Friedrich HazardGard SH14J30B-A Guide

Other Friedrich Air Conditioner manuals

Friedrich

Friedrich Uni-Fit UE10 Original operating instructions

Friedrich

Friedrich MR24UY3J User manual

Friedrich

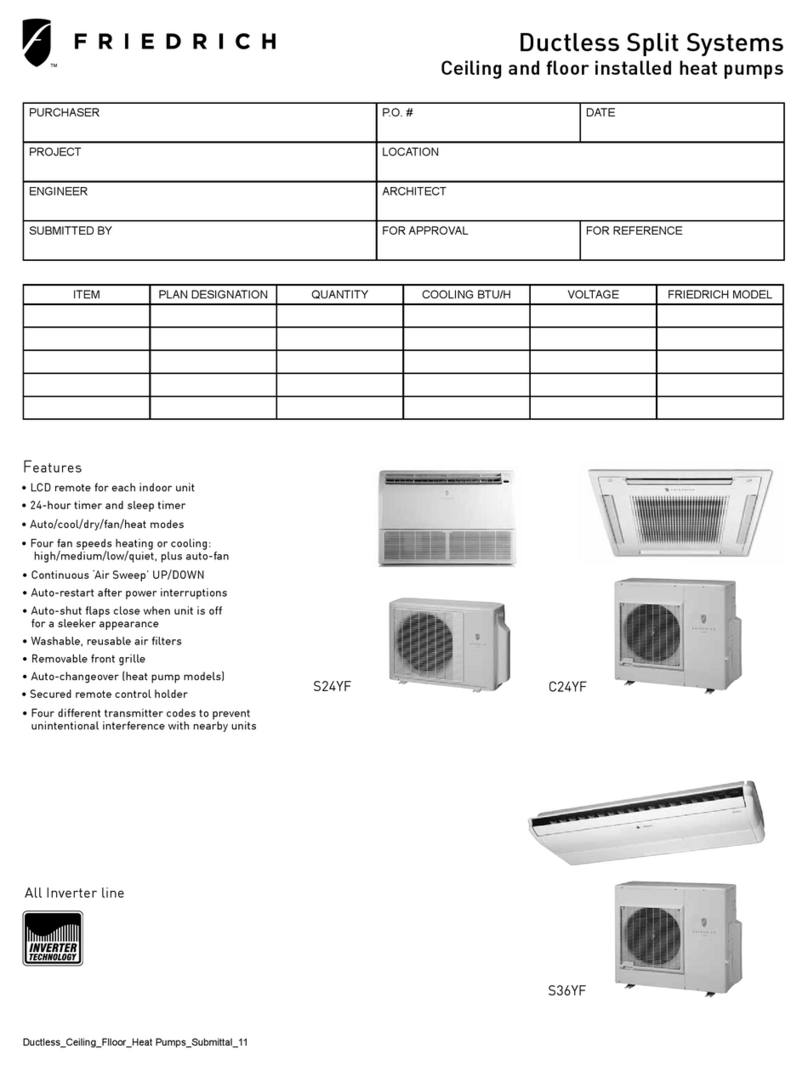

Friedrich C24YF User manual

Friedrich

Friedrich QuietMaster KM18L30 User manual

Friedrich

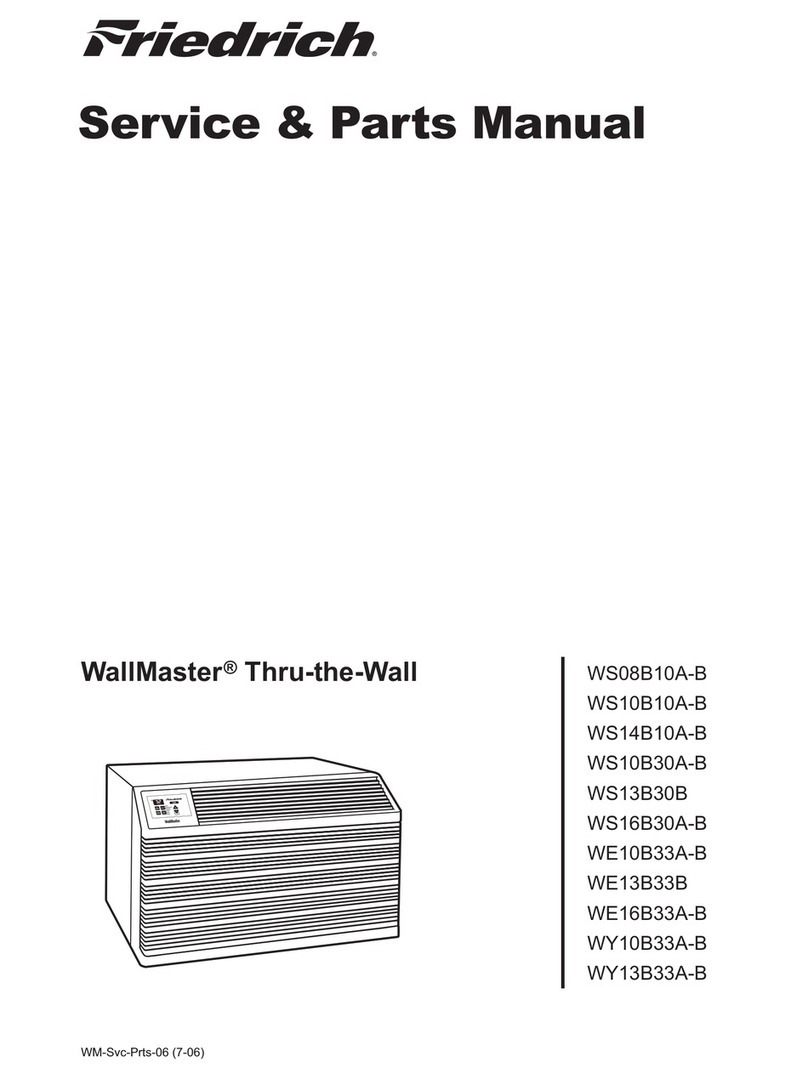

Friedrich WallMaster WE10B33A Building instructions

Friedrich

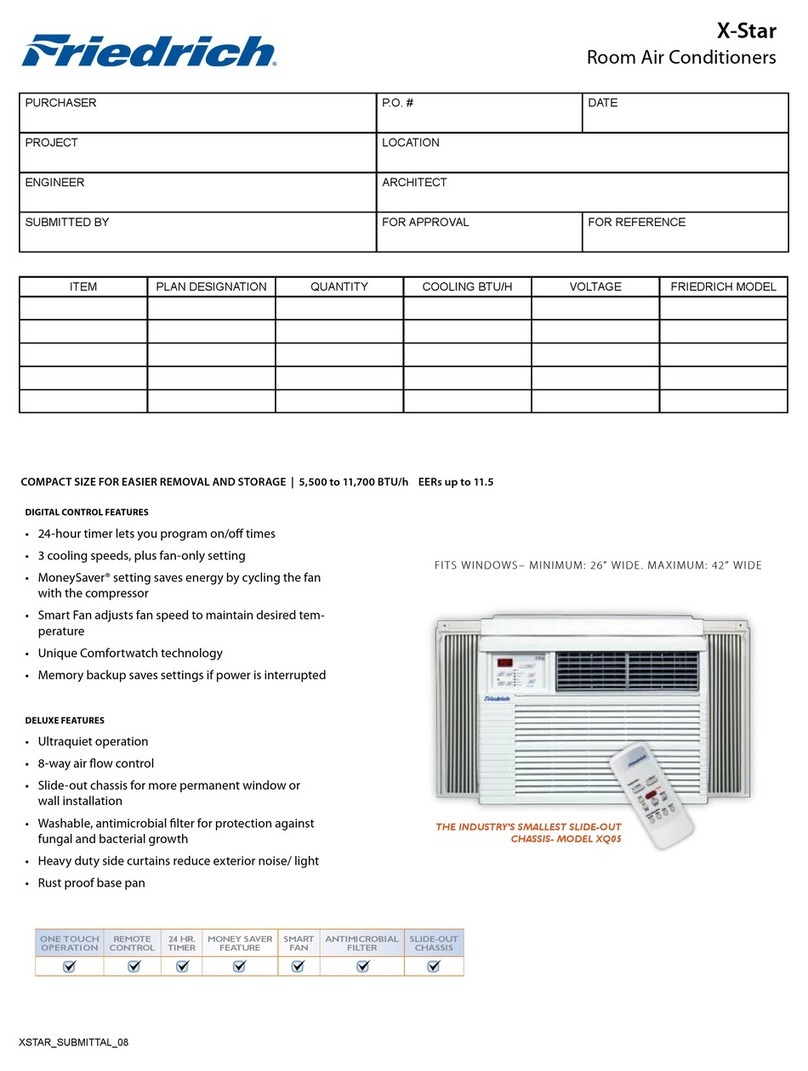

Friedrich X-Star XQ05L10A User manual

Friedrich

Friedrich CP10 User manual

Friedrich

Friedrich MW18C3E User manual

Friedrich

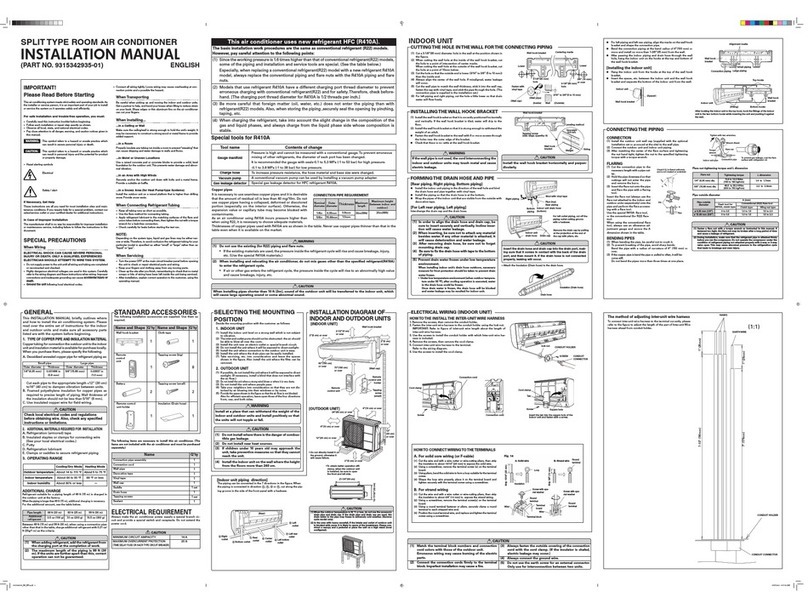

Friedrich 9315342935-01 User manual

Friedrich

Friedrich CP10E10 Series User manual

Friedrich

Friedrich P/N9368987060-01 User manual

Friedrich

Friedrich MS24Y3F User manual

Friedrich

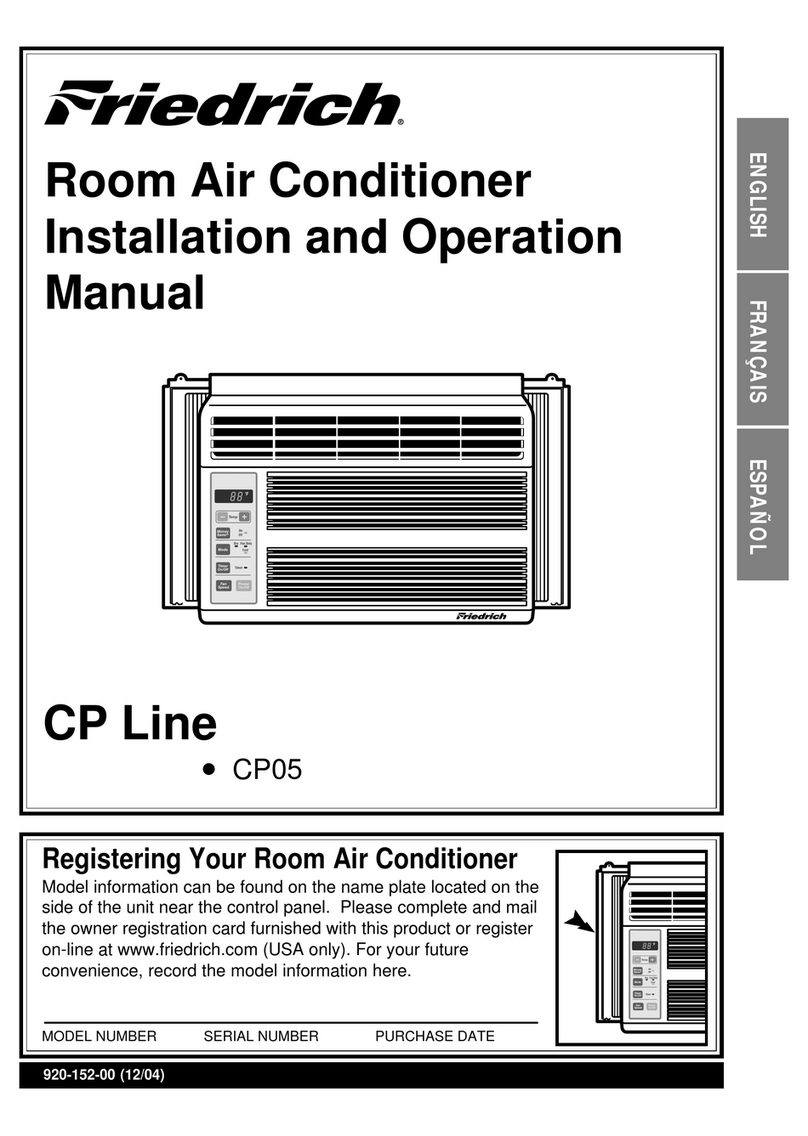

Friedrich CP Line CP05 User manual

Friedrich

Friedrich MR09Y1F User manual

Friedrich

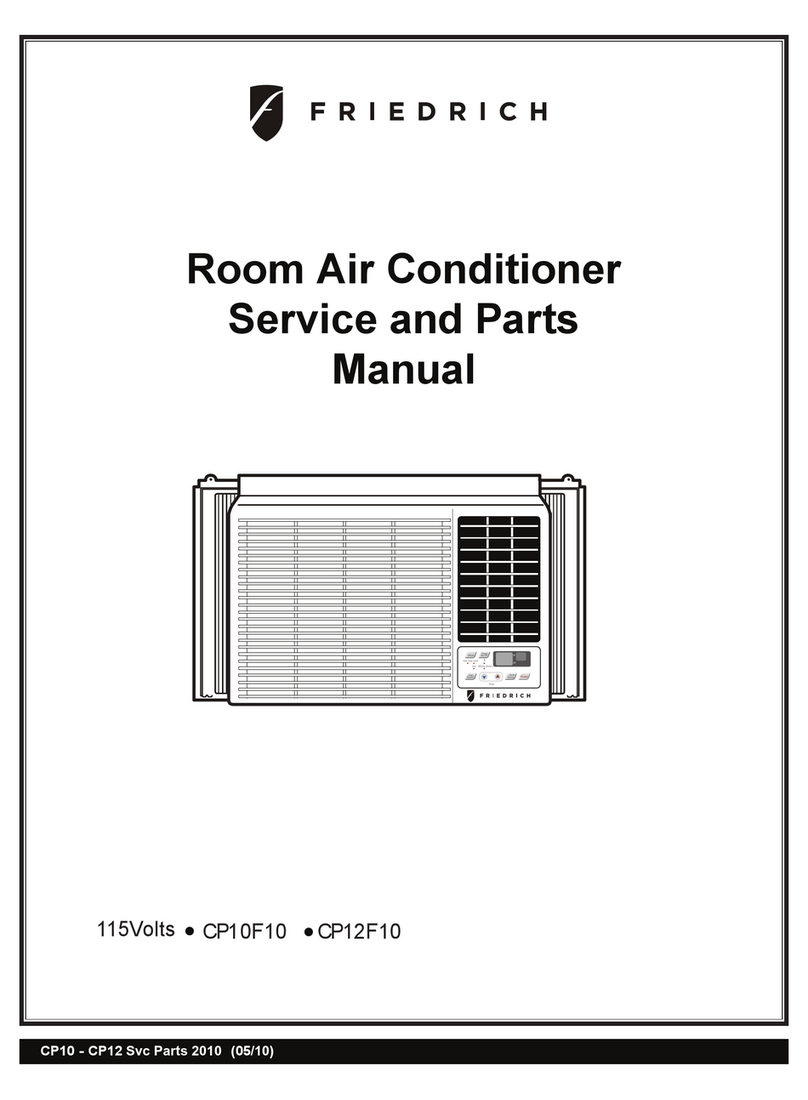

Friedrich CP12F10 Building instructions

Friedrich

Friedrich WallMaster PE07K User manual

Friedrich

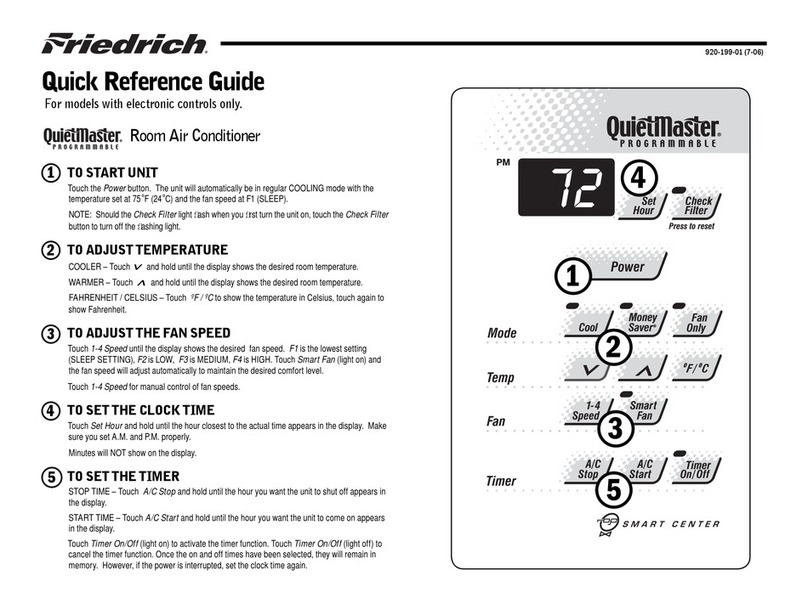

Friedrich QUIETMASTER Programmable SM18L30A User manual

Friedrich

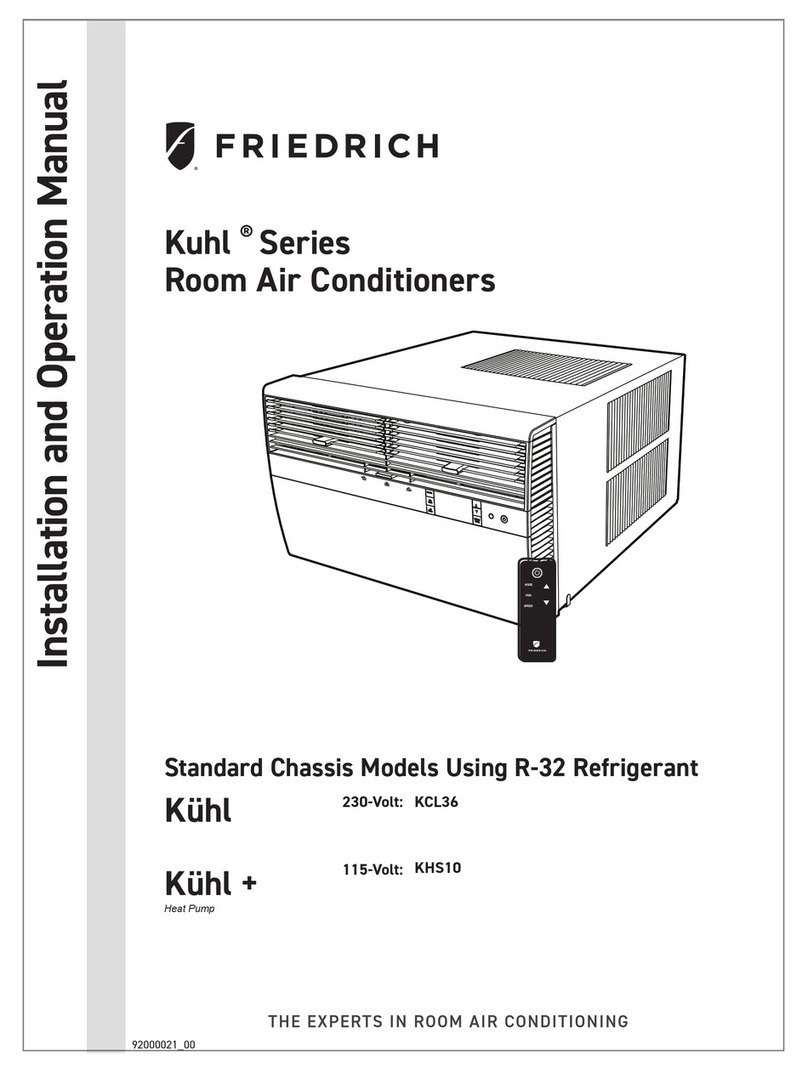

Friedrich Kuhl KCL36 User manual

Friedrich

Friedrich M18CJ User manual

Friedrich

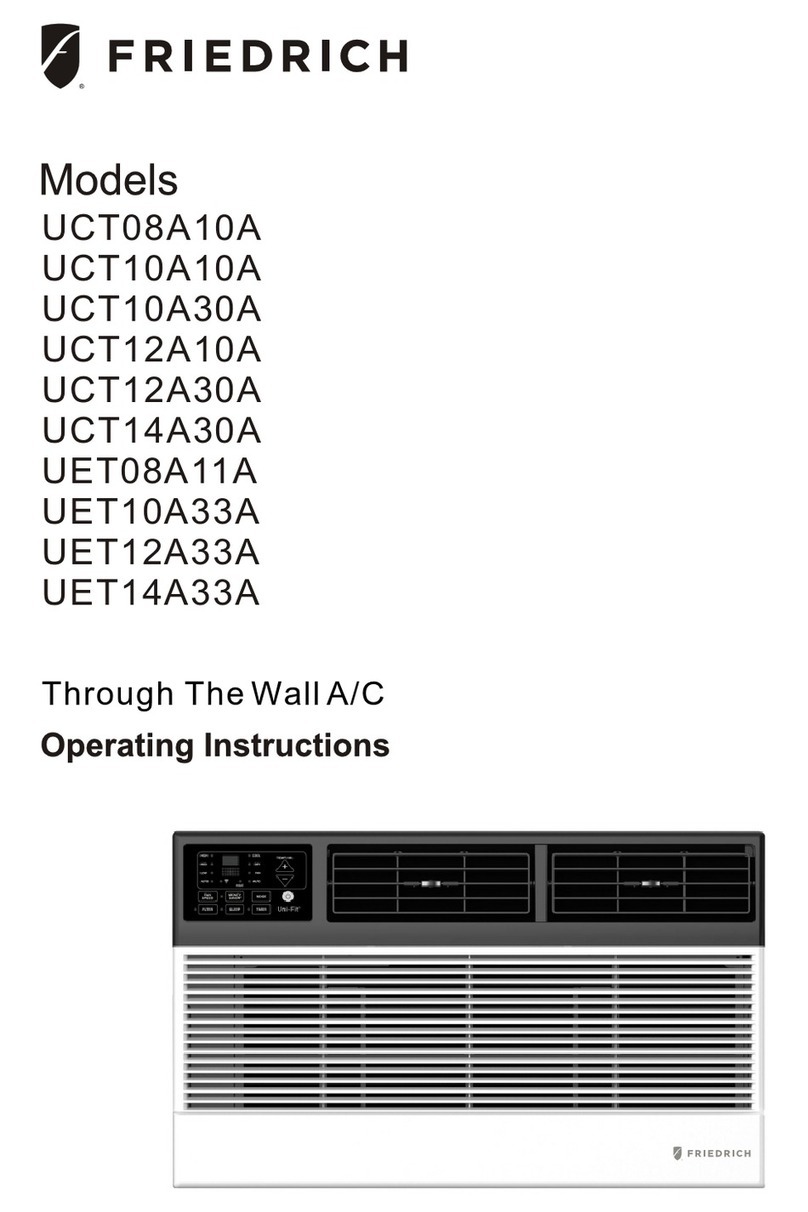

Friedrich UCT08A10A User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions