Formula THIRTYFIVE QR15 User manual

MANUALE ISTRUZIONI

OPERATING MANUAL

MANUEL D’INSTRUCTIONS

BETRIEBSANLEITUNG

MANUAL DE INSTRUCCIONES

29"

17

WARNING! BEFORE INSTALLING AND USING THIS NEW FORMULA S.a.s. PRODUCT

IT IS CRITICAL TO YOUR SAFETY THAT YOU READ AND STRICTLY ADHERE TO THE IN-

STRUCTIONS IN THIS MANUAL. FAILURE TO DO SO COULD CAUSE SERIOUS INJURY

AND/OR INVALIDATE YOUR LEGAL RIGHTS.

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE AS IT CONTAINS

INFORMATION CRITICAL TO YOUR SAFETY.

WARNING! DO NOT INSTALL OR DISASSEMBLE THIS FORMULA S.a.s. PRODUCT ON

YOUR OWN!

Always seek the help of a professional mechanic. If you decide to ignore this impor-

tant warning, keep in mind that you are doing so EXCLUSIVELY at your own risk.

Note: AS WITH ANY MANUAL, THIS ONE MAY BE UPDATED. CONTACT YOUR FORMU-

LA S.a.s. DEALER, OR CHECK OUR WEB SITE, (www.formula-italy.com) TO RECEIVE

ANY SUCH UPDATES.

This manual contains information for the safe use, proper mounting and maintenance of THIR-

TYFIVE forks. Following the rules contained in this manual will ensure the safe use and longest

life of your THIRTYFIVE forks.

Carefully follow the SAFETY GUIDELINES to assure appropriate use and service of

THIRTYFIVE forks.

In this handbook you will find the following safety symbols:

CAUTION: Directs your attention toward unsafe practices, which could result in damage

to the equipment or minor injury.

WARNING: Directs your attention toward unsafe practices, which could result in serious

injury or death.

It is impossible to anticipate every situation that may occur while riding a bicycle. This manual

makes no representation about the safe use of the bicycle under all conditions. There are risks

associated with the use of any bicycle that cannot be predicted or avoided. By choosing to ride

a bicycle, you assume the responsibility for that risk. Read and understand your bicycle owner’s

manual before using your bicycle.

GENERAL SAFETY GUIDELINES

•Neverputyourhandsnearorinsiderotatingparts.Protectivefive-fingerglovesthatdonotreduce

sensitivity or your ability to grip should be used during repair.

•Beforestartinganymountingoperations,carefullycheckfordangerousconditionsattheworksite.

If too dark, use all available light sources and make sure they work properly before starting work.

•AllmaintenanceoperationsmustbecarriedoutsolelybypersonnelauthorizedbyFORMULAS.a.s.

•Ensurethatthequickreleaseistightenedcorrectly.Bouncethebikeonthegroundfromaheight

GB TRANSLATION OF THE ORIGINAL INSTRUCTION MANUAL

18

of about 10cm/4” to ensure that there are no loose parts. Riding with an improperly adjusted

wheel quick release can allow the wheel to wobble or fall off the bicycle causing injury or

death.

•Beforeriding,verifythatthebrakesonyourbicycleareinstalledandadjustedcorrectly.Improp-

erly installed and adjusted brakes may cause a crash and result in property damage, serious

injury, or death.

•Makesurecablesandhosesdonotimpedethesteeringofthebicycle.

•Ifmountingthebicycleinarackdesignedtoholdtheforkbyitsdropouts,avoidtiltingthe

bicycle to either side. Doing so could cause structural damage to the fork. Be sure the bike is

fastened securely, with the quick-release mechanism tight and the rear wheel properly secured.

If the bicycle ever tilts on, or falls from a bicycle rack, do not ride it until it has been examined

byanauthorizeddealer,servicecenter,orbyFORMULAS.a.s..Astructurallydamagedforkleg

or dropout failure can cause a sudden loss of control, resulting in serious injury or death.

•Wetweatherimpairstractionandbraking,makingitmuchmoredifficulttocontrolthebike.

Moreattentionmustbepaidwhileridinginwetconditionsinordertoavoidaccidents.

•THIRTYFIVEforksdonotincludereflectorsforpublicroaduse.THIRTYFIVEforksaredesigned

foruseincompetitiveoff-roadridingandracing.ProperreflectorsmeetingtheConsumerProd-

uctSafetyCommission’s(CPSC)requirementsshouldbeinstallediftheforkwillbeusedon

public roads.

•Alwayswearaproperlyfittedandfastenedhelmetwhileriding.Makesurethehelmetisap-

proved in the country of use.

•Learnandcomplywiththelocalrulesoftheroadandcyclingregulations.Alwaysridecarefully

and responsibly.

•Wearclose-fittingclothesthatmakeyoueasytosee(fluorescentorbrightcolors).

•Ifyourideatnight,useadequatelightsandreflectorsthatarecleanandfittedsecurely.

THIRTYFIVE FORKS SAFETY GUIDELINES

•TheTHIRTYFIVEforksproducedbyFORMULAS.a.s.aredesignedexclusivelyforuseontwo

wheelbicycles. THIRTYFIVE forksshould notbeused forelectric bicyclesor tandem(multi-

person)bicycles.Anyotheruseistobeconsideredhazardous.FORMULAS.a.s.shallnotbeheld

liable for any consequences from improper use.

•Iftheforkeverlosesoilormakesunusualnoises,stopridingandhaveitinspectedbyFORMULA

S.a.s.oranauthorizeddealer.Continuingtouseamalfunctioningforkcancauseasuddenloss

ofcontrol,resultinginseriousinjuryordeath.Somesounds,suchasoilflow,minorclicks,and

springrattle,areconsiderednormal.Whenindoubt,consultyourlocalFormuladealer.

•THIRTYFIVEforkshaveacrown/steerer/uppertubeassembly.Thesepartsarepressedto-

gether through a single precision pressing operation. Replacing any of these parts requires a

completenewupperassembly.Neverattempttoremoveorreplacethesteereroruppertubes

independentlyfromthecrown. NEVERATTEMPTTOCUT THREADSINTO THE THREADLESS

STEERER.Modifyingthecrown/steerer/uppertubeassemblycancauselossofcontrolofthe

bicycle and serious injury or death.

•Impact,falls,improperorharshuseofthebicyclemaycompromisethestructuralintegrityofthe

forks, significantly reducing their lifespan.

•Havetheforksregularlyinspectedbyaqualifiedmechanicforanycracks,deformation,signsof

fatigueorwear.Useofpenetratingfluidorothervisualenhancerstolocatecracksonpartsis

19

recommended.

•Ifinspectionrevealsanydeformation,cracks,signsofimpactorstress,nomatterhowslight,

immediately replace the component. Excessively worn components also require immediate re-

placement.

•Thefrequencyatwhichinspectionisrequireddependsonmanyfactors.AskaFORMULAS.a.s.

dealer to recommend an inspection and service schedule that is right for you.

•Ifyouweighmorethan90kg/198Ibsbeespeciallycarefulandhavethebikeinspectedmore

frequently.

•Partsthathavebeenbentordamagedinanaccident,orastheresultofimpact,mustbeimme-

diatelyreplacedwithgenuineFORMULAS.a.s.replacementparts.

•TheuserofTHIRTYFIVEforksexpresslyrecognizesthattherearerisksinherentinbicycleriding,

including but not limited to failure of a bike component, resulting in an accident, personal injury

or death.

•BypurchasingandusingtheseTHIRTYFIVEforkstheuserexpressly,voluntarilyandknowingly

accepts and/or assumes these risks, including but not limited to the risk of passive negligence on

thepartofFORMULAS.a.s.,i.e.hidden,latentorobviousdefectsandexemptsFORMULAS.a.s.

from liability to the fullest extent permitted by law against any resulting damage.

•CarefullyreadtheTHIRTYFIVEforksinstructionsbeforeuse.

•Carefullyfollowthescheduledmaintenanceprogramasindicatedintherelativeparagraph.

•AlwaysusegenuineFORMULAS.a.s.replacementparts.

By purchasing and using these THIRTYFIVE fork, the user expressly, voluntarily and knowingly

accepts and/or assumes these risks, including but not limited to the risk of passive negligence on

thepartofFORMULAS.a.s.,i.e.hidden,latentorobviousdefectsandexemptsFORMULAS.a.s.

from liability to the fullest extent permitted by law against any resulting damage.

ENVIRONMENTAL NOTES

In order to protect the environment, please follow to these simple instructions to correctly dis-

poseofFORMULAS.a.s.products:

1)Thepackagingdoesnotrequirespecialdisposalbecauseitisnotdangerousinanyway;we

suggest recycling paper and plastic.

2)Itisalsorecommendedtorecyclethemetalpartsafteruse.

For both points mentioned above, it is recommended to dispose of waste following national

regulationsthroughspecializedwastedisposalcompanies.

20

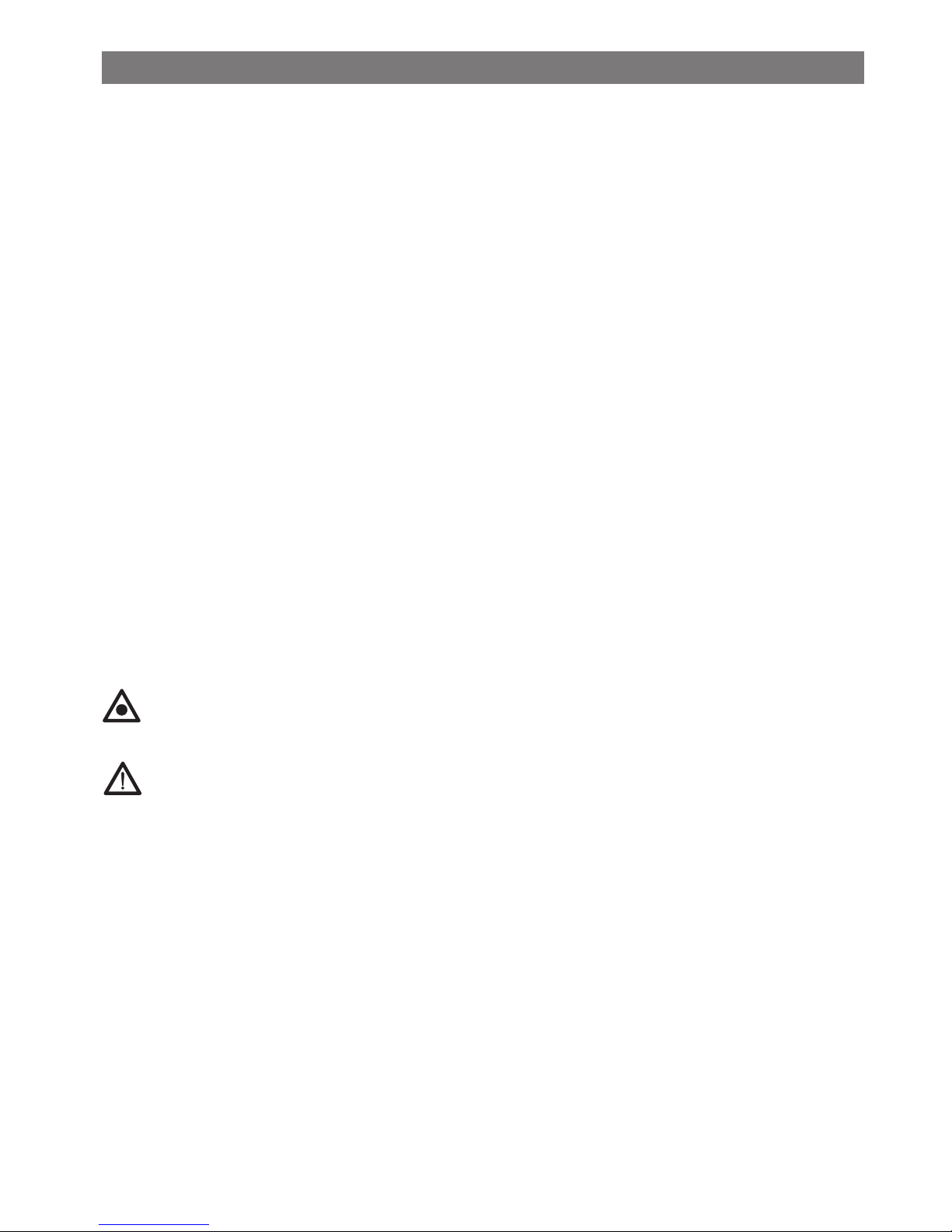

1TECHNICAL SPECIFICATIONS THIRTYFIVE 35-29” 100-140

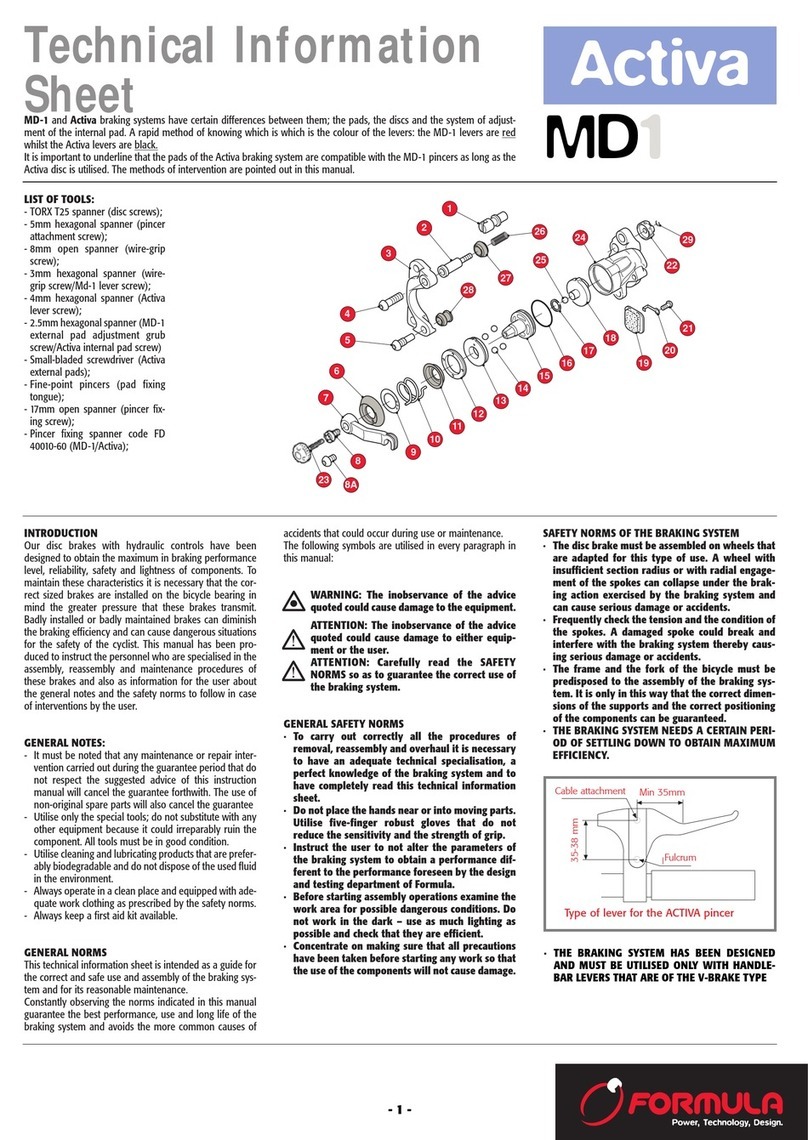

ThemaincomponentsandspecificationsoftheFORMULATHIRTYFIVEforksaregivenbelow:

Ref Name

1Steerertube

2Crown

3Uppertube

4Lowerleg

5 Disc brake posts

6 Rebound knob

7 Dropout

8Compressionadjustment

9Airvalve

10 Lockoutlever

11 Lockoutthresholdadjustment

Description Tire

Color Type Head sleeve Travel in mm L = mm Ø C S

White

QR15 1/5”TAPERED 100 120 140 746(mm)

29,3(inch)

61(mm)

2,4(inch)

Black

WARNING: Do not use a tire if any measurement exceeds the maximum dimen-

sions shown above. Using larger tires is not recommended and can cause serious

or fatal injuries.

L=

S

ø

Ø C

1

8

4

5

67

2

3

9

10

11

21

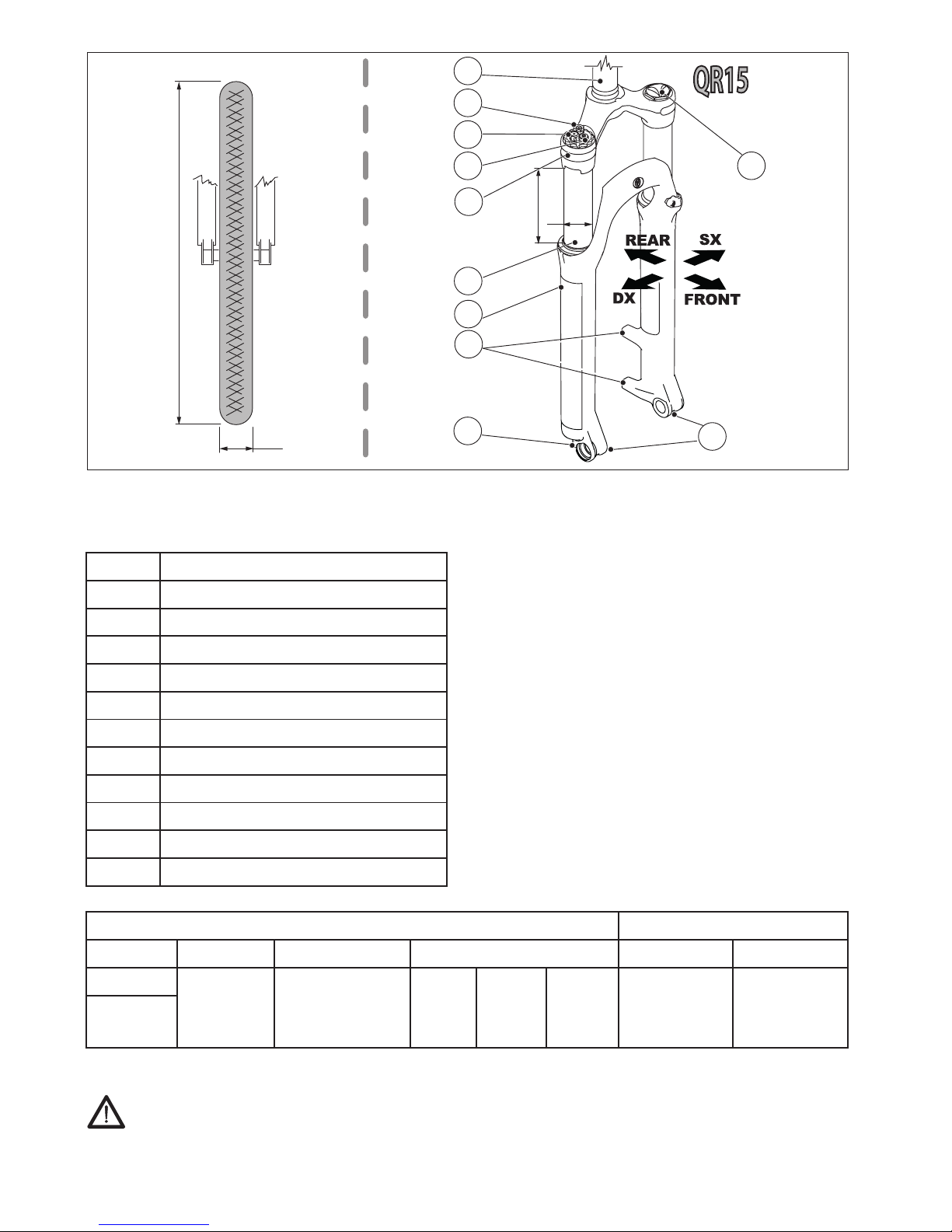

1TECHNICAL SPECIFICATIONS THIRTYFIVE 35-29” 150-160

ThemaincomponentsandspecificationsoftheFORMULATHIRTYFIVEforksaregivenbelow:

Ref Name

WARNING:

The monolith ref. 4 and the internal com-

ponents are NOT INTERCHANGEABLE

with the version of fork

Thirtyfive 35-29“100-140

1Steerertube

2Crown

3Uppertube

4Lowerleg

5 Disc brake posts

6 Rebound knob

7 Dropout

8Compressionadjustment

9Airvalve

10 Lockoutlever

11 Lockoutthresholdadjustment

Description Tire

Color Type Head sleeve Travel in mm L = mm Ø C S

White

QR15 1/5”TAPERED 150 160 746(mm)

29,3(inch)

61(mm)

2,4(inch)

Black

WARNING: Do not use a tire if any measurement exceeds the maximum dimen-

sions shown above. Using larger tires is not recommended and can cause serious

or fatal injuries.

L=

S

ø

Ø C

1

8

4

5

67

2

3

9

10

11

22

1.1 Disc brakes

Disc brakes with 203 mm rotors may be used on FORMULA THIRTYFIVE forks. Do not use rotors

larger than 203 mm. Install disc brakes and torque all fasteners according to manufacturer’s

specifications. Install, route and check that all cables or hydraulic hoses are securely fastened to

the lower leg and will not move during compression of the fork.

WARNING: Tighten the brake calipers to the brake manufacturer’s torque spec-

ifications.

1.2 Wheels

Consult the technical specifications provided by the wheel manufacturer to install and secure the

wheels to the forks.

1.3 Lubricants

Only use hydraulic oil, lubricant and grease included in the kit sold by FORMULA.

CAUTION: Do not use lubricants other than those recommended above. Use of

other lubricants may damage the fork and make it unsafe.

Threadlocker for screws

Apply a liberal mount (where indicated) of medium strength threadlocker all the way around

the thread. After applying, clean any excess threadlocker with a cloth. Let dry at least 24 hours

before installing.

WARNING: The threadlocker used for assembly is dangerous to skin and eyes.

Consult and adhere to the warnings on the threadlocker container before use.

Our kit include:

Hydraulic Oil Idemitsu OJ01 and Lubricating Oil Ballistol.

For the cartridge use only hydraulic oil Idemitsu OJ01. For the air spring chamber use a mix

composed by 50 % of Idemitsu OJ01 and 50% by Ballistol. For the legs lubrication, use a mix

composed by 50 % of Idemitsu OJ01 and 50% by Ballistol.

23

10

2 INSTALLATION

WARNING: Installation of THIRTYFIVE suspension forks requires specific knowl-

edge, equipment and expertise. General mechanical skills are not sufficient to

correctly install the THIRTYFIVE suspension forks.

Formula strongly recommends that a qualified service center authorized by FORMULA

install the fork on your bicycle. Improperly installed forks can cause damage to the

THIRTYFIVE suspension and serious injury or death.

-Formuladoesnotauthorizetheendusertoinstalltheforkonthebike.

WARNING: Failure to follow these guide-

lines may result in serious injury or death.

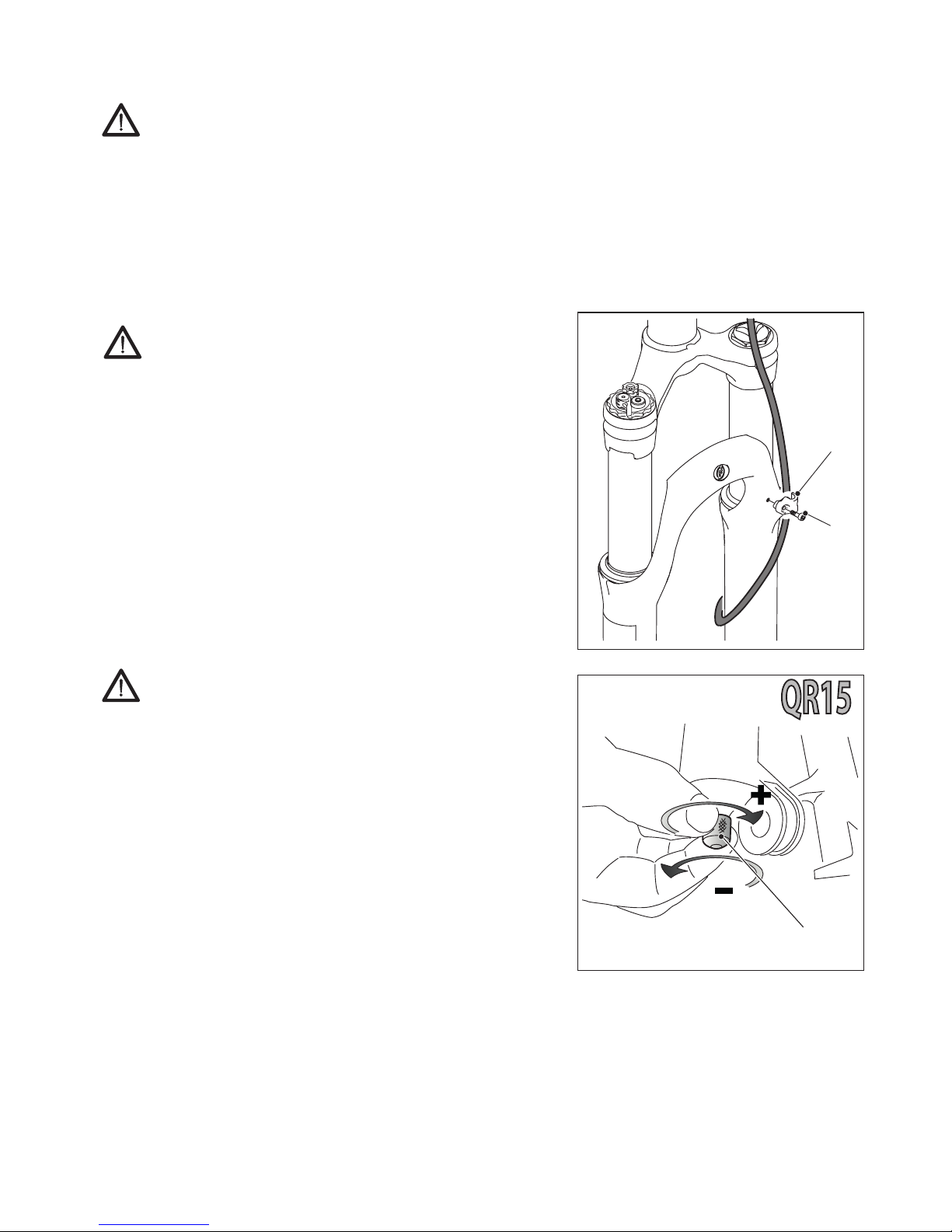

2.1 Installing the hose clamp

-Securethediscbrakehosetotheforkwithclamp(8).

-Loosenthescrew(9)andmovetheclampoverthehose

(8).

-Insertthehoseinsidethehoseclamp(8).

-Tightento2/3Nm.

3 USE

GENERAL SAFETY NOTE: Do not keep the

fork fully at the end of the race for a period

exceeding 10 days.

If that happens you can verify that the hy

draulic system is not working properly.

3.1 Suspension Adjustments

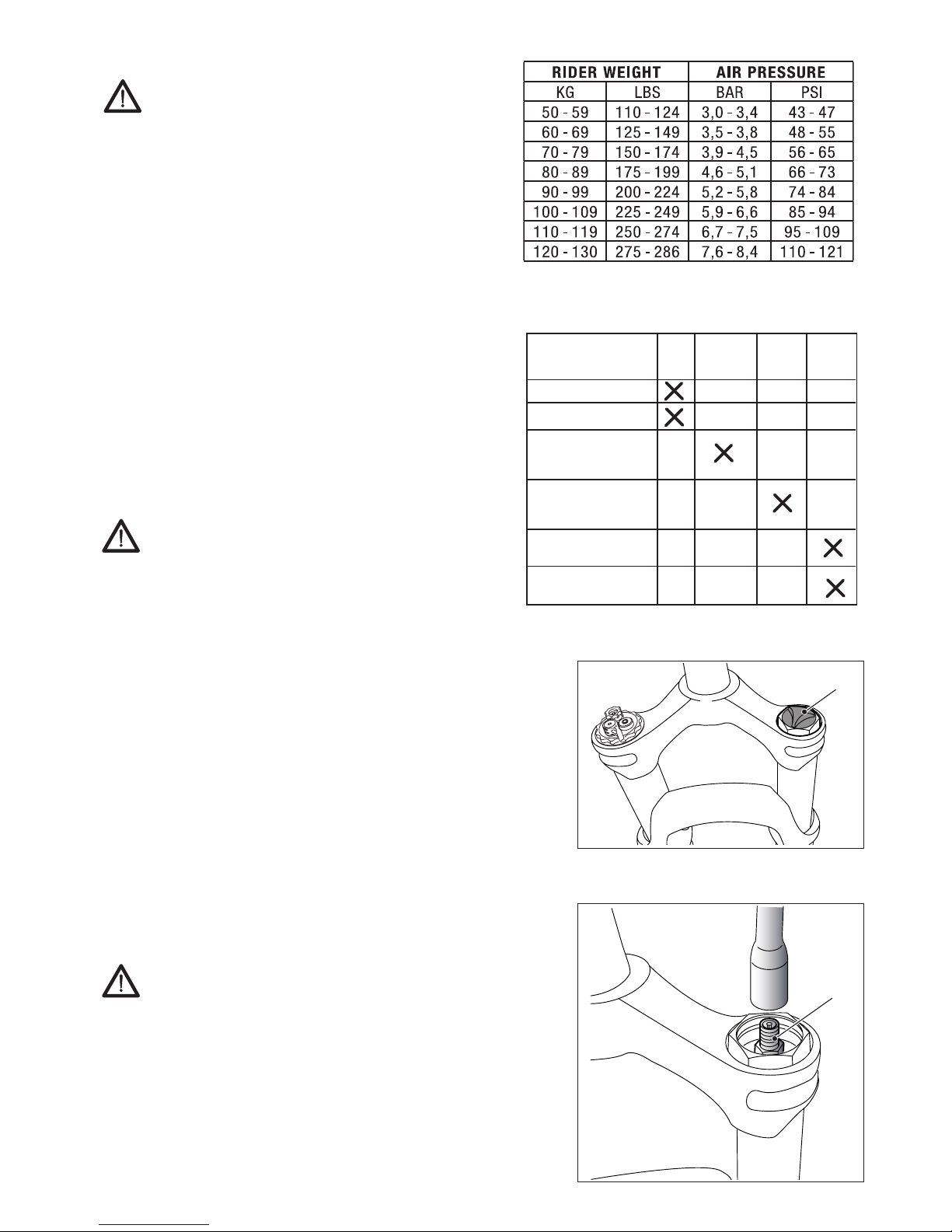

-Usethereboundadjuster(10)toadjusthowquicklythe

fork returns to its extended position after being com-

pressed.

-Correctlysettingthereboundspeedallowsthebicycle

to properly track the terrain.

- Rebound that is set too fast will cause the fork to feel springy and uncontrolled and exhibit

excessive return speed

- Rebound that is set too slow will not allow the fork to extend quickly enough to prepare for the

next bump.

-Turningtheadjuster(10)clockwise(towardthe+sign)addshydraulicdampingandslowsthe

rebound speed.

-Turningtheadjuster(10)counter-clockwise(towardthe-sign)removeshydraulicdampingand

speeds up the fork rebound speed.

8

9

24

3.2 Adjusting hydraulic compression

Lever(11)isusedtograduallyadjusthydrauliccompres-

sion.

-Lever(25)canbeusedtoopenorclosethefastener.

-Adjuster(30)istoadjustthelockoutthresholdwhenit’s

in the closed setting.

WARNING: NEVER use lever (25) in the closed position when riding downhill

since the hydraulic suspension will not work in the proper way in case of obsta-

cles and this may lead to loss of control of the bike and to serious accidents or death.

3.3 Adjusting the air pressure

-Use a high pressure pneumatic shock pump (12) to

change the pressure in the THIRTYTREE.

-Removethevalvecap(13).

-Connecttheend(14)ofthepumptoforkvalve(15)so

thatpressuregauge(16)willreadthepressure.

CAUTION: Do not over tighten the pump (14)

as the seal will be damaged.

WARNING: The maximum allowable pres-

sure is 125psi.

-If there is no pressure in the fork, the pressure gauge

(16)willnotreadavalue.

-Compress the pump (12) a few times to increase the

pressure. The pressure should increase slowly.

-If the pressure rapidly increases, make sure the pump is

properlyconnectedtothevalve(15).

-The pressure can be reduced by pressing the black relief

valve(17)onthepump(12).

-Pressthereliefvalvehalfwaytosteadilyreleasepressure.

-Pressthereliefvalvecompletelydowntorelievesmallamountsofpressure(slightadjustment).

-Detachthepump(12)byunscrewing(14).

-Installthevalvecap(13).

17

14

16 12

13

15

11

25 30

25

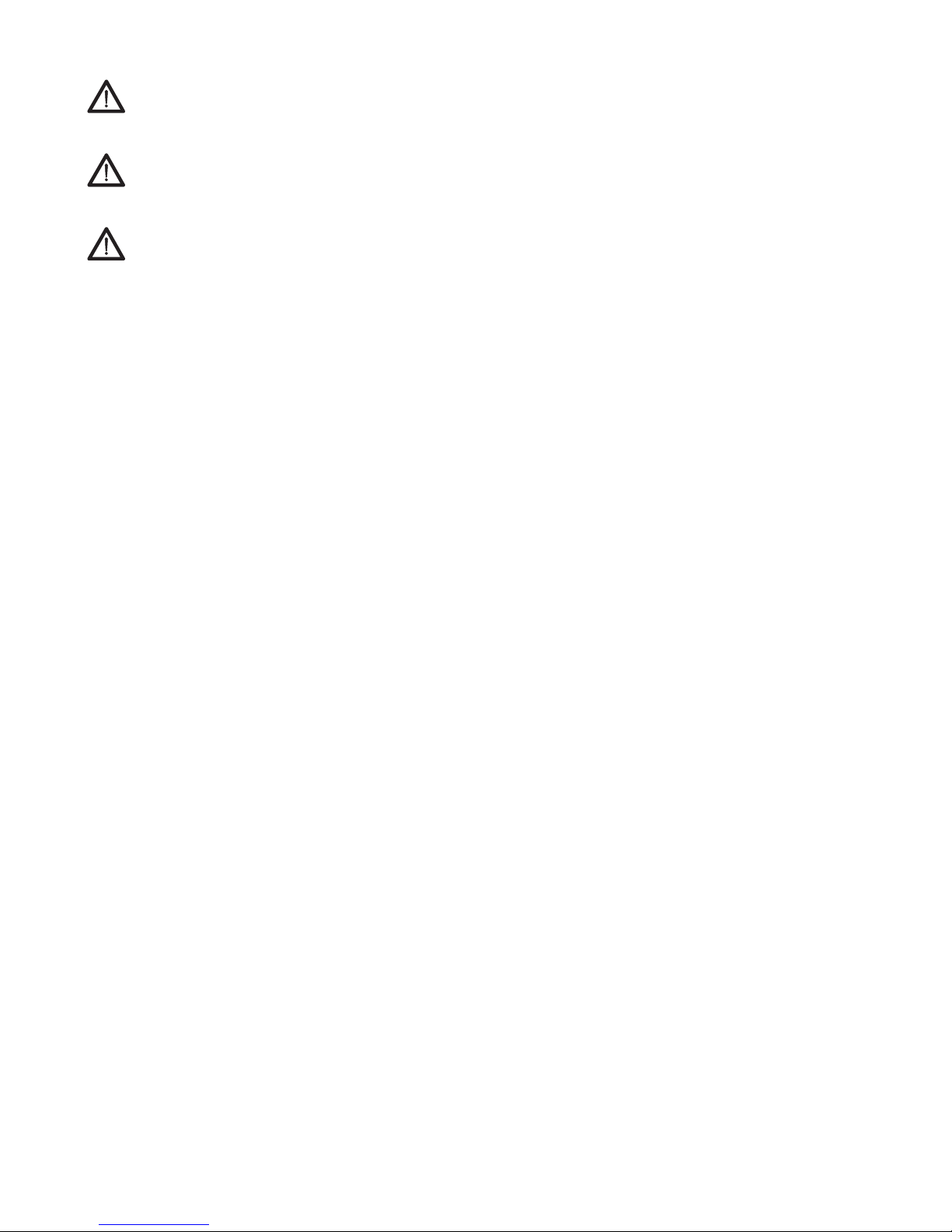

WARNING: When pump (12) is connect-

ed, pressure will (16) read 2-8 PSI (0.114-

0.55 BAR) less than the actual reading

due to the air that enters the pump

hose. Consult table 1 to obtain informa-

tion about the pressure to be used.

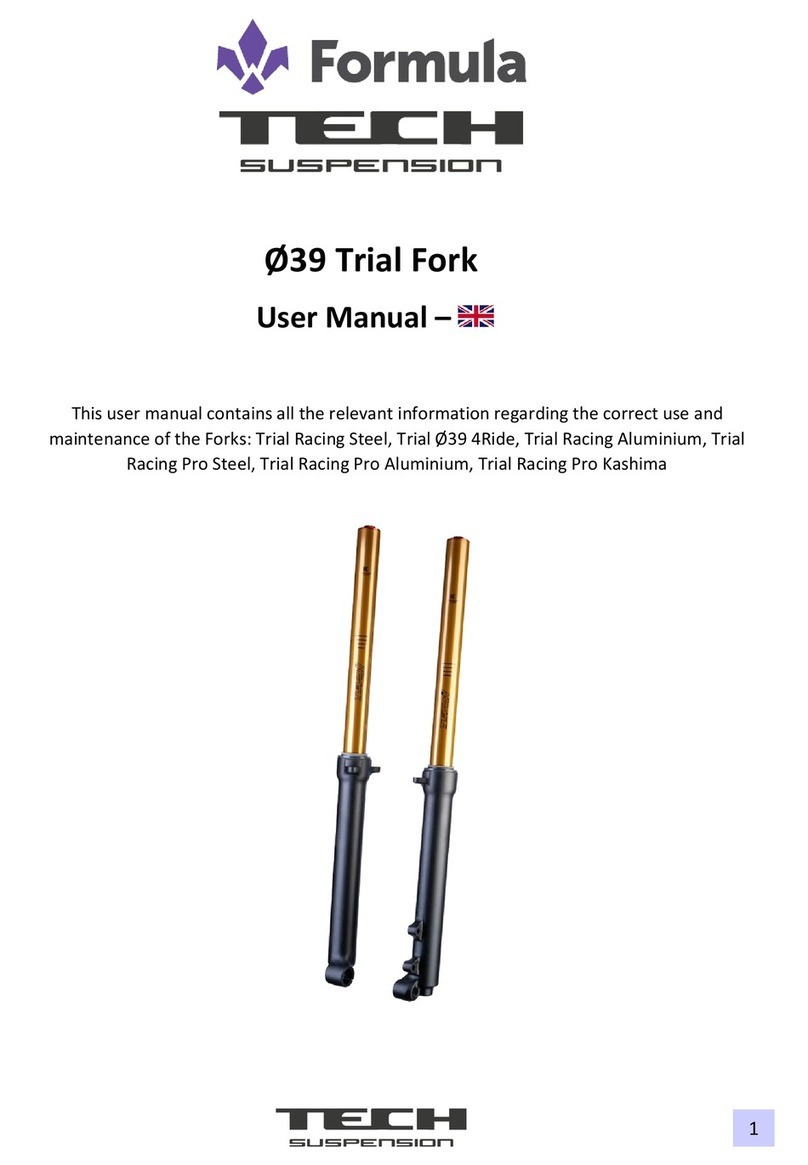

4 MAINTENANCE

MAINTENANCEINTERVALTABLE

Complywiththefollowingmaintenanceintervalsin

order to preserve the functionality and performance

of your Formula fork..

WARNING: In case of frequent use of the fork

under extreme stresses, maintenance

operations will have to be carried out

more frequently, based on the actual use con-

ditions.

(*) Do not use high-pressure water

(**) Do not use solvents and degreasing pro

ducts that may damage fork components

(***) http://support.formula-suspension.com

Use genuine spare parts and lubricants recommended

by Formula.

4.1 Modifying fork travel

TomodifyFORMULATHIRTYFIVEforktravel,addorre-

move inner travel spacers.

WARNING: Before making any changes, bring the

positive chamber pressure to 0 (zero), see the

relevant paragraph.

Failure to carry out this operation may lead to

serious damage to components and even to the

operator.

-Removetheairvalvecap(1).

1

2

Procedure

First

Use

Every

Ride/

Competition

Every

30 Hours/

6 Months

Every

100 Hours

/1 Year

Basic setting (***)

Expert setting (***)

External cleaning

with water and

neutral detergent (*)(**)

Internal fork leg cleaning

- oil seal and bushing

wear check (***)

Hydraulic oil cartridge

replacement (***)

Air spring

maintenance(***)

26

-Install the pneumatic pump as di-

rected in paragraph 3.3. Bring the

air pressure to 0(zero) making

sure all the air has been let out.

-Use a 10 mm socket wrench to

loosentheairvalve(2).

-Turn over the fork and empty the

oil present in the air cylinder.

-Removethereboundknob(3)by

pulling it up.

-Usea4mmhexwrenchtoloosen

thelockscrews(4)and(5).

-Removethelowerlegby(6)pull-

ing it up.

-Pushthepiston(7)fullyinsidethe

cylinder.

-Removetheretentionring(8)with

asmallflatbladescrewdriver(9).

-Removetheentiresleeve(7)with

the piston and spring assembly

from the cylinder.

-Placethesleeve(7)onatablewiththepiston

(11)facingdown.

-Deviatethespringassembly(12)bypushing

on the plastic part and not directly pulling the

springs. Release the retainer that holds the

spring assembly.

-Insertspacers(13)whereneeded,asshown

in the figure, and then engage the retainer

again.

3

4

5

6

9

87

7

10

12

27

WARNING: The travel of the FOR-

MULA THIRTYFIVE 29 fork cannot exceed

140 mm.

- Lubricate the O-Ring (14) with grease (see

“Recommendedlubricants”).

- Install the piston and spring assembly (7)

back into the lower leg. The piston assembly

should be at the same height as the cylinder.

- Install cap (10) into the lower leg with the

larger circumference on top. Secure the cap

withtheretentionring(8).

WARNING: Incorrectly positio-

ning the snap-ring (8) may cause the

fork to malfunction and therefore

may cause serious injury or death.

14

7

8

10

28

2

16

7

15

6

-

WARNING: Before assembling, make

sure the threads of the valve and cap

are clean and degreased.

- Apply threadlocker completely around the valve thread (2). Install the valve using a 10 mm

socket wrench, tightening to 5 Nm. Use the high pressure pneumatic shock pump to inflate the

fork (as directed in paragraph 3.3) to the required pressure.

-Align the keyway on the two piston assemblies (7-15).

-Install the lower legs (6). Be extremely careful not to damage or bend the dust seals (16). Repla-

ce them if they are damaged in any way.

-Before placing the lower legs (6) against the piston assemblies(7-15), add 10cc of

-Slide the lower leg (6) until it contacts the piston keyways (7-15).

Turn the fork upright and put 5cc of oil

composed by 50% of Idemitsu OJ01 and

by 50% of Ballistol into the air cylinder

(2).

oil composed

by 50% of Idemitsu OJ01 and by 50% of Ballistol with a syringe, as shown in the figure below.

29

-Apply medium strength threadlocker

aroundthethreadofscrews(4-5).Ap-

ply grease to the o-rings on the screws.

-Install the screws (4-5) and tighten to

6-7 Nm.

-Push the rebound knob (3) fully into

place, making sure it is secure.

-Actuatetheforkafewtimestoverifyit

works properly.

4.2 Issues - Causes - Remedies

This chart mentions some issues that may be encountered when using the fork along with the

possible causes and remedies.

WARNING: The operations listed below and accompanied by this symbol must

be carried out only by authorized service centers.

Fork not using full travel Oilleveltoohigh,airpressure

too high

Checkoillevel( )

Reduce air pressure

Fork extends too quickly,

violent rebound after bum-

ps

Rebound damping insufficient Increase rebound damping

Steerer tends to “close”

when turning

Excessive rebound damping Decrease rebound damping

Fork slow during extention

or “packs-up” over multiple

bumps

Excessive rebound damping Decrease rebound damping

Bump noise during return

but without violent re-

bound

Excessive rebound damping Decrease rebound damping

Dust seal leaks oil Dust seal damaged ( )Replacedustseal

Largeamountofoilonup-

per tubes or oil leaks from

bottom of fork

Sealsdamaged,uppersmaybe

damaged

( )Replaceallsealsandhave

uppers inspected

Fork “sticky”, does not work

like new

Sealsdirty,forkrequiresmain-

tenance

( )Replaceallseals

Oillossfrombottomoffork Bottomnut/screwlooseO-ring

damaged

Tighten the nut or screw

( )ReplaceO-ring

Lossofsensitivity Slidebushingsworn

Oilold

( )Replaceslidebushings

( )Changeoil

3

4

5

30

WARNING: If the fork ever loses oil, do not use the bike.

Find and repair any oil loses before using the bike again.

WARNING: Seals and upper tubes should be kept clean to avoid damage to fork

seals and upper tubes.

WARNING: If the fork sags, immediately adjust compression or check the oil

level.

Incorrect compression adjustment may cause damage to the fork, serious injury

or death.

Only a qualified bicycle technician or authorized suspension service center

should adjust the oil level.

READ CAREFULLY!

FORMULAS.a.s.extendstotheoriginalpurchaserofitsforksalimitedwarrantythattheforksare

free of defects in material and/or workmanship for a period of two years from date of purchase.

WHAT PROTECTION DO I RECEIVE FROM THE WARRANTY?

FORMULAS.a.s.will,atitsdiscretion,repairorreplacethedefectiveproductunderwarranty.

WARRANTY CONDITIONS AND LIMITATIONS

1. The manufacturer guarantees its products to be free from defects in materials or workmanship

for 24 months from the date of purchase. You must establish proof of purchase with a manda-

torydocument(salesreceiptorinvoice)showingthedateandplaceofretailpurchaseofthe

product in order to obtain warranty service. .

2. Thevalidityofthiswarrantyissubjecttothefollowing:

(a)-Theclaimmustbeinitiatedwithineight(8)daysofdiscoveryofthepotentialdefect;

(b)-EveryclaimmustbesubmittedtotheFORMULAS.a.s.dealerfromwhichtheproductwas

purchased, with the understanding, however, that the discretion as to the acceptability of

theclaimisexclusivelyFORMULA’s;

(c)-OnlyaFORMULAS.a.s.Dealercanshiptheallegedlydefectiveproduct,withtheaccom-

panying documentation.

Failure to comply with these procedures will invalidate the claim; in which case the

product will be made available to the owner for thirty (30) days and then destroyed.

31

3.Thiswarrantydoesnotcoverdamagesresultingfrom:

a. Incorrect transport and installation. Incorrect installation refers to failure

to follow the safety guidelines and instructions outlined in the Instructions

manual.

b. Unintended and inappropriate use of the product. Unintended and inappropri-

ate use refers to use of the product for purposes different from those for which

it was specifically designed and manufactured. Some unintended purposes in-

clude cross country and UCI sanctioned downhill races.

c. Use of materials or spare parts that do not carry the Formula trademark THIR-

TYFIVE forks. FORMULA S.a.s. shall not guarantee conformity, safety, service

life and performance of Formula THIRTYFIVE forks if materials and spare parts

that do not carry the Formula trademark and/or are non-compatible and/or

are not suitable and/or are not expressly authorized are used.

d. Lack of appropriate or reasonable maintenance or storage, washing with

harsh materials, use of corrosive agents, prolonged exposure to solvents.

e. Products on which the serial number and/or production code have been al-

tered, damaged and/or removed.

f. Modifications made by persons not duly authorized by Formula without being

approved by Formula.

g. Normal wear and tear or deterioration due to the use of the product.

h. The result of rider mishap or crash.

4.Retailers,wholesalers,importersoranyoneelseapartfromFORMULAS.a.s.maynotmodify

this warranty in any way.

5. This warranty does not affect the statutory rights of the consumer or any rights the purchaser

may have against the dealer pursuant to the sales contract.

6.ThelawsofItalygovernallmattersarisingoutoforrelatingtothiswarranty.Anydisputesor

legal actions by purchaser arising out of or relating to this warranty shall be brought in court

inPrato.

76

Formula S.a.s. di “Formula Group S.r.l.” & C.

Via Erbosa, 63 - 59100 Prato (Italia)

Tel. +39 0574 603 609

Fax +39 0574 611 046

Information may be enhanced for improvement without prior notice. All rights reserved.

Le informazioni possono essere modificate senza preavviso. Tutti i diritti riservati.

REV. Luglio2015

Table of contents

Other Formula Bicycle Accessories manuals

Formula

Formula TECH SUSPENSION TJ2 User manual

Formula

Formula 151239 Series User manual

Formula

Formula 4 Racing User manual

Formula

Formula NERO R User manual

Formula

Formula MOD User manual

Formula

Formula R1 Racing User manual

Formula

Formula FD40292-20 User manual

Formula

Formula MD1 Manual

Formula

Formula Linea User manual

Popular Bicycle Accessories manuals by other brands

Specialized

Specialized Elite CylcoComputer user manual

Sigma

Sigma BC 16.16 manual

Playcore

Playcore Dero Setbacks installation instructions

VDO Cyclecomputing

VDO Cyclecomputing x3dw instruction manual

Cateye

Cateye RAPID X2 manual

buratti meccanica

buratti meccanica Clorofilla Trail Use and maintenance manual