Formula 151239 Series User manual

1

Ø39 Trial Fork

User Manual –

This user manual contains all the relevant information regarding the correct use and

maintenance of the Forks: Trial Racing Steel, Trial Ø39 4Ride, Trial Racing Aluminium, Trial

Racing Pro Steel, Trial Racing Pro Aluminium, Trial Racing Pro Kashima

2

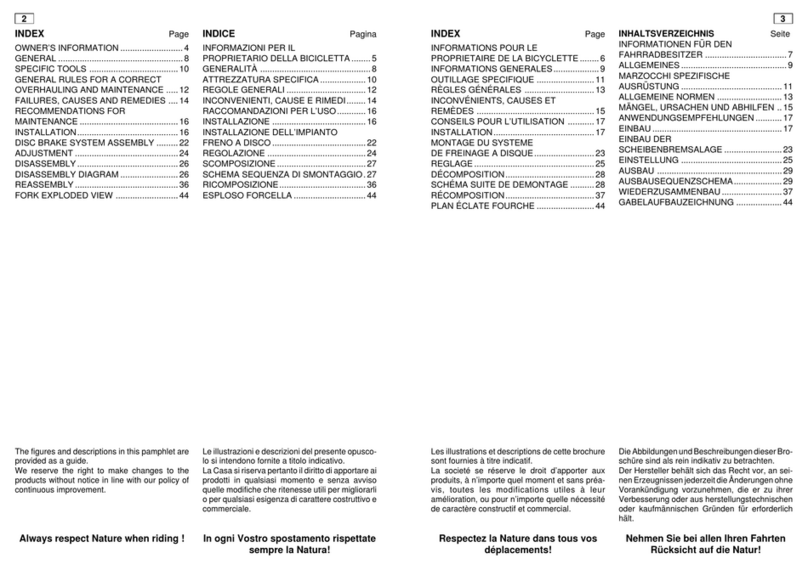

Index

Important Information and Maintenance Intervals: .........................................................................................3

Maintenance Intervals ...........................................................................................................................................3

Oil Level Sheet........................................................................................................................................................4

Required Tools .......................................................................................................................................................6

Fork Settings...........................................................................................................................................................7

Extension setting ..................................................................................................................................................7

Compression setting (only on some models).....................................................................................................7

End stroke setting.................................................................................................................................................7

Spring preload setting ..........................................................................................................................................7

Cleaning the Dust Seals........................................................................................................................................8

Oil Change Left Leg...............................................................................................................................................9

Oil Change Left Leg.............................................................................................................................................12

Seals Replacement Left Leg ..............................................................................................................................15

Seals Replacement Right Leg............................................................................................................................20

3

Important Information and Maintenance Intervals:

IMPORTANT

Repeatedly using our products in extreme conditions requires more frequent servicing.

Using unrecommended high-pressure washing methods, using unrecommended

spare parts, solvents and lubricants not recommended by Formula reduce the life

span of our products.

IMPORTANT

Formula recommends only ORIGINAL spare parts and lubricant products

Do not attempt assembly and disassembly operations on this product. Formula

recommends consulting servicing technicians for these activities and finding eventual

cracks, deformations, or evidence of damage due to fatigue or wear: if the inspection

shows the presence of such problems, even if minor, immediately replace the

component –with no attempts of repair.

SAFETY INFORMATION

Always wear nitrile gloves and safety glasses when working on the fork.

Ensure correct disposal of waste materials and liquids.

Maintenance Intervals

To keep the fork efficient during normal usage and ensure proper maintenance, follow the maintenance

intervals chosen by Formula:

Procedure

Before and

After any use

Every 8 Hours

1 Month

Every 35 Hours

3 Month

Every 100 Hours

1 Year

Washing with water and mild soap. Visual inspection.

Cleaning dust seals (if dust or mud is present)

Oil change

Full inspection

4

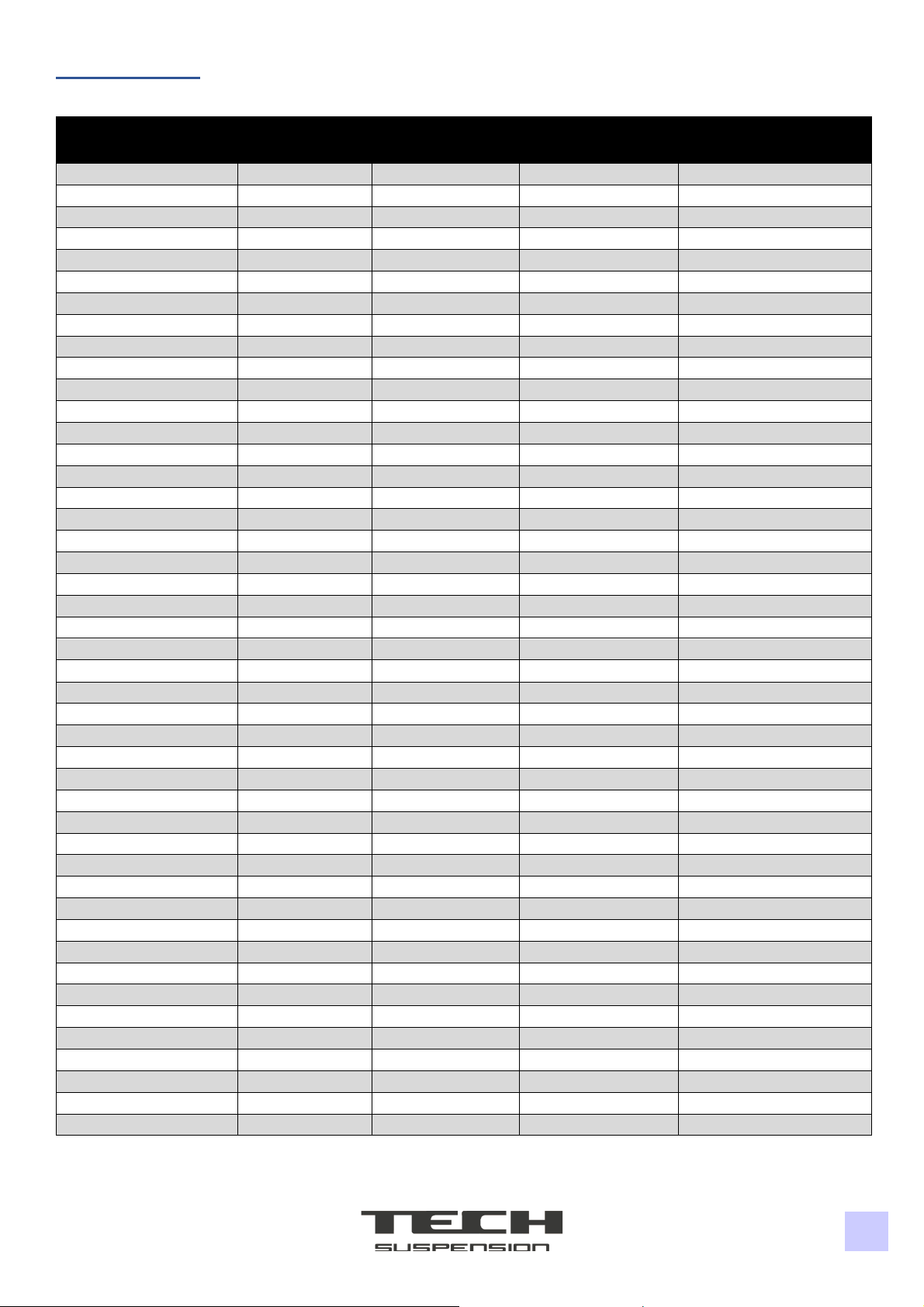

Oil Level Sheet

Fork Code

151239XXX

SX/Left (mm)

DX/Right (mm)

MY

Customer

000

118,0

118,0

2019 - 2022

Ø39 Standard

031

110,0

55,0

2011 - 2014

Beta

051

110,0

55,0

2011 - 2017

Sherco

054

130,0

75,0

2014

Sherco

055

130,0

75,0

2016

Sherco

056

130,0

75,0

2016

Sherco

057

130,0

75,0

2018

Sherco

058

130,0

75,0

2020

Sherco

059

140,0

85,0

2022

Sherco

101

110,0

55,0

2012

Jotagas

111

110,0

55,0

2012

Gas Gas

113

130,0

75,0

2014 - 2015

Jotagas

113

130,0

75,0

2013 - 2015

Gas Gas

113

130,0

75,0

2014 - 2015

Ossa

116

130,0

75,0

2016

Gas Gas

116

130,0

75,0

2017

Sherco

116

130,0

75,0

2017

Scorpa

119

130,0

75,0

2016

Gas Gas

121

100,0

50,0

2014

Honda

122

125,0

70,0

2014

Honda

123

100,0

50,0

2015

Honda

125

100,0

50,0

2016

Honda

127

125,0

60,0

2016

Honda

128

100,0

50,0

2017

Honda

129

130,0

70,0

2017

Honda

151

130,0

75,0

2015

Vertigo

152

130,0

75,0

2015

Vertigo

153

130,0

75,0

2016

Vertigo

154

130,0

75,0

2019

Vertigo

155

130,0

75,0

2019

Vertigo

156

130,0

75,0

2020

Vertigo

157

130,0

75,0

2020

Vertigo

158

130,0

75,0

2021

Vertigo

159

130,0

75,0

2021

Vertigo

171

130,0

75,0

2015

TRS

173

130,0

75,0

2017

TRS

174

130,0

75,0

2017

TRS

175

110,0

55,0

2018

TRS

176

110,0

55,0

2019

TRS

177

130,0

75,0

2020

TRS

178

110,0

55,0

2021

TRS

179

130,0

75,0

2021

TRS

185

130,0

75,0

2020

Electric Motion

186

130,0

75,0

2020

Electric Motion

187

118,0

118,0

2023

Electric Motion

5

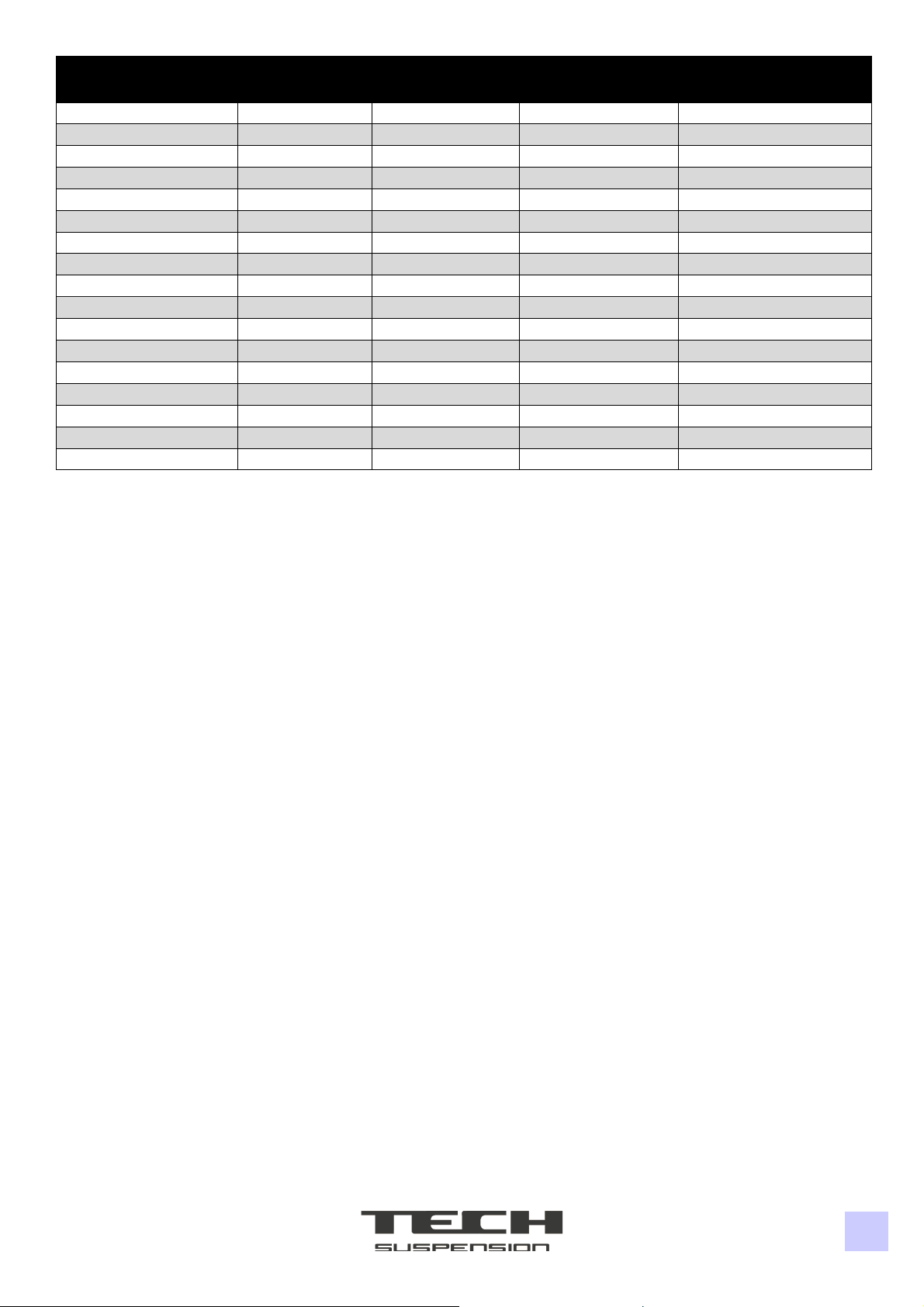

Fork Code

151239XXX

SX/Left (mm)

DX/Right (mm)

MY

Customer

200

130,0

75,0

2017

Gas Gas

202

130,0

75,0

2020

Gas Gas

203

130,0

75,0

2020

Gas Gas

204

125,0

70,0

2022

Gas Gas

205

125,0

70,0

2022

Gas Gas

207

125,0

70,0

2022

Gas Gas

231

125,0

70,0

2018

Honda

232

100,0

50,0

2018

Honda

233

130,0

70,0

2020

Honda

234

125,0

60,0

2022

Honda

250

2020

TRS

260

130,0

75,0

2022

Arctic Leopard

261

130,0

75,0

2022

Arctic Leopard

262

130,0

75,0

2022

Arctic Leopard

992

130,0

75,0

2022

Aftermarket

993

130,0

75,0

2023

Aftermarket

994

130,0

75,0

2023

Aftermarket

6

Required Tools

Description

Position

Q.ty

Part number

Bushing and Oil Seal Tool

1

1

0800DU007

Stanchion Tube Tool

2

1

080004000

Cartridge Assembly Tool

3

1

080008000

▪Bench vise;

▪Wrench key - 14 mm, 17 mm;

▪Hex key - 1,5 mm, 12 mm;

▪Flathead screwdriver;

▪Torque wrench;

7

Fork Settings

The forks have different settings to fine-tune their performance based on the rider’s needs. Settings adjustments

must be performed by an experienced technician. Setting a fork improperly could make the bike hard to ride and

could cause severe or fatal injuries.

Extension setting

Tools:

Flathead screwdriver.

Procedure:

The extension setting is located on the cap of the right leg. Turning the regulator clockwise will lower the

rebound speed; Turning the regulator anti-clockwise will increase the rebound speed. Usually, the

regulation is done by starting in a fully clockwise position and then turning anti-clockwise the regulator

between 16 and 22 clicks, depending on the temperature outside.

Compression setting (only on some models)

Tools:

Hex key 2 mm.

Procedure:

The compression setting is located on the lower screw of the right leg. This setting controls progressively

through the entirety of the compression stroke. Usually, starting with the regulator fully screwed you need to

unscrew the regulator by 2-3 turns (1 turn equals 360°).

End stroke setting

Tools:

Hex key 2 mm.

Procedure:

The end stroke setting is located on the lower screw of the left leg. This setting only affects the last 45 mm

of the stroke. Usually, the regulator is kept in a fully closed position. If the rider is light and unable to reach

the end stroke, the regulator can be turned anti-clockwise.

Spring preload setting

Tools:

Flathead screwdriver.

Procedure:

The spring preload setting is located on the cap of the left leg. This setting allows to increase the preload

up to 10 mm is a very personal setting. We suggest starting with the preload set halfway (fully screwed and

then unscrewed by 5 turns) and then regulating it by one turn at a time to obtain the ideal setting.

8

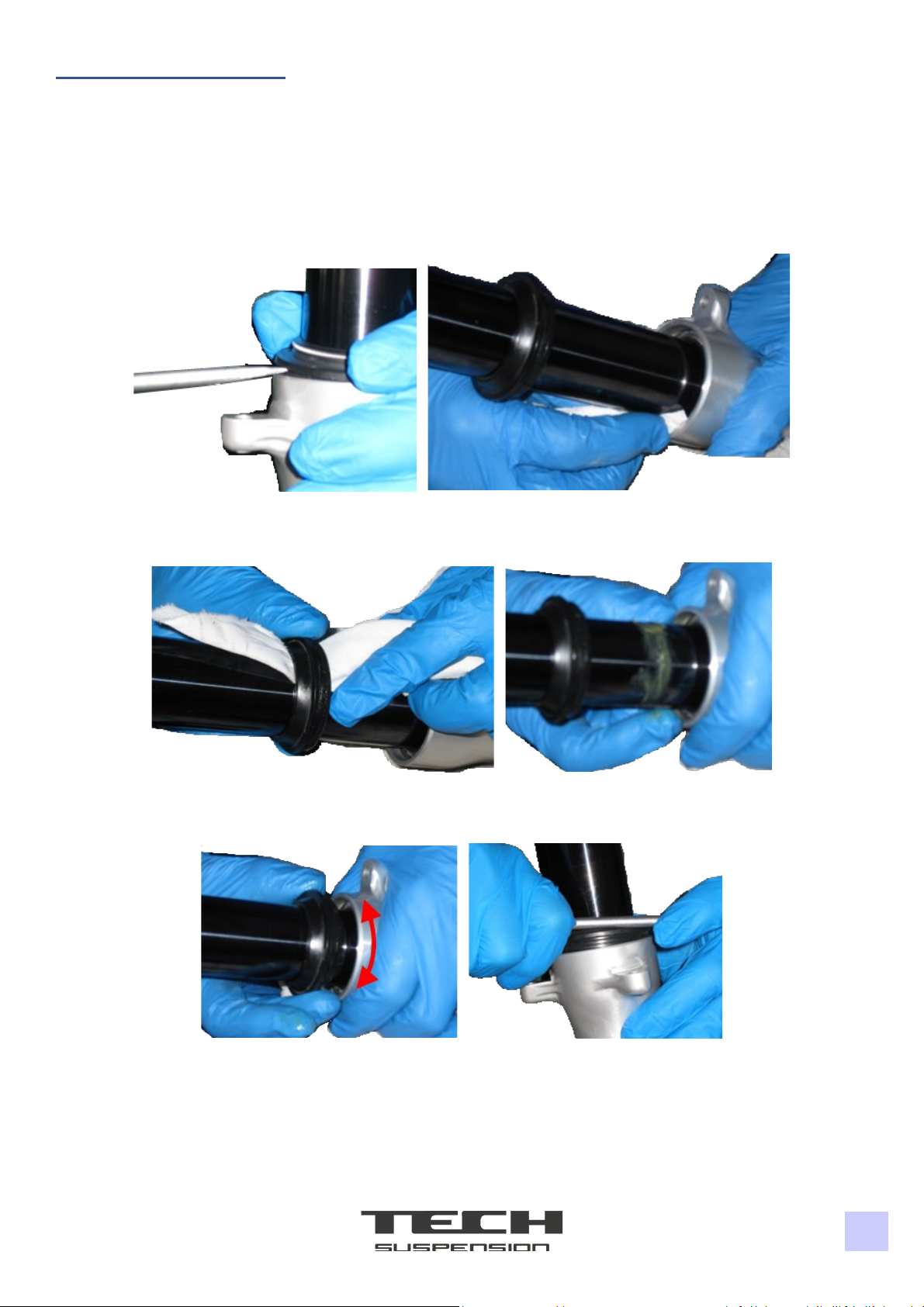

Cleaning the Dust Seals

Tools:

Flathead screwdriver, microfiber cloth.

Procedure:

1. Before proceeding accurately clean the fork;

2. Remove the dust seal by leveraging on its side with a flat-head screwdriver. Remove any dirt residue from the

dust seal and the oil seal with a microfiber cloth;

3. Insert a microfiber cloth inside the dust seal to remove dirt residue from the internal diameters, then apply

grease on the tube;

4. Rotate the dust seal on the grease and insert the dust seal in its housing by pushing on its outer diameters with a

screwdriver;

-End of Procedure-

9

Oil Change Left Leg

Tools:

Description

Position

Part number

Stanchion Tube Tool

2

080004000

Combined wrench 17 mm, Hex key 12 mm

Procedure:

1. Before proceeding accurately clean the fork;

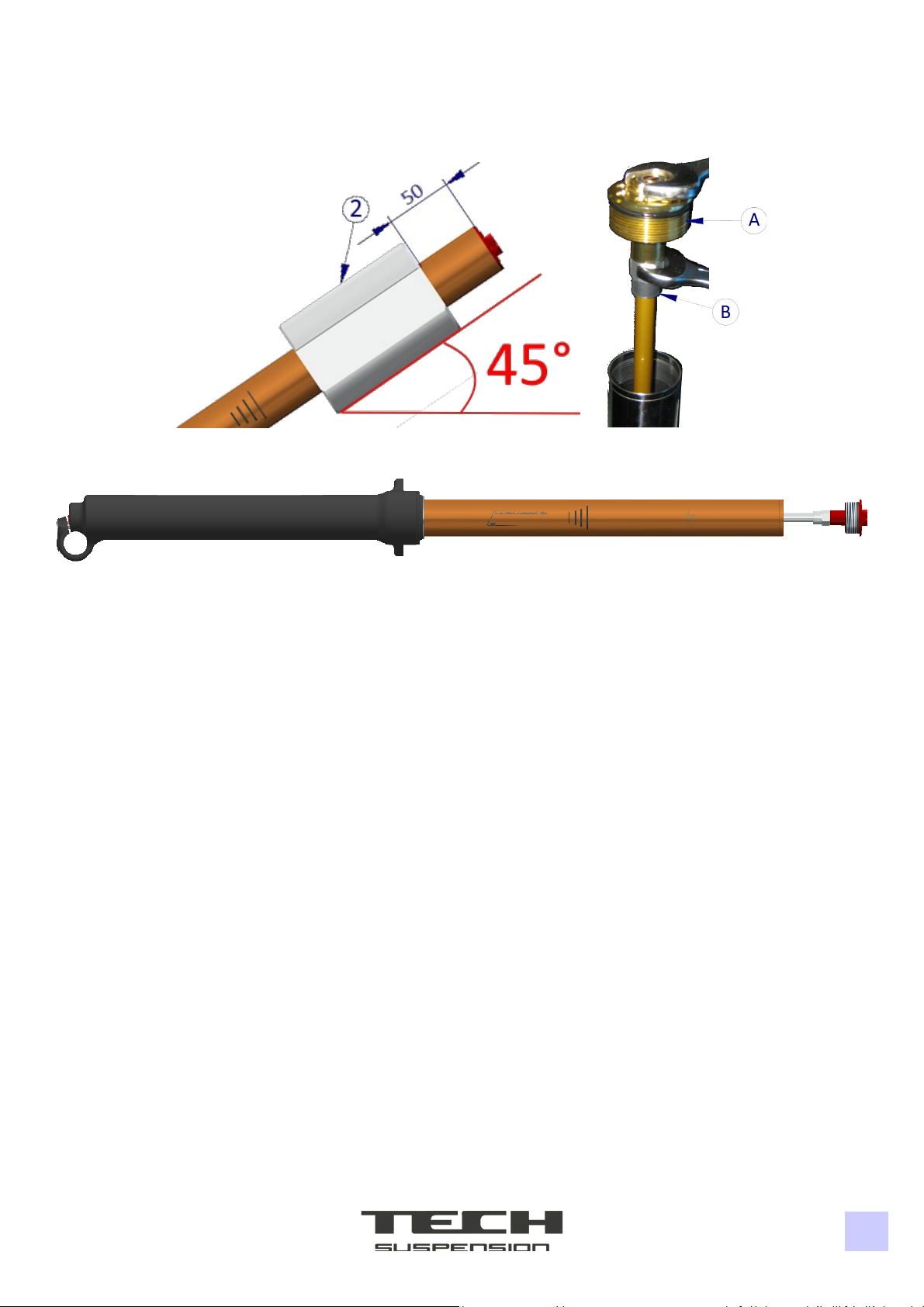

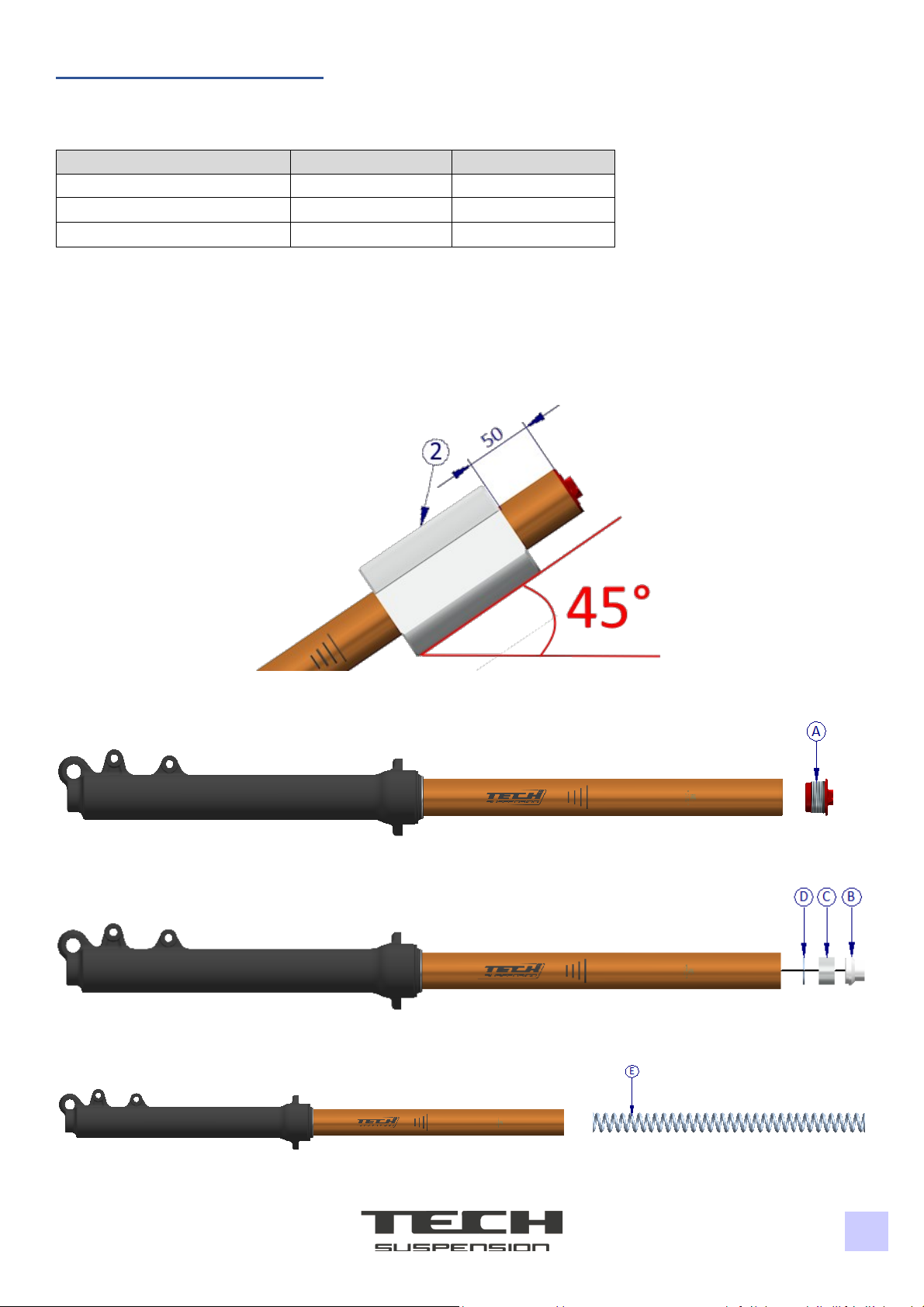

2. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the tube come out of the tool by 50 mm.

Keep the fork in this position until step N°6;

3. Unscrew the cap (A) with a 17 mm combined wrench and clean it;

4. Remove the conical spacer (B), the spacer (C) and the washer (D);

5. Slowly remove the spring (E) with a cloth. Clean properly the spring from oil residues;

10

6. Remove all oil from the fork and dispose of it according to local laws;

7. Put the fork in a vertical position and insert 250 mL of Oil OJ01 (SAE05). Move the tube up and down multiple

times, then push it to the end of the stroke;

8. Measure the oil level from the edge of the tube and adjust the level according to the sheet on page 4/5;

11

9. Insert the spring (E) inside the fork;

10. Insert in the same order components D, C, B;

11. Manually screw cap (A) on the tube. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the

tube come out of the tool by 50 mm and tighten the cap (A) with a 17 mm combined wrench and a tightening

torque of 10/12 Nm;

-End of Procedure-

12

Oil Change Right Leg

Tools:

Descrizione

Posizione

Part number

Stanchion Tube Tool

2

080004000

Combined wrench 14 mm, 17 mm, Hex key 1,5 mm, 12 mm

Procedure:

1. Before proceeding accurately clean the fork;

2. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the tube come out of the tool by 50 mm.

Keep the fork in this position until step N°6;

3. Unscrew the cap (A) with a 17 mm combined wrench and remove it from the tube. Insert a 14 mm combined

wrench on the locknut (B) and disassemble the two components. Remove the cap (A) and clean it;

13

4. Keep the cap (C) inside the cartridge stem. Remove all the oil inside the cartridge by moving up and down the

stem and dispose of it according to local laws;

5. Put the fork in a vertical position and insert 250 mL of Oil OJ01 (SAE05). Move the cartridge stem up and down

multiple times until the rebound has homogenous braking;

6. Measure the oil level from the edge of the tube and adjust the level according to the sheet on page 4/5;

14

7. Screw the locknut downwards (B). Manually screw the cap (A) on the stem;

8. Manually screw cap (A) on the tube. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the

tube come out of the tool by 50 mm. Screw the locknut (B) on the cap (A). Hold the locknut with a 14 mm

combined wrench and screw the cap (A) with a 17 mm combined wrench and a tightening torque of 10/12 Nm;

9. Tighten the cap (A) on the tube with a 17 mm combined wrench and a tightening torque of 10/12 Nm.

-End of Procedure-

15

Seals Replacement Left Leg

Tools:

Description

Position

Part number

Bushing and Oil Seal Tool

1

0800DU007

Stanchion Tube Tool

2

080004000

Cartridge Assembly Tool

3

080008000

Combined wrench 17 mm, Hex key 12 mm

Procedure:

1. Before proceeding accurately clean the fork;

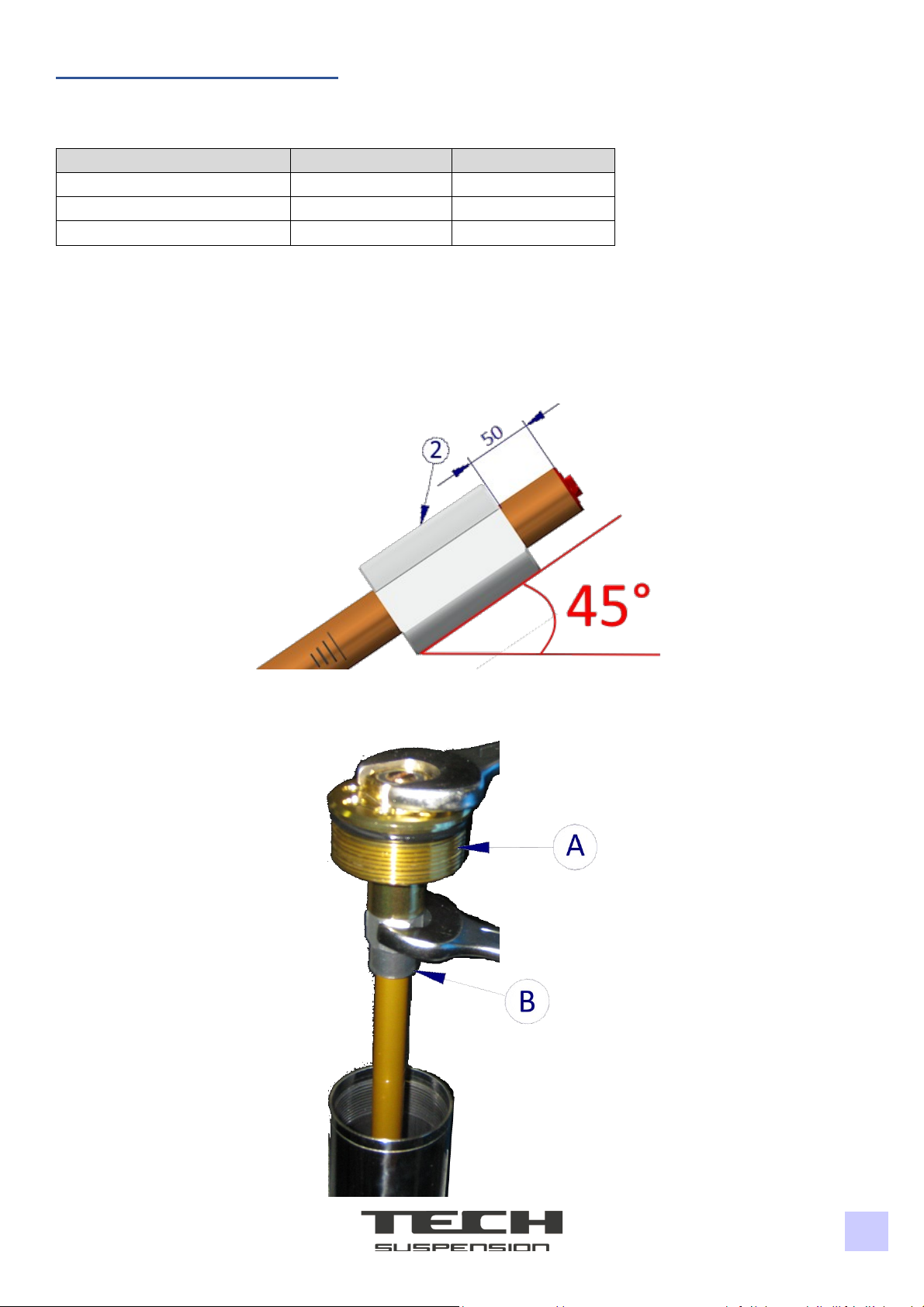

2. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the tube come out of the tool by 50 mm.

Keep the fork in this position until step N°6;

3. Unscrew the cap (A) with a 17 mm combined wrench and clean it;

4. Remove the conical spacer (B), the spacer (C) and the washer (D);

5. Slowly remove the spring (E) with a cloth. Clean properly the spring from oil residues;

16

6. Remove all oil from the fork and dispose of it according to local laws;

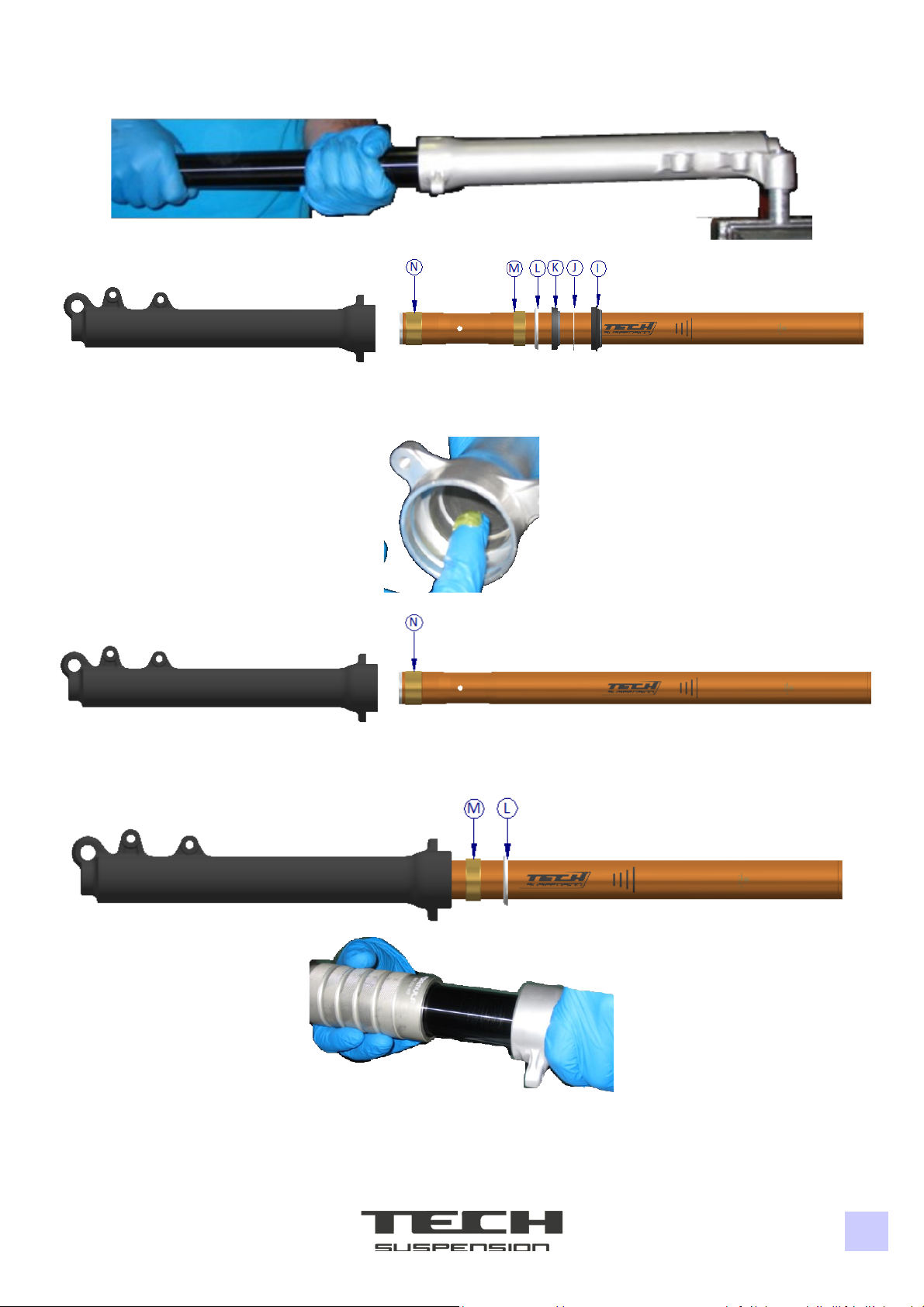

7. Tighten the wheel’s axle in a bench wise with aluminium plates and insert the leg on the axle;

8. Push the tube inside the leg (end stroke) and insert Tool 3 inside the tube to disassemble the pumping stem (G),

then unscrew the regulator for the end stroke (F) with a 12 mm hexagonal key;

9. Extract the regulator and the copper washer (F). Remove the pumping stem (G);

10. Turn the fork upside down to remove the end stroke cone (H);

11. Remove the dust seal (I) by leveraging on its side with a flat-head screwdriver, then remove the seeger ring (J)

from its housing;

17

12. Tighten the wheel’s axle in a bench wise with aluminium plates and insert the leg on the axle. Forcefully pull the

tube out of the leg ad remove all parts from the tube (I-N);

13. Replace the bushing (N) with a new one. Apply grease on the bushing and oil seal housing;

14. Insert the tube with the new bushing (N) inside the leg;

15. Insert the upper bushing (M) and the oil seal support washer (L) on the tube. Push the parts inside with Tool 1

from the side without knurling;

18

16. Insert the oil seal (K) with Tool 1 from the side with the knurling. Manually insert the seeger ring (J) in its housing

making sure it’s properly assembled;

17. Apply grease in the highlighted area. Rotate the dust seal (J) on the grease and insert the dust seal in its housing

by pushing on its outer diameters with a screwdriver;

18. Insert the pumping stem (G) along with the end stroke cone (H) inside the tube;

19. Push the tube inside the leg (end stroke) and insert Tool 3 inside the tube to assemble the pumping stem (G).

Push Tool 3 against the pumping stem (G) and screw the regulator for the end stroke (F) with a 12 mm hexagonal

key and a tightening torque of 23,5/25,5 Nm;

20. Put the fork in a vertical position and insert 250 mL of Oil OJ01 (SAE05). Move the tube up and down multiple

times, then push it to the end of the stroke;

19

21. Measure the oil level from the edge of the tube and adjust the level according to the sheet on page 4/5;

22. Insert the spring (E) inside the fork;

23. Insert in the same order components D, C, B;

24. Manually screw cap (A) on the tube. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the

tube come out of the tool by 50 mm and tighten the cap (A) with a 17 mm combined wrench and a tightening

torque of 10/12 Nm;

-End of Procedure-

20

Seals Replacement Right Leg

Tools:

Description

Position

Part number

Bushing and Oil Seal Tool

1

0800DU007

Stanchion Tube Tool

2

080004000

Cartridge Assembly Tool

3

080008000

Combined wrench 14 mm, 17 mm, Hex key 1,5 mm, 12 mm

Procedure:

1. Before proceeding accurately clean the fork;

2. Tighten the tube on a bench vise with Tool 2 with an angle of 45°. Let the tube come out of the tool by 50 mm.

Keep the fork in this position until step N°6;

3. Unscrew the cap (A) with a 17 mm combined wrench and remove it from the tube. Insert a 14 mm combined

wrench on the locknut (B) and disassemble the two components. Remove the cap (A) and clean it;

Table of contents

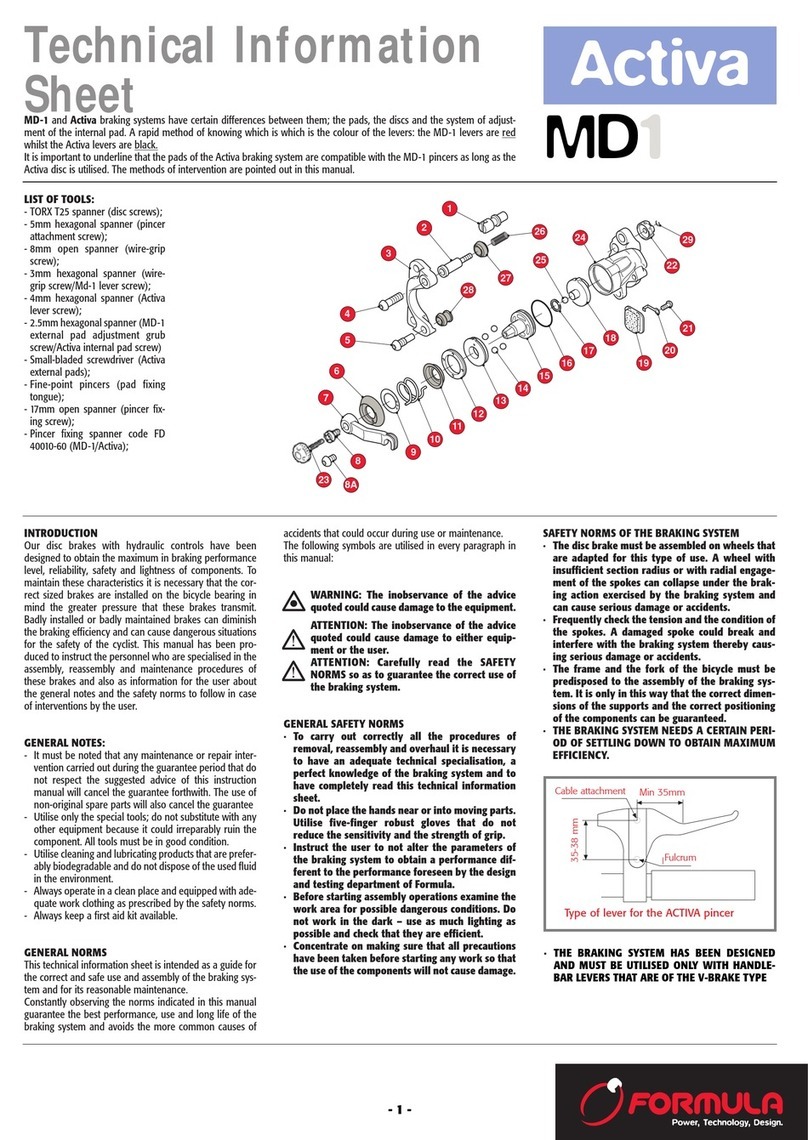

Other Formula Bicycle Accessories manuals

Formula

Formula MD1 Manual

Formula

Formula MOD User manual

Formula

Formula FD40292-20 User manual

Formula

Formula TECH SUSPENSION TJ2 User manual

Formula

Formula NERO R User manual

Formula

Formula Linea User manual

Formula

Formula THIRTYFIVE QR15 User manual

Formula

Formula 4 Racing User manual

Formula

Formula R1 Racing User manual

Popular Bicycle Accessories manuals by other brands

Cycling Sports Group

Cycling Sports Group DT-3267 instruction manual

Miche

Miche EVO MAX BB30 Mount instructions

Bobike

Bobike Go Maxi Carrier Assembly instructions

Grin Technologies

Grin Technologies Phaserunner V3 quick start guide

Asaklitt

Asaklitt JY-7129-200 Instructions for use

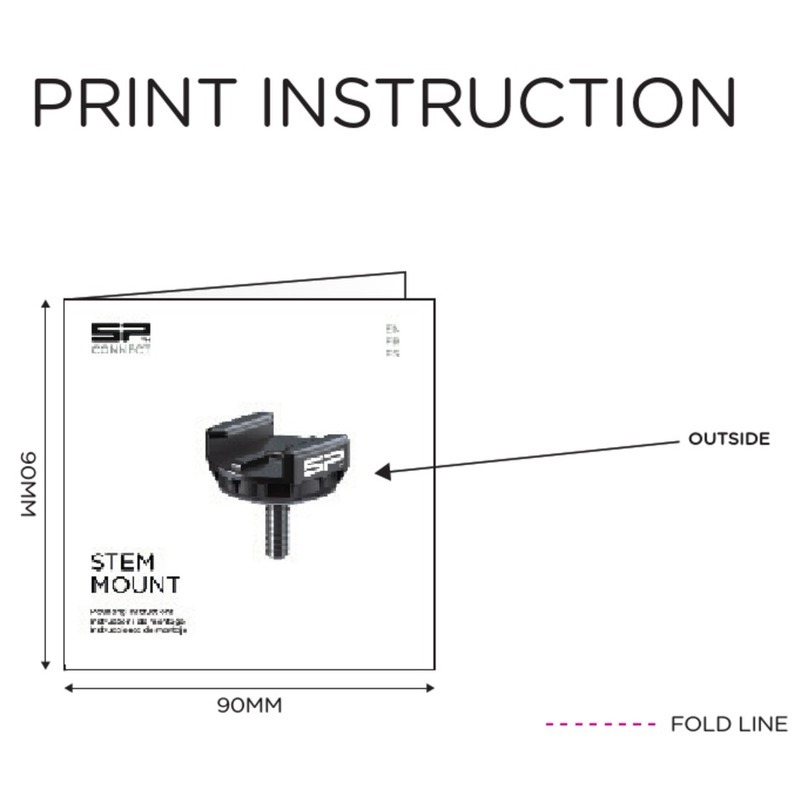

SP CONNECT

SP CONNECT STEM MOUNT Mounting instructions