2

Tableof contents

SAFETYINSTRUCTIONS.......................................................................................................................3

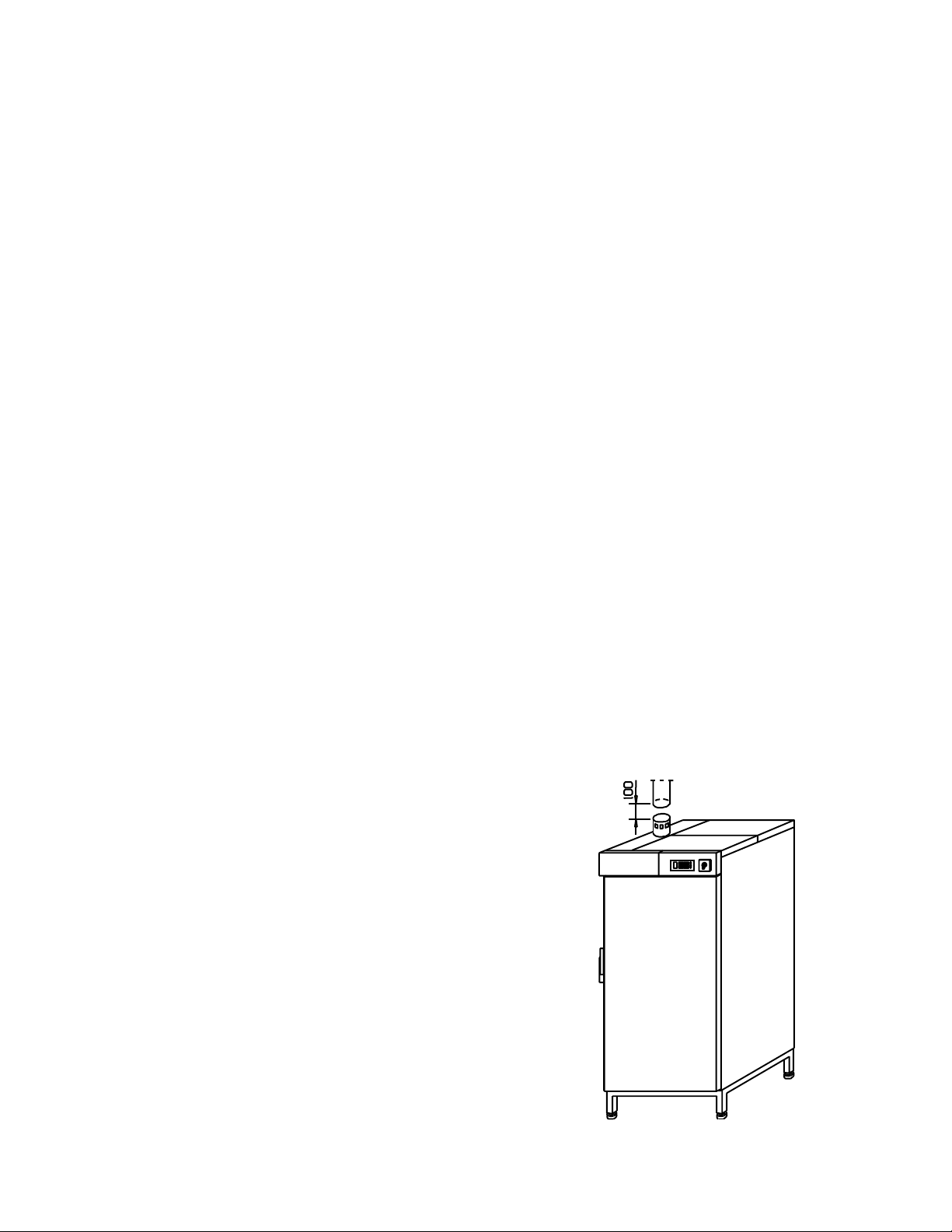

1.0GENERALOF THEDRYINGCABINET............................................................................................4

2.0INSTALLATIONINSTRUCTIONS......................................................................................................4

3.0OPERATIONINSTRUCTION..............................................................................................................5

4.0PROGRAMS.........................................................................................................................................7

5.0PROGRAMMING..................................................................................................................................8

6.0MAINTENANCE...................................................................................................................................9

6.1 PROGRAMMEBUTTONCHECKMODE (ONLYFORCHECKING)....................................................................10

6.2.MALFUNCTIONINDICATIONCODE ER 10..............................................................................................10

7.0TECHNICALSPECIFICATIONS......................................................................................................11

7.1DIMENSIONALDRAWING......................................................................................................................11

7.1.2TECHNICALDATA .............................................................................................................................11

7.2DIMENSIONALDRAWING (PASS-THROUGH MODEL)................................................................................12

7.2.2TECHNICALDATA .............................................................................................................................12

7.3CIRCUITDIAGRAM...............................................................................................................................13

7.3CIRCUITDIAGRAM /JAPANMODELS .....................................................................................................14

7.4SPARE PARTS DRAWING ......................................................................................................................15

7.5SPARE PARTS LIST...............................................................................................................................16

8.0DECLARATIONOF CONFORMITY................................................................................................17

9.0GUARANTEECONDITIONS............................................................................................................18