Formula MOD User manual

1

MANUALE ISTRUZIONI - OPERATING MANUAL - MANUEL D’INSTRUCTIONS -

BETRIEBSANLEITUNG - MANUAL DE INSTRUCCIONES

2

TORX® è un marchio registrato di CAMCAR / TEXTRON INC. Tutti i marchi appartengono ai

rispettivi proprietati.

TORX® is a registered trademark of CAMCAR / TEXTRON INC. All trademarks are the property

of their respective owners.

TORX® est une marque déposée de CAMCAR / TEXTRON INC. Toutes les marques appartien-

nent aux propriétaires respectifs.

TORX® ist ein registriertes Warenzeichen der CAMCAR / TEXTRON INC. Alle Warenzeichen

gehören den respektiven Eigentümern an.

TORX® es una marca registrada de CAMCAR / TEXTRON INC. Todas las marcas pertenecen a

los respectivos propietarios.

3

WARNING! BEFORE INSTALLING AND USING THIS NEW FORMULA S.a.S PRODUCT IT

IS CRITICAL TO YOUR SAFETY THAT YOU READ AND STRICTLY ADHERE TO THE IN-

STRUCTIONS

IN THIS MANUAL. FAILURE TO DO SO COULD CAUSE SERIOUS INJURY

AND/OR AFFECT YOUR LEGAL RIGHTS.

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE AS IT CONTAINS

INFORMATION CRITICAL TO YOUR SAFETY.

WARNING! DO NOT INSTALL OR DISASSEMBLE THIS FORMULA S.a.S PRODUCT ON

YOUR OWN!

Always seek the help of a professional mechanic. If you decide to ignore this import-

ant safety warning, keep in mind that you are doing so EXCLUSIVELY at your own risk

and strictly follow all Formula installation and disassembly instructions.

Note: AS WITH ANY MANUAL, THIS MAY BE PERIODICALLY UPDATED. CONTACT

YOUR FORMULA S.a.S DEALER, OR CHECK OUR WEB SITE, (www.rideformula.com)

TO RECEIVE ALL SUCH UPDATES.

This manual contains information for the safe use, proper mounting and maintenance

of MOD shock sets. Following the rules contained in this manual will ensure the safest

use, best performance

and longest life of your MOD shock and will avoid the most common product use/

maintenance inconveniences and problems.

Carefully follow the SAFETY GUIDELINES to assure appropriate use and service of

Mod shock guidelines

MOD SHOCK SAFETY GUIDELINES

• MOD shocks sets produced by FORMULA S.a.S are designed exclusively for use on

two wheels bicycles. Any other use is to be considered hazardous. FORMULA S.a.S

shall not be held liable for any consequences from improper usage.

• The lifespan of MOD shock depends on many factors, such as rider size and weight,

spring and frame used and normal wear and tear on the bicycles.

• Check the condition of the spring regularly and replace it when necessary.

• Impact, falls, excessive, improper or harsh use of the bicycle may compromise the

structural integrity of the shocks, significantly reducing their lifespan. Short life-

wheel components need to be replaced more often.

• Have the shock regularly inspected by a qualified mechanic for any cracks, deforma-

tion, signs of fatigue or wear.

• If inspection reveals any deformation, cracks, signs of impact or stress, no matter

how slight, immediately replace (not repair) the component. Excessively worn com-

ponents also require immediate replacement.

• The frequency at which inspection is required depends on many factors. Ask a FOR-

MULA S.a.S dealer to recommend an inspection and service schedule that is right

for you.

• Use of the product by individuals who weigh more than 120kg/265Ibs is not recom-

mended. If you weigh more than 120kg/265Ibs be especially careful and have the

bike inspected more frequently.

• Parts which have been bent or damaged in an accident or as the result of impact,

must be immediately replaced with genuine FORMULA S.a.S replacement parts.

• Check with a qualified mechanic to ensure that the selected MOD shock is suitable

for the required type of use and to establish an inspection and service schedule that

is right for you.

• Tools supplied by other manufacturers for wheels similar to MOD shock may not be

TRANSLATION OF THE ORIGINAL INSTRUCTION MANUAL

4

compatible with MOD shock. Likewise, tools provided by FORMULA S.a.S may not be

compatible with components/wheels supplied by other manufacturers. Check with a

qualified mechanic or 5 tool manufacturer to ensure compatibility before using tools

supplied by one manufacturer on components/wheels supplied by another manu-

facturer.

• Failure to verify compatibility of the tools may cause the component to work incor-

rectly or break, resulting in an accident, personal injury or death.

• The user of MOD shock expressly recognizes that there are risks inherent in bicycle

riding, including but not limited to failure of a bike component, resulting in an acci-

dent, personal injury or death.

• By purchasing and using these MOD shock, the user expressly, voluntarily and know-

ingly accepts and/or assumes these risks, including but not limited to the risk of

passive negligence on the part of FORMULA S.a.S, i.e. for hidden, latent or obvious

defects and exempts FORMULA S.a.S from liability to the fullest extent permitted by

law against any resulting damage.

• Ensure there are no damaged or loose hardware.

• Always make sure that the shock is marked “MOD”.

• Make sure the shock is true before use.

• Carefully read the FORMULA MOD shocks instructions before use.

• Carefully follow the scheduled maintenance program as indicated in the relative para-

graph.

• Always use genuine FORMULA S.a.S replacement parts.

ENVIRONMENTAL NOTES

In order to protect the environment, please follow these simple instructions to cor-

rectly dispose of FORMULA S.a.S products:

1) The packaging does not require special disposal because it is not dangerous in any

way; we suggest recycling paper and plastic.

2) It is also recommended to recycle the metal parts after use. For both points men-

tioned above, it is recommended to dispose of the waste following national regula-

tions through the appropriate specialized waste disposal companies.

CHECK BEFORE EVERY RIDE:

In order to guarantee your health and maximum enjoyment, check before every ride

that FORMULA MOD shock absorber is ready.

• Make sure the shock absorber is clean: using water and neutral soap, clean the out-

side of the suspension by hand. Subsequently, after a splash of water, act with a dry

and soft cloth to remove the residues;

ATTENTION: do not use solvents or degreasers. They can damage external sur-

faces. Do not use high pressure water sprayers directly on the shock absorber

joints, in particular near the hydraulic seals which could be seriously damaged and

compromise the functioning of the suspension.

• Inspect the outside of the shock absorber. Check if there are no breakages and / or

damages. If present, contact the FORMULA dealer immediately for inspection or re-

pair. Do not use the shock absorber in this case.

• Make sure that the frame coupling screws are tightened to the correct tightening

torque as recommended by the frame manufacturer. The hardware does not play

with the coupling screws. If yes, immediately replace them, see manual at

paragraph “b”.

• Also make sure that the coil spring is properly preloaded as recommended by para-

graph “e”.

5

ENVIRONMENTAL NOTES

In order to protect the environment, please follow these simple instructions to

correctly dispose of FORMULA S.a.S products:

1) The packaging does not require special disposal because it is not dangerous in any

way; we suggest recycling paper and plastic.

2) It is also recommended to recycle the metal parts after use.

For both points mentioned above, it is recommended to dispose of the waste following

national regulations through the appropriate specialized waste disposal companies.

INDEX:

1.1 Formula hardware installation;

1.2 Installing shocks on a MTB frame;

1.3 SAG and Adjustments;

1.4 Hydraulic regulation:

1.4.1 Rebound;

1.4.2 Compression;

1.4.3 Lockout;

1.5 CTS (compression tuning system) replacement;

1.6 Spring replacement;

1.7 Maintenance intervals

1.8 Formula spacer for reduction stroke

1.9 Problems - Causes - Remedies

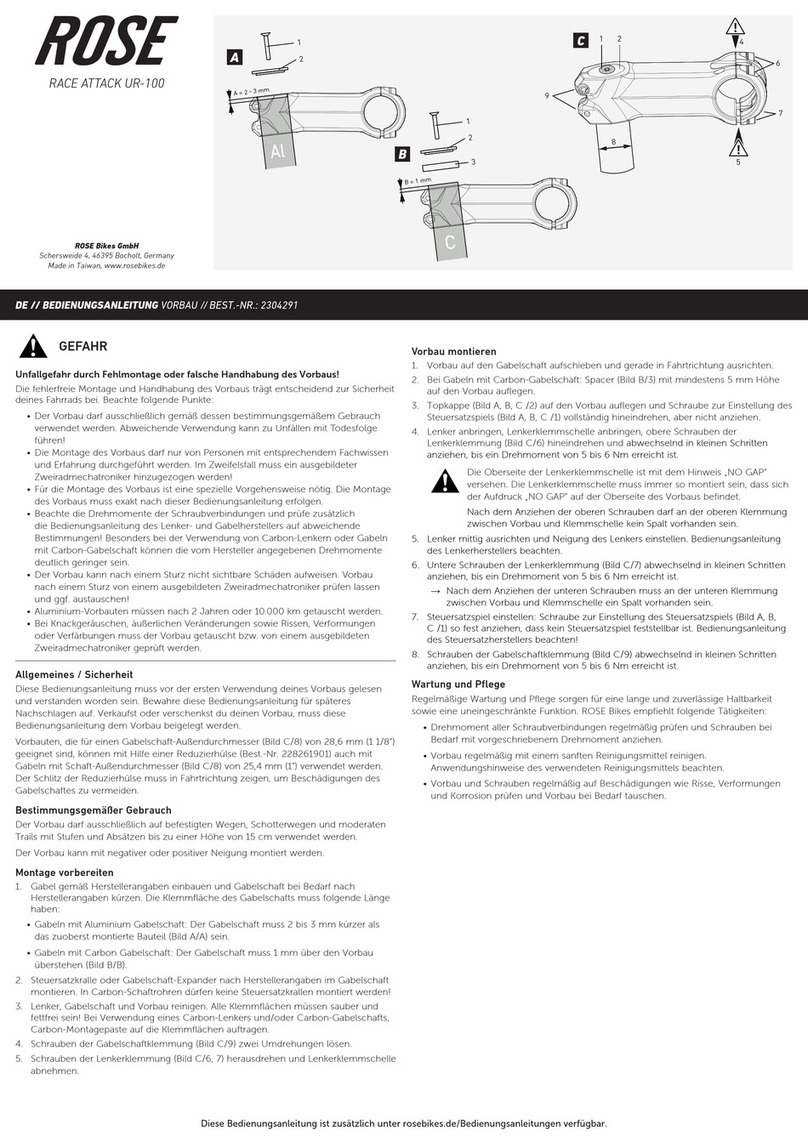

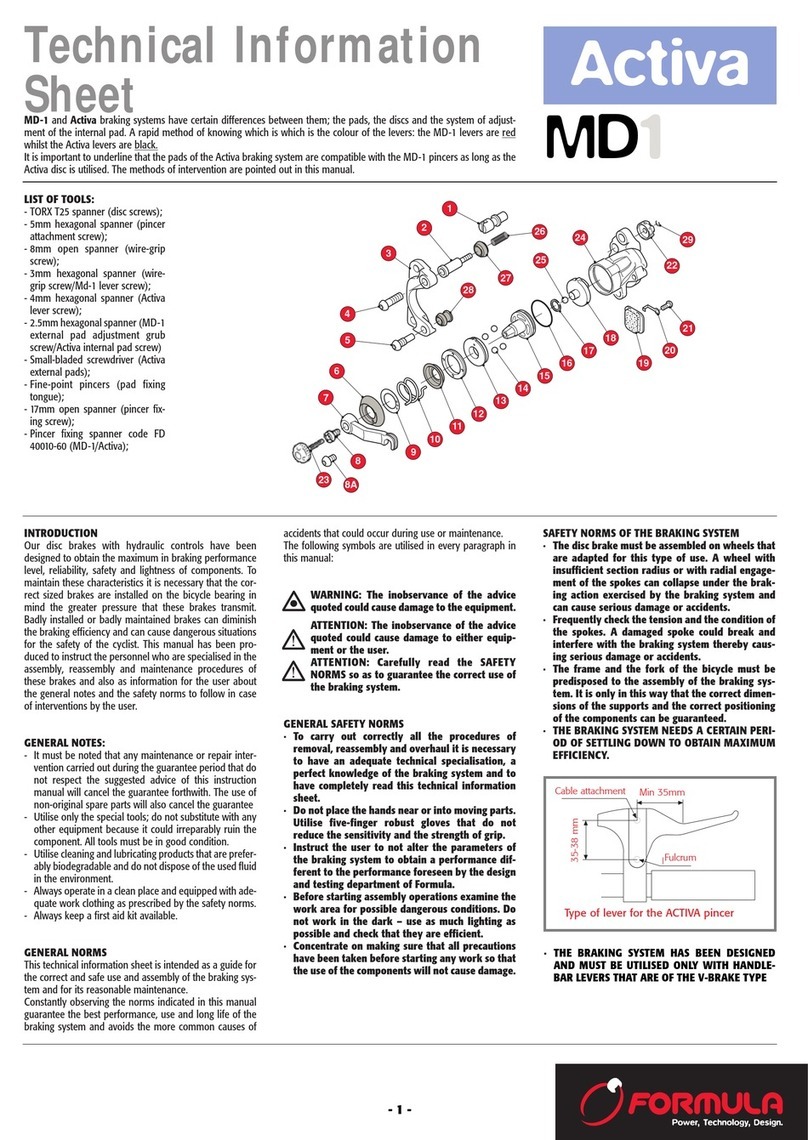

1.1 Formula hardware installation:

Formula hardware kit may differ depending on the customer’s request regarding its

frame. The bushings (DU) are already installed on the rear shock absorber.

For STANDARD attack shocks, the kit includes (figure A):

a) n.2 assembly pins;

b) n.4 spacers;

c) n.4 Orings;

For TRUNNION shocks:

a) n.1 mounting pin;

b) n.2 spacers;

c) n.2 Orings.

ATTENTION: The screws for the TRUNNION connection are supplied by the

frame manufacturer. FORMULA assumes no responsibility for damage or mal-

functions due to the condition of these screws.

Fig. A

6

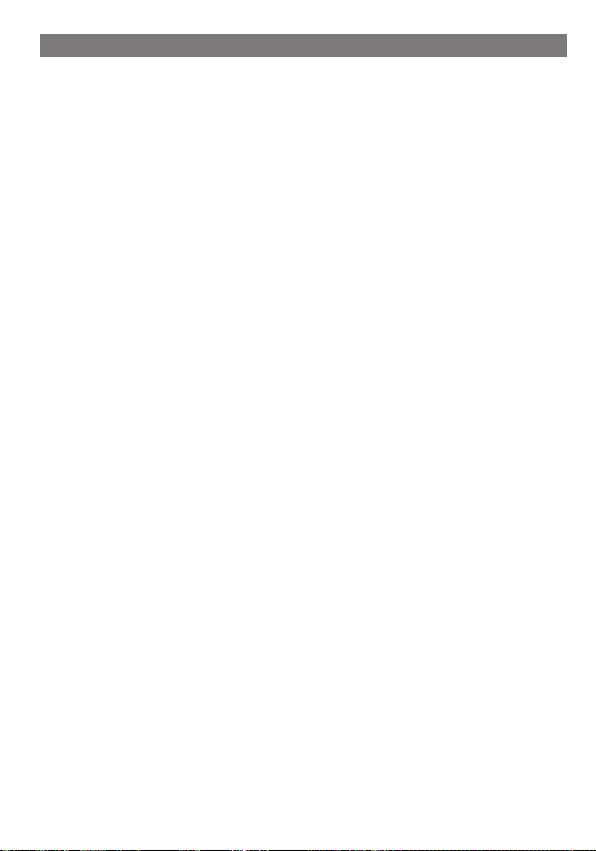

INSTALLATION PROCEDURE (do the same also for the opposite part of the shock):

1) Insert the pin into the eye of the shock (figure B);

2) Insert Orings in the seats of the spacers: apply Formula grease on the OR seat (figure

C), then insert and check the homogeneous adhesion to the surface of the groove.

Then apply Formula grease on the OR too (figure D);

3) Inserting spacers on mounted pin (figure E);

End procedure

Fig. B

Fig. C Fig. D

Fig. E

GREASE

GREASE

7

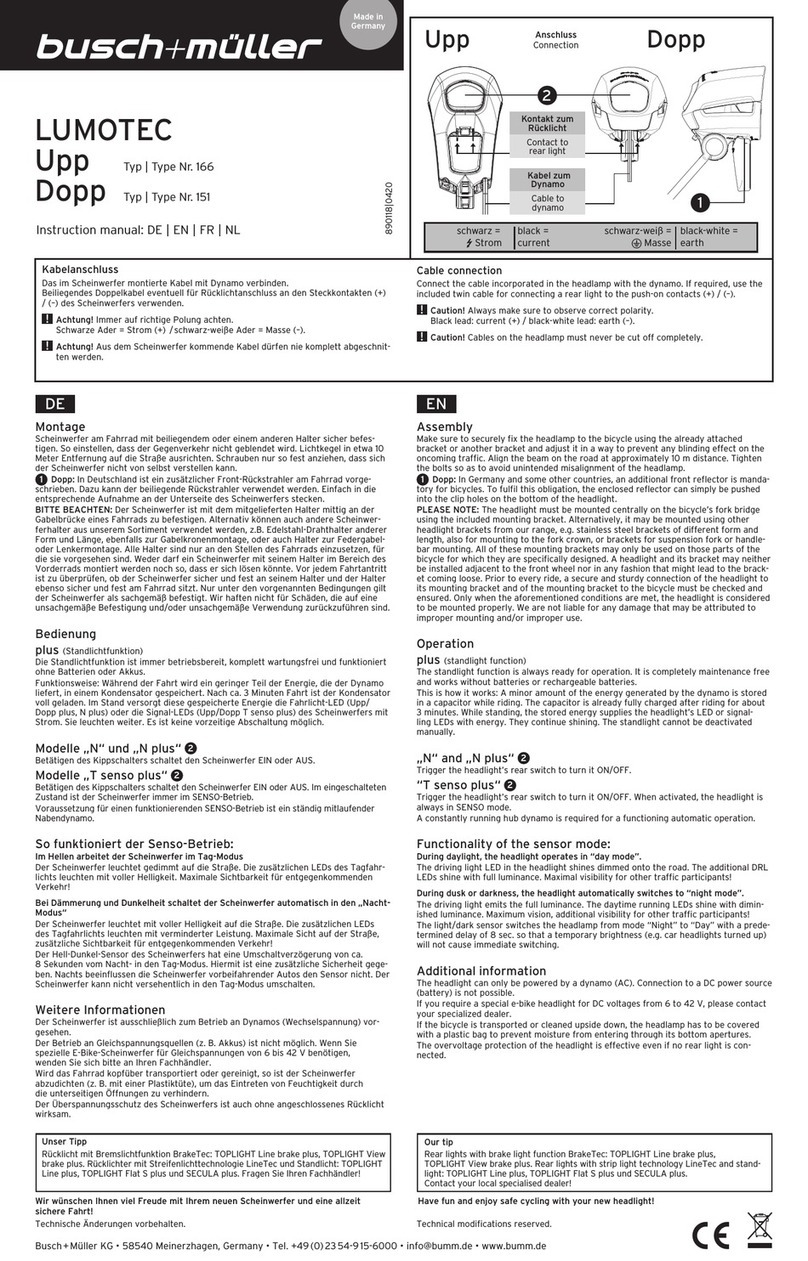

1.2 Installing shock on a MTB frame:

ATTENTION: Suspension setting should be different between different bi-

cycle manufacturer. All maintenance operations must be carried out solely by

personnel authorized by FORMULA S.a.S.

FORMULA assumes no responsibility for breakages and damage to people and / or

things due to this non-compatibility. The result of such non-compliance can lead

to DEATH. Contact the FORMULA Dealer and don’t use the shock.

WARNING: FORMULA recommend DO

NOT INSTALL THE SHOCK on frame

with the eyelets as showed in figure on

the left. The axes of the eyelets MUST

BE perpendicular to the same plane as

showed in figure on the right.

FORMULA assumes no responsibility for

breakages and damage to people and / or

things due to non-compliance. This is valid

until further notice.

8

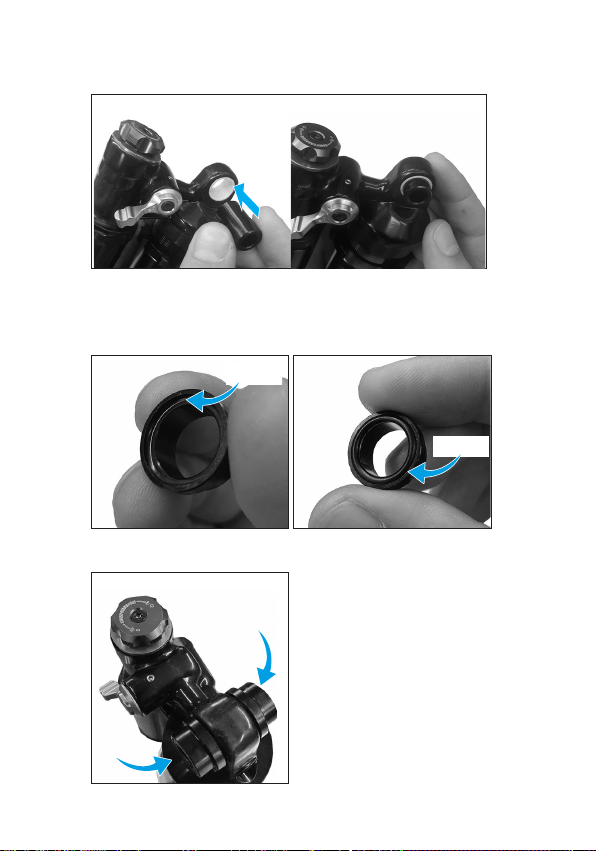

If MOD shock is not already supplied on the bicycle, it’s necessary check the frame

compatibility:

1) Remove the spring from the shock as written in paragraph “e”;

2) Install the Formula hardware on the shock as written in paragraph “b” according to

the specific measures of the frame;

3) Insert MOD shock into the frame and tighten the screws of it (figure F).

4) Slowly Compress and extend the rear part of the frame making the whole stroke.

Inspect if there is interference with the frame (figure G);

5) Remove the shock from the frame;

6) Install the spring with the correct preload as showed in paragraph “e” and install

MOD shock.

End procedure

Fig. F Fig. G

9

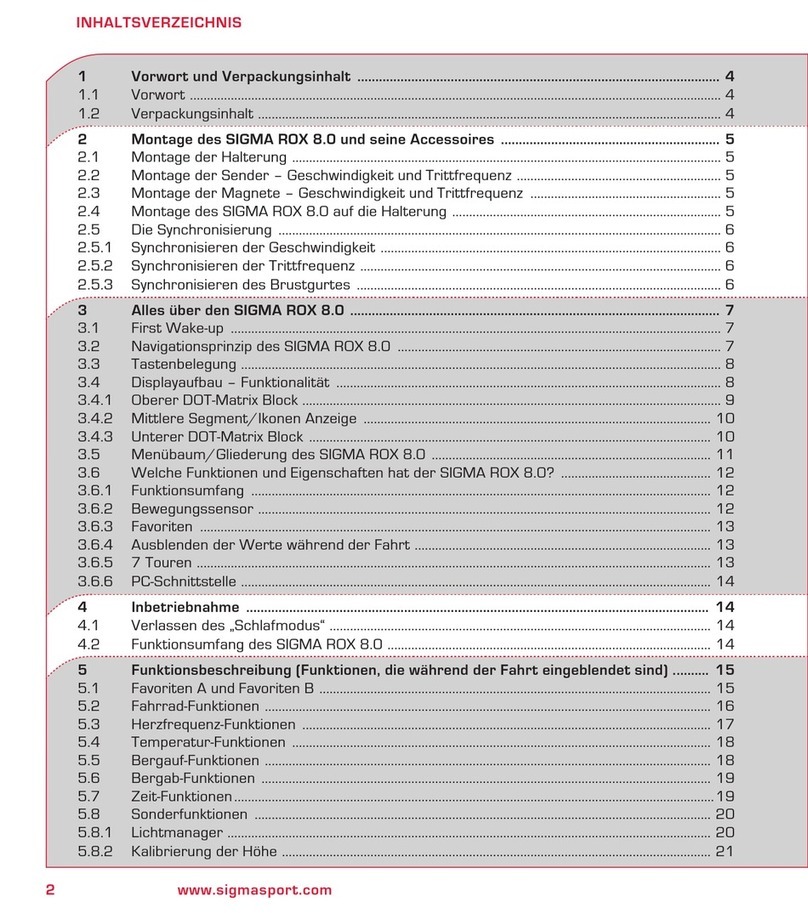

1.3 SAG and adjustments:

Detecting the SAG can be useful to have an initial idea of the response of the shock

absorber (complete with spring) with respect to our weight and the cycling discipline

that you want to practice.

Here is the measurement procedure:

a) Measure the distance between the two

eyelets of the shock absorber (eye-to-eye,

in mm) of the rear shock absorber moun-

ted on the bike (figure H).

b) Wearing your own complete

equipment for MTB output

and with the help of a per-

son, position yourself on

the bike in a normal riding

position and measure the

distance between the two

eyelets which will necessar-

ily be decreased (figure I).

c) Taking these two measurements, calculate the SAG;

Example: MOD shock, Length x Stroke: 230x65 mm. 1° measure: 230 mm;

2° measure: 210,5 mm;

Difference between the measures: 19,5 mm.

Use this formula: SAG(%)=

(230 - 210,5)

(Shock stroke) x 100

Fig. H

Fig. I

10

The result is 30% of SAG. Here below is a reference table for measurement:

STROKE 15%SAG 20%SAG 25%SAG 30%SAG 35%SAG 40%SAG

55 mm 8,25 mm 11 mm 13,75 mm 16,5 mm 19,25 mm 22 mm

65 mm 9,75 mm 13 mm 16,25 mm 19,5 mm 22,75 mm 26 mm

75 mm 11,25 mm 15 mm 18,75 mm 22,5 mm 26,75 mm 30 mm

FORMULA recommends 30% of SAG for the Enduro / Gravity discipline. For the trunnion

attack, it will have a different length but the calculation formula remains the same.

ADJUSTMENTS:

If the SAG is not the desired one, here’s how we can operate (figure J):

• To increase the value of SAG, need

to decrease the preload: rotate

with the RIGHT hand the preload

nut COUNTERCLOCKWISE (blue ar-

row), taking care not to drop below

the minimum preload value (2 mm).

If this does not allow the desired

value to be obtained, a lower stiff-

ness spring (lbs/in) must be used.

• To decrease it instead, rotate the

threaded ring CLOCKWISE (orange

arrow) making sure not to exceed

with the preload in addition to the

maximum allowable (5 mm). Here

too, if we fail to obtain the target

value, it will be necessary to change

the spring with a higher stiffness.

For the coil replacement consult paragraph “e”.

Fig. J

11

1.4 HYDRAULIC REGULATION:

ATTENTION:

Shock setup may vary between different bicycle manufacturers.

1.4.1 REBOUND:

The extension adjustment is provided on

the head of the shock absorber, acting on

the appropriate RED color register (figure K).

This adjustment concerns the second phase

of the shock cycle, which occurs following a

compression.

The extension range is intrinsically connec-

ted to the stiffness (lbs/in) of the coil spring

used: a spring with a higher stiffness value

corresponds to a higher elastic response

than it and consequently a higher hydraulic

force in extension will be required for the

shock absorber. To increase this force, turn

the RED knob CLOCKWISE.

Higher the stiffness value of the spring, the faster the rebound will be for the same

click. Going for example from 400 lbs/in to 450 lbs/in to obtain the same rebound we

will have to turn the knob clockwise one or two clicks. Vice versa for a spring of lower

stiffness.

FORMULA recommends with initial configuration, to close the whole register clockwise

and to unscrew anticlockwise by 6 clicks.

1.4.2 COMPRESSION:

The compression adjustment is provided

on the shock absorber body, acting on the

appropriate on the CTS with BLUE register

(figure L).

The compression phase is the first that oc-

curs following, for example, an impact with

the ground.

The compression range here too can be

influenced by the spring. Turn the knob

CLOCKWISE to increase the hydraulic force

that the shock absorber performs when it is

compressed; this allows for higher hydraulic

support in the rear of the bicycle.

Conversely, by opening the register, for example, you will have less support.

FORMULA recommends as an initial configuration, to close the whole register in a

CLOCKWISE direction and to unscrew in an anticlockwise direction by 9 clicks.

If you are not satisfied with the range available, FORMULA offers the possibility of in-

tervening on compression thanks to CTS (Compression Tuning System) technology. For

more information, visit the FORMULA website.

Fig. K

Fig. L

12

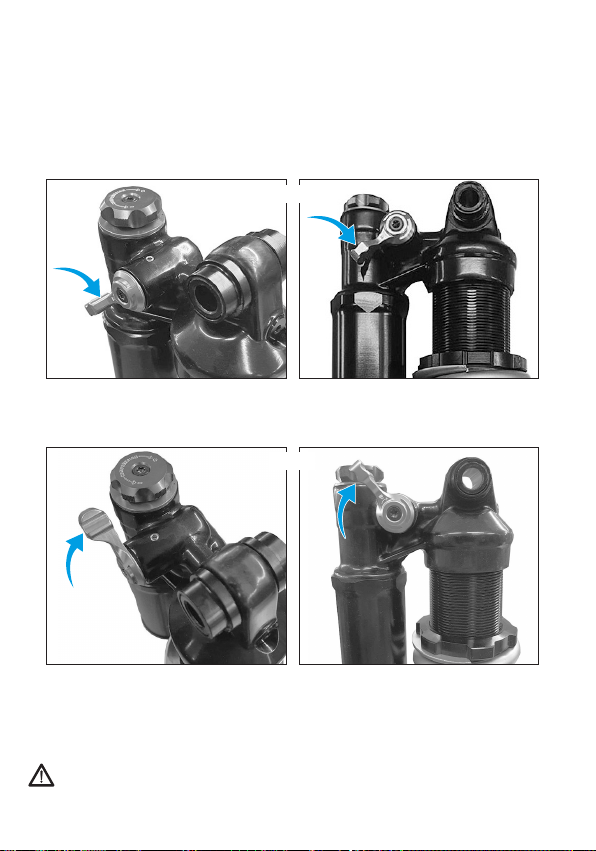

1.4.3 LOCKOUT:

The lockout adjustment allows for greater support from the shock absorber to de-

crease energy dissipation during the pedaling phase and consequently increase effi-

ciency. It is positioned on the shock body, acting on the GOLD-colored lever.

There is the possibility of having 2 positions:

• OPEN position is obtained by turning anticlockwise: we recommend using this config-

uration during the descent or technical climbs (figure M).

• CLOSED position is obtained by turning clockwise: we recommend using this config-

uration while pedaling.

The hydraulic system designed for the MOD rear shock absorber also includes the

THRESHOLD (or lockout force) function: it acts when the lockout is active; exceeding

a pressure value designated inside the shock absorber, a passage opens allowing the

reduction of this avoiding breakage of the suspension.

ATTENTION: If anomalies are found on the adjustments (eg. Knob does not turn)

contact a FORMULA dealer who will inspect it and / or carry out maintenance.

Fig. M

Fig. N

13

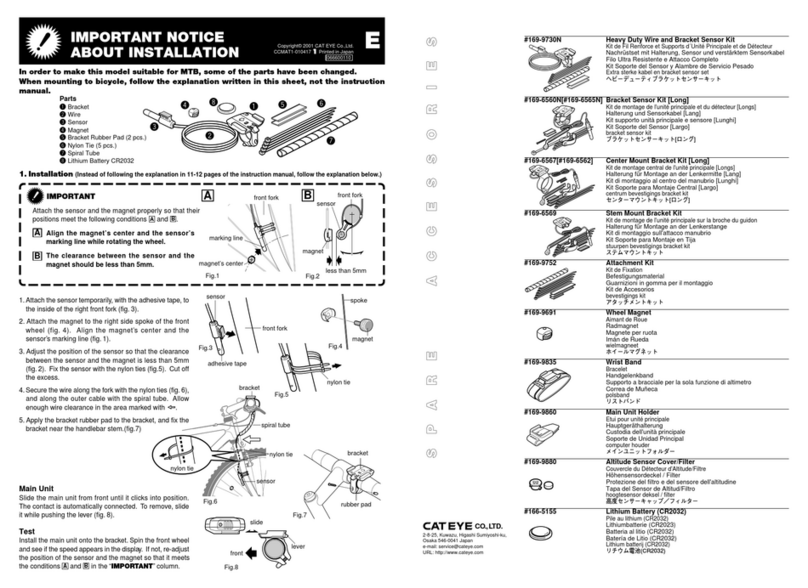

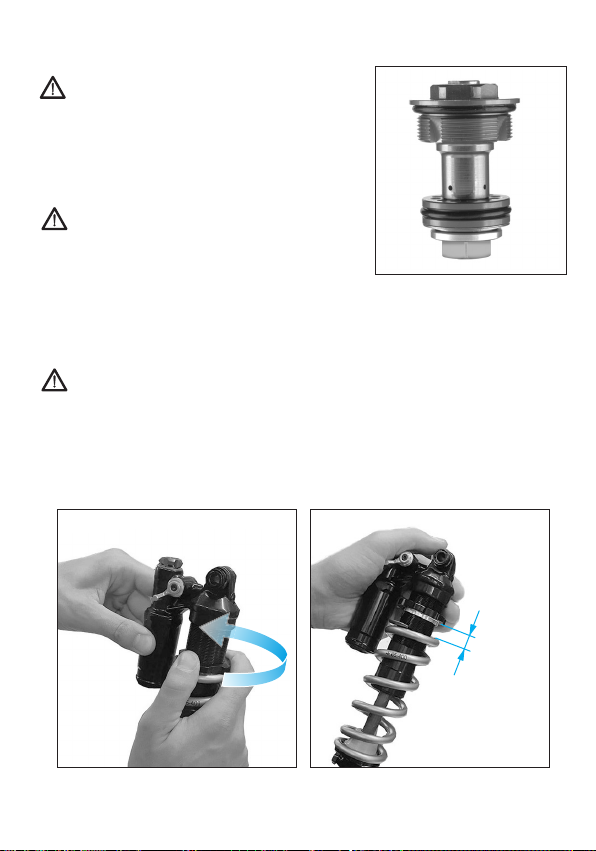

1.5 CTS (COMPRESSION TUNING SYSTEM) REPLACEMENT:

ATTENTION: FORMULA is not responsible for

any damage to parts of the shock absorber

due to this operation and/or to people. Contact a

specialized mechanic. Strictly follow this proced-

ure. Failure to comply can cause suspension mal-

functions and cause DAMAGE AND DEATH.

ATTENTION: Use the ONLY FORMULA suspension

pump for this operation.

Follow the entire procedure shows on the For-

mula website or Formula’s Youtube channel.

1.6 SPRING REPLACEMENT:

ATTENTION: FORMULA declines all responsibility for the use of a different spring to

the FORMULA one, suitably designed and tested with our products.

The procedure for replacing the coil spring on the rear shock absorber is as fol-

lows:

1) Remove the shock from the frame;

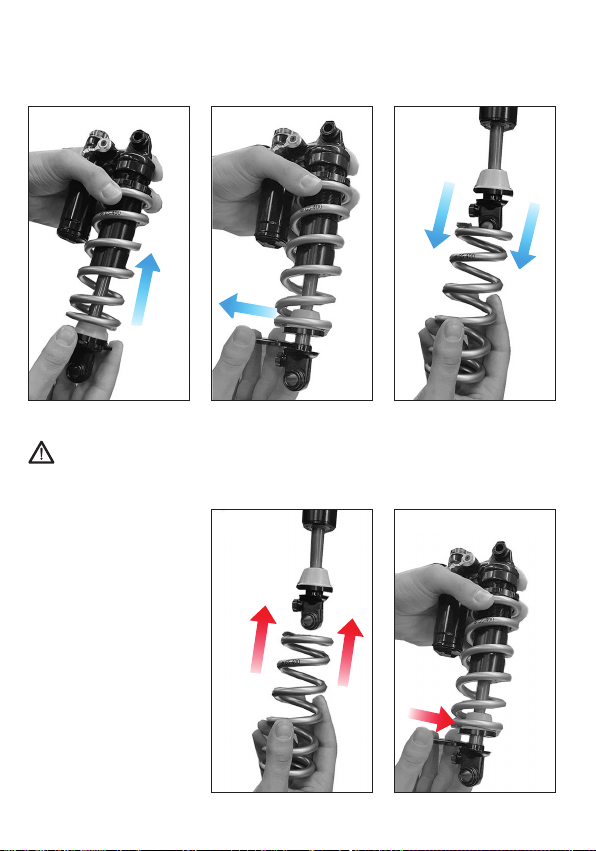

2) Unscrew the spring preload ring nut COUNTERCLOCKWISE (figure O) until the spring

is free to move (figure P);

Fig. O Fig. P

14

3) Push up and keep the spring (figure Q) while removing the spring locking ring nut

(figure R) by sliding it off the rod and remove the spring from the shock absorber. If

the hardware is too wide, it need to remove it before the spring;

ATTENTION: during this operation do not scratch the stem. This could compro-

mise the suspension and damage it.

4) Insert the spring to be

installed (figure T) and

keep it up and reinsert

the locking ring (figure

U);

Fig. Q Fig. R Fig. S

Fig. T Fig. U

15

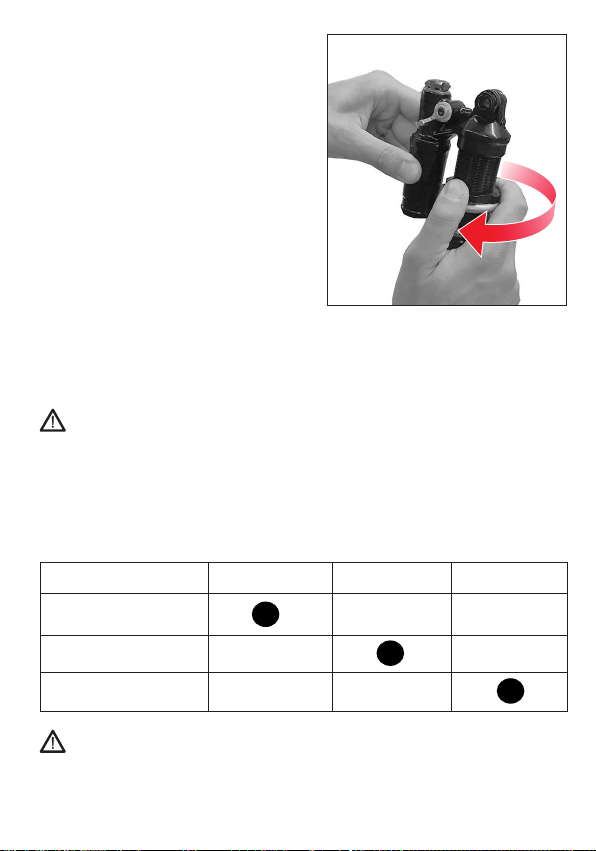

5) Screw the threaded ring in a CLOCKWISE

direction (figure V), following the FOR-

MULA directive: preload min. Permissible

2 mm, preload max. Allowable 5 mm.

Each turn is 1,25 mm preload.

For control the preload measure the dis-

tance between the body and the thread

ring before and after applying the preload

(the difference must be in the range writ-

ten above);

6) If necessary, put the cup containing the

end stroke bumper in correct position.

End procedure

1.7 Maintenance interval:

To guarantee and maintain the characteristics and behavior of the rear shock absorber

during normal conditions of use, FORMULA recommends following a product mainte-

nance interval.

ATTENTION: to use the rear shock absorber in extreme conditions frequent-

ly, maintenance operations must be repeated more frequently. Furthermore,

using spare parts, high pressure washing methods, solvents and lubricants that

are NOT RECOMMENDED BY FORMULA also drastically reduces the maintenance

interval and also the suspension life. FORMULA therefore RECOMMENDS ONLY

ORIGINAL spare parts and FORMULA lubricating products. FORMULA recommends

contacting a mechanic specialized in the FORMULA technical service, in agreement

with FORMULA with all the specifications for maintenance.

Here are the service intervals below, to ensure a minimum of maintenance:

CAUTION: FORMULA strongly recommend for extreme condition of usage, as

Bikepark, DH and Freeride and in worst environmental conditions as extremely

dry, dusty or wet muddy, to perform maintenance earlier than the intervals listed

above. For more information on the types of interventions to be performed, consult

the FORMULA website.

Fig. V

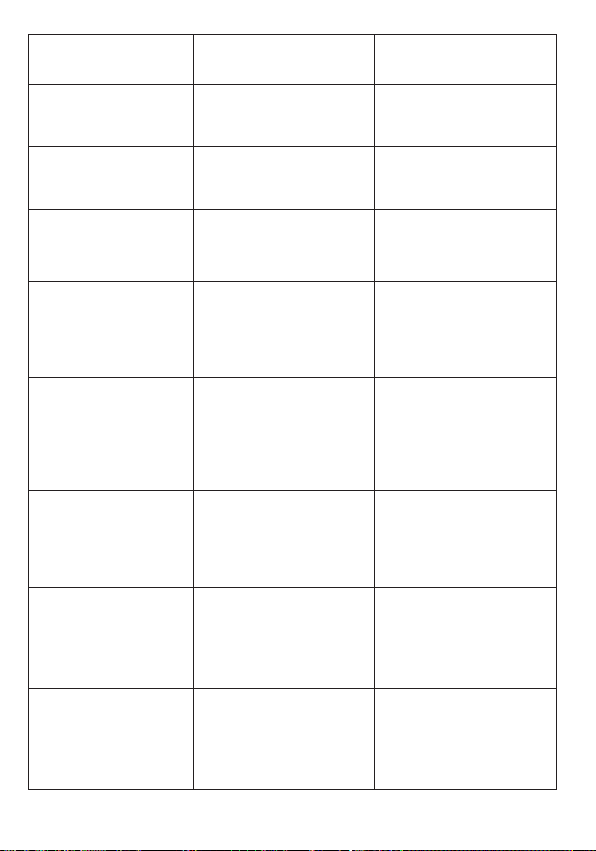

Procedure Every ride Every 30 hrs/ Every 200 hrs/

3 months 1 year

External cleaning with

water and neutral soap

and visual inspection

SAG, spring preload and

damper setting controls

full shock service

16

1.8 Formula spacer for reduction stroke:

Formula MOD is provided with 55 mm or 65 mm standard strokes. For frames who

require different one, Formula offers stroke reduction spacers in the following dimen-

sions: 2.5 mm, 5 mm and 7.5 mm.

Formula reduction stroke spacer can be easily installed and removed without aid of

tools.

WARNING: FORMULA strongly recommend to not use this spacer when it’s not

required. Please follow the instruction below for the correct installation, do not

fit the spacer in other position.

The installation procedure is:

• Remove the spring preload;

• Remove the spring ring and the spring;

• Push up the washer with the bumper close to the cylinder;

• Insert the spacer along the stem by hand under the washer in the correct way as

showed in figure, this allows to connect these components each other;

• Install the spring;

• Insert the spring ring under the spacer with the flat surface facing the spring;

17

• Pull down the group with bumper, washer and spacer against the spring ring;

• Pull down the spring against the spring ring and apply the correct spring preload;

End procedure

1.9 PROBLEMS - CAUSES – REMEDIES:

This paragraph reports some problems that may occur when using the shock, their

possible causes and remedy.

ATTENTION: The operations listed below and accompanied by this symbol must

be performed exclusively by Authorized Service Centers.

Following a jump, the

rear hurls me forward

Rebound too excessive Turn CLOCKWISE the re-

bound adjuster by 1 or 2

clicks

The spring is free to ro-

tate axially around the

shock

Preload below the mini-

mum allowed

Turn CLOCKWISE the thre-

aded ring

The shock absorber has

little sensitivity and is

very supported on the

back, the bike is too un-

balanced on the front

Spring too preloaded or

compression too high

Turn the threaded ring

counterclockwise. Or turn

the CTS compression regi-

ster counterclockwise by 1

or 2 clicks

18

I can’t get the sag I wa-

nted

Spring too smooth or too

hard

Change spring

Play on the compression

adjuster

The screw has come loose Tighten the screw with a

TORX T10 play on the re-

bound adjuster

Play on the rebound

adjuster

The screw has come loose Tighten the screw with a

TORX T10 play on the re-

bound adjuster

Play on the lockout lever The screw has come loose Tighten the screw with a

TORX T10 play on the re-

bound adjuster

Lockout locks less or no

longer works

Pressure loss inside the

suspension

Do not use the shock ab-

sorber. Contact a specia-

lized FORMULA center for

inspection and mainte-

nance

CTS does not satisfy my

desired range of settin-

gs

Make sure to perform a

descending test and check

Change the CTS, see the

website: www.ridefor-

mula.com. FORMULA

recommends contacting a

specialized center for this

operation.

Oil leak Leakage from the seals Do not use the shock

absorber. Contact a

specialized FORMULA

center for inspection and

maintenance

Ribbed rod Debris or contacts have

carved the anodized sur-

face

Do not use the shock

absorber. Contact a

specialized FORMULA

center for inspection and

maintenance

The shock seems too

soft or deflated, causing

me to make too many

stops

Check and reset the pres-

sure of 95 psi in the tank

with the exclusive help of

the FORMULA suspension

pump.

If the problem persists do

not use the shock absor-

ber. Contact a specialized

FORMULA center for

inspection and mainten

19

READ CAREFULLY!

FORMULA S.a.S provides the original purchaser of its Shock with a limited warranty

that the Shock is free of defects in material and/or workmanship for a period of two

years from date of purchase.

WHAT PROTECTION DO I RECEIVE FROM THE WARRANTY?

FORMULA S.a.S will, at its discretion, repair or replace the defective product under

warranty

WARRANTY CONDITIONS AND LIMITATIONS

1. FORMULA S.a.S guarantees its new products to be free from defects in materials or

workmanship for 24 months from the date of purchase. You must establish proof

of purchase with an original sales document (sales receipt or invoice) showing the

date and place of retail purchase of the product in order to obtain warranty service.

FORMULA S.a.S gives no guarantee of whatever nature for non-new products.

2. The validity of this warranty is subject to the following:

(a)-The claim must be notified within eight (8) days of discovery of the potential

defect;

(b)-Every claim must be submitted to the FORMULA S.a.S Dealer from which the

product was purchased, with the understanding, however, that the discretion

as to the acceptability of the claim is exclusively FORMULA’s; Warranty claims

for products purchased directly from Formula shall be processed by FORMULA

S.a.S.

(c)-Only a FORMULA S.a.S Dealer can ship the allegedly defective product to the

manufac-turer, with the accompanying documentation.

Failure to comply with these procedures will invalidate the claim; in which case

the product will be made available to the owner for thirty (30) days and then des-

troyed.

3. This warranty does not cover damages resulting from:

a. Incorrect transport and installation. Incorrect installation refers to failure

to follow the safety guidelines and instructions outlined in these instruc-

tions manual and or on the web-site www.rideformula.com.

b. Unintended ad inappropriate use of the product. Unintended ad inappropri-

ate use refers to use of the product for purposes different from those for

which it was specifically designed and manufactured having regard to rea-

sonably foreseeable use. Unintended purposes include, but are not limited

to, cross country UCI sanctioned downhill races.

20

c. Use of materials or spare parts that do not carry the Formula trademark

for LINEA wheels. FORMULA S.a.S shall not guarantee conformity, safety,

service life and performance of Formula LINEA wheels if materials and spare

parts that do not carry the Formula trademark and/or are non-compatible

and/or are not suitable and/or are not expressly authorized are used.

d.Lack of appropriate or reasonable maintenance or storage, washing with

harsh materials, use of corrosive agents, prolonged exposure to solvents.

e. Products on which the serial number and/or production code have been

altered, damaged and/or removed.

f. Modifications made by persons not duly authorized by Formula without be-

ing approved by Formula.

g. Normal wear and tear or deterioration due to the use of the product.

4. Retailers, wholesalers, importers or anyone else apart from FORMULA S.a.S may

not modify this warranty in any way.

5. This warranty does not affect the statutory rights of the consumer or any rights

the purchaser may have against the dealer pursuant to the sales contract.

6. The laws of Italy govern all matters arising out of or relating to this warranty. Any

disputes or legal actions by purchaser arising out of or relating to this warranty

shall be brought exclusively before the court of Prato, Italy.

Table of contents

Other Formula Bicycle Accessories manuals

Formula

Formula THIRTYFIVE QR15 User manual

Formula

Formula Linea User manual

Formula

Formula R1 Racing User manual

Formula

Formula 4 Racing User manual

Formula

Formula 151239 Series User manual

Formula

Formula MD1 Manual

Formula

Formula NERO R User manual

Formula

Formula TECH SUSPENSION TJ2 User manual

Formula

Formula FD40292-20 User manual

Popular Bicycle Accessories manuals by other brands

Bowers & Wilkins

Bowers & Wilkins BIKE.GUARD CURV manual

Ergon

Ergon BA3 User instructions

Rose electronics

Rose electronics XTREME GRAND TOUR CROMO owner's manual

Sigma

Sigma ROX 11.1 EVO Short manual

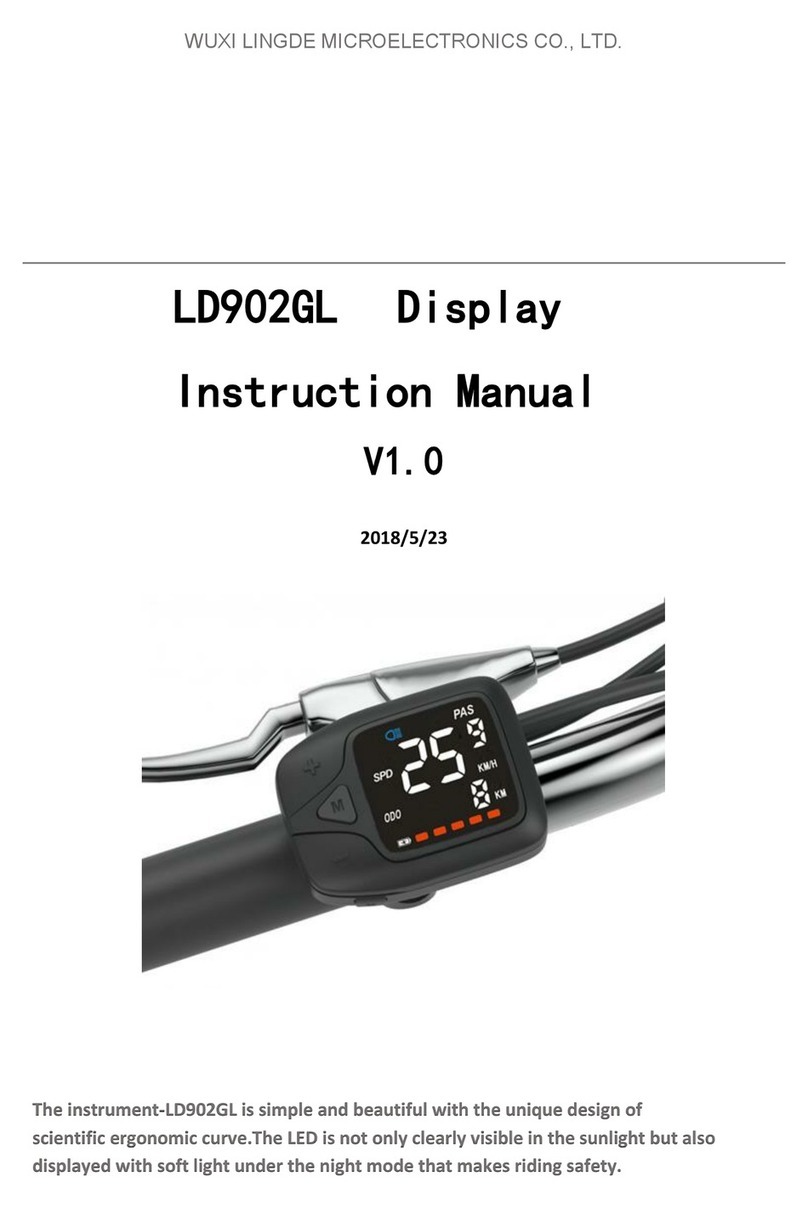

Wuxi LingDe Microelectronics

Wuxi LingDe Microelectronics LD902GL instruction manual

ERGOTEC

ERGOTEC UP & DOWN 3 Assembly and safety instructions