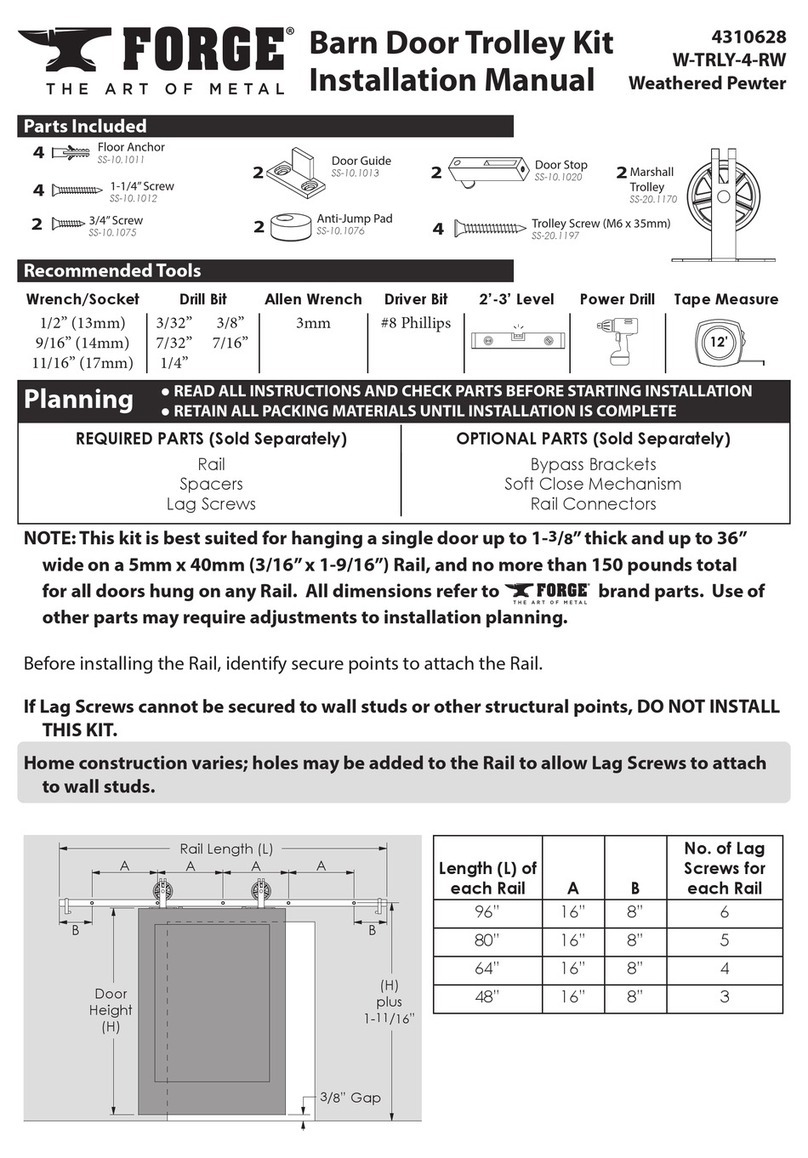

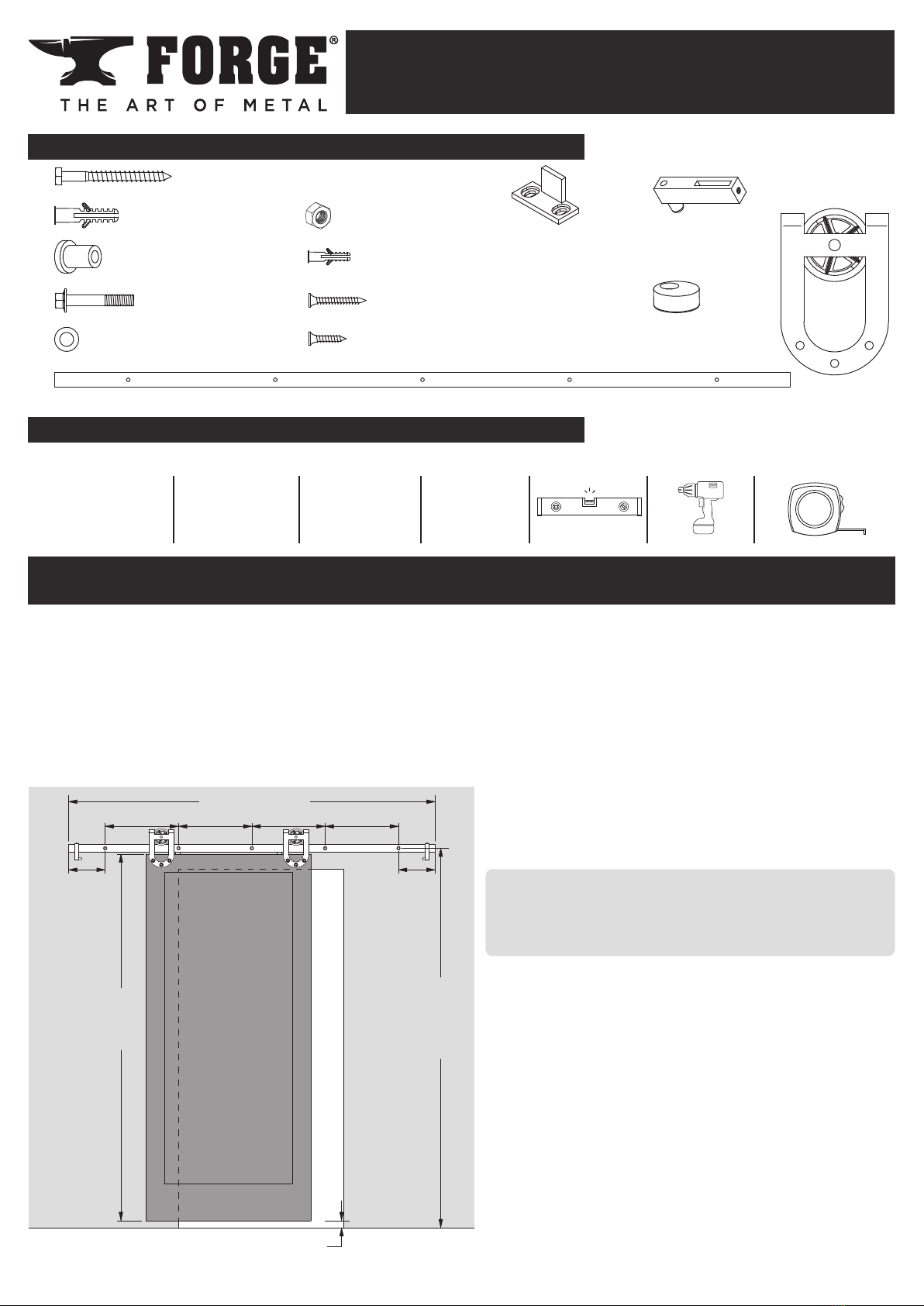

Forge W-KIT-4-BK-1PC User manual

80” [2032mm]

A

A- 16” [406mm]

B- 8” [204mm]

Door

Height

(H)

(H)

plus

1-5/8”

[41.5mm]

3/8” [9.5mm] Gap

AAA

B B

2

5

6

2

2

6

4

42

1

2

6

5

5

Wrench/Socket Drill Bit Allen Wrench Driver Bit 2’-3’ Level Power Drill Tape Measure

1/2” (13mm)

9/16” (14mm)

11/16” (17mm)

3/32”

7/32”

1/4”

3/8”

7/16”

3mm #8 Phillips

12'

NOTE: This kit is best suited for doors up to 1-3/8”thick, up to 36” wide, and no more than

150 pounds.

Before installing the Rail, identify secure points to attach the Rail.

For most wall installations, it is necessary that the Lag Screws are secured to wall studs.

For Lag Screws that cannot be secured to a

wall stud, it will be necessary to use the

Wall Anchors to secure the Lag Screws

into the wall.

Home construction varies; holes may be

added to the Rail to allow Lag Screws

to attach to wall studs.

IMPORTANT:

If at least FOUR Lag Screws cannot

be secured to wall studs or other

structural points, DO NOT INSTALL

THIS RAIL KIT.

Barn Door Rail Kit

Parts Included

Recommended Tools

Planning

Installation Manual

4310491

W-KIT-4-BK-1PC

Iron Black

●READ ALL INSTRUCTIONS AND CHECK PARTS BEFORE STARTING INSTALLATION

●RETAIN ALL PACKING MATERIALS UNTIL INSTALLATION IS COMPLETE

Lag Screw

SS-10.1006

Door Guide

SS-10.1013

Door Stop

SS-10.1005

Anti-Jump Pad

SS-10.1076

Clyde

Trolley

SS-20.1172

Nut (M10-1.5)

SS-10.1010

Floor Anchor

SS-10.1011

1-1/4” Screw

SS-10.1012

3/4” Screw

SS-10.1075

Wall Anchor

SS-10.1002

Spacer

SS-10.1007

Bolt (M10-1.5 x 50)

SS-10.1246

Washer

SS-10.1009

Rail

SS-20.1147

Set Screw

WALL

X

W

Y

Z

T

D

E

Mark the location of pilot holes for the Lag Screws using a pencil, measuring tape, and level.

Refer to the diagram for proper hole spacing.

Home construction varies; holes may be added to the Rail to allow Lag Screws to attach

to wall studs. Use drill bits suitable for mild steel and a light oil such as a 3-in-1 oil to aid in

drilling. Use a 3/32” bit for a pilot hole. Use a 7/16” bit for the nished hole.

The holes should be located at a height from the oor 1-5/8” greater than the door height (H).

If the oor is uneven or not level, measure from the highest point on the oor around the

door.

Proper hole location should leave a 3/8”(9.5mm) gap under the door.

IMPORTANT

If the rail is not installed level, the door may slide open or closed without warning.

Drill 7/32” pilot holes to locate the Lag Screws at each mark on the wall. For any pilot hole NOT

in line with a wall stud or structural member, drill a 3/8” hole and insert a Wall Anchor into the

hole.

2 - Mount the Rail

IMPORTANT

If the Door Stops will be located between the outermost

Lag Screws, they should be placed loose on the Rail at

this time.

Place the Door Stop with the rubber bumpers facing the

center of the Rail and the Set Screw facing UP.

(1)Allow at least 3/4”clearance above the trolley.

(2)The nominal distance with the door hung to run vertical and the

wall straight and plumb. Improper installation, warped doors, extra

hardware, or decorative protrusions may reduce the clearance space.

(3)Any additional rail and hardware mounted with a bypass bracket

system should allow this amount of space or more for proper operation

of this barn rail kit.

Door

Thickness

Trolley Top

to Rail Center

Door to

Rail Center

Bypass

Clearance

Trolley

Clearance

Bolt

Clearance

Door

Clearance

TD(1) (3) EW(3) X(2) Y(2) Z(2)

1-3/8” 4-3/8” 1-1/4” 2-1/4”9/16”1/8”9/16”

1” 4-3/8” 1-1/4” 2-1/4”9/16”1/8”15/16”

1 - Drill Holes to Mount the Rail

Planning (continued)

5/16”

(Rail not shown for clarity)

M

IMPORTANT

The widest part of the Spacer should be placed on the wall.

Place a Lag Screw through the hole in the Rail aligning with the

outermost pilot hole on one side, through a Spacer, and drive

the Lag Screw into the pilot hole. DO NOT fully tighten Lag

Screw.

2 - Mount the Rail (Continued)

Repeat process for a Lag Screw on the opposite end of Rail. DO NOT fully tighten Lag Screw.

Insert remaining Lag Screws through Rail holes and Spacers, and drive into pilot holes. DO NOT

fully tighten Lag Screws.

After all Lag Screws and Spacers are in place, use a level on top of the Rail to make sure it is

properly level. While making sure the Rail is level, tighten all Lag Screws securely.

3 - Install Trolleys and Hang the Door

Mark the location of the center hole for the Trolleys on the front of the door as shown in the

diagram. Drill the hole using a 7/16” bit.

4 - Install Anti-Jump Pads

Drill two 3/32” pilot holes in the top of the door and

located between and near the Trolleys, as shown

in the diagram, in order to mount the Anti-Jump

Pads.

Place the Anti-Jump Pads on the top of the door

and attach with the 3/4” Phillips Screws.

Make sure the Anti-Jump Pad is positioned so that

the hole is towards the front side of the door and

the body of the Pad is underneath the Rail.

Insert a Bolt through the center hole and

into the door. Make sure the trolley is

vertical and mark the locations of the

remaining holes. Remove Trolleys and

drill holes using a 7/16” bit.

Insert the Bolts through the Trolley and

the door. Add a Washer and Nut to

each Bolt. Hand tighten both Nuts

before securing with a wrench.

Hang the door on the Rail. Make sure

both rollers are in contact with the Rail

and that the door is level.

M

2-5/16”

(T)

plus

3/32”

(2mm)

Door

Thickness (T)

Floor

Anchor

1-1/4”

Screw

Locate the Door Guides on either side of the door, as close

to the doorway as possible. See the diagram for proper

Move the door to the desired closed position. Place a Door Stop so that the bumper contacts

the door and the set screw is facing up. Secure the Door Stop by tightening the set screw.

Move the door to the desired open position and repeat with the remaining Door Stop.

5 - Install Door Guides and Secure Door Stops

OTHER QUESTIONS?

spacing.

If the oor is not solid

wood, it may be

necessary to use

the Floor Anchors in

addition to the screws.

Drill 3/32” pilot holes if

using screws only, or

1/4” pilot holes if using

Floor Anchors.

REV-06

NEED EXTRA PARTS or OPTIONAL ACCESSORIES?

Additional parts and accessories are available exclusively at

www.menards.com/barndoorhardware

or your local Menards store, including rails, rail connectors, spacer kits,

soft-close mechanisms, bypass brackets, locks, and handles.

NOTE: If installing a soft-close mechanism (431-0451), check the soft-close instructions

BEFORE beginning installation.

NOTE: If installing bypass brackets (431-0446, 431-0447, 431-0452), check the bypass bracket

instructions BEFORE beginning installation.

DO NOT RETURN TO THE STOREContact Customer Care

1-800-721-4191

Monday – Friday

8 - 5 Central Time

This manual suits for next models

1

Other Forge Door Opening System manuals