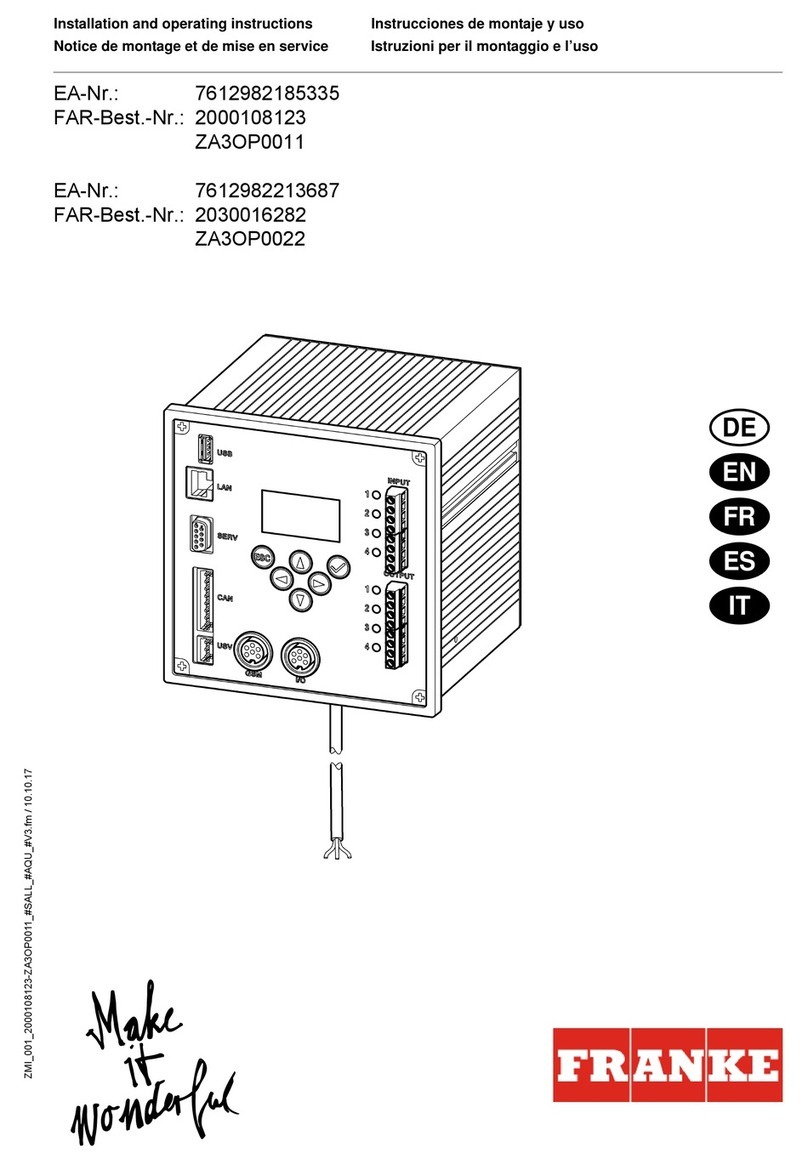

GMKPc JKL Controllers

Operation manual

1Technical parameters

1.1 Operating voltage: 380 V±20% 50 Hz

1.2 Input current: ≤5 A

1.3 Output contact capability: 250V/5A AC 380 V/3A AC

1.4 Operating way: automatic cycle and continuous operation

1.5 Throw-in threshold: more than 1.1 Ic and less than COSφsetting value

1.6 Throw out threshold: lead

1.7 COSφsetting: adjustable between 0.90 and 0.99

1.8 Delay time setting: adjustable between 10 and 99 S

1.9 Over voltage setting: adjustable between 410 and 470 V, voltage return difference:

8-10 V

1.10Number of return circuits setting: adjustable between 1 and 10/12 (1-5/7)

1.11Throw-in/out locking time of same set capacitance: more than 60 S

2. Operating conditions

2.1 Height above sea level: not higher than 2000 m

2.2 Ambient temperature: lower than +40℃and higher than -10℃

2.3 Air relative humidity: 85% at 25℃

2.4 Applicable for the occasions without any flammable and explosive media, and free of

conductive dust or corrosive air.

3. Input and wiring

3.1 Input current shall adopt the signal from current transformer of main distribution panel

supplied.

3.2 Input voltage phases B and C shall be adopted if using input current signal A. That

means that another two phases shall be adopted whenever using any phase of

current signal.

3.3 The contact P is connected with the contact B when the coil voltage of contactor is

380 V (see the diagram at the back). The contact P is connected with the contact N

when coil voltage is 220 V.\

3.4 Input current shall adopt the signal from current transformer of main distribution panel

supplied.

3.5 Input voltage phases B and C shall be adopted if using input current signal A. That

means that another two phases shall be adopted whenever using any phase of

current signal.

3.6 The contact P is connected with the contact B when the coil voltage of contactor is

380 V (see the diagram at the back). The contact P is connected with the contact N

when coil voltage is 220 V.

4. Parameter setting

4.1 In the setting state, automatically return to automatic state if not pressing any key

within 20 seconds.

4.1 Press ◎key, the manual light will turn on. Then press ▲key for gradually throwing

in and ▼key for gradually throwing out.

4.2 Press ◎key and hold for 3 seconds and then the setting light will turn on and

functional code F-0 will display. Press ◎key, COSφsetting value will display. Press

▲or ▼key for reset.

4.3 Press ◎key, functional code F-1 will display. Press ◎key again, delay setting

value will display. Press▲or ▼key for reset.

4.4 Press ◎key, functional code F-2 will display. Press ◎key again, overvoltage

setting value will display. Press▲or ▼key for reset.

4.5 Press ◎key, functional code F-3 will display. Press ◎key again, value of number

of return circuits setting will display. Press▲or ▼key for reset.

4.6 Press ◎key, functional code F-4 will display. Press ◎key again, self-test setting

value will display. Press▲or ▼key for reset.

4.7 Press ◎key, functional code F-5 will display. Press ◎key again, value of

accumulated throwin/out cycles will display. Press▲or ▼key for reset.

4.8 After completion of above-mentioned setting parameters, press ◎key and hold for 3

seconds, the automatic light will turn on. In this case, confirm the amended setting

value.

4.9 Shortcut: Press ◎key, the manual light will turn on. Double click ◎key, the setting

light will turn on and functional code F- □will display. Press ▲or ▼key to select

the functional code. Then press ◎key again, the relative setting parameter will

display correspondingly. Press ▲or ▼key to reset. Double click ◎key after

reset and the automatic light will turn on.

4.10In the setting state, automatically return to automatic state if not pressing any key

within 20 seconds.

The GMKPc JKL58 - 12 Step Controller

The GMKPc JKL58 - 7 Step Controller