FLUITECO SMC 2

INDEX

1. INTRODUCTION................................................................................................ 4

2. PREFACTION..................................................................................................... 4

2.1 Symbology of warning...........................................................................................................5

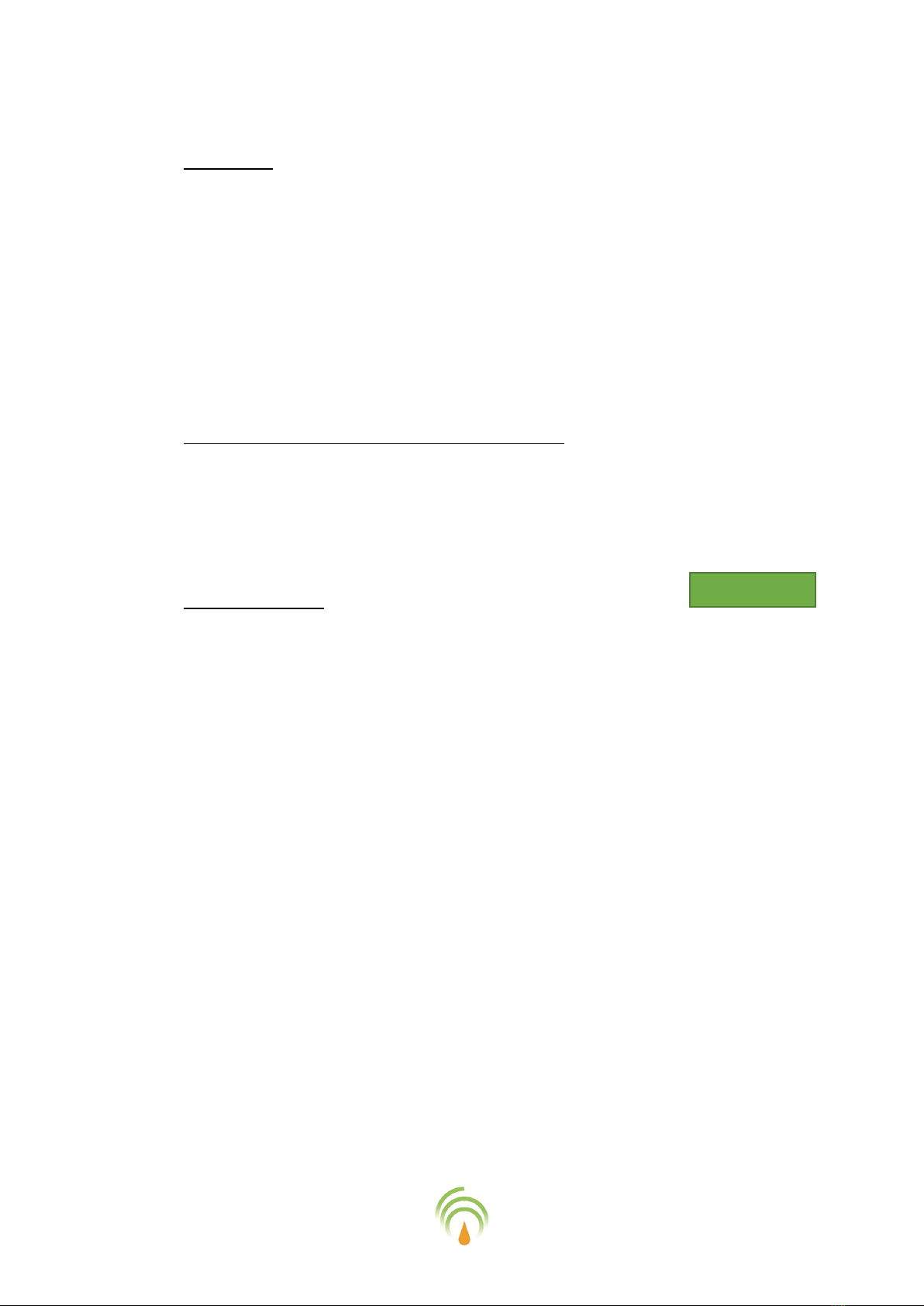

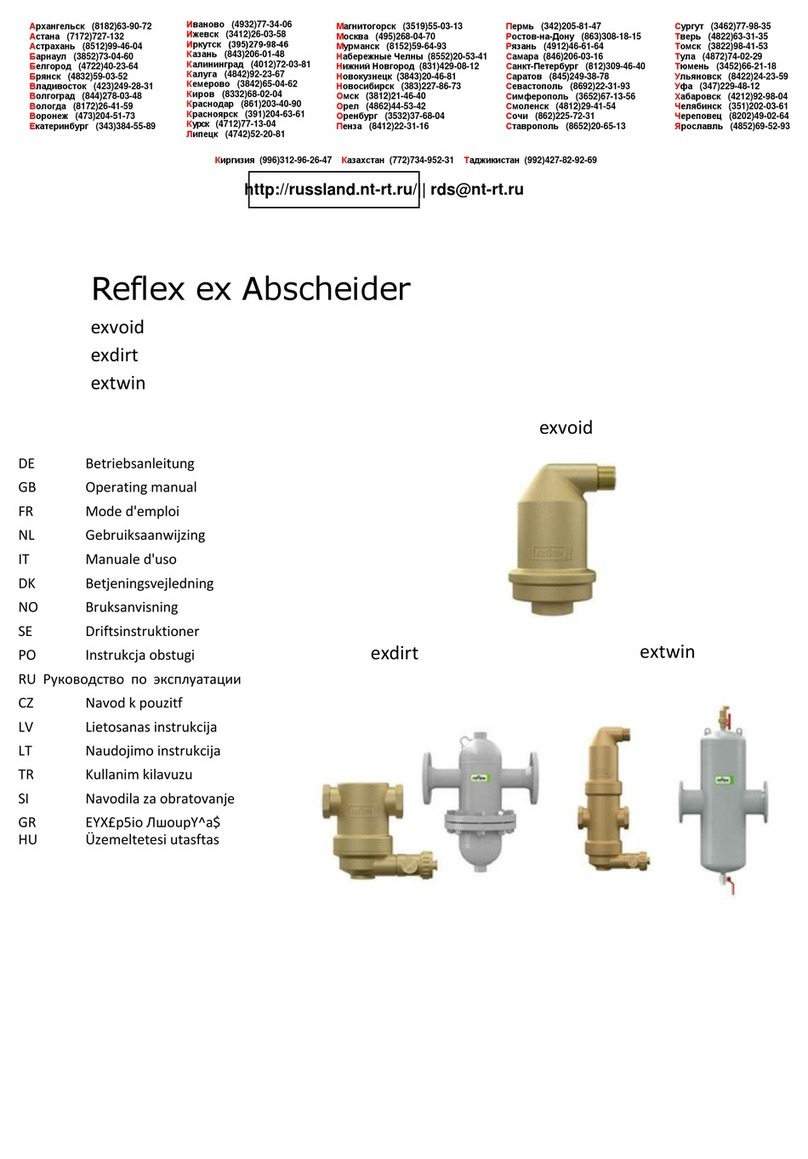

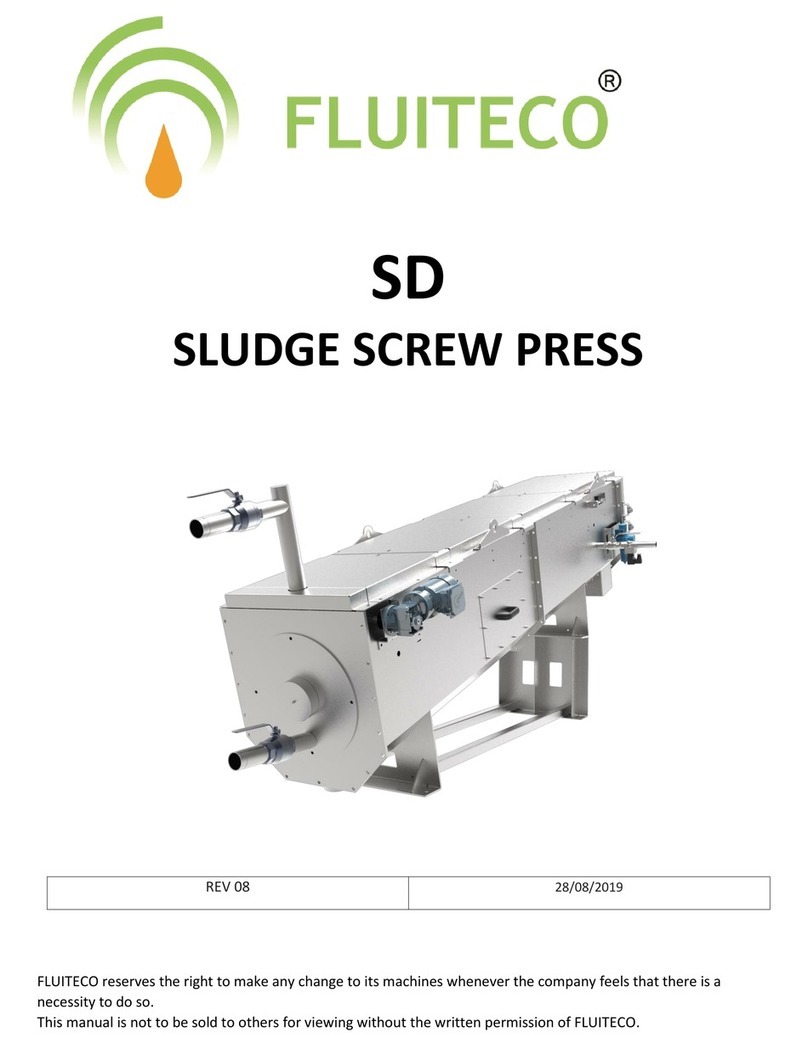

2.2 Identification of the machine................................................................................................5

2.3 Guarantee..............................................................................................................................6

2.4 Manufacturer’s declaration (Type A) Machine.....................................................................6

2.5 Technical service ...................................................................................................................6

3. RECEIVING AND INSTALLATION........................................................................ 7

3.1 Purpose..................................................................................................................................7

3.2 Conditions on the usage limits..............................................................................................7

3.3 Unloading ..............................................................................................................................7

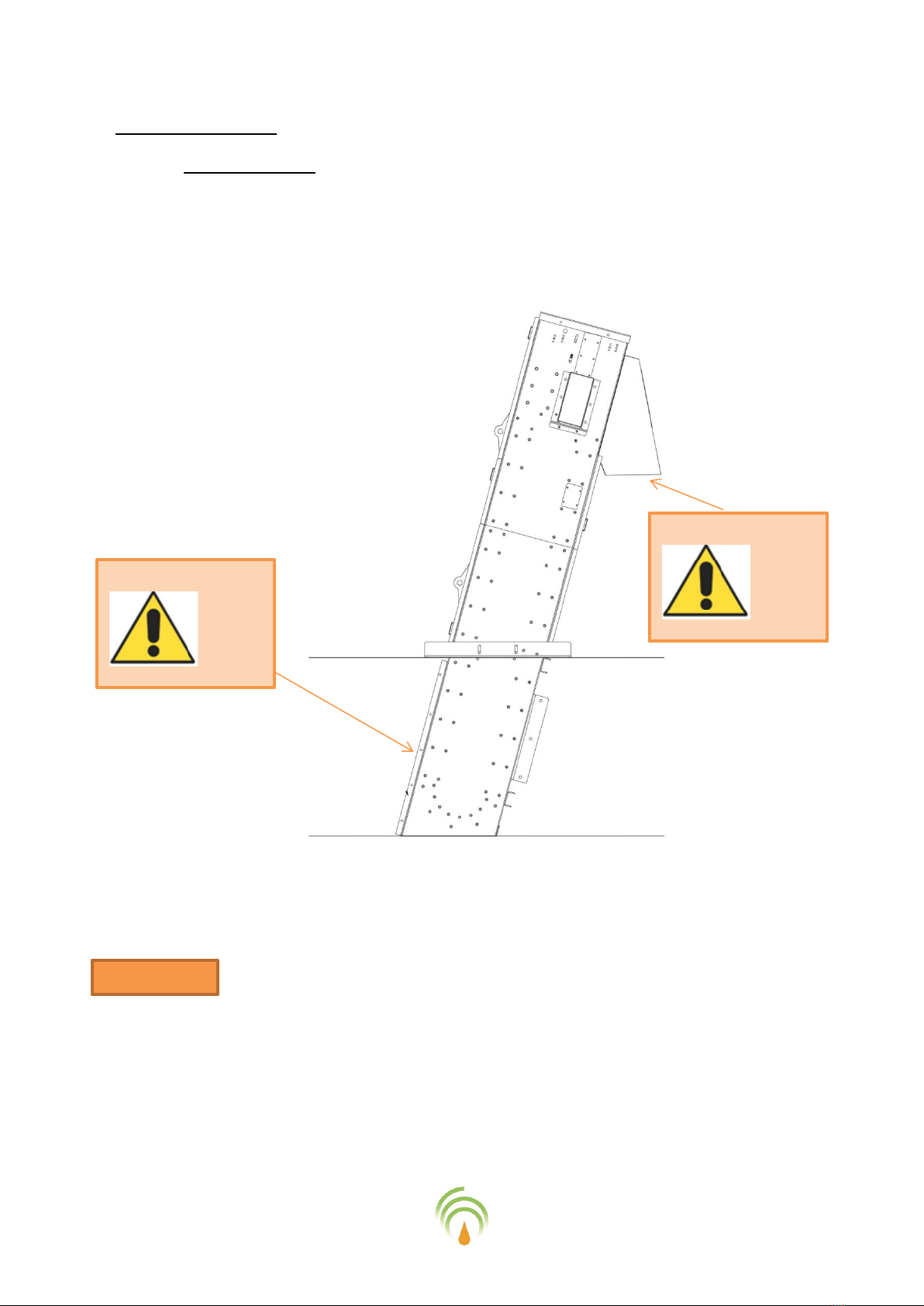

3.4 Installation procedure...........................................................................................................8

4. SECURITY NORMS .......................................................................................... 10

4.1 Improper usage ...................................................................................................................10

4.2 Safe usage............................................................................................................................11

4.3 Individual safety devices .....................................................................................................12

4.4 Plant’s safety devices ..........................................................................................................12

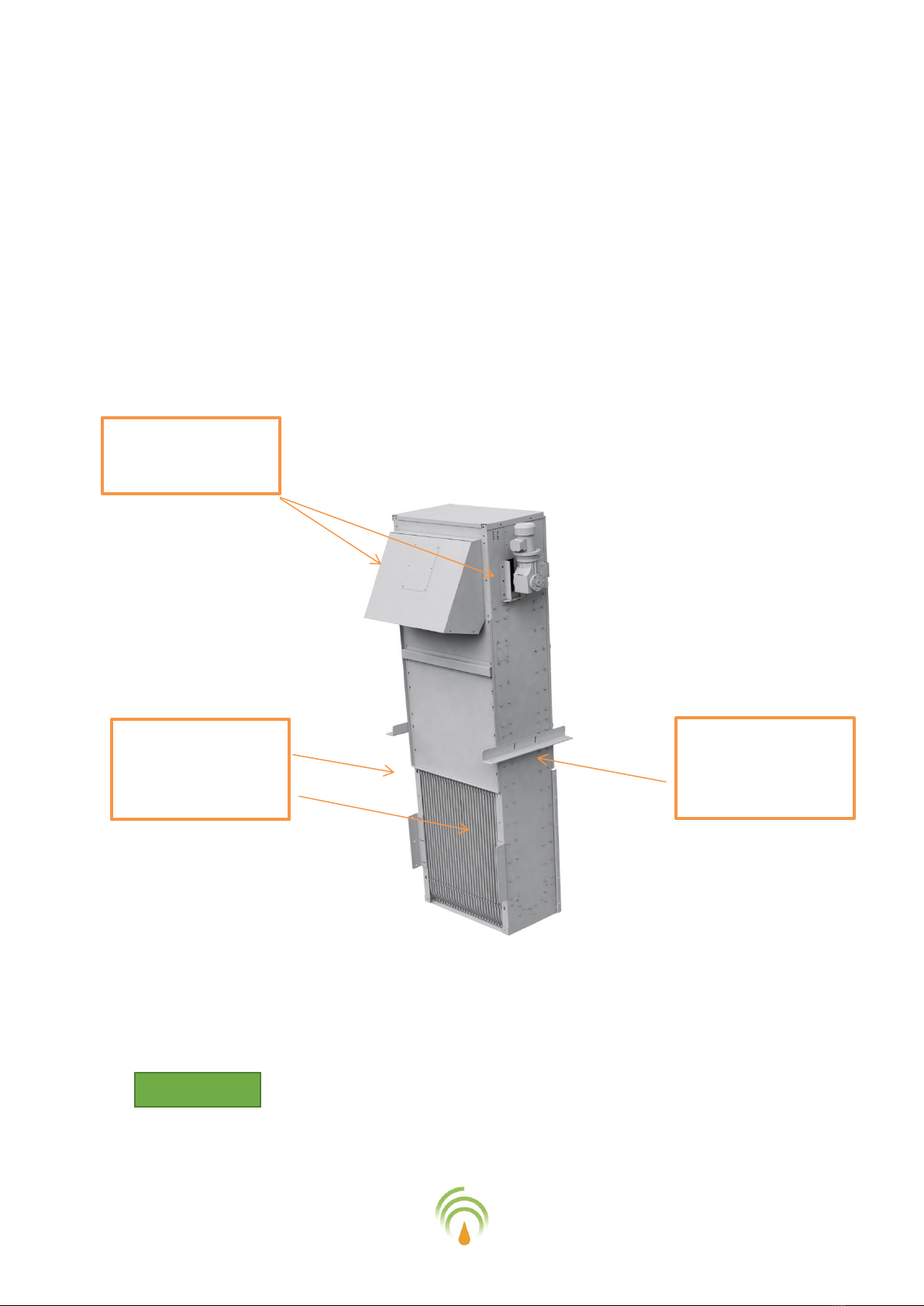

5. DESCRIPTION AND CHARACTERISTICS ............................................................ 13

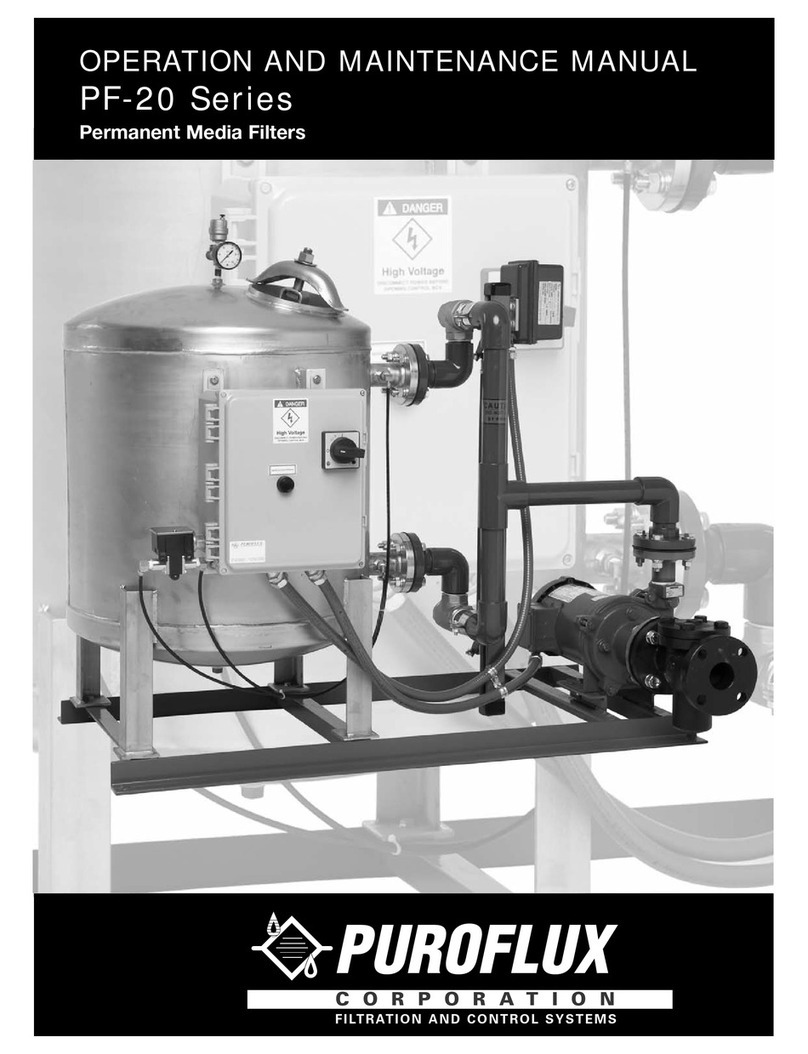

5.1 Proper usage and description of the working process........................................................13

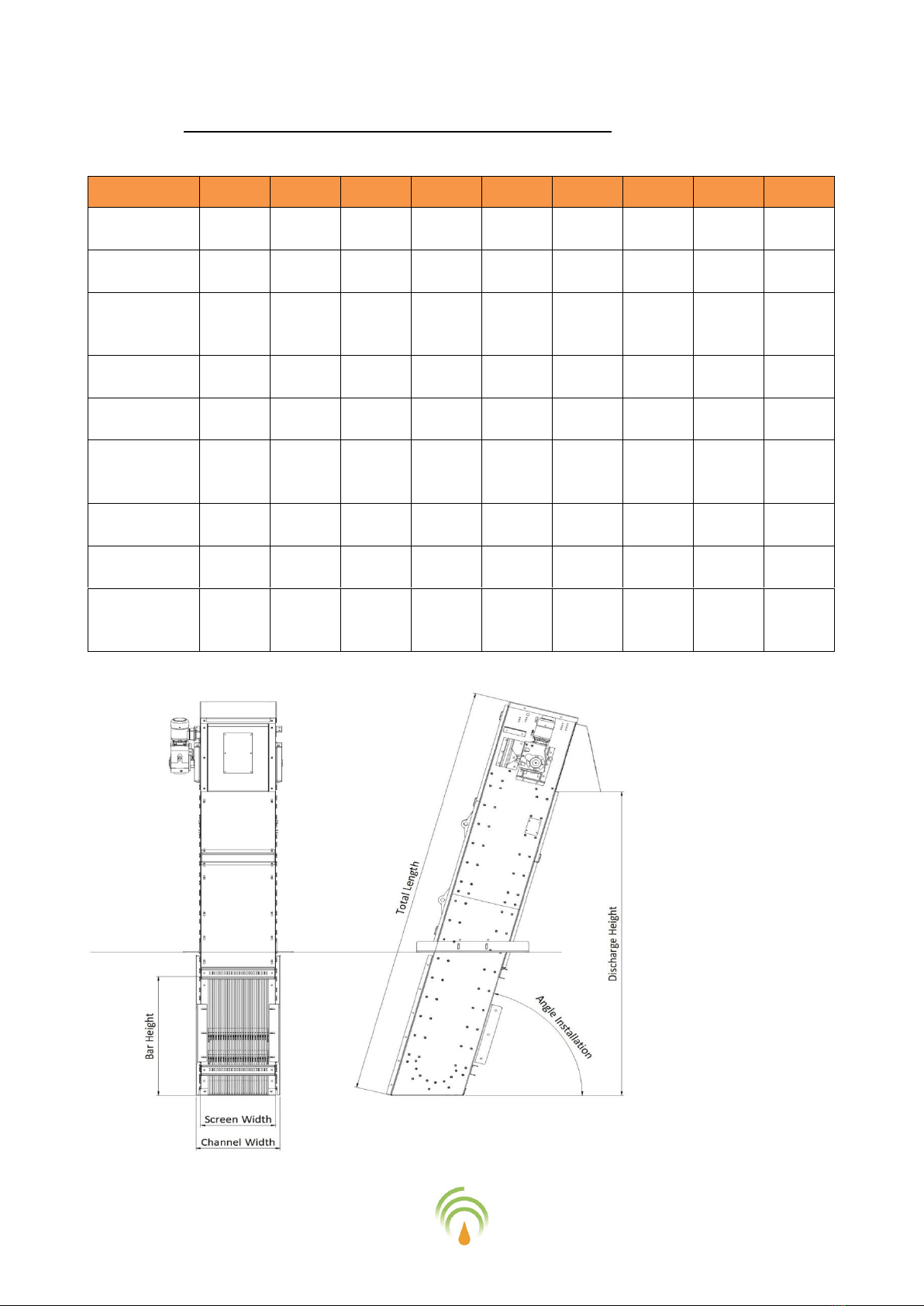

5.2 Dimensional characteristics of the standard models..........................................................14

5.3 Characteristics of the effluent that can be dealt with ........................................................15

6. USAGE OF THE MACHINE ............................................................................... 15

6.1 Starting procedure ..............................................................................................................15

7. ORDINARY MAINTENANCE............................................................................. 17

7.1 Safety conditions in case of maintenance...........................................................................17

7.2 Cleaning...............................................................................................................................17

7.3 Periodic check......................................................................................................................17

7.4 Special maintenance ...........................................................................................................19

7.4.1 Replacement of the gearmotor ...................................................................................19

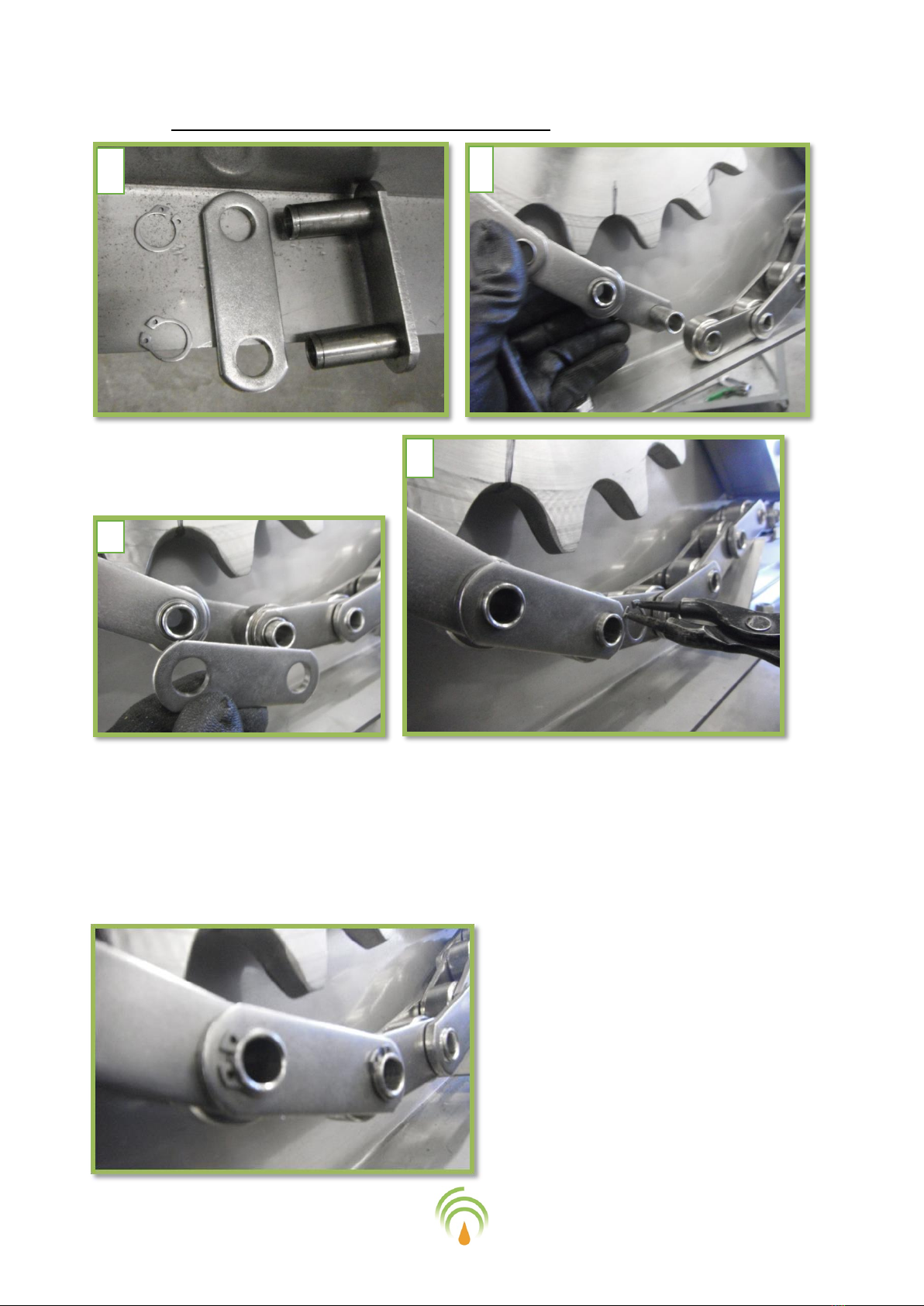

7.4.2 Replacement of chain ..................................................................................................19