TABLE OF CONTENTS

CHAPTER 1. OVERVIEW................................................................. 4

1.1 BOX CONTENT AND FEATURES ................................................4

CHAPTER 2. INSTALLATION ....................................................... 6

2.1 HARDWARE INSTALLATION.......................................................6

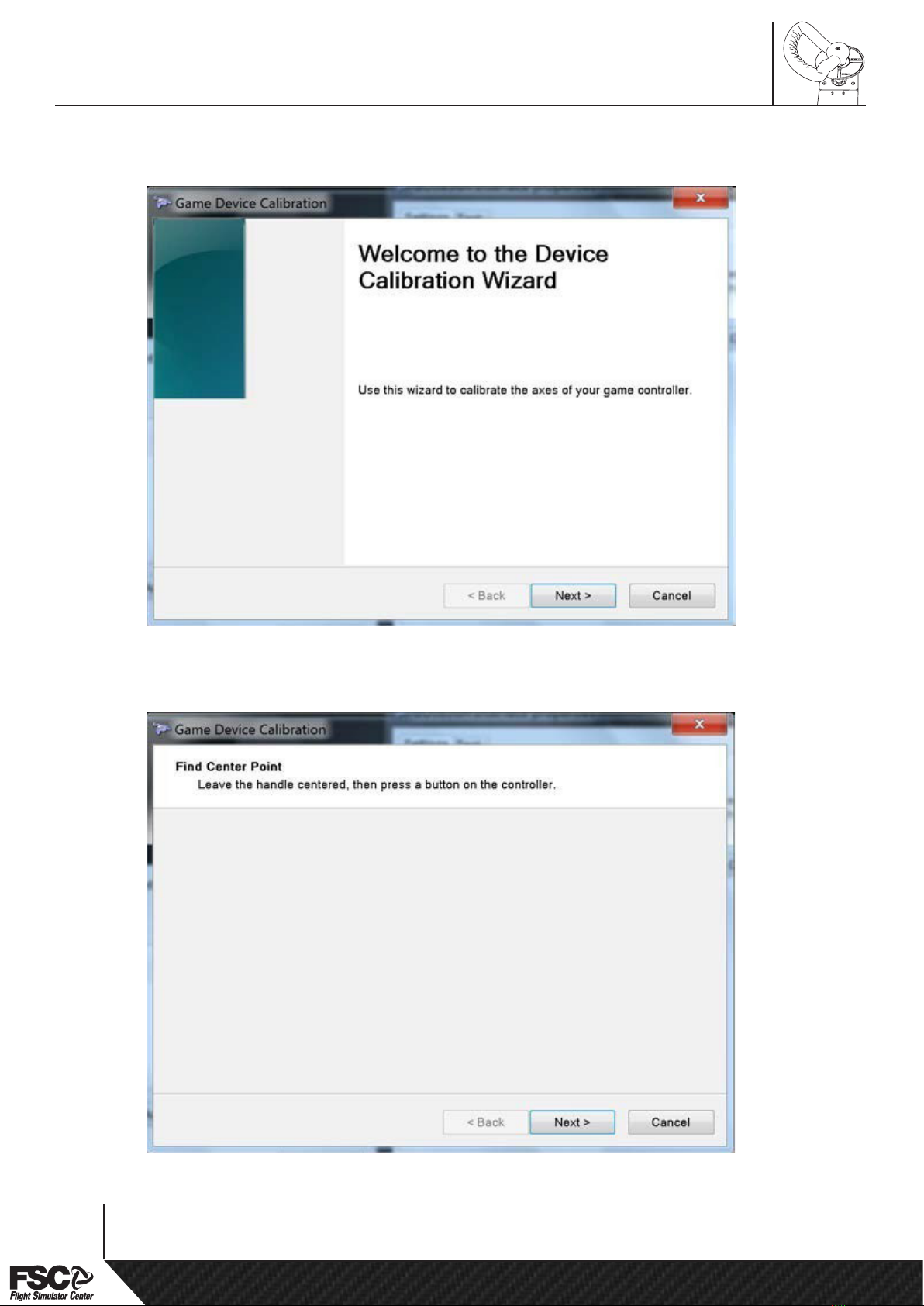

2.2 SOFTWARE SETTINGS AND CALIBRATION..............................7

CHAPTER 3. SETUP .......................................................................... 14

3.1 ADJUSTING THE REACTION FORCE AND RETURN TO

ZERO SPEED...................................................................................... 14

APPENDIX A

A1 DIMENSION AND WEIGHT .............................................................15

APPENDIX B

B1 SCHEMATICS ...................................................................................17

APPENDIX C

C1 DRILLING TEMPLATE......................................................................18

APPENDIX D

D1 POTENTIOMETER REPLACEMENT................................................19

APPENDIX E

E1 MECHANICAL RE-ALIGNMENT / LOOSING THE KEYLESS

LOCKING DEVICE .................................................................................21

HOW TO CONTACT SUPPORT ...........................................................22

DISCLAIMER

All product names, logos, and brands are property of their respective owners.

www.fsc.it

Installation and Operation Manual

3