25, (25H), 28 and 28SJ, 35, 35SJ, 43T, 44T,

(44HT), and 44TSJ Collet Handpieces:

To insert or change accessories, insert pin

provided into the pilot hole and through the

spindle hole (turn spindle to align holes). Loosen

chuck nut slightly with wrench provided. Insert

shank of accessory into collet. Tighten chuck nut

with wrench, keeping pin in pilot hole. Test for a

secure hold by pulling on accessory. Remove pin.

Chuck Type —30®,30SJ,

and (30H) Handpieces:

These handpieces have a

geared 3-jaw #0 chuck.

Open chuck jaws as far as necessary with key pro-

vided. Insert shank of accessory fully into the

chuck. Tighten all three jaws with chuck key until

accessory is secure and centered. If accessory

does not run true, reopen jaws, rotate accessory

and retighten. To release accessory, reopen chuck

jaws with key and pull out accessory.

Hammer Type —15, 15D, and 15SJ

Handpieces: These handpieces have a threaded

spindle. Thread anvil or stylus into threaded spindle

as far as it will go with clockwise motion. Insert pin

provided into cross hole in anvil or stylus. Tighten

and remove pin. To release accessory, insert pin

into the cross hole and unthread.

Quick Change Type —10, 10D, 18, 18D, 18SJ,

20, 20D, 20SJ, 52, 52D, and 52SJ Handpieces:

Keep an accessory in these handpieces at all

times, during both operation and storage, or

damage to the collet and handpiece may

result. These handpieces accept only 2.35mm

(3/32″)shank accessories.

10 and 10D Handpieces:

To insert bur, turn lever 180º clockwise towards the

back (shaft connection end) of handpiece. Insert or

change a 2.35mm (3/32″)shank bur and turn lever

180º forward counterclockwise. Make sure lever

is completely locked into the forward position.

Never change burs while handpiece is running.

18, 18D, and 18SJ Handpieces:

These handpieces have a

lever on the side of the

handpiece. Push the spring

loaded lever down to open

the collet and release the shank of accessory

(2.35mm or 3/32″only). Insert accessory while

holding the lever down.

Never push lever down

while handpiece or flexible shaft is rotating.

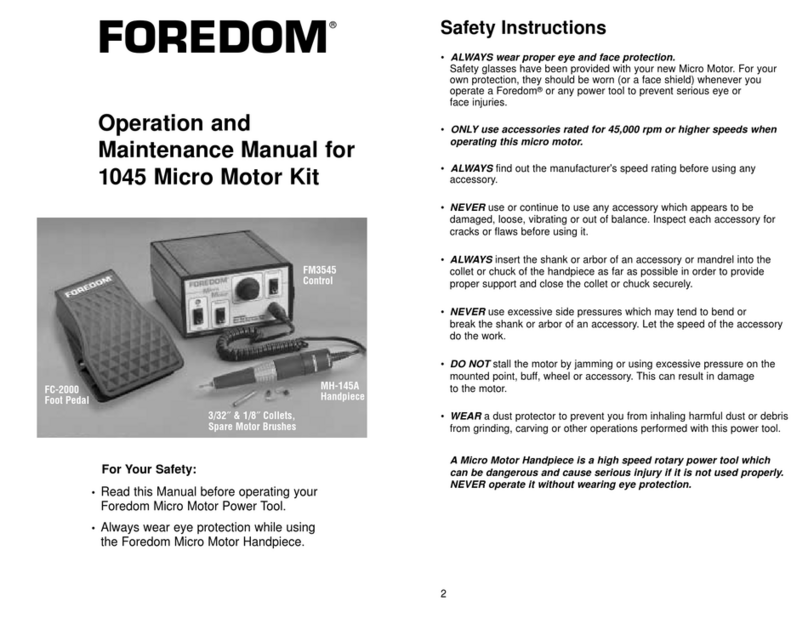

Attaching Accessories to Handpieces

Directions for attaching accessories to handpieces

vary according to the type of handpiece being

used. Locate the model number of your Foredom

handpiece from the photos at left.

Always wait for

the motor, flexible shaft and accessory to come to

acomplete stop before changing an accessory.

Handpieces listed in brackets are for use with

Series SRH models only. Attach the accessory

according to the following:

Collet Types —8, 8D, 25, (25H), 28, 28SJ, 35,

35SJ, 43T, 44T, 44TSJ, (44HT) Handpieces:

Acollet is an interchangeable slotted cylinder that

fits inside the front of a handpiece for holding the

shank of a bur or other rotary accessory. The

diameter size of the collet must match the diame-

ter of the accessory’s shank.

General Directions:Be sure to use the correct

shank size. The correct shank will fit snugly inside

the collet. Caution: Never tighten a collet unless

an accessory has been inserted. Tightening an

empty collet or inserting an accessory which is too

small or too large may damage the collet.

Changing Collets in 25, (25H), 28, 28SJ, 35,

35SJ, 43T, 44T, 44TSJ & (44HT) Handpieces:

1. Insert pin provided into the pilot hole and

through the spindle hole (turn spindle to align

holes). Apply wrench and unscrew chuck nut

by turning counterclockwise.

2. Remove chuck nut to

expose collet.

3. Pull collet out of

handpiece spindle.

4. Slip new collet in place

and screw on chuck nut.

To insert accessory: insert shank as far as

possible into the collet. Tighten chuck nut. Test for

asecure hold by pulling on accessory. Remove

wrenches. To release an accessory, follow the

same steps. Accessories can be released when

chuck nut is loosened. If accessory does not run

true, loosen chuck nut, rotate accessory,

and retighten.

8, 8D, and 8SJ Handpieces:

Tochange a collet:slide back the chuck guard

and use one wrench to hold the spindle and the

other to unscrew the chuck nut by turning

counterclockwise. Remove chuck nut to expose

collet and pull collet out of handpiece shaft. Slip

new collet in place and tighten chuck nut

with wrenches.

9

Pilot/

Spindle

Hole