FONON SBM Series User manual

1

Introduction

Technical Support

Disclaimer

Thank you for purchasing a product in the SBM series. This product is warranted to be free of

manufacturing defects for one year from the date of purchase. If you cannot find the solution to your

particular application, or, if for any reason you need additional technical assistance. Our technical

support group is glad to work with you in answering your questions, please use the ways as following:

Tel: 844.44.LASER (52737)

Fax: (407) 804-1002

Email: Fonon_Web_Contact@sfinkx.com

Web: www.fonon.us

Address: 400 Rinehart Road #1000, Lake Mary, FL 32746

The information provided in this document is believed to be reliable. However, no responsibility is

assumed for any possible inaccuracies or omissions. Specifications are subject to change without

notice. The Windows 2000/XP/Vista are registered trademarks of Microsoft. Other trademarks are the

property of their respective owners.

Fonon reserves the right to make changes without further notice to any products herein to improve

reliability, function, or design. Fonon does not assume any liability arising out of the application or use of

any product or circuit described herein; neither does it convey any license under its patent rights, nor

the rights of others.

Special Symbols

Failure to follow instructions may lead to product damage, or error.

Failure to follow instructions may lead to injury by electric shock.

Failure to follow instructions may lead to injury by invisibleradiation.

2

Chapter 1

Safety

Contents

Introduction.....................................................................................................1

Technical Support.......................................................................................1

Disclaimer ..................................................................................................1

Special Symbols..........................................................................................1

Safety Regulation ......................................................................................4

Name Plate and Warning Labels ..................................................................6

Safety Protection Device............................................................................9

Chapter 2:

I nsta llation .................................................................................. 11

Unpack and Locate Machine........................................................................ 11

Package Contents Lis t...............................................................................16

Part Names and Functions ........................................................................ 17

Hardware Installation ................................................................................ 23

Check environment............................................................................. 23

Connect AC power cable..................................................................... 23

Driver Installation ..................................................................................... 25

Install Driver ......................................................................................25

Uninstall Driver ..............................................Error! Bookmark not defined.

Change USB Cable to Another Port ...............Error! Bookmark not defined.

Core lDR AW Setup.................................................................................... 34

AutoCad Setup ........................................................................................38

Chapter 3:

Operation ....................................................................................... 47

Operator Position ...................................................................................... 47

Basic Operation Flow.................................................................................48

Machine Operation .................................................................................. 49

Control Panel ......................................................................................... 49

Operating Menu....................................................................................... 52

Print Driver Operation ............................................................................. 65

Laser Tab ................................................................................................ 65

Job Tab ................................................................................................... 73

Cut & Engrave Setup...........................................................................75

Page Tab ................................................................................................ 76

Page Setup ........................................................................................76

Job Title ............................................................................................ 77

Repetition .......................................................................................... 77

Material ............................................................................................. 77

Position Mode ................................................................................... 77

Power Scale............................................................................................. 79

Custom Power Scale ......................................................................... 79

Product Tools........................................................................................... 80

3

Chapter 1

Safety

System Upgrade ................................................................................. 80

Chapter 4:

Maintenance .................................................................................81

Daily Cleaning..........................................................................................81

Weekly Cleaning ...................................................................................... 84

Chapter 5:

Tr oubles hooting ........................................................................ 86

Append i c es ................................................................................................. 87

App endix 1: Specifications......................................................................87

App endix 2: Dimensions ......................................................................... 88

Appendix 3: Suggested Powe r and Speed Settings ................................. 90

4

Chapter 1

Safety

Safe ty Regulation

The SBM series uses a CO2 Laser as a light source. It is classified as a class-IIIR

product by CDRH (the Center for Devices and Radiological Health).

Wavelength: 10.6μm

Maximum output power: 30 ~ 100 W

Visibility: Invisible

When operating the SBM series, be sure to always comply with the safety

regulations as following:

Do not attempt to modify or disassemble any component of the machine

without Fonon technical support.

Do not open the doors of chassis and access the laser tube or

electronic components, especially while the machine power is on.

Connect the machine to a grounded outlet. Verify that the voltage of the

outlet is correct for the machine.

Do not disable the interlocks which are on top and front doors.

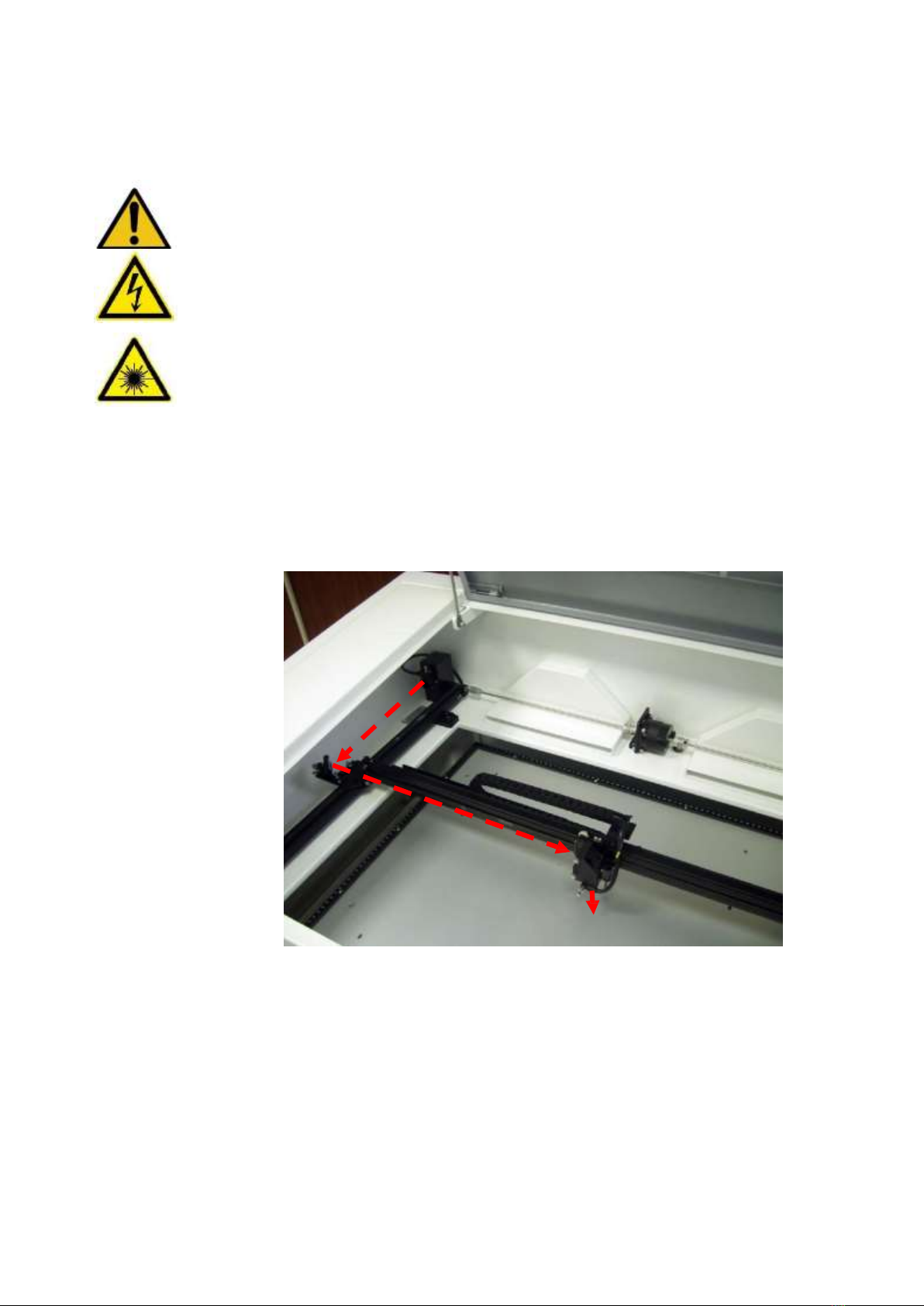

Be careful about the path of the invisible laser beam shown in figure.

Otherwise, eye or skin injury may result.

5

Chapter 1

Safety

Do not watch the laser beam directly during operation. Bright light caused by

the lasing process can damage the eye.

The side and rear doors are fixed by screws for safety. If you open these

doors, the SBM will become a Class 4 laser device. For your safe, please

wear protective goggles.

The laser beam may cause fire. Never leave machine along without other

operator watching during the laser cutting and engraving process. Keep a fire

extinguisher near the machine at all times.

Blowing materials with air flow from nozzle while cutting or engraving can

avoid fire occurring and also obtain good quality.

Verify that materials used in the engraver are proper for lasing. Never

engrave or cut substrates that contain PVC or Teflon .

Good efficiency of exhaust system makes you avoid breathing dust, debris or

poison gas.

Please comply with maintenance schedule as chapter 4 to keep SBM working

well.

Before you execute auto focusing function, please make sure that there will

be no crashing between motion system and other objects. For safety, it is

NOT recommended to use auto focusing function on inequality materials.

6

Chapter 1

Safety

Name Plate and Warning Labels

The labels as following are affixed to the SBM. These labels must never be

removed. If they are damaged or tampered for any reason, please request for Fonon

immediately to replace them.

1

4

4

2

2

3

2

7

Chapter 1

Safety

1

2

5

8

Chapter 1

Safety

3

4

5

9

Chapter 1

Safety

Safe ty Protection Device

Interlock

The laser beam will not be emitted if you open the top or front doors. When any door

is opened, the LED indicator of “DOOR” on control panel will be off.

Both doors close Any door opens

Laser Switch

Laser switch on control panel can shut down the power of laser system immediately,

and it has no effect on motion system. Compared with interlock, Turning off laser

switch can save power. When you turn on laser switch, the LED indicator of “LASER”

on control panel will be on (it needs to take more than 5 seconds to warm up laser

tube while you turn it on).

ON

OFF

Chapter 1

Safety

10

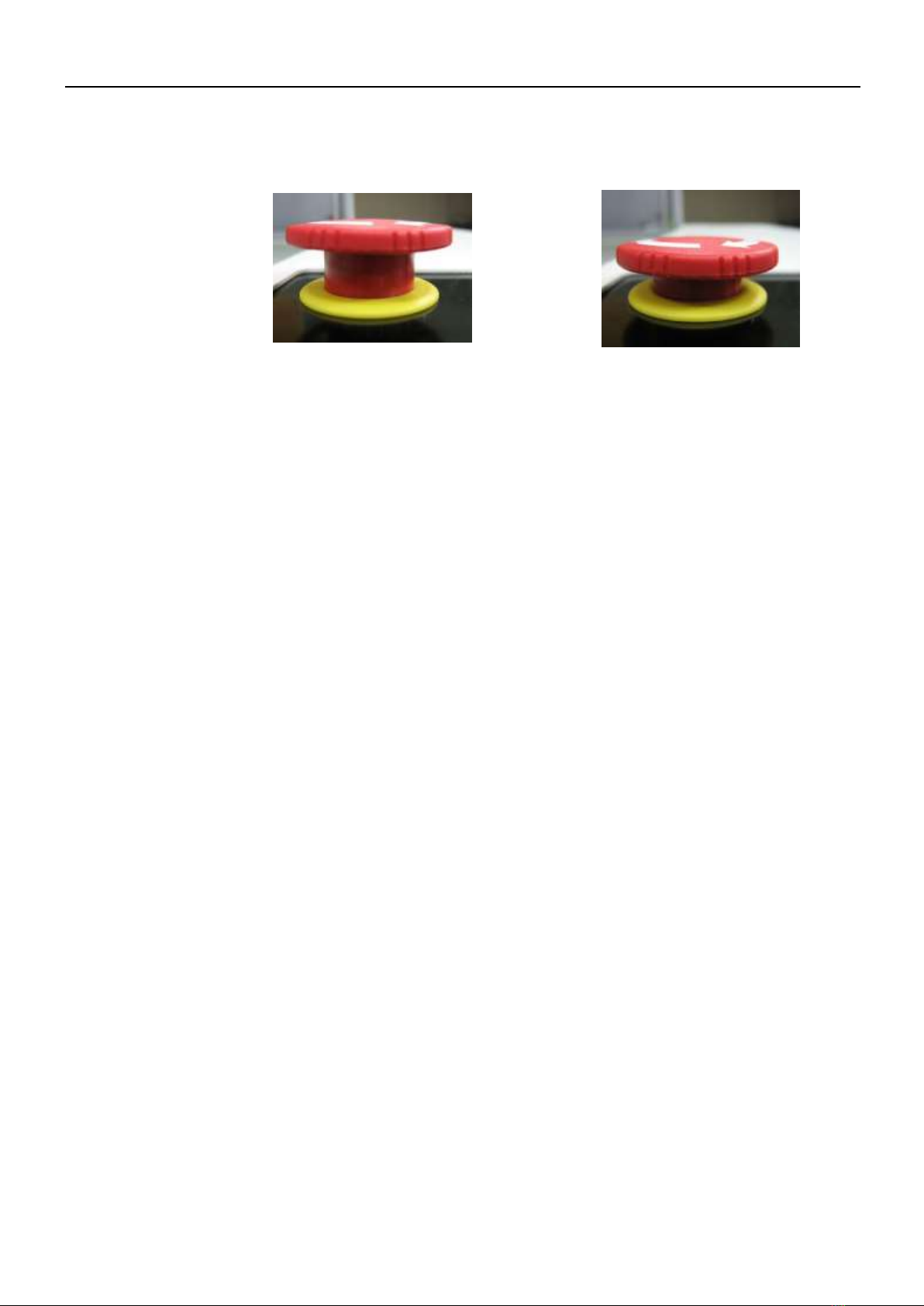

Emergency Stop Switch

Pressing the red pushbutton can shut down the main power of system immediately

when emergency condition occurs. And turning right the red pushbutton can recover

the power (Before recovering power, please clear the trouble in the machine first).

ON

OFF

Chapter 2

Installation

11

Chapter 2:

Installation

Unpack and Locate Machine

Remove the strings.

1. Remove the protective bag.

Chapter 2

Installation

12

2. Remove the upper box. (If you order slide board.)

3. Remove the top cover.

Chapter 2

Installation

13

4. Remove the side cover and foam.

5. Remove the protective bag.

Chapter 2

Installation

14

6. Remove the foam at bottom .

7. Place the slide board which is in the upper box and roll down

the machine. (If you order slide board.)

Chapter 2

Installation

15

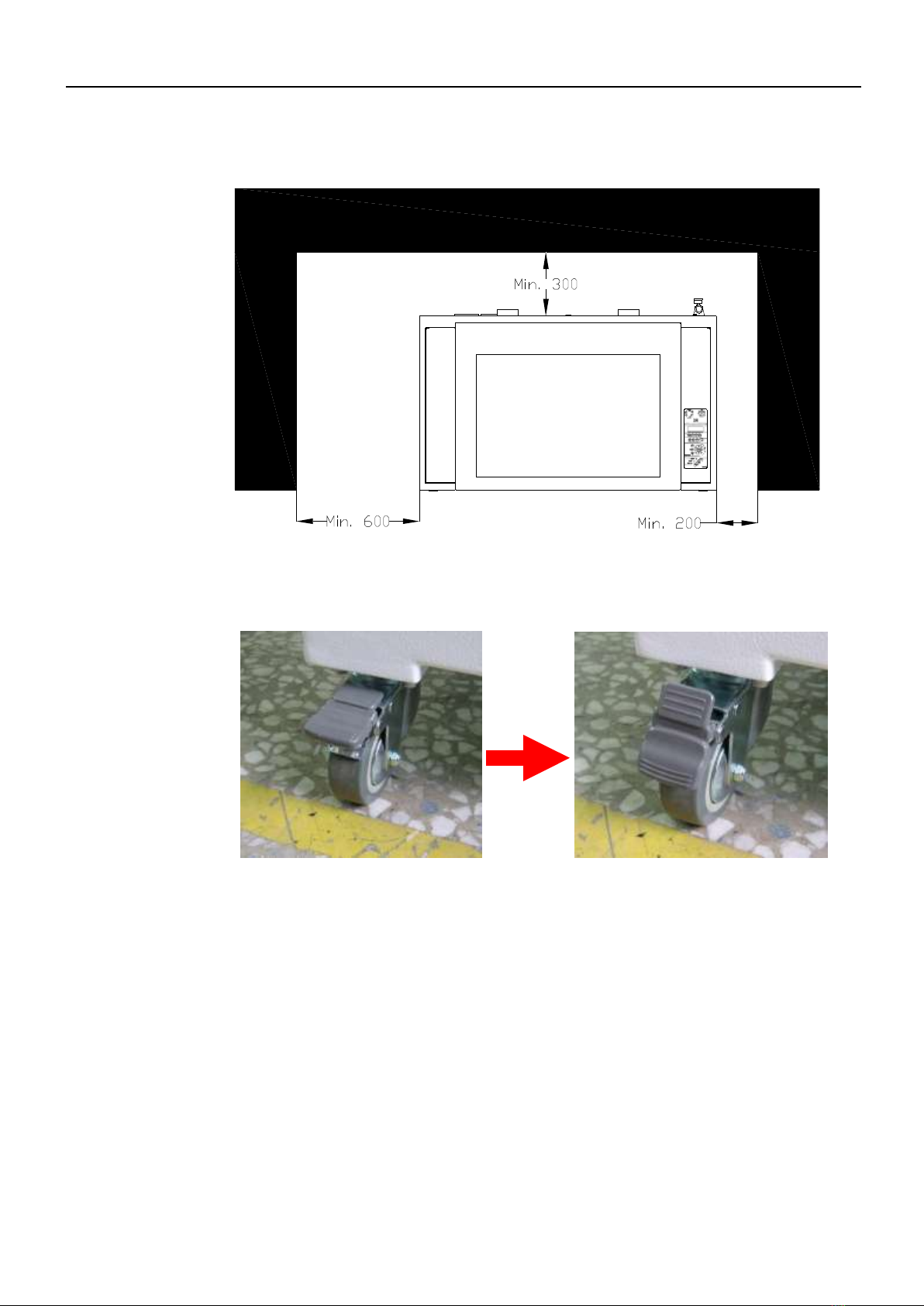

8. Locate the machine and keep the recommended space for

maintenance.

Unit: mm

9. Lock the wheels to fix the machine in place.

Chapter 2

Installation

16

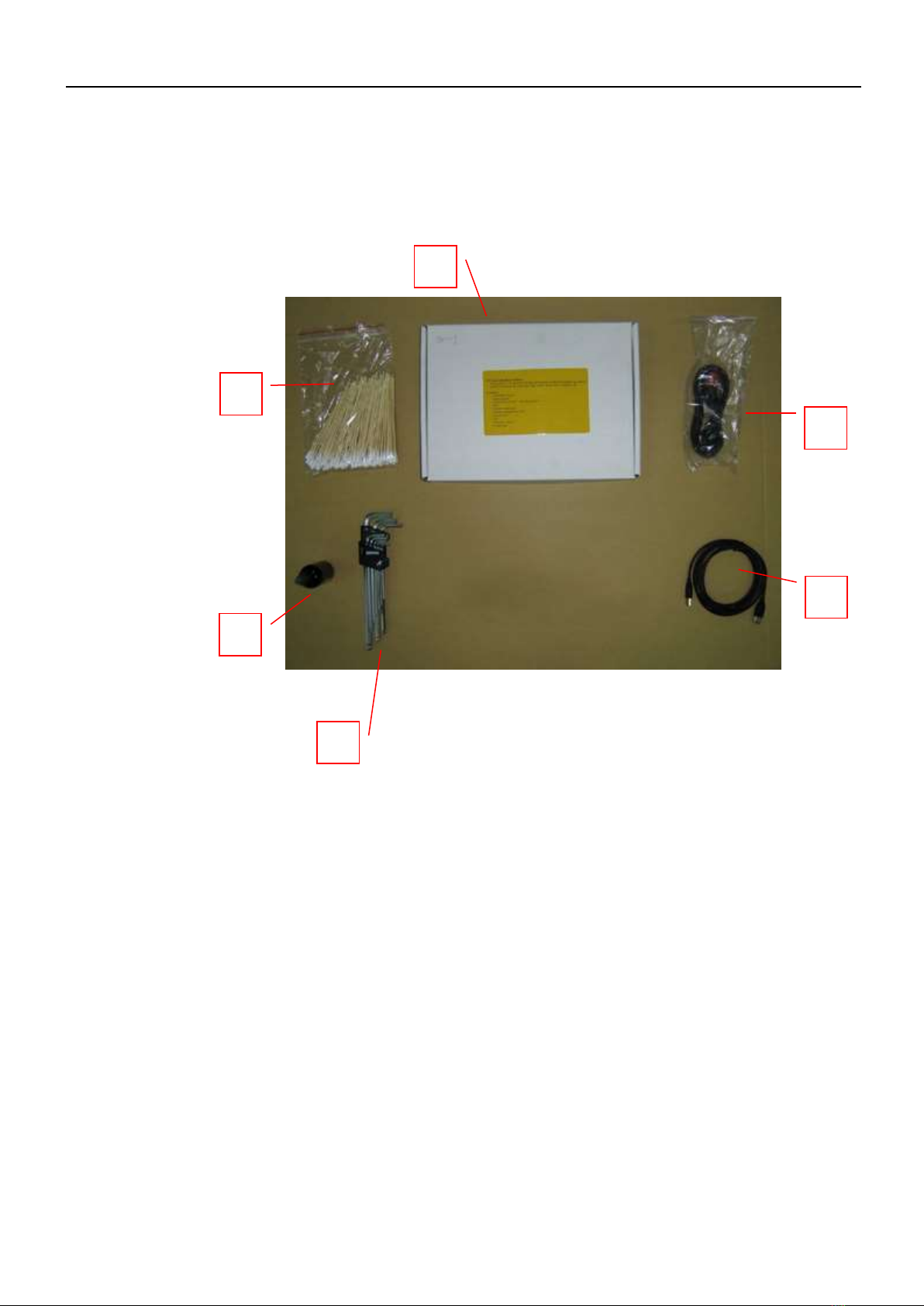

Package Contents Lis t

This section explains the package contents of the SBM. The packages include the

following components. Before using the unit, check that all components have been

included in the packages.

1Box 5 USB Cable

2Cotton Swab 6 Power Cable

3Alcohol Dropper

4Allen Wrench

2

1

4

8

7

3

Chapter 2

Installation

17

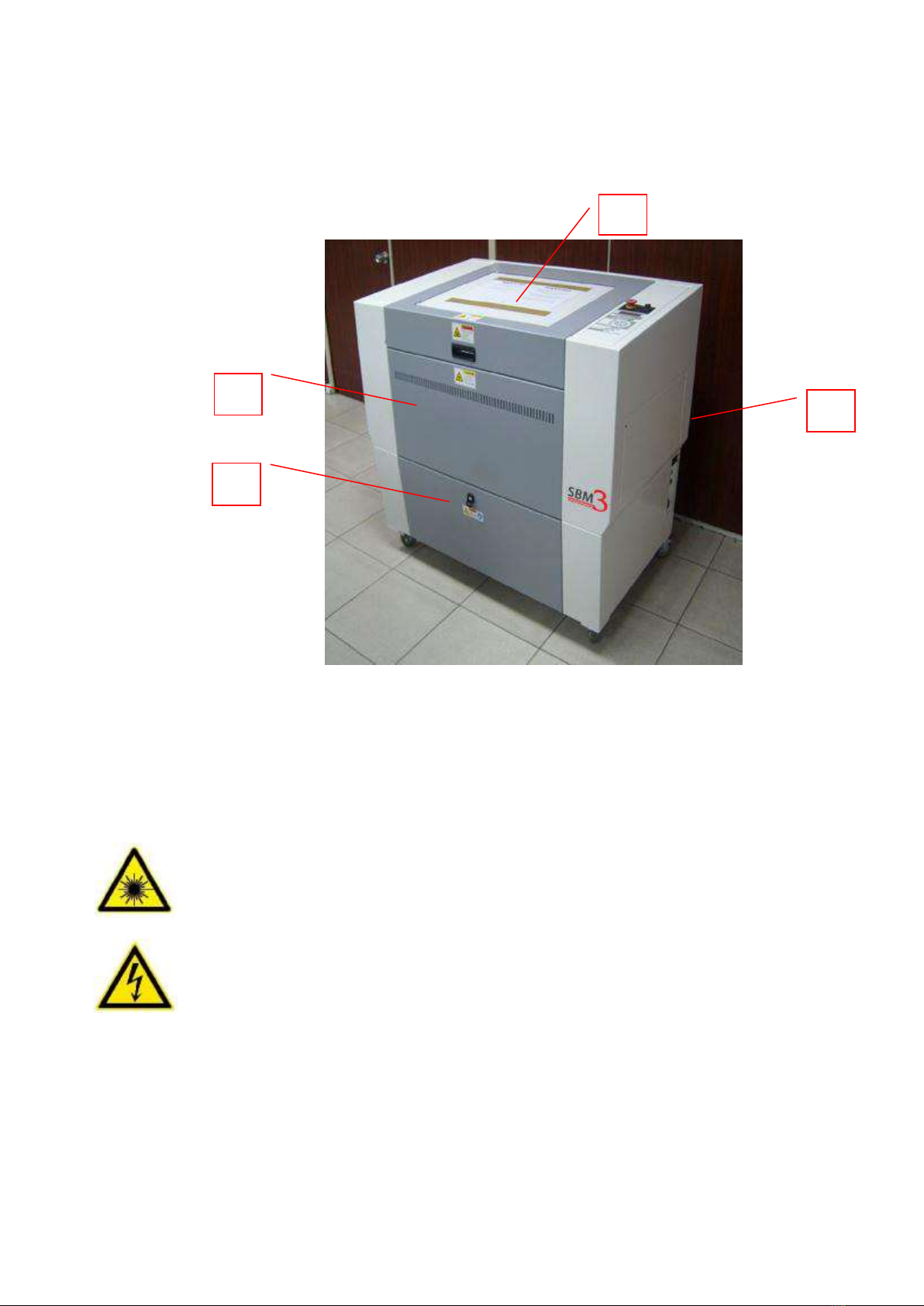

Part Names and Functions

This section explains the main part names and functions of the SBM.

1 Lid

This lid has interlock sensors for safety. If you open this door, the laser will be not

emitted.

2 Front Door

This door has interlock sensors for safety. If you open this door, the laser will be not

emitted.

3 Side Door (Right)

You can work on long materials through two side doors. These doors have no

interlock sensors, so they are locked by screws for safety. If you open these doors,

the system becomes a Class 4 laser device.

4 Front Door of Chassis

Mostly opening this door is for maintaining. Do NOT open this door if it’s not

necessary, especially the machine power is on.

2

3

4

Chapter 2

Installation

18

Exhaust Port

These two ports can exhaust the smoke which is caused by cutting or engraving.

These ports have to be connected to blower through pipes

Rear Door

You can work on long materials through front door and this door. This door also has

no interlock sensors, so it is locked by screws for safety. If you open this door, the

system becomes a Class 4 laser device.

Air Filter

This part provides air assist through the hose which is connected to air compressor.

Fans

These parts can dissipate the heat in the chassis which is caused by laser generator.

Rear Door of Chassis

Mostly opening this door is for maintaining. Do NOT open this door if it’s not

necessary, especially the machine power is on.

Side Door (Left)

You can work on long materials through two side doors. These doors have no

interlock sensors, so they are locked by screws for safety. If you open these doors,

the system becomes a Class 4 laser device.

Side Door of Chassis

Mostly opening this door is for maintaining. Do NOT open this door if it’s not

necessary, especially the machine power is on.

8

10

5

6

7

11

9

Chapter 2

Installation

19

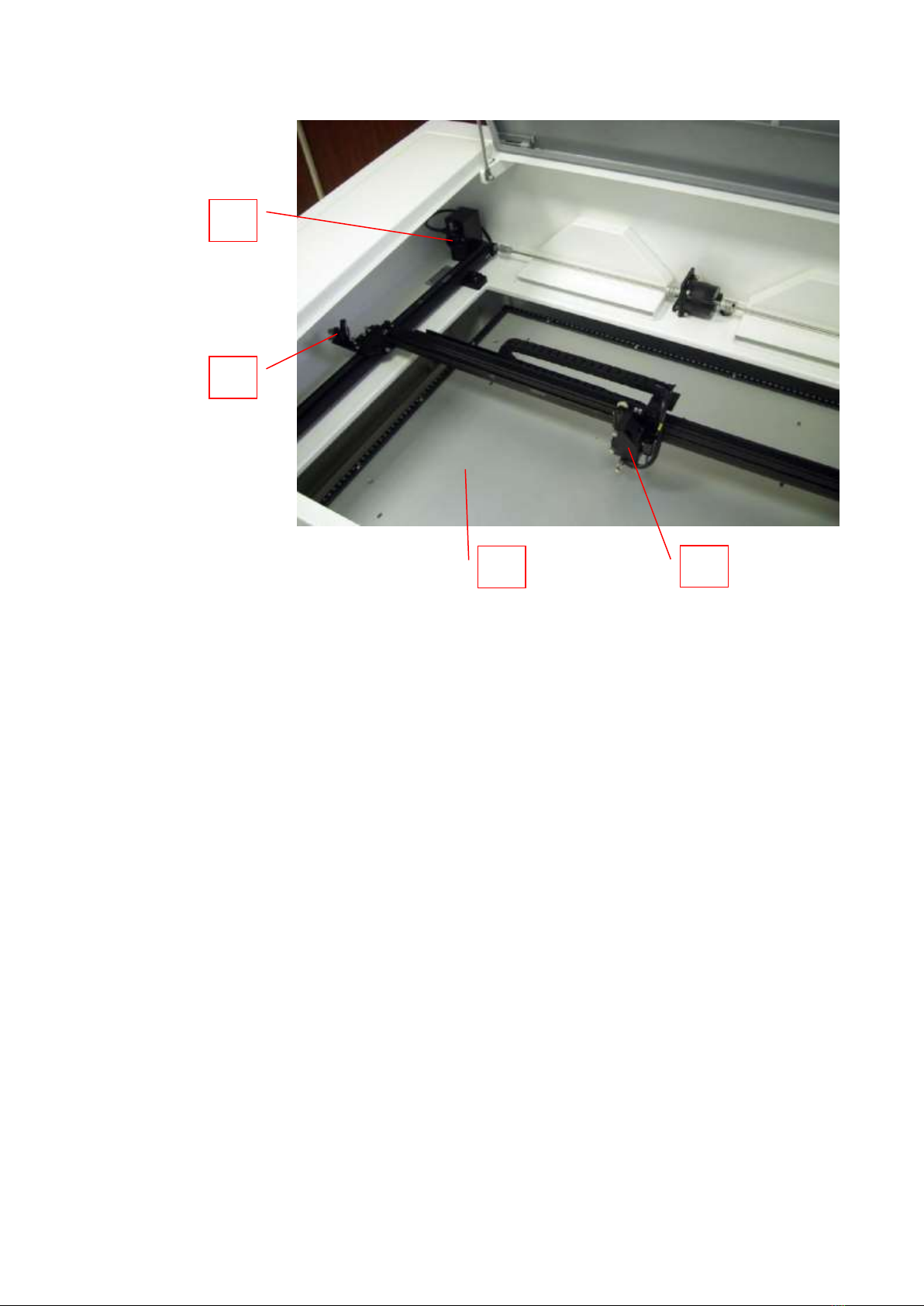

Window Lens

This part can protect 1st ~3rd mirror against dusts or debris. It should be cleaned this

lens daily. (See “Maintenance,” chapter 4)

4th Mirror

This part reflects laser beam to carriage. Also, it should be cleaned this lens daily.

(See “Maintenance,” chapter 4)

Table

This part can carry materials for cutting and engraving. You can move it up and down

by the keys on control panel. (See “Basic Operations,” Chapter 3)

Carriage

This part includes 5th mirror, focal lens, nozzle, and auto focus set. You can move it

left, right, forth and back by the keys on control panel. (See “Basic Operations,”

Chapter 3)

14

15

12

13

This manual suits for next models

1

Table of contents