3. Install the batteries

so

that the polarity markings

on

the

batteries match the markings

on

the battery door.

4.

Snap the battery door shut.

NOTE

If

both batteries are not installed with the correct

polarity, thebatterytestmayindicate thatthebatteries

are good, but the probe will not operate.

OPERATION

Battery Test

' \ I I

CT]

I/

\ \

{

-9~mv

} •

~

00.0mV

O.K.

~

~~

+

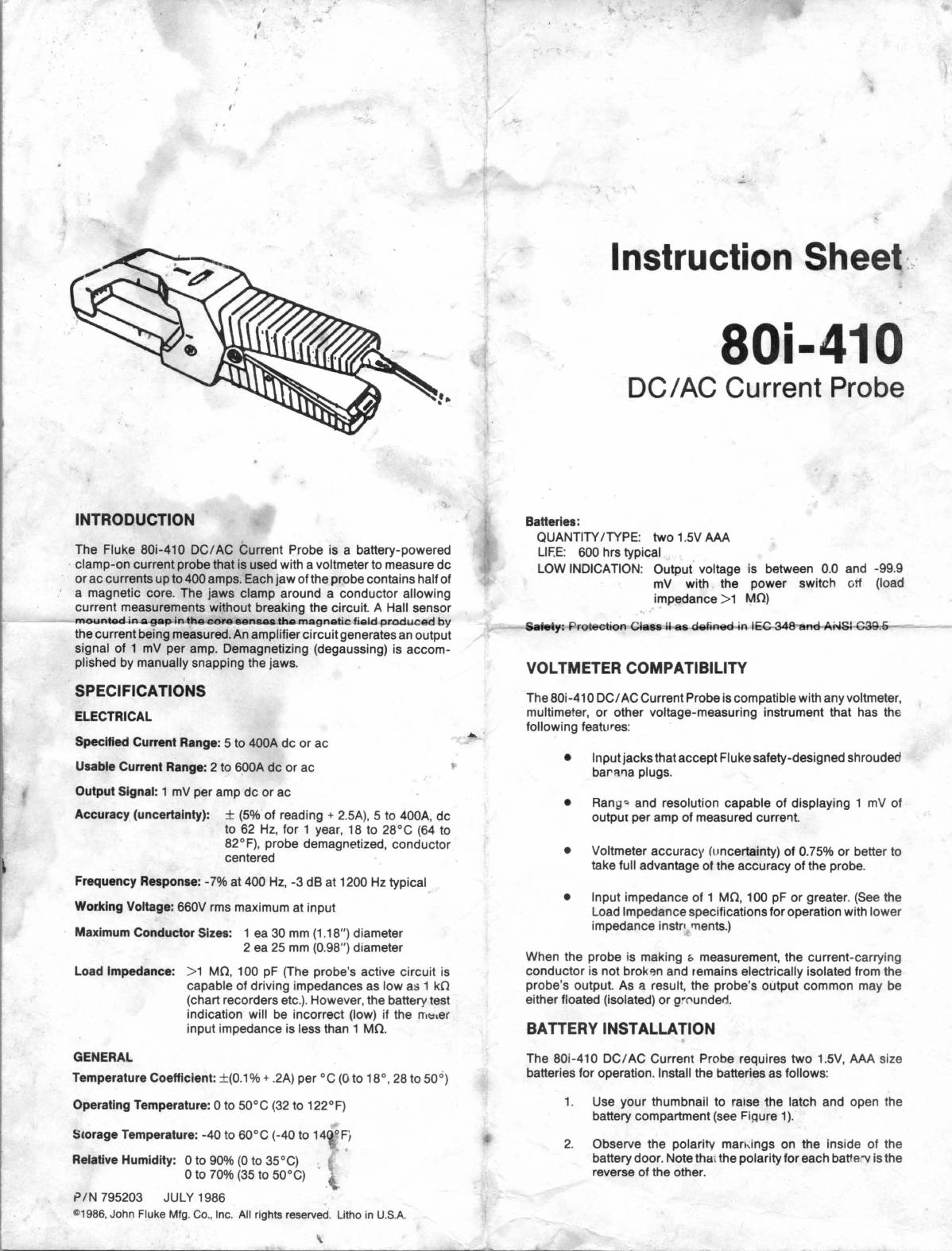

Figure 1.

Use the following procedure to test the batteries:

1.

Connectthe probe output leads to the voltmeter inputs:

black to COMMON or

r.

ow

,and red to

VetT

.

2.

Setthe voltmeterfunction to

de

millivolts

(de

mV==),

and

turn the voltmeter power

on.

3.

Select a range capable of displaying 170

mV

de.

4.

Verify that the power switch on the probe is in the

OFF

position.

5.

Observe the voltmeter reading.

If

the reading falls

between -100.0 and -170.0

mV,

the probe is ready for

use.

(New batteries should read approximately -150

mV.)

If the reading falls between

0.0

and -99.9

mV,

the

batteries should be replaced. If the voltmeter reading is

positive, either the test leads are reversed or the

batteries are installed incorrectly.

Demagnetizing

When the 80i-410

DC/

AC

Current Probe has been used for a

currentmeasurementand then removed from the conductor,asmall

amo_unt

of residual magnetism often remains

in

the core. This

residual magnetism will generate a de offset at the probe output.

In

otherwords, the voltmeter will show asmall de reading even though

there is no current passing through the jaws of the probe. The

residual magnetism should not cause a problem for ac current

measurement because the ac voltage function

in

most multimeters

is ac coupled; therefore, the de offsetwill not

be

displayed. However,

for de current measurements, the

de

offset caused by the residual

magnetism will contributeto reading errors. The residual magnetism

can

be

minimized

as

follows

(see

Figure

2):

1.

Use

the thumb and forefinger of one hand to grasp the

probe

in

the middle where the two screw heads are

exposed.

2. With your other hand, compress the handles together,

then release them suddenly. The jaws should come

together with a snapping action.

3.

Repeat the above procedure twice.

Figure 2.

NOTE

The

snapping action will not damage the jaws

if

the

mating surfaces are kept clean. ·

Alternate Demagnetizing Procedures

Ifaconductor carrying ac current is available, clampthe jawsofthe

probe around the conductor, wait a few seconds, then slowly

remove the probe.

If

a conductor carrying de current is available,

clampthe jawsofthe probe around the conductor.Then removethe

probe and clamp itaround the conductor again so that the current

flows through the jaws

in

the opposite direction.

Making Measureme·nts ·

Use the following procedure to make current measurements

(see

Figure

3):

~

~

..CC).Qll~~~)ioiba-.OU:~lt.J.i~~~~~~~:..&Apw.I~

~~~-

(black to COMMON or

LOW

and

red

to

VOLTS)

.

2.

Selectthe appropriateac orde function on thevoltmeter.

3.

Turn on the voltmeter and select a voltage range to

display the expected value

(1

mV

per

amp).

4.

Turn the probe ON/OFF switch located on the probe

handle to the

ON

position.

5.

Observe the voltmeter reading. If necessary, demag-

netize the probe.

6.

Clampthejawsofthe probe around the conductorto

be

measured.Position the probeso thattheconductoris

in

the center of the jaw opening for the most accurate

reading.

7.

Observe the voltmeter display. The reading

in

millivolts

is equivalent to the current

in

amps

(i.e.,

5

mV

=SA). A

positive polarity reading indicates thatthe de current is

flowi

ng

in

th

e direction of the arrow

on

the probe.

Figure 3.