Formula NERO R User manual

1

Vers. 03

2

TORX® è un marchio registrato di CAMCAR / TEXTRON INC. Tutti i marchi appartengono ai

rispettivi proprietati.

TORX® is a registered trademark of CAMCAR / TEXTRON INC. All trademarks are the property

of their respective owners.

TORX® est une marque déposée de CAMCAR / TEXTRON INC. Toutes les marques appartien-

nent aux propriétaires respectifs.

TORX® ist ein registriertes Warenzeichen der CAMCAR / TEXTRON INC. Alle Warenzeichen

gehören den respektiven Eigentümern an.

TORX® es una marca registrada de CAMCAR / TEXTRON INC. Todas las marcas pertenecen a

los respectivos propietarios.

3

WARNING! BEFORE INSTALLING AND USING THIS NEW FORMULA. PRODUCT IT IS

CRITICAL TO YOUR SAFETY THAT YOU READ AND STRICTLY ADHERE TO THE IN-

STRUCTIONS IN THIS MANUAL. FAILURE TO DO SO COULD CAUSE SERIOUS INJURY

AND/OR INVALIDATE YOUR LEGAL RIGHTS.

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE AS IT CONTAINS

INFORMATION CRITICAL TO YOUR SAFETY.

WARNING! DO NOT INSTALL OR DISASSEMBLE THIS FORMULA. PRODUCT ON

YOUR OWN!

Always seek the help of a professional mechanic. If you decide to ignore this im-

portant warning, keep in mind that you are doing so EXCLUSIVELY at your own risk.

Note: AS WITH ANY MANUAL, THIS ONE MAY BE UPDATED. CONTACT YOUR FOR-

MULA. DEALER, OR CHECK OUR WEB SITE, (www.rideformula.com) TO RECEIVE

ANY SUCH UPDATES.

This manual contains information for the safe use, proper mounting and mainte-

nance of NERO forks. Following the rules contained in this manual will ensure the

safe use and longest life of your NERO forks.

Carefully follow the SAFETY GUIDELINES to assure appropriate use and service of

NERO forks.

In this handbook you will find the following safety symbols:

CAUTION: Directs your attention toward unsafe practices, which could result in

damage to the equipment or minor injury.

WARNING: Directs your attention toward unsafe practices, which could result

in serious injury or death.

It is impossible to anticipate every situation that may occur while riding a bicycle. This

manual makes no representation about the safe use of the bicycle under all condi-

tions. There are risks associated with the use of any bicycle that cannot be predicted

or avoided. By choosing to ride a bicycle, you assume the responsibility for that risk.

Read and understand your bicycle owner’s manual before using your bicycle.

GENERAL SAFETY GUIDELINES

•Never put your hands near or inside rotating parts. Protective five-finger gloves that

do not reduce sensitivity or your ability to grip should be used during repair.

•Before starting any mounting operations, carefully check for dangerous conditions at

the work site. If too dark, use all available light sources and make sure they work prop-

erly before starting work.

•All maintenance operations must be carried out solely by personnel authorized by FOR-

MULA.

•Make sure that the Wheel Pin is correctly adjusted. Bounce your bicycle off the

ground from about 10cm/4” to check the presence of loose parts.

TRANSLATION OF THE ORIGINAL INSTRUCTION MANUAL

4

A locking device not correctly adjusted can cause the wheel detachment..

• After inserting the wheel, first screw the wheel pin (1) to 18 Nm, then tighten the

safety lock nut (5). The lock nut has a left-hand thread so it is screwed counterclock-

wise and unscrewed clockwise.

•Before riding, verify that the brakes on your bicycle are installed and adjusted cor-

rectly. Improperly installed and adjusted brakes may cause a crash and result in

property damage, serious injury, or death.

•Make sure cables and hoses do not impede the steering of the bicycle.

•When using the bicycle in the wet, remember that the grip of the tires on the ground

decreases, making it more difficult to control the vehicle. Furthermore, it must be

borne in mind that due to the progressive drying of the braking surface during brak-

ing, the braking power may vary abruptly, so pay more attention when driving in

wet conditions to avoid possible accidents. NERO forks are not designed for use on

public roads.

•NERO forks are designed for competitive off-road riding and racing.

5 1

4 1

3 1

21

1 1

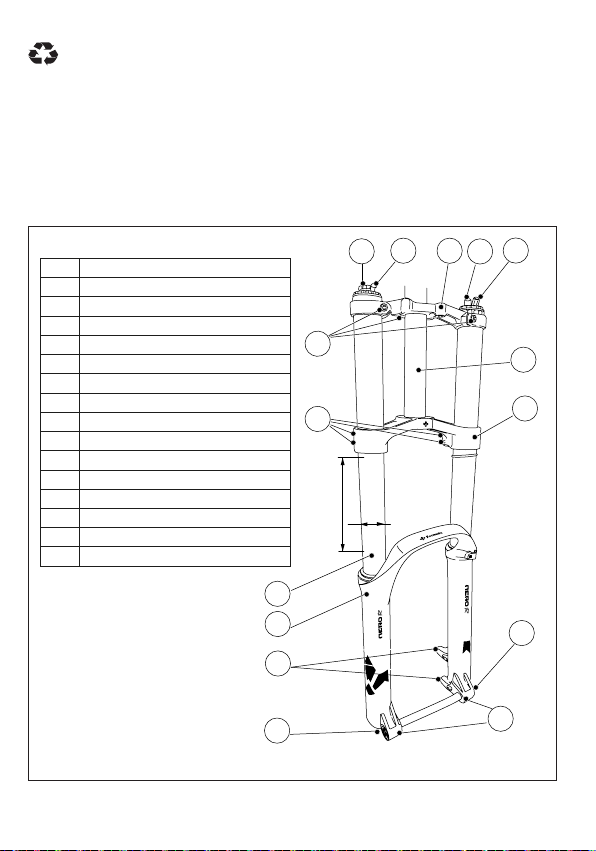

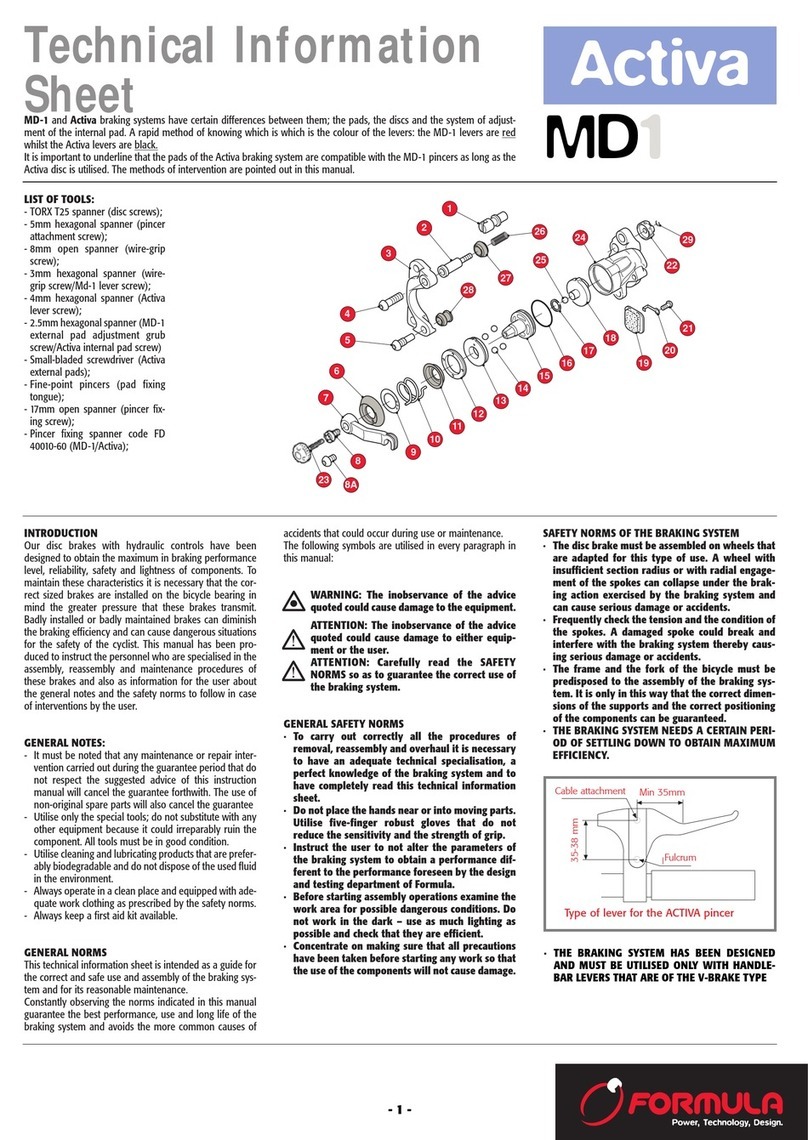

Pos DENOMINAZIONE COMPONENTI - PART NAME Q. CODICE / CODE

LOCK NUT with LEFT HAND THREAD SB-B043-05

SHIM FOR CONICAL AXEL SB-R052-15

CONICAL BUSH WHEEL AXLE SB-B035-05

AXLE BUSH Ø20 SB-B037-05

WHEEL AXLE CONICAL SEAT Ø20 DH SB-P089-05

4

3

1

Legs

2

5

Use the tightening

torque marked on

the pin surface.

5

NERO FORKS SAFETY GUIDELINES

•The NERO forks produced by FORMULA. are designed exclusively for use on two

wheel bicycles. Any other use is to be considered hazardous. FORMULA. shall not be

held liable for any consequences from improper use.

•If the fork ever loses oil or makes unusual noises, stop riding and have it inspected

by FORMULA. or an authorized dealer. Continuing to use a malfunctioning fork can

cause a sudden loss of control, resulting in serious injury or death. Some sounds,

such as oil flow, minor clicks, and spring rattle, are considered normal. When in

doubt, consult your local FORMULA dealer.

•NERO forks have a crown / steerer . These parts are pressed together through a

single precision pressing operation. Replacing any of these parts requires a com-

plete new upper assembly. Never attempt to remove or replace the steerer indepen-

dently from the crown. NEVER ATTEMPT TO CUT THREADS INTO THE THREADLESS

STEERER. Modifying the crown / steerer assembly can cause loss of control of the

bicycle and serious injury or death.

•Impact, falls, improper or harsh use of the bicycle may compromise the structural

integrity of the forks, significantly reducing their lifespan.

•Have the forks regularly inspected by a qualified mechanic for any cracks, deforma-

tion, signs of fatigue or wear. Use of penetrating fluid or other visual enhancers to

locate cracks on parts is recommended.

•If inspection reveals any deformation, cracks, signs of impact or stress, no matter

how slight, immediately replace the component. Excessively worn components also

require immediate replacement.

•The frequency at which inspection is required depends on many factors. Ask a FOR-

MULA. dealer to recommend an inspection and service schedule that is right for you.

•If you weigh more than 90kg/198 Ibs be especially careful and have the bike in-

spected more frequently.

•Parts that have been bent or damaged in an accident, or as the result of impact,

must be imme-diately replaced with genuine FORMULA. replacement parts.

•The user of NERO forks expressly recognizes that there are risks inherent in bicycle

riding, including but not limited to failure of a bike component, resulting in an ac-

cident, personal injury or death.

•By purchasing and using these NERO forks the user expressly, voluntarily and

knowingly accepts and/or assumes these risks, including but not limited to the risk

of passive negligence on the part of FORMULA., i.e. hidden, latent or obvious defects

and exempts FORMULA. from liability to the fullest extent permitted by law against

any resulting damage.

•Carefully read the NERO forks instructions before use.

•Carefully follow the scheduled maintenance program as indicated in the relative

paragraph.

•Always use genuine FORMULA. replacement parts.

By purchasing and using these NERO fork, the user expressly, voluntarily and know-

ingly accepts and/or assumes these risks, including but not limited to the risk of pas-

sive negligence on the part of FORMULA., i.e. hidden, latent or obvious defects and

exempts FORMULA. from liability to the fullest extent permitted by law against any

resulting damage.

6

ENVIRONMENTAL NOTES

In order to protect the environment, please follow to these simple instructions to

correctly dispose of FORMULA. products:

1)The packaging does not require special disposal because it is not dangerous in any

way; we suggest recycling paper and plastic.

2) It is also recommended to recycle the metal parts after use.

For both points mentioned above, it is recommended to dispose of waste following

national regulations through specialized waste disposal companies.

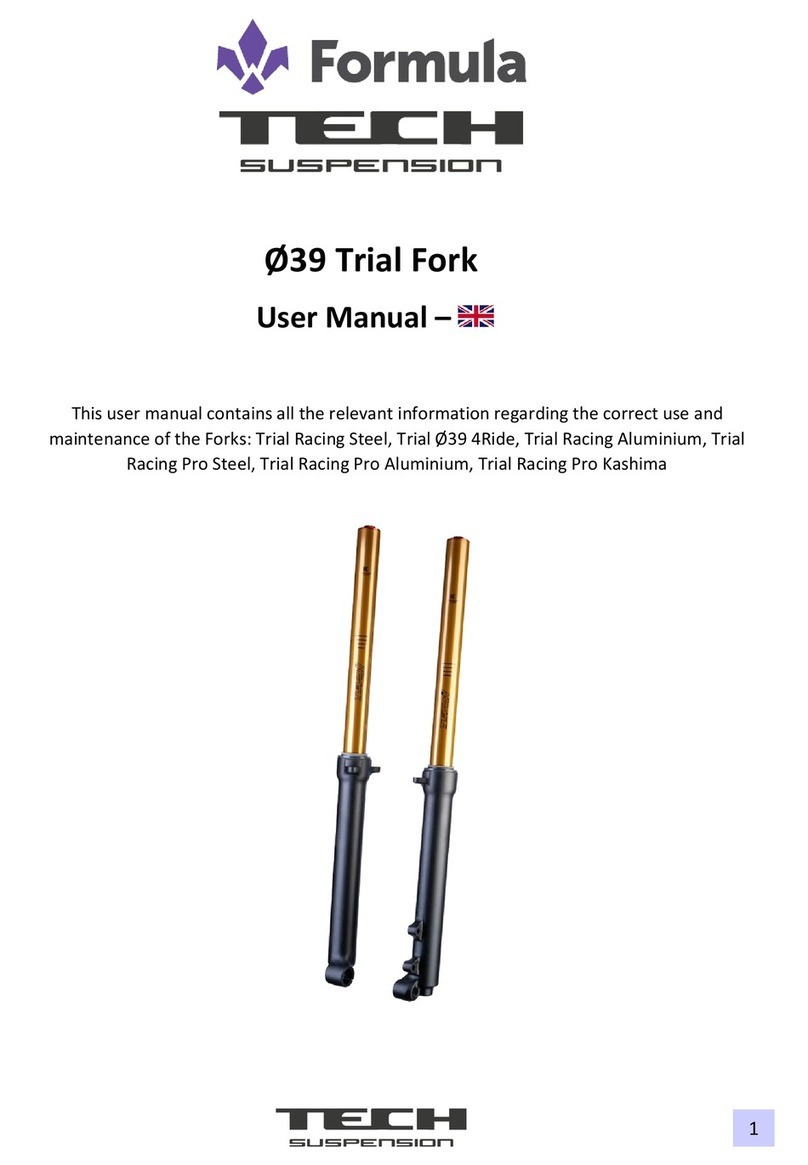

L= ø

1

9

5

6

78

2

4

11 12 10

13

3

14

15

Pos Name

1

Steering tube

2

Upper triple clamp

Lower triple clamp

3

Stanchion tube

4

Lower leg

5

Disc brake connection

6

Rebound knob

7

Wheel connection

8

Low speed compression adjustment

9

Gold air valve

10

High speed compression adjustment

11

Silver air valve

12

13

Bronze air valve

Upper clamp screws

14

15

Bottom clamp screws

* It is possible to request an upper triple clamp with different height to adapt to frames with a shorter tube

7

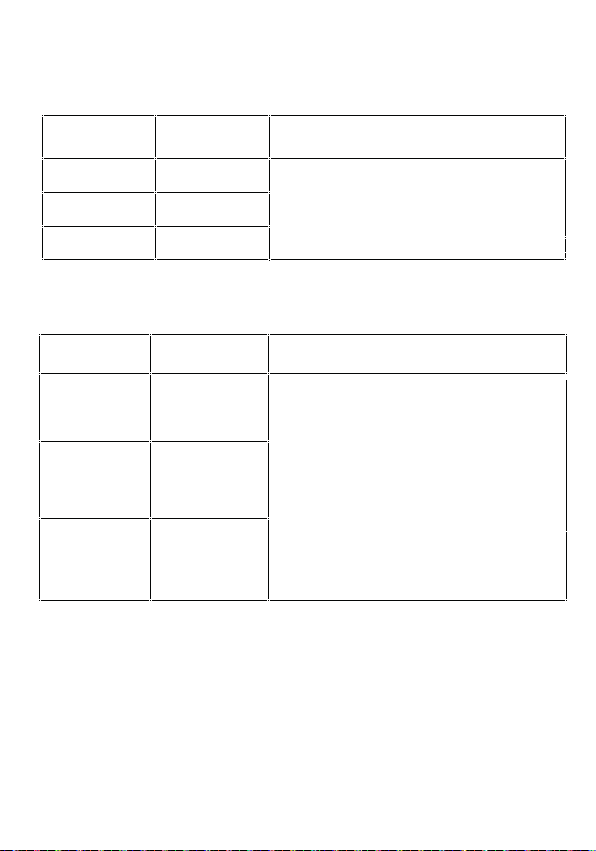

1TECHNICAL SPECIFICATIONS NERO

FORKS 27.5”

FORKS 29”

* The value for “axle to crown” can be changed removing the pipes from the plates.

Fork

Travel

Axle To Crown

± 5.0 mm (*) Tire Size limit

200mm 581 27.5 x 2.50 inch wide

Any tire size greater than 2.35 inch wide

must be checked

with fork fully compressed and have a

minimum of 6.0 mm

“tire to crown” clearance.

190mm 571

180 mm 561

200mm 593 29 x 2.50 inch wide

Any 29 inch tire size greater than 2.35 inch wide

must be checked with fork fully compressed and

have a minimum of 6.0mm “tire to crown”

clearence

27.5 x 3.0 inch wide

Any tire size greater than 2.70 inch wide must be

checked with fork fully compressed and have a

minimum of 6.0 mm “tire to crown” clearance.

190mm 583

180mm 573

Axle To Crown

± 5.0 mm (*)

Fork

Travel Tire Size limit

8

WARNING: Every time the value “axle to crown” is changed, make sure that

the distance between the crown and the tire is greater than 6 mm.

In addition, make sure that the words “end stroke” on the pipe remains below the

lower plate (3).

Gap / Tire / Crown control

It can also be checked by defeating the

air and checking that 6mm remains.

END STROKE written control

1.1 Triple clamp screws tightening torque

Upper steering triple clamp screws = 6 Nm

Lower steering triple clamp screws = 8 Nm (2 screw per side model).

Corsa + 6mm

9

1.2 Disc brakes

Install disc brakes and torque all fasteners according to manufacturer’s specifica-

tions. Install, route and check that all cables or hydraulic hoses are securely fastened

to the lower leg and will not move during compression of the fork.

WARNING: Tighten the brake calipers to the brake manufacturer’s torque

specifications.

1.3 Wheels

Consult the technical specifications provided by the wheel manufacturer to install

and secure the wheels to the forks.

1.4 Lubricants

Only use hydraulic oil, lubricant and grease included in the kit sold by FORMULA.

Hydraulic oil Idemitsu OJ01, Formula FX and Grease Formula Fork Seal.

In the cartridge, use hydraulic oil Idemitsu OJ01 only.

For lubrication of legs and tubes, use Formula FX only.

CAUTION: Do not use lubricants other than those recommended above. Use

of other lubricants may damage the fork and make it unsafe.

Threadlocker for screws

Apply a liberal mount (where indicated) of medium strength threadlocker all the way

around the thread. After applying, clean any excess threadlocker with a cloth. Let dry

at least 24 hours before installing.

WARNING: The threadlocker used for assembly is dangerous to skin and

eyes. Consult and adhere to the warnings on the threadlocker container be-

fore use.

10

2 INSTALLATION

WARNING: Installation of NERO suspension forks requires specific knowl-

edge, equipment and expertise. General mechanical skills are not sufficient

to correctly install the NERO suspension forks.

FORMULA strongly recommends that a qualified service center authorized by

FORMULA install the fork on your bicycle. Improperly installed forks can cause

damage to the NERO suspension and serious injury or death.

-FORMULA does not authorize the end user to

install the fork on the bike.

WARNING: Failure to follow these guide-

lines may result in serious injury or death.

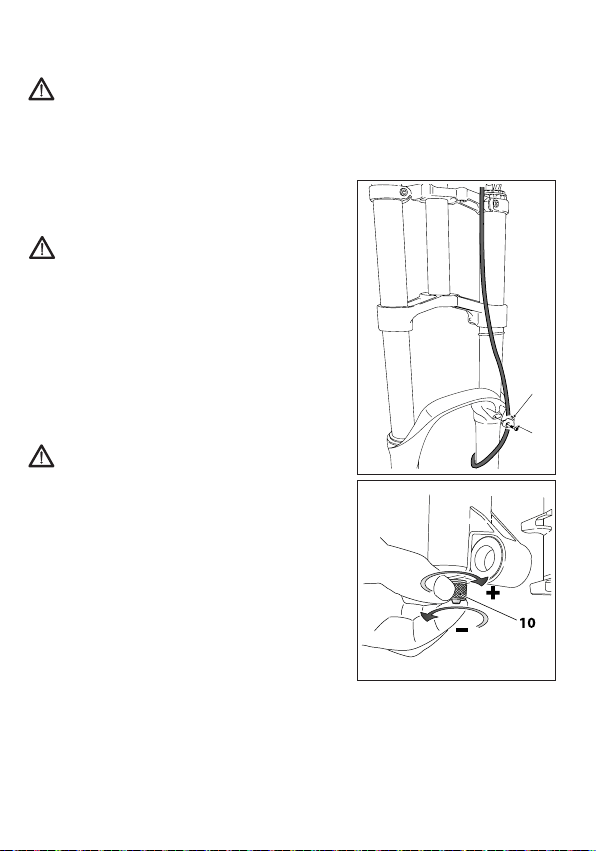

2.1 Installing the hose clamp

-Secure the disc brake hose to the fork with clamp

(8).

-Loosen the screw (9) and move the clamp over

the hose (8).

-Insert the hose inside the hose clamp (8).

-Tighten to 2/3 Nm.

3 USE

GENERAL SAFETY NOTE: Do not keep the

fork fully at the end of the race for a period

exceeding 10 days.

If that happens you can verify that the hydraulic

system is not working properly.

3.1 Suspension Adjustments

-Use the rebound adjuster (10) to adjust how

quickly the fork returns to its extended position

after being compressed.

-Correctly setting the rebound speed allows the

bicycle to properly track the terrain.

-Rebound that is set too fast will cause the fork to

feel springy and uncontrolled and exhibit exces-

sive return speed

-Rebound that is set too slow will not allow the fork to extend quickly enough to

prepare for the next bump.

-Turning the adjuster (10) clockwise (toward the + sign) adds hydraulic damping and

slows the rebound speed.

-Turning the adjuster (10) counter-clockwise (toward the - sign) removes hydraulic

damping and speeds up the fork rebound speed.

8

9

11

3.2 Adjusting hydraulic compression

- The knob (11) is used to progressively adjust hy-

draulic compression in high speeds.

- The knob (25) is used to progressively adjust hy-

draulic compression in low speeds.

3.3 Adjusting the air pressure

The setting of the 3Air system is used to adjust the

curve of the air spring specific for any type of need.

Changing pressures in the Gold chamber (end

stroke - Fig. 1), Silver chamber (main Fig. 2), Bronze

chamber (negative Fig. 3), it is possible to obtain a

spring where initial sensitivity as well as end stroke

progression vary, with the same central support.

11 25

Fig. 2

Fig. 1

T

O

R

Q

U

E

1

8

N

m

INFLATING

Silver (positive)

Bronze (negative)

Fig. 3

+10 PSI

-10 PSI

(N)

3 AIR SPRING FORCE

(mm)

FORK TRAVEL

Gold

+10 PSI

-10 PSI

(N)

3 AIR SPRING FORCE

(mm)

FORK TRAVEL

Bronze

12

If pressure in the Silver chamber is chan-

ged, also the stiffness of the spring can be

changed to fit the weight of the rider.

For a simpler and more accurate operation, the

Nero R fork is equipped with an innovative high

pressure pump (Fig. 4) compatible with all the su-

spensions.

A quick-release pump has been used instead of a

traditional second screw, so as to avoid any air leak

when the pump is disconnected from the valve.

The 3Air system provides unlimited possibilities for trying customized settings.

Just follow a few simple rules:

1) always follow this inflation sequence: Gold - Silver - Bronze;

2) set the Gold valve with a pressure that is greater than or equal to pressure in the

Silver chamber;

3) always inflate the Bronze chamber with a pressure which is at least 20 PSI greater

than pressure in the Silver chamber.

4) you cannot check the Silver chamber without first deflating the Bronze.

The table below is given for reference on the

leg of the fork.

Follow the instructions given in the video tu-

torial found in link bit.ly/3air-setup to know

how to easily set the 3Air system in Nero R.

80kg Rider

70kg Rider

60kg Rider

(N)

3 AIR SPRING FORCE

(mm)

FORK TRAVEL

17

14

16 12

Fig. 4

Silver

13

3.4 NEOPOS

Formula air suspensions can be provided with Neopos system.

Neopos is an innovation that will change your riding experience.

it is a technology that improves the positive chamber behaviour by allowing your air

fork to achieve levels of comfort, response and predictability once unthinkable.

Neopos has been designed to be compatible with Formula forks only.

To install Neopos on Nero R:

1- Deflate the chambers following the inflation steps in reverse order: bronze, silver

e gold.

2- Loosen the top plug with the specific tool delivered in the aftermarket package

and remove the upper unit.

3- Add one or more Neopos items inside the positive chamber (up to three Neopos

items, regardless of the stroke of the fork).

4- Reinstall the upper unit with a 30 Nm tightening torque.

5- Add the desired pressure again starting from the deflated chambers.

Further information about installation is available in our website:

www.rideformula.com

4 MAINTENANCE

MAINTENANCE INTERVAL TABLE

Comply with the following maintenance in-

tervals in order to preserve the functionality

and performance of your FORMULA fork..

WARNING: In case of frequent use of the

fork under extreme stresses, maintenance

operations will have to be carried out more

frequently, based on the actual use condi-

tions.

(*) Do not use high-pressure water

(**) Do not use solvents and degreasing products that may damage fork compo-

nents

Use genuine spare parts and lubricants recommended by FORMULA.

Procedure

First

Use

Every

Ride/

Competition

Every

30 Hours/

6 Months

Every

100 Hours

/1 Year

External cleaning

with water and

neutral detergent (*)(**)

Internal fork leg cleaning

- oil seal and bushing

wear check

Hydraulic oil cartridge

replacement

Air spring

maintenance

14

4.2 Issues - Causes - Remedies

This chart mentions some issues that may be encountered when using the fork along

with the possible causes and remedies.

WARNING: The operations listed below and accompanied by this symbol

must be carried out only by authorized service centers.

Fork extends too quic-

kly, violent rebound af-

ter bumps

Rebound damping insuf-

ficient

Increase rebound damping

Steerer tends to “close”

when turning

Excessive rebound dam-

ping

Decrease rebound dam-

ping

Fork slow during exten-

tion or “packs-up” over

multiple bumps

Excessive rebound dam-

ping

Decrease rebound dam-

ping

Bump noise during re-

turn but without violent

rebound

Excessive rebound dam-

ping

Decrease rebound dam-

ping

Dust seal leaks oil Dust seal damaged ( ) Replace dust seal

Large amount of oil on

upper tubes or oil leaks

from bottom of fork

Seals damaged, uppers

may be damaged

( ) Replace all seals and

have uppers inspected

Fork “sticky”, does not

work like new

Seals dirty, fork requires

maintenance

( ) Replace all seals

Oil loss from bottom of

fork

Bottom nut/screw loose

O-ring damaged

Tighten the nut or screw

( ) Replace O-ring

Loss of sensitivity Slide bushings worn

Oil old

( ) Replace slide bushings

( ) Change oil

15

WARNING: If the fork ever loses oil, do not use the bike.

Find and repair any oil loses before using the bike again.

WARNING: Seals and upper tubes should be kept clean to avoid damage to

fork seals and upper tubes.

WARNING: If the fork sags, immediately adjust compression or the pressure

of the chambers.

Incorrect compression adjustment may cause damage to the fork, serious

injury or death.

READ CAREFULLY!

FORMULA. extends to the original purchaser of its forks a limited warranty that the

forks are free of defects in material and/or workmanship for a period of two years

from date of purchase.

WHAT PROTECTION DO I RECEIVE FROM THE WARRANTY?

FORMULA. will, at its discretion, repair or replace the defective product under war-

ranty.

WARRANTY CONDITIONS AND LIMITATIONS

1. The manufacturer guarantees its products to be free from defects in materials or

workmanship for 24 months from the date of purchase. You must establish proof

of purchase with a mandatory document (sales receipt or invoice) showing the

date and place of retail purchase of the product in order to obtain warranty service.

.

2. The validity of this warranty is subject to the following:

(a)-The claim must be initiated within eight (8) days of discovery of the potential

defect;

(b)- Every claim must be submitted to the FORMULA. dealer from which the prod-

uct was purchased, with the understanding, however, that the discretion as to

the acceptability of the claim is exclusively FORMULA’s ;

(c)-Only a FORMULA. Dealer can ship the allegedly defective product, with the

accompanying documentation.

Failure to comply with these procedures will invalidate the claim; in which case

the product will be made available to the owner for thirty (30) days and then de-

stroyed.

16

3. This warranty does not cover damages resulting from:

a. Incorrect transport and installation. Incorrect installation refers to failure

to follow the safety guidelines and instructions outlined in the Instructions

manual.

b. Unintended and inappropriate use of the product. Unintended and inap-

propriate use refers to use of the product for purposes different from those

for which it was specifically designed and manufactured. Some unintended

purposes include cross country and UCI sanctioned downhill races.

c. Use of materials or spare parts that do not carry the FORMULA trademark

NERO forks. FORMULA. shall not guarantee conformity, safety, service life

and performance of FORMULA NERO forks if materials and spare parts that

do not carry the FORMULA trademark and/or are non-compatible and/or

are not suitable and/or are not expressly authorized are used.

d. Lack of appropriate or reasonable maintenance or storage, washing with

harsh materials, use of corrosive agents, prolonged exposure to solvents.

e. Products on which the serial number and/or production code have been

altered, damaged and/or removed.

f. Modifications made by persons not duly authorized by FORMULA without

being approved by FORMULA.

g. Normal wear and tear or deterioration due to the use of the product.

h. The result of rider mishap or crash.

4. Retailers, wholesalers, importers or anyone else apart from FORMULA. may not

modify this warranty in any way.

5. This warranty does not affect the statutory rights of the consumer or any rights

the purchaser may have against the dealer pursuant to the sales contract.

6. The laws of Italy govern all matters arising out of or relating to this warranty. Any

disputes or legal actions by purchaser arising out of or relating to this warranty

shall be brought in court in Prato.

17

Information may be enhanced for improvement without prior notice. All rights reserved.

Le informazioni possono essere modificate senza preavviso. Tutti i diritti riservati.

www.rideformula.com

FORMULA S.a.s. di “Formula Group S.r.l.” & C.

Via Erbosa, 63 - 59100 Prato (Italia)

Tel. +39 0574 603 609

Fax +39 0574 611 046

Reg. Imprese Prato / C.F. / P.IVA 02081070977

PEC: [email protected]

Cap. Soc. 500.000,00 € i.v.

Table of contents

Other Formula Bicycle Accessories manuals

Formula

Formula MOD User manual

Formula

Formula R1 Racing User manual

Formula

Formula FD40292-20 User manual

Formula

Formula TECH SUSPENSION TJ2 User manual

Formula

Formula Linea User manual

Formula

Formula MD1 Manual

Formula

Formula 151239 Series User manual

Formula

Formula 4 Racing User manual

Formula

Formula THIRTYFIVE QR15 User manual

Popular Bicycle Accessories manuals by other brands

Specialized

Specialized Elite CylcoComputer user manual

Sigma

Sigma BC 16.16 manual

Playcore

Playcore Dero Setbacks installation instructions

VDO Cyclecomputing

VDO Cyclecomputing x3dw instruction manual

Cateye

Cateye RAPID X2 manual

buratti meccanica

buratti meccanica Clorofilla Trail Use and maintenance manual