Sesamo PROSWING User manual

Automatic Operator for swinging doors

OPERATING INSTRUCTIONS

PROSWING (m)

PROSWING (M)

Operating instruction

2

3

Index

Technical specifications .................................................................................................. pag. 6

Function Low-energy ...................................................................................................... pag. 6

Warnings for the installer and general safety ................................................................ pag. 7

Recycling and disposal .................................................................................................. pag. 7

Intended use .................................................................................................................. pag. 8

Limit of use .................................................................................................................... pag. 8

Types of arms.................................................................................................................. pag. 9

Arm extensions................................................................................................................ pag. 10

Dimensions...................................................................................................................... pag. 10

Preliminary checks.......................................................................................................... pag.11

Automatism fixing............................................................................................................ pag. 11

Aluminum base holes positioning .................................................................................. pag. 13

Pull arm installation ........................................................................................................ pag. 14

Push arm installation ...................................................................................................... pag. 18

Preliminary checking ...................................................................................................... pag. 21

Wiring power supply ...................................................................................................... pag. 22

Control board Proswing (M) .......................................................................................... pag. 22

Wiring .............................................................................................................................. pag. 23

External peripherals connectors-Input .......................................................................... pag. 24

External peripherals connectors-Output ........................................................................ pag. 25

Dip-switches setting ........................................................................................................ pag.26

Parameters adjustment-display ...................................................................................... pag. 27

Start up............................................................................................................................ pag. 30

Message or errors code.................................................................................................. pag. 31

Operating logics.............................................................................................................. pag. 32

Electric lock selection and setting.................................................................................. pag. 33

PROSWING (M)

3

PROSWING(M)

Operating instruction

4

Operating instruction

PROSWING (M)

Selectors terminal board ................................................................................................ pag. 35

External peripheral power connector(15Vdc) ................................................................ pag. 35

Wiring and use for double Proswing .............................................................................. pag. 36

Inter lock wiring and use ................................................................................................ pag. 39

Installation batteries (OPTIONAL) .................................................................................. pag. 40

Logic switch .................................................................................................................... pag. 42

Connector for PC-Unit connections................................................................................ pag. 42

Delivery modality ............................................................................................................ pag. 42

SESAMO reserves the right to change the technical specifications of the products, even without notice.

Operating instruction

PROSWING (M)

5

Thank you for choosing this product. For best automatism

performance, Sesamo recommends you carefully read and

follow the installation and use instructions found in this

manual. Installation of this automatism must only be perfor-

med by the professionally qualified personnel for whom this

manual is addressed. Any errors during installation may be

harmful to people or things. Packaging material (wood, pla-

stic, cardboard, etc.) should not be scattered in the environ-

ment or left within the reach of children as potential sources

of danger. Every installation phase must be performed in

accordance with the regulations in force and following Good

Technique standards. Before beginning installation make

sure that the product is integral and has not been damaged

during transportation or by poor storage conditions. Before

installing the product make sure that each architectural and

structural element of the entrance (girder fastening surfaces,

casings, guide, etc.) is appropriate and sufficiently robust to

be automated. Conduct a careful risk analysis and make sui-

table modifications to eliminate conveyance, crushing, cut-

ting and hazardous areas in general. Do not install the pro-

duct in environments where gas, steam or inflammable

fumes are present. The manufacturer is not liable for any

neglect of “good technique” or specific regulations in the con-

struction of the casing to be motorised and any collapse of

the same. All automatic entrance safety and protection devi-

ces (photocells, active sensors, etc.) must be installed in

accordance with the regulations and directives in force, with

the completed risk analysis, system type, use, traffic, forces

and inertia in play. Pay careful attention to area where the

following may occur: crushing, cutting, conveyance and any

other type of hazard in general applying, if necessary suita-

ble indications. Indicate the motorised door identification

information on every installation. Make sure that the

upstream electrical system is correctly dimensioned and has

all the opportune protections (circuit breakers and fuses).

Only use original spare parts in maintenance and repairs. Do

not tamper or alter devices in the automatism and all the

safety devices in the control panel for any reason. The

manufacturer is not liable if parts within the automatism are

altered or tampered with or if safety devices other than those

indicated by the manufacturer are used in the system. The

automatism installer must provide the automatic entrance

manager with the use manual and all the information requi-

red for correct use in automatic and manual modes (even for

electronic locking) and in the event of emergency.

Pay careful attention to the messages in this manual that are

marked with the hazard symbol. They can either be warnings

aimed at avoided potential equipment damage or specific

signals of potential hazard to the installer and others.

This device was designed to automate pedestrian swinging

doors. Any other use is considered contrary to the use fore-

seen by the manufacturer who therefore shall not be held lia-

ble.

Machine directive

The installer who motorised a door becomes the automatic

door machine manufacturer according to directive

2006/42/CE and must:

• Arrange the Technical Booklet with the documents indica-

ted in attachment VII of the Machine Directive and keep them

for at least 10 years.

• Draft the CE declaration of conformity according to attach-

ment II-A of the machine directive and provide the use with a

copy.

• Apply the CE markings on the motorised door according to

point 1.7.3 of attachment I of the machine directive.

For more information and for assist installers in applying the

specifications of the directives and of European standards

concerning the safe use of motorised gates/doors consult

the guidelines available on internet at the address

www.sesamo.eu

DECLARATION OF INCORPORATION

(Directive 2006/42/CE, Annex II, part B)

Manufacturer: SESAMO S.R.L.

Address: Str. Gabannone 8/10 -

15030 Terruggia – AL -

ITALY

Declares that the product PROSWING (m)

- is built to be incorporated in a machine to build a machine

considered by Directive 2006/42/CE

- is conform to the essential safety requirements set out in

annex I of the directive with the exclusion of the following

points: 1.2.4.3, 1.2.4.4, 1.3.4, 1.3.5, 1.3.7, 1.3.8.2, 1.4, 1.5.3,

1.5.7, 1.5.14, 1.5.15, 1.5.16

- is conform to the following other CE directives:

2004/108/CE Electromagnetic Compatibility, 2006/95/CE

Low Voltage

- have been applied the following harmonized norms:

EN 60335 - 1 EN 61000 - 6 - 2

EN 50366 EN 61000 - 6 - 3

And also declares that:

- relevant technical documentation has been fulfilled in

accordance with part B of annex VII of the Directive; this

documentation, or part of it, will be transmitted, by post or

mail, in response to a reasonable request by the national

authorities

- the person authorized to compile the relevant technical

documentation is: SESAMO SRL, Strada Gabannone, 8/10 -

15030 Terruggia (AL) - Italy

- the partly completed machinery must not be put into servi-

ce until the final machinery into which it is to be incorporated

has been declared in conformity with the relevant provisions

of the Machinery Directive 2006/42/CE

SESAMO S.R.L. Director

February 2012 ALDO AMERIO

Technical specifications

In the diagram there is the max door weights related with the door widths:

Function LOW-ENERGY

PROSWING (M) can be set in the order to meet requirements of Low-Energy application according DIN 18650 or BS 7036-

4.

In Low-Energy mode safety is ensured by:

- low speed;

- reduced dynamic/static force.

ATTENTION: Installation of safety sensors monitoring opening and/or closing path is an option to consider after risk

assessment evaluation.

Power supply 230V +/- 10% ac 50 Hz

Nominal power 85 W

Nominal motor torque 45 Nm

External device power 12Vdc – 12W max

Emergency battery power 24V 1,3 Ah

Opening time 3 ÷ 6 sec (70 °/s ÷ 20 °/s)

Closing time 4 ÷ 15 sec (40 °/s ÷ 10 °/s)

Max opening angle 110°

Wing dimension 700 ÷ 1400 mm

Working temperature Inside automatsm from -10°C to +50°C

Anti-crushing Automatic traction restriction in presence of obstacles

Weight 10,5 kg approx

Service Intensive

PROSWING (M)

Operating instruction

6

Warnings for the installer and general safety

1) It is important for the safety of the people installing the automatism according to the regulations. A wrong installation or

use of the product might lead to serious damages to people.

2) Read carafully the operating instructions before installing the product.

3) Store the operating instructions for future reference.

4) This automatism has been designed and built exclusively for the use specified in this documentation. Any different use not

stated herain could affect the integrity of the product and/or represent danger situation.

5) SESAMO declines any responsabilty from misuse or different use from which it was intended.

6) Do not install the product in explosive enviroment: the presence of flamabel gases or fumes is a serious safety hazard.

7) SESAMO is not responsible for the failure to comply with the Good Technical construction procedure of the door to be auto-

mated, as well as deformations that may occur to the door when using the same.

8) Before making any service to the product, take off power supply.

9) Instal a bi-polar switch to cut off power supply.

10) Verify functionality of ground wiring.

11) Safety devices (norm EN 12978) protect possible dangerous areas from mechanical risks during movement, as. anticras-

hing, conveying, shearing.

12) For mainteinance use only genuine SESAMO spare parts.

13) Do not modify components that belongs to the whole automatism.

14) The installer must supply end user all the informations in case of manual operating in emergency.

15) End user shall refrain from any attemp to repair or direct intervenction and ask only to qualified personnel.

16) Installation must be done only from a qualified personnel and in full compliance with regulations.

17) Everything not including in this operating instruction manual is not allowed.

18) This operating instructions manual is only intended for qualified personnel.

Recycling and disposal

RECYCLING OF THE AUTOMATISM AND PACKAGING

This product is built with different materials. The major parts (aluminium, plastic, iron,wires) are solid urban waste. They can be

recycled through collection and disposal in authorized centers.

Other components (control boards, etc.) may contain pollutants. They need to be removed and hand over to companies autho-

rized to recover and dispose them.

The packaging (paperboard, plastics etc.) are solid urban waste and they can be disposed of without any problem, simply per-

forming waste collection for recycling.

Before proceding it is always reccomendr to verify local specific norm for disposal.

PLEASE RECYCLE!

7

PROSWING (M)

Operating instruction

Intended use

The device must be used to automate pedestrian swinging door only.

This device is an electro mechanical system that allow to open and close a swinging door using a trasmission arm.

Door is closed through a motor/spring system or only spring while power is off.

Programmable electronic control board allows correct functionning depending on the type of installation.

Limit of use

ATTENTION: Do not exceed door weight and width as shown in the diagram in “technical specification” paragraph.

To each type of arm correspond a different type of jamb dimension: do not exceed this value (see Paragraph “arm installa-

tion”).

This device is intended only for swinging pedestrian door, dry and inside use.

SESAMO shall not be held liable for any other use contrary to the use foreseen.

RIGID PULL ARM ARTICULATED PUSH ARM

MAX JAMB DEPTH [A] -50 ÷ +100 mm

0 ÷ 300 mm

(depending on the type of arm:

standard or long)

DISTANCE FROM THE ALU-

MINIUM BASE AND DOOR

BRACKET [B]

67 ÷ 127 mm 35 ÷ 95 mm

A

B

-50 +100

B

A

300

PROSWING (M)

Operating instruction

8

Types of arm

ATTENTION: For proper positionning, please refer to the paragraph “Arm Installation”.

PULL ARM

The pulling arm can be fitted:

- PULL (it is used when the automatism is installed

on the same side of the door opening).

STANDARD PUSH ARM

The pushing arm can be fitted :

- PUSH (it is used when the automatism is installed

on the opposite side of the door opening).

LONG PUSH ARM

The long push arm can be fitted:

- PUSH (it is used when the automatism is installed

in the opposite side of the door opening).

jamb depth = 0 ÷ 150 mm

jamb depth = 150 ÷ 300 mm

jamb depth = -50 ÷ 100 mm

Fig. 1

Fig. 2

Fig. 3

9

PROSWING (M)

Operating instruction

Dimensions

Arm extensions

ATTENTION: For a correct positionning refer to “arm installation” paragraph.

L=50 mm L=70 mm L=90 mm

Fig. 4

L=30 mm

(standard)

Fig. 5

56

130

664

86

94

17 630 17

PROSWING (M)

Operating instruction

10

Preliminary checks

Before installing the automatism please check:

- verify the installation does not create dangerous situations;

- prearrange proper pipes and counduits for the wires, granting the protection of the same against mechanical dama-

ges;

- the surface where fixing the automatism has to be resistant. Use screws, bolts, etc. adequate to the type of surface;

- the structure of the door has to be strong to hold the weight of the automatism as well the hinges, also check to not

have friction between fixed and mobile parts;

- use proper equipment and tools to install in security and in accordance with the regulations.

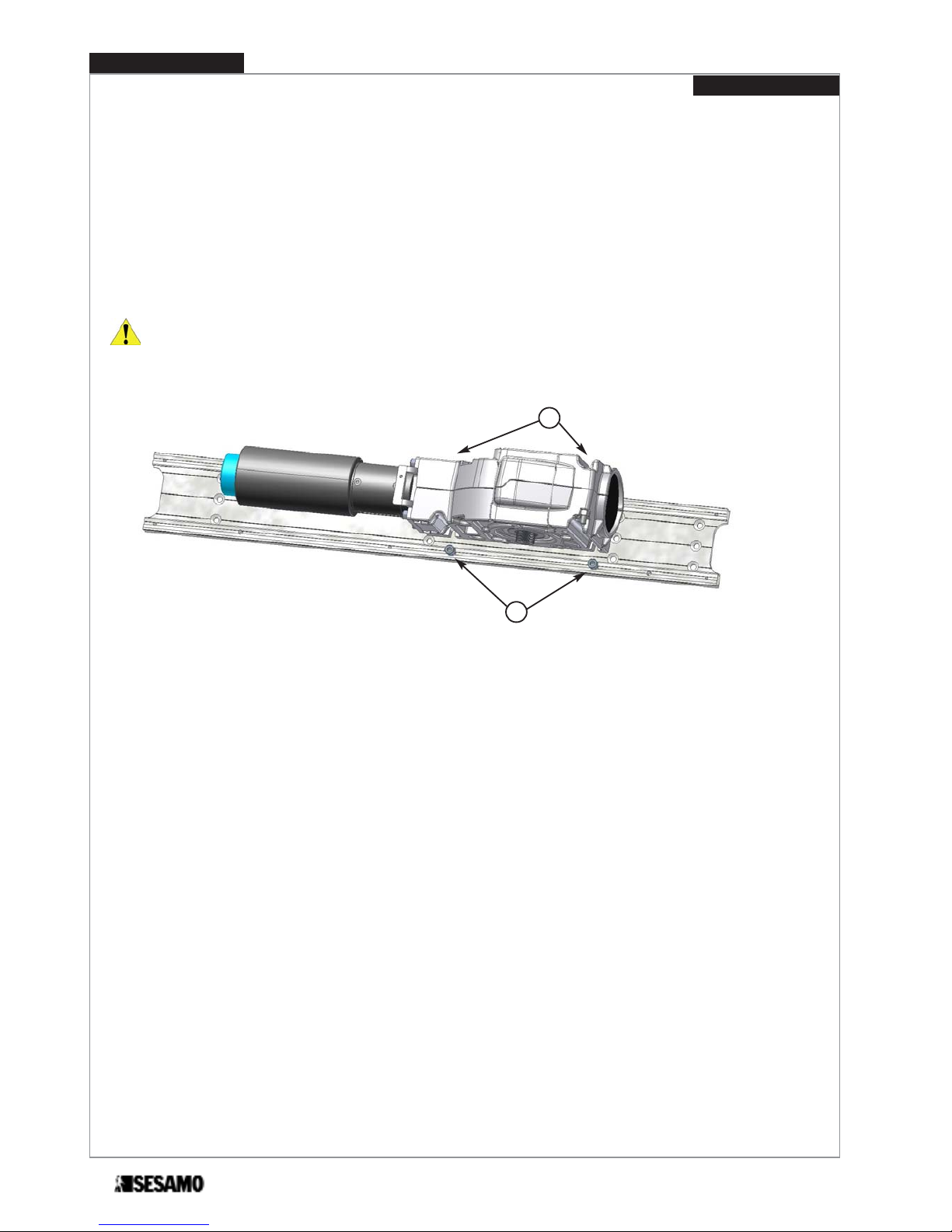

Automatism Fixing

REF. DESCRIPTION

ACover fixing screws

BAluminum cover

CControl board fixing screws

DControl board

EGear motor fixing screws

FGear motor

GTransformer fixing screws

HTransformer

IEnd caps fixing screws

LEnd cap opposite transformer side

MEnd cap transformer side

NAluminum base

OBattery group (OPTIONAL)

C

B

C

A

I

M

H

G

E

L

O

F

N

D

Fig. 6

11

PROSWING (M)

Operating instruction

To fix automatism proceed as follows:

1- remove cover (Fig.6 part.B);

2- disconnect all wiring (encoder, switches, transformer, motor) on control board;

3- unscrew the 2 screws (Fig.6 part.C) and remove control board with its support (screws remain between control board and

support);

4- unscrew the 2 screws (Fig.6 part.G) and remove transform;

5- unscrew the 4 screws (Fig.6 part.E) and remove gear motor;

6- unscrew screws (Fig.6 part.I)and remove end caps (Fig.6 part.M ed L);

7- fix aluminium base (Fig.6 part.N) to thre structure following instructions of the following paragraphs, dipending on arm type;

8- reassemble all components but end caps and aluminium cover.

ATTENTION: to make easier reassembling gear motor, partially screw the screws (Fig. 7 part. E), then lean gear motor

on to them. Insert screws (Fig. 7 part. F).

Tight all screws paying attention that gear motor axis is perpendicular to the door top edge.

Fig. 7

E

F

PROSWING (M)

Operating instruction

12

Drilling holes according to the type of screws chosen and fix the base only after verifying the “Positioning dimensions”

listed in the paragraph concerning the type of arm selected.

Fig. 8

With double automatism prearrange the conncetion (wiring) between the two single automatisms.

84

76 88

202

234 30

Aluminum base holes positioning

19,5

19,5 22,5

22,5

Fig. 9

84

76

88 202 23430

19,5

19,5 22,5

22,5

hinge axis

hinge axis

13

PROSWING (M)

Operating instruction

14

Operating instruction

PROSWING (M)

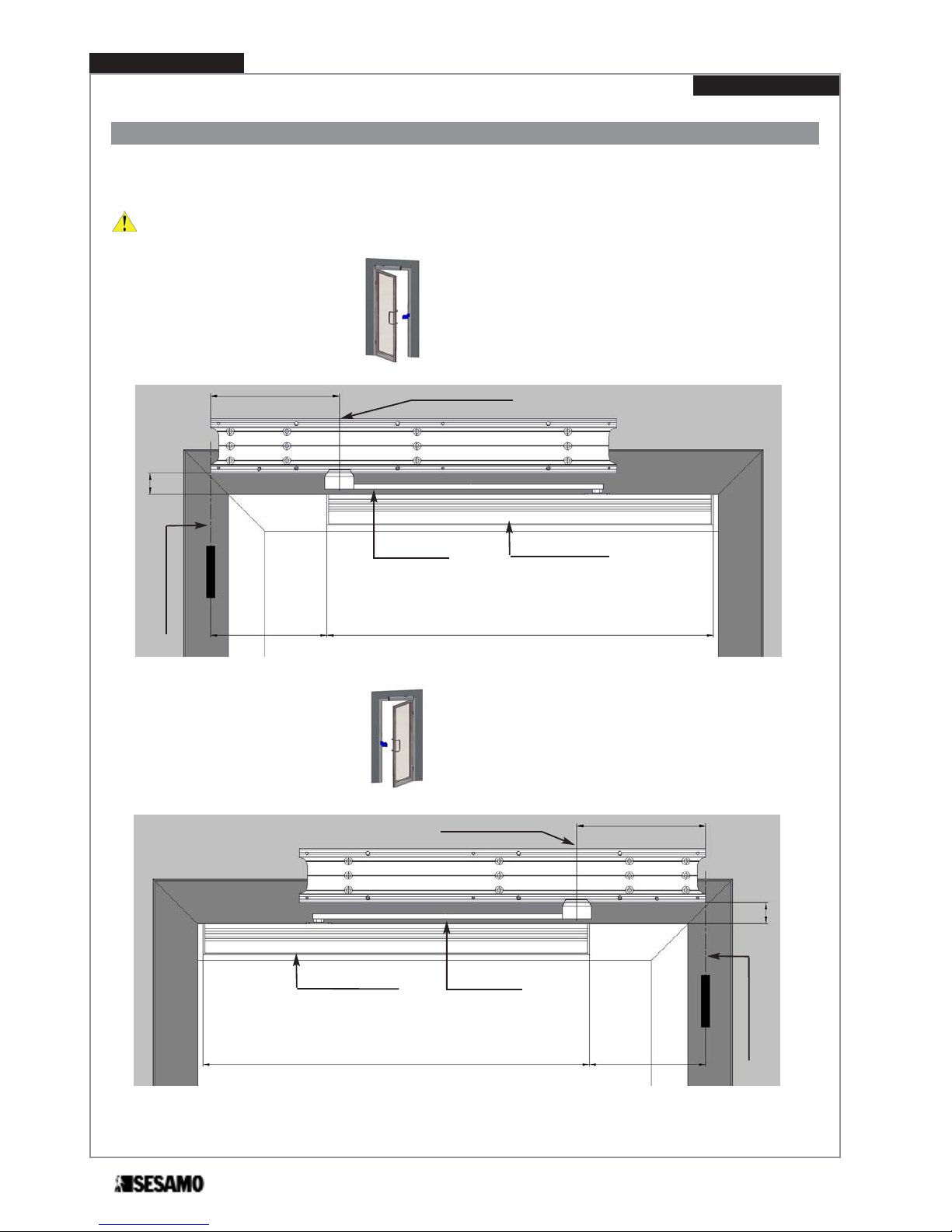

Pull arm installation

Pull arm positioning

Pull arm has to be used when automatism is installed on the same side of door opening.

ATTENTION: For a correct positionning always refer to the hinge axis and gear motor axis, as shown in Fig.10 e 11.

Door opening RIGHT (see Fig. 11)

Door opening LEFT (see Fig. 10)

Fig.10

Hinge axis

Pull arm Sliding guide

Gear motor axis

600

180

C

200

Fig. 11

AHinge axis

Pull arm

Sliding guide

600 180

C

200

Gear motor axis

Operating instruction

PROSWING (M)

15

Sliding guide

Gear motor axis

OPENING

DIRECTION

56

C

ATTENTION: final tightening

of the screws must be performed

only after checking that vertical

positioning of the automatism

allow a good parallelism between

hinge axis and gear motor axis.

Therefore, after fixing the pulling

arm and its guide, the coupling

bolt of the arm with the cylindric

skid have not to create force in

opening/closing cycle.

A positioning error of the automa-

tism might create bending bet-

ween the bolt of the pulling arm

and the cylindric skid more than

the allowed tolerance, damage

parts of the automatism.

32

ARM EXTENSION DIMENSION “C”

Arm extension standard 35

Arm extension (L= 50 mm) 55

Arm extension (L= 70 mm) 75

Arm extension (L= 90 mm) 95

Upper door level

Fig. 12

Jamb depth=-100 mm

Within jamb depth maximum opening angle is proportionally reduced.

Jamb depth=+50 mm

Sliding guide installation

1- Unthread profile (Fig.13 Part.I) and drill 4 holes on the “V” mark on guide profile.

2- Fix guide profile horizontally to the door following dimensions shown in Fig.12.

P

O

I

Fig. 13

4- Insert washer (Fig.14 part.B) and screw (Fig.14 part.C) into arm extension (Fig.14 part.A).

5- Insert arm (Fig.14 part.D) in the arm extension slot, and tight screws (Fig.14 part.E)..

A

B

C

D

E

Fig. 14

PROSWING (M)

Operating instruction

16

6- Insert arm extension (Fig.14 part.A) on the shaft and tight screw (Fig.14 part.C) until arm extension is well fixed to gear motor

shaft.

7- Insert skid (Fig.15 part.G) inside the guide (Fig.15 part.O) and slightly open door.

8- Rotate arm until reaching skid (Fig 15 part. F).

9- Screw skid shaft (Fig.15 part.F) into the arm (Fig.15 part.Q).

10-Insert guide cover profile (Fig.15 part. I)

11-Insert right end cap (Fig.15 part.M) and the left end cap (Fig.15 part.N) onto the guide with their screws (Fig.15 part.L).

I

F

LN

O

P

M

Fig. 15

Q

Verify the dimension about 15 mm (Fig. 16)

Fig. 16

15 mm

17

PROSWING (M)

Operating instruction

Diagram for door opening RIGHT (Fig. 17)

Hinge axis

Door bracket

Motor reducer axis

200

Diagram for door opening LEFT (Fig. 18)

Fig. 17

Hinge axis

Door bracket

Motor reducer axis

200

Fig. 18

Push arm installation

Push arm is used when automatism is installed on the opposite side of door opening.

ATTENTION: For a correct positionning always refer to the hinge axis and gear motor axis, as shown in Fig.17 e 18.

PROSWING(M)

Operating instruction

18

Operating instruction

PROSWING(M)

19

272.5

55

Hinge axis

Door bracket

Fig. 19

35

ARM EXTENSION DIMENSION “E”

Arm extension standard 8

Arm extension (L= 50 mm) 28

Arm extension (L= 70 mm) 48

Arm extension (L= 90 mm) 68

Fig. 20

OPENING

DIRECTION

Push arm

Door bracket

56

Motor axis

Jamb lower edge

ATTENTION: final tightening of the screws must be perfored only after checking arm can easily rotate under door

jamb (Fig.20).

E

Increasing jamb depth, maximum opening angle is proportionally reduced.

25

Jamb depth=0÷300 mm

For PUSH ARM proceed as follows:

1- Insert washer (Fig.21 part.B) and screw (Fig.21 part.C) into arm extension (Fig.21 part.A).

2- Insert arm (Fig.21 part.D) in the arm extension slot, as show in Fig. 21 and tighten screws (Fig.24 part.E).

3- Unscrew screws M8 x 16 (Fig.21 part.G).

4- Fix door bracket (Fig.24 part.F) to the door following dimension shown in Fig. 19 e 20.

5- Insert arm extension (Fig.21 part.A) into gear motor shaft.

6- Tight screw (Fig.21 part.C) until arm extension (part 1) is well fixed to gear motor shaft.

7- Keeping door closed, rotate arm as show in Fig. 22 and tight screws M8 x 16 (Fig. 21 Part. G).

Fig. 21

A

B

C

ED

F

G

Fig. 22

Fix PUSH ARM to the door

PROSWING(M)

Operating instruction

20

Other manuals for PROSWING

1

This manual suits for next models

1

Table of contents

Other Sesamo Door Opening System manuals

Sesamo

Sesamo Digidor User manual

Sesamo

Sesamo PROSWING User manual

Sesamo

Sesamo SwinGo User manual

Sesamo

Sesamo Puma Millenium User manual

Sesamo

Sesamo Roto K3 User manual

Sesamo

Sesamo Digidor User manual

Sesamo

Sesamo PROSWING R Simple manual

Sesamo

Sesamo MILLENNIUM SERIES Operating instructions

Sesamo

Sesamo PIUMA User manual

Sesamo

Sesamo smart PRO User manual