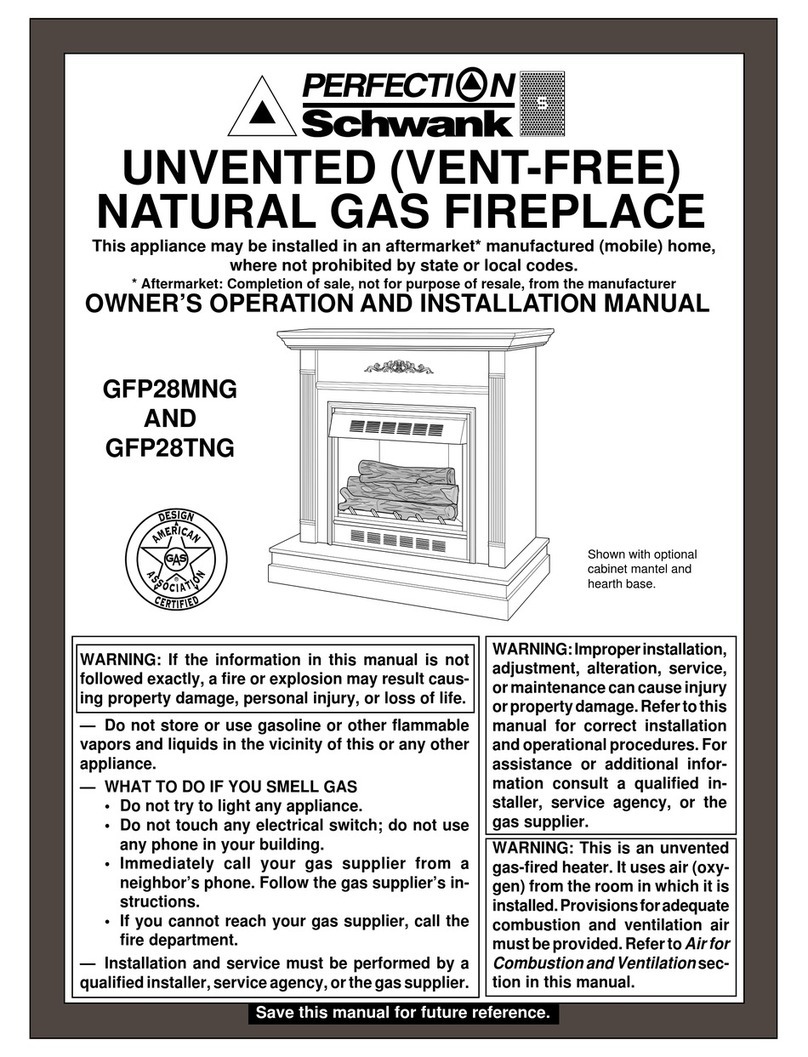

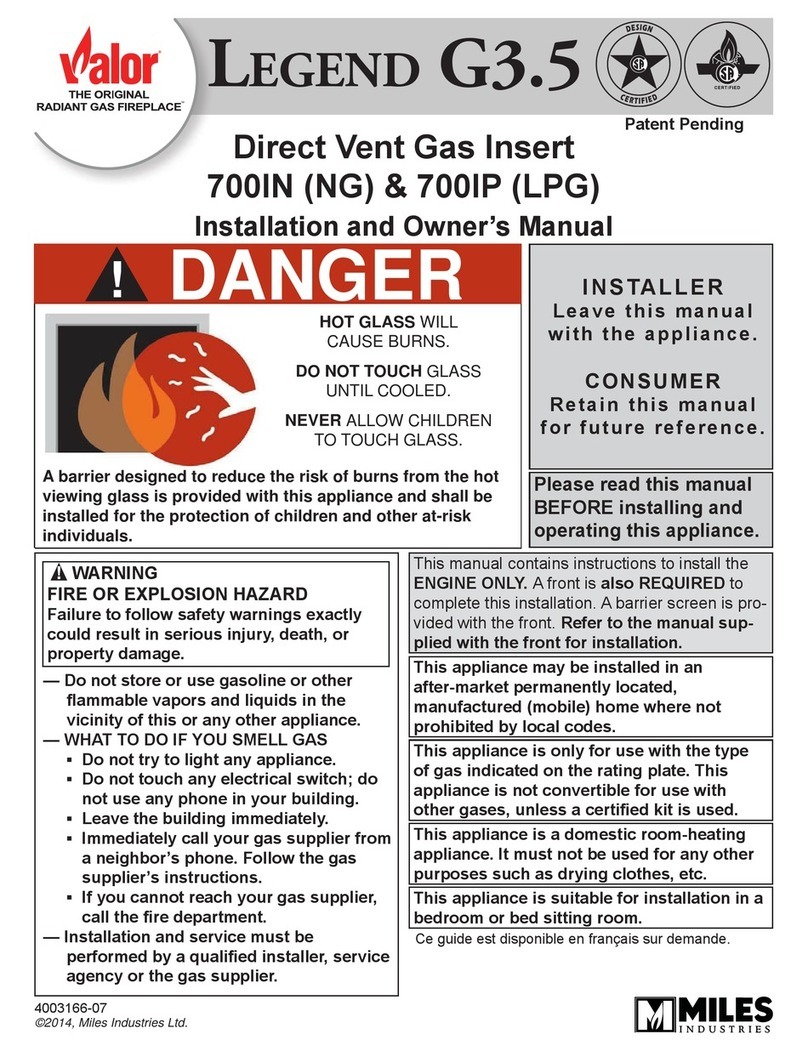

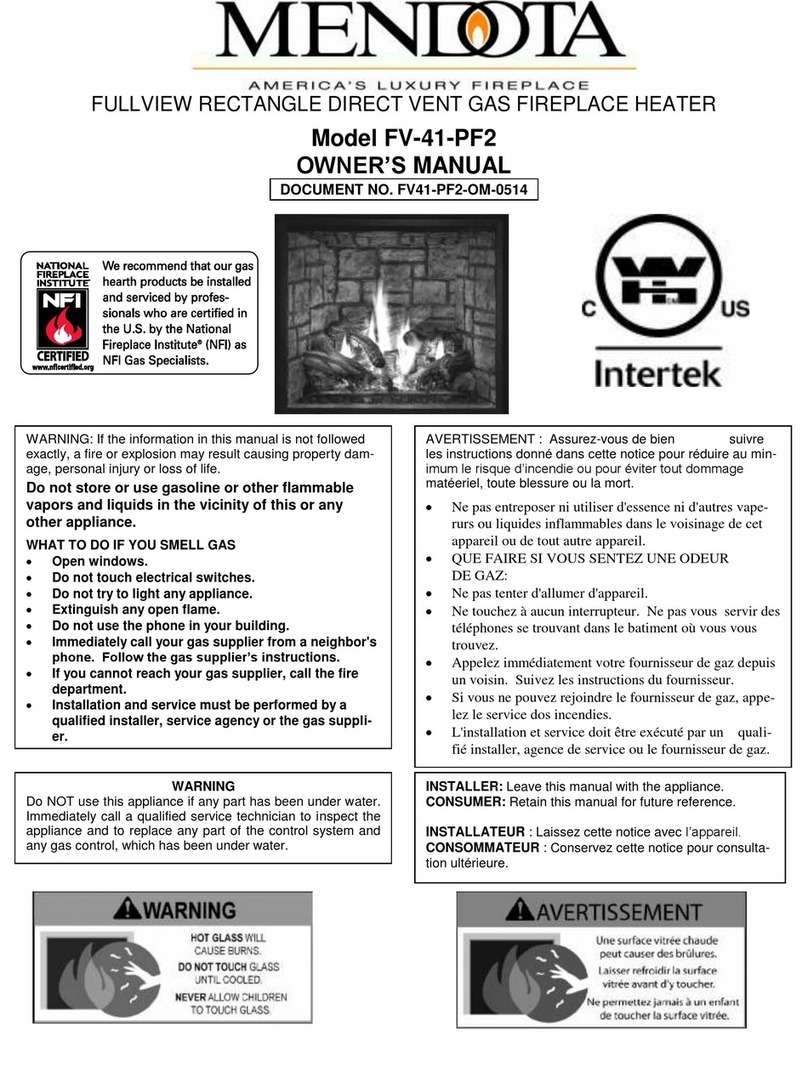

PREPARING TTHE OOPENING

Before installing the fire, check the flue using a smoke pellet, if alterations to the flue or flue throat are necessary

carry out this check after the work is done. All of the smoke should travel up the flue and exit correctly from the

terminal. If problems are found, DO NOT fit the fire until corrective action is completed.

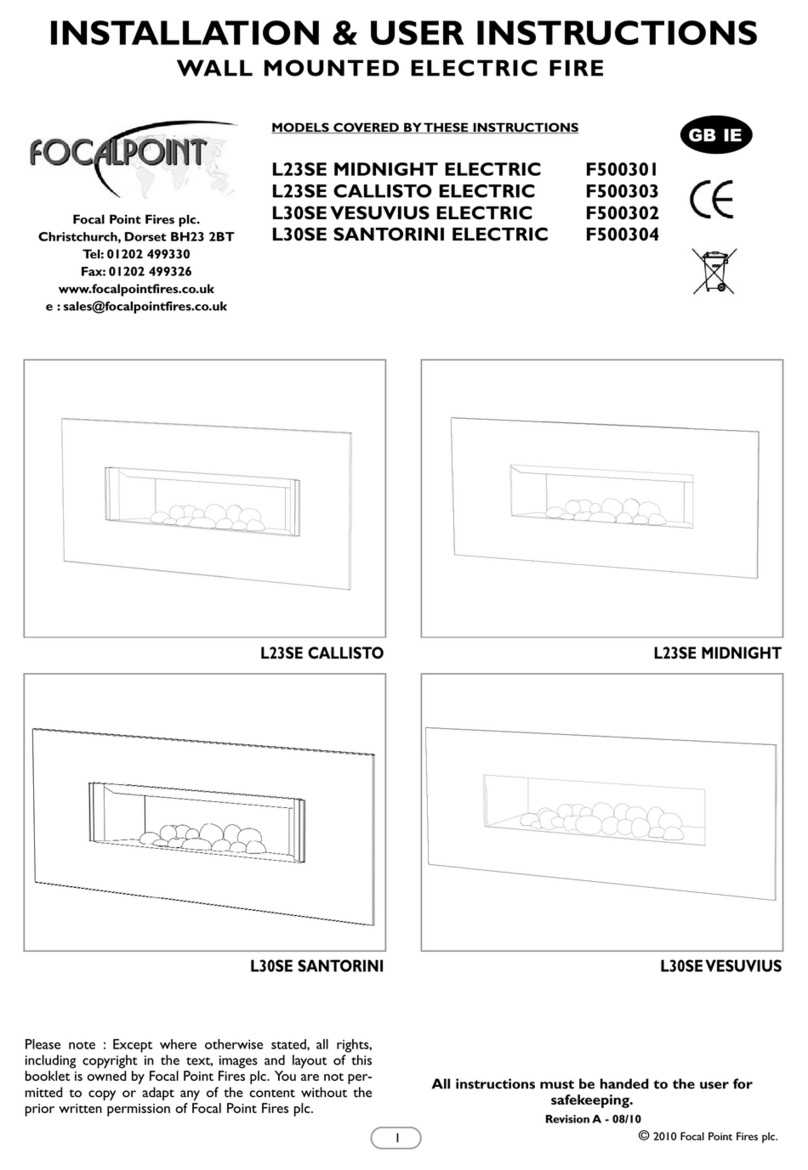

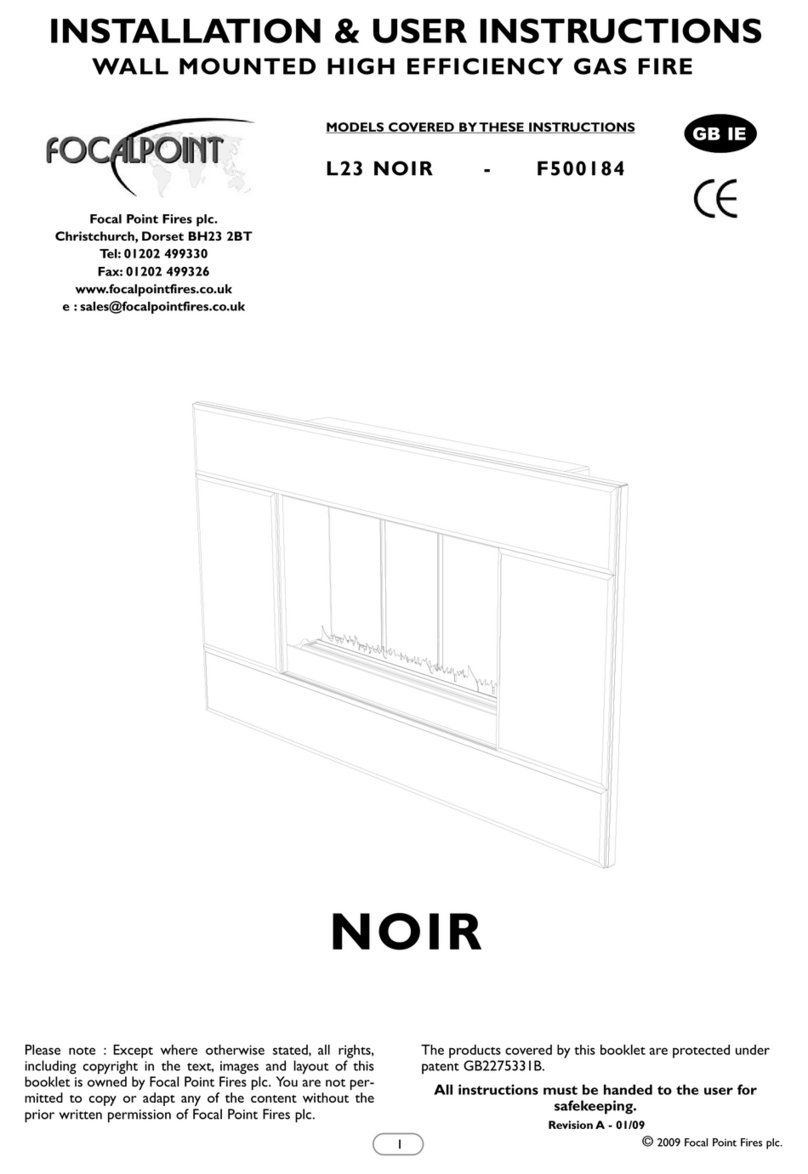

This appliance is designed to fit into a purpose-made builders open-

ing. The opening WIDTH and HEIGHT dimensions should be between

785mm and 865mm wide, and 615mm to 710mm high. Opening

DEPTH should be 350mm or greater. Opening DEPTHS include any

plaster or infill panels which form part of the installation.

IMPORTANT ::The sstructural iintegrity ooftthe wwall aand fflue/flue tthroat

must bbemmaintained. IItiisrrecommended tthat tthis sstage ooftthe iinstalla-

tion bbeuundertaken bbyaaqqualified bbuilder.

Obtain a suitable lintel. We would suggest either a pre-cast concrete

or steel lintel. Minimum bearing lengths - Generally lintels should be

bedded the correct way up on the supporting bearings in the mortar.

The recommended minimum bearing length for use in 3.5N/mm2

blockwork is 100mm in openings up to 1000mm.

Fit the lintel, and remove brickwork as necessary in order to make an

opening to the correct size. Brick up the old opening and base to the

dorrect height. Ensure the base of the opening is level and flat.

Make good the front wall surface around the opening, ensuring that

the surfaces are true, vertical and flat in order to ensure a good seal

when the firebox is fitted. This front surface must be non-combustible

and capable of withstanding 150OC.

Offer up the firebox to the opening to check the fit is good. Ensure

that it slides in correctly, the sealing face sits flat and square to the

wall or back panel, and that the base is firm on the openings base. At

this stage it is essential to ensure that the spigot outlet of the fire is

not restricted in any way.

Remove the firebox and take any necessary measurements before mak-

ing good and preparing for final installation.

SCREW FIXING. For fixing by screw, mark and drill the fireframe or

base, and the relevant points in the opening or on the wall. Rawlplugs

will again be required. Pre-punched holes are not proided for this pur-

pose to allow you to choose the optimum positions.

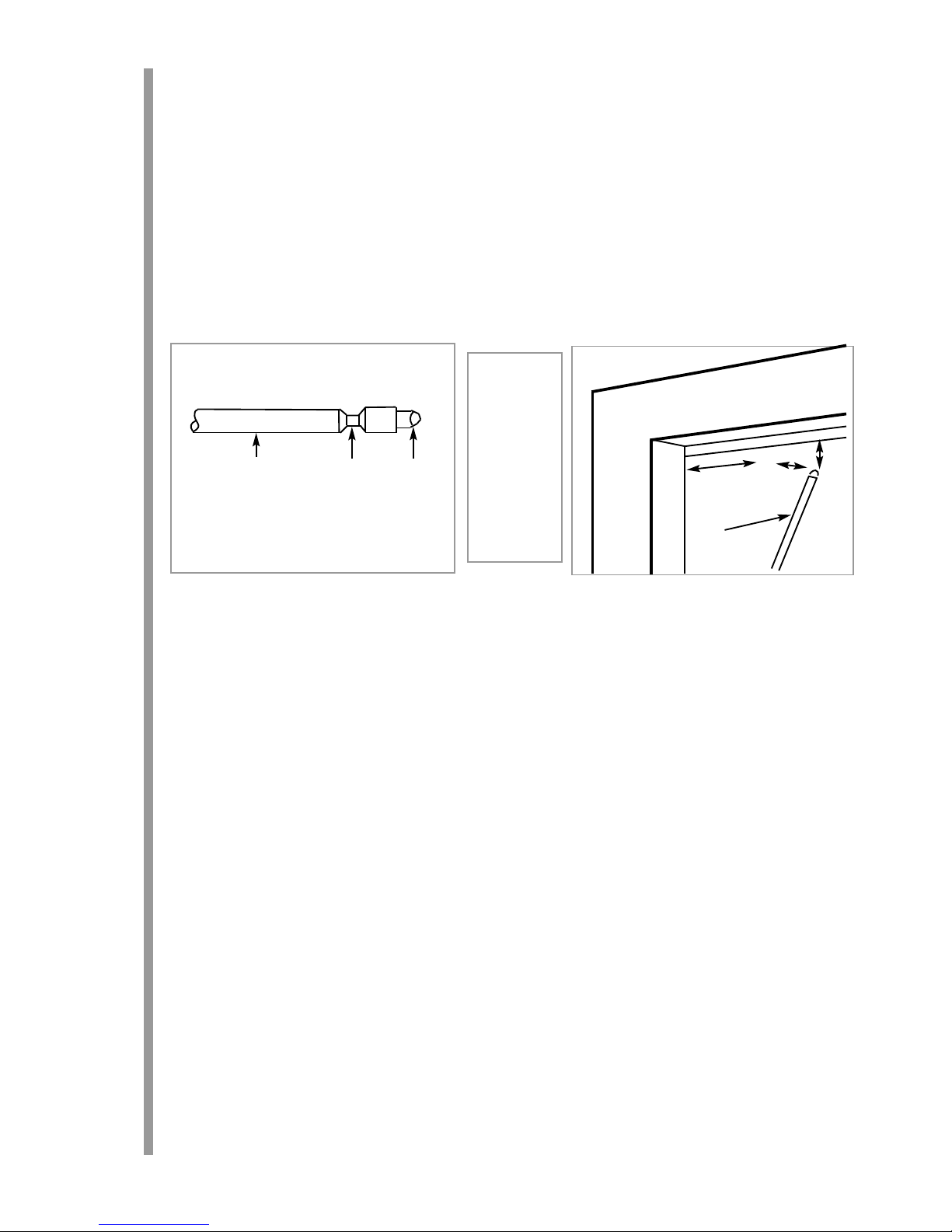

GAS SUPPLY. Following preparation for the fixing method, the con-

cealed gas supply, where required, can now be put into place. Refer to

the gas supply section for suggested pipe routes. The ends of the sleev-

ing in which the gas pipe is run should be sealed. The ends of the 8mm

supply pipe should be temporarily sealed to prevent the ingress of debris during fixing.

The non-combustible hearth unit should now be secured in place, which may be protected using surplus pack-

aging material during fitting.

CABLE FIXING. For fixing of the fire by the cable method, see the relevant section. The cable fixing locations

should be marked on the back of the opening and the holes drilled. Fit the fibre rawlplugs and eyebolts to these

holes.

Note: PPlassticcrrawlpluggssaare NNOT ssuitable ffor tthissaappliccation.

5

9.0

Old fireplace opening

Mark out lintel position

Create opening

to correct size

Insert lintel

Fill in old fireplace opening and

base, to give level, flat bed surface.

These areas MUST be non-combustible

flat and level to ensure good seal.

Make good wall surface