- 3 -

ZMI_001_2000108123-ZA3OP0011_#SEN_#AQU_#V3.fm

0English

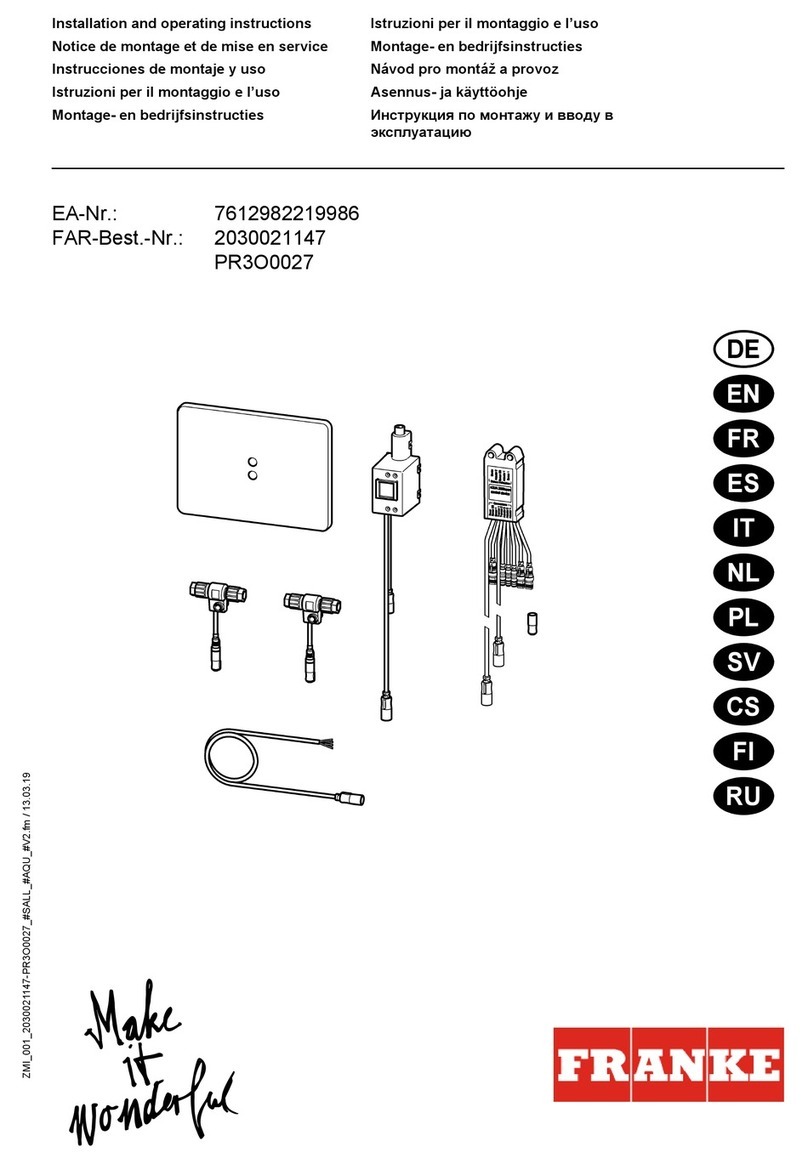

ECC2 Function Controller - A3000 open with

Ethernet Connection, 230 V AC / 24 V DC

2000108123

2030016282 .......................... including BMS data protocols

Please refer to the graphics in the German Installation and Operating Instructions.

Contents

1. Abbreviations and Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description of Product

5. Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Special Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

9. Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

10. Pin Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation, Function and Commissioning

11. Assembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

12. Display with Menu Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

13. Permissions / Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

14. Display for Staff Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

15. Settings in Technician Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

16. Start Web Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

17. Connection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

18. UPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Maintenance

19. Fault Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

20. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

21. Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18