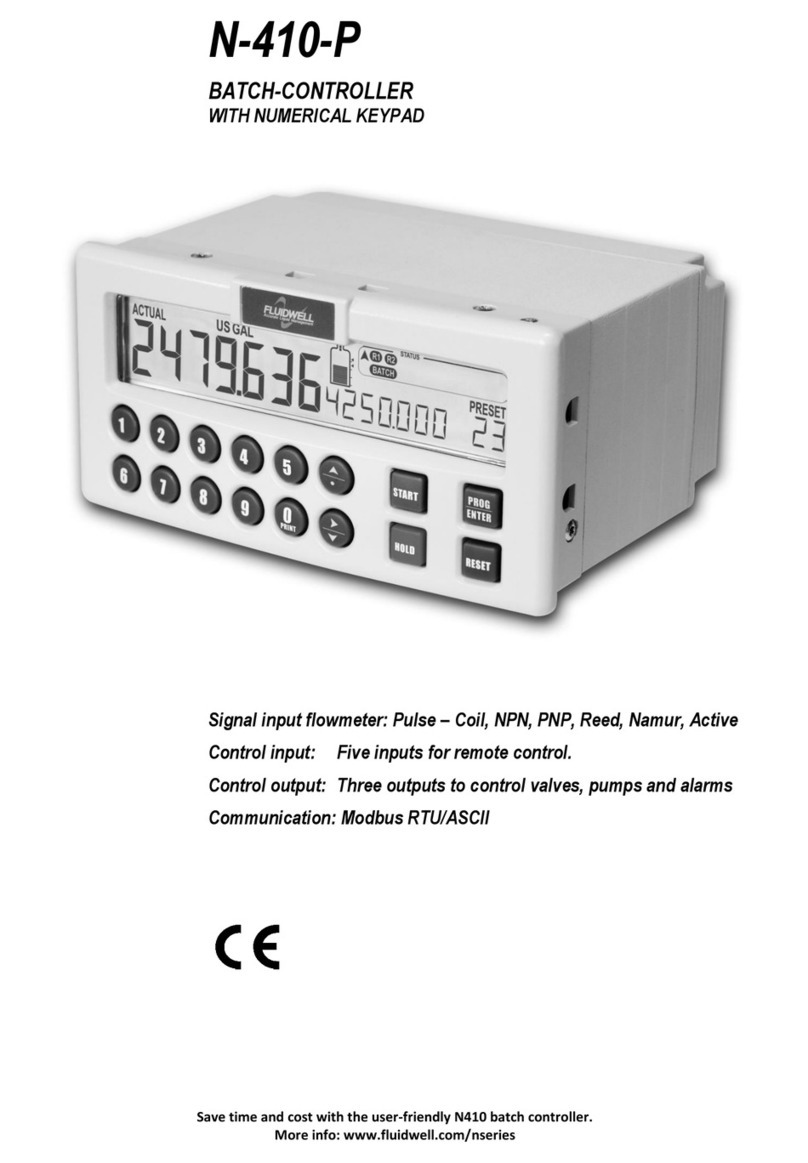

Other Fluidwell Controllers manuals

Fluidwell

Fluidwell F074-A User manual

Fluidwell

Fluidwell F130-P User manual

Fluidwell

Fluidwell N-410-P User manual

Fluidwell

Fluidwell F Series User manual

Fluidwell

Fluidwell F130-P User manual

Fluidwell

Fluidwell F131-P User manual

Fluidwell

Fluidwell F124-P User manual

Fluidwell

Fluidwell F030-A User manual

Fluidwell

Fluidwell F132-P User manual

Fluidwell

Fluidwell D Series User manual

Popular Controllers manuals by other brands

CrimeStopper

CrimeStopper FS-60 Operation instructions

Endress+Hauser

Endress+Hauser Liquiline Control CDC90 operating instructions

YASKAWA

YASKAWA MP2300S user manual

Lightwave Research

Lightwave Research Data Flash AF 1000 user manual

SURAN

SURAN ENDA EHTC7425A manual

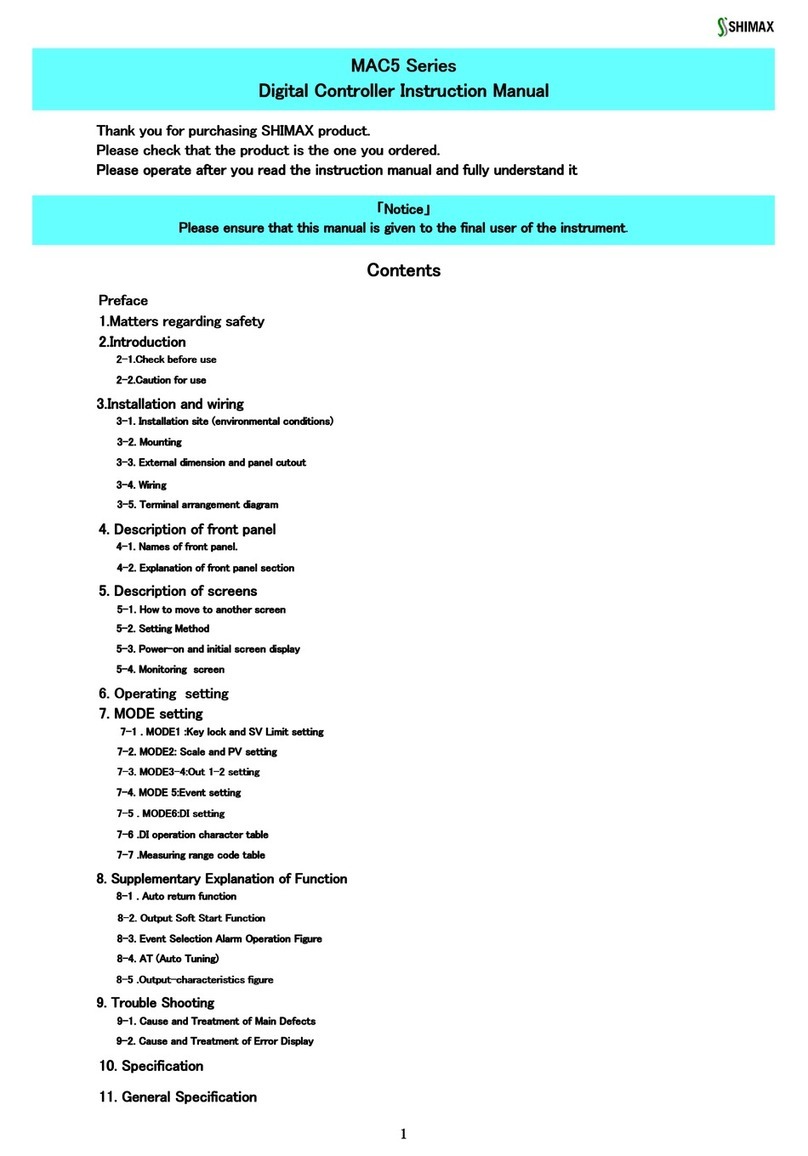

Shimax

Shimax MAC5 Series instruction manual