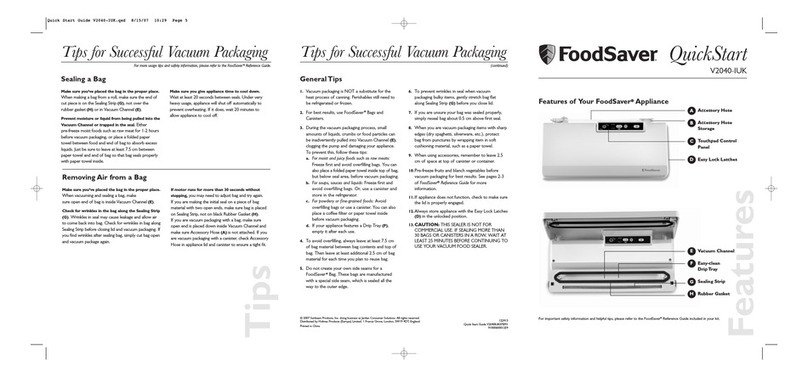

Tips

Tips voor su esvol va umeren

Voor meer gebruikstips en veiligheidsinformatie, zie de meegeleverde FoodSaver“ handleiding.

Het sealen van een zak

Zorg ervoor dat het deksel van het apparaat goed gesloten is

en de zak op de juiste wijze geplaatst is.

Wanneer een zak gemaakt wordt van een rol,

zorg ervoor dat de openzijde van de te

maken zak op de seal strip(G) ligt, niet over

het rubber(H) of in de vacumeerkamer(E).

Voorkom dat vocht of vloeistof in de vacuümkamer wordt

gezogen of op de seal naad terechtkomt.

Dit kan door vochtige voedingswaren zoals

rauw vlees 1?2 uur voor te vriezen of een

opgevouwen keukenpapier in de zak te doen

om overtollig vocht te absorberen. Wel

minstens 7,5 cm ruimte laten tussen

keukenpapier en het einde van de zak, zodat

deze op de juiste wijze gesealed wordt met

het keukenpapier erin.

Lucht verwijderen uit een zak

Zorg ervoor dat het apparaat de tijd heeft om af te koelen.

Wacht minstens 20 seconden na elk

vacumeerproces. Bij overmatig gebruik

schakelt het apparaat automatisch uit, om

oververhitting te voorkomen. Indien dit

gebeurt, wacht dan minstens 20 minuten om

het apparaat af te laten koelen.

Zorg ervoor dat de zak op de juiste wijze geplaatst is.

Wanneer een zak gevacumeerd of gesealed

wordt, ervoor zorgen dat de openzijde van

de zak in de vacumkamer geplaatst is.

Controleer de zak op rimpels of plooien langs de seal strip

(G) voor het vacumeren.

Plooien in de gesealde naad kunnen lekkage

veroorzaken of weer lucht in de zak laten.

Controleer dus op plooien in de zak langs de

seal strip, alvorens het deksel te sluiten en het

vacumeerproces te starten. Mochten zich toch

plooien in de zak bevinden na het sealen, de

zak openknippen en opnieuw vacumeren en

Opbergtip

Het apparaat altijd opbergen met het slot (D) ontgrendeld.

85

4

Vacuum Packaging and Food Safety

The vacuum packaging process extends the

life of foods by removing most of the air

from the sealedcontainer, thereby reducing

oxidation, which affects nutritional value,

flavour and overall quality. Removing air can

also inhibit growth of microorganisms, which

can cause problems under certain conditions:

Mould — Easily identified by its fuzzy

characteristic. Mould cannot grow in a low

oxygen environment,therefore vacuum

packaging can slow the growth of mould.

Yeast — Results in fermentation, which can be

identifiedby smell and taste. Yeast needs

water, sugar and amoderate temperature to

grow. It can also survive withor without air.

Slowing the growth of yeast requires

refrigeration, while freezing stops it

completely.

Bacteria — Results in an unpleasant odour,

discolouration and/or soft or slimy texture.

Under the right conditions,C lo str idium bo tulinum

(the organism that causes Botulism) can grow

without air and

sometimes cannot be detected by smell or

taste. Although it is extremely rare, it can be

very dangerous.

To preserve foods safely, it is critical that you

maintainlow temperatures. You can

significantly reduce the growth of

microorganisms at temperatures of 4¡C or

below.Freezing at ?17¡C does not kill

microorganisms, but stops them from growing.

Forlong?term storage, always freeze perishable

foods thathave been vacuum packaged, and

keep refrigerated after thawing.

It is important to note that vacuum packaging

is NOT a substitute for canning and it cannot

reverse the dete rio ration of foods. It can only

slow down the changes in quality. It is difficult

to predict how long foods will retain their

top?quality flavour, appearance or texture

because it depends on age and condition of

the food on the day it was vacuumed

packaged.

MPORTANT: Vacuum packaging is NOT a substitute

for refrigeration or freezing. Any perishable foods

that require refrigeration must still be

refrigerated or frozen after vacuum

packaging.

Food Preparation and Reheating Tips

Thawing and Reheating Vacuum Packaged Foods

Always thaw foods in either a refrigerator or

microwave do not thaw perishable foods

at room temperature. Make sure to cut

corner of bag before placing it in microwave.

We recommended that you place bag on a

microwave?safe dish to avoid liquids from

spilling out.

To reheat foods in a microwave oven, make

sure to remove them from bag and place it

on a microwave?safe dish. DO NOT REHEAT

FOODS IN A MICROWAVE WITHOUT

REMOVING THEM FROM BAG. You can also

reheat foods in FoodSaver¤ Bags by placing

them in water at a low simmer below 75¡C

(170¡F).

Preparation Guidelines for Meat and Fish:

For best results, pre?freeze meat and fish for 1?

2 hoursbefore vacuum packaging in a

FoodSaver

TM Bag. This helpsretain the juice and

shape, and guarantees a better seal.

If it?s not possible to pre?freeze, place a folded

paper towel between meat or fish and top of

bag, but below seal area. Leave paper towel in

bag to absorb excess moisture and juices

during vacuum packaging process.

Note: Beef may appear darker after vacuum

packaging due to the removal of oxygen. This

is not an indication of spoilage.

Preparation Guidelines for Hard Cheeses:

To keep cheese fresh, vacuum package it after

each use. Make your FoodSaver

TM Bag extra

long, allowing 2.5 cm of bag material for each

time you plan to open and reseal in addition

to the 7.5 cm room younormally leave

between contents and seal. Simply cut sealed

edge and remove cheese. When you?re ready to

repackage the cheese, just drop it in bag and

reseal.

MPORTANT: Soft cheeses should never be

vacuum packaged.

Preparation Guidelines for Vegetables

Vegetables need to be blanched before vacuum

pack ag ing. This process stops the enzyme

action that could lead to loss of flavour, colour

and texture.

To blanch vegetables, place them in boiling

water or in the microwave until they are

cooked, but still crisp. Blanching times range

from 1 to 2 minutes for leafy greens and peas;

3 to 4 minutes for snap peas, sliced courgette

or broccoli; 5 minutes for carrots; and 7 to11

minutes for corn on the cob. After

blanching,immerse vegetables in cold water

to stop the cookingprocess. Finally, dry

vegetables on a towel before vacuum

packaging.

Note: All vegetables (including broccoli,

Brusselsprouts, cabbage, cauliflower, kale,

turnips) naturally emit gases during storage.

Therefore, after blanching, they must be

stored in freezer only.

Guidelines for Va uum Pa kaging