Page 3of 18 Fuji Electric Europe GmbH

CONTENTS

0. Introduction..........................................................................................................................4

1. Connections.........................................................................................................................4

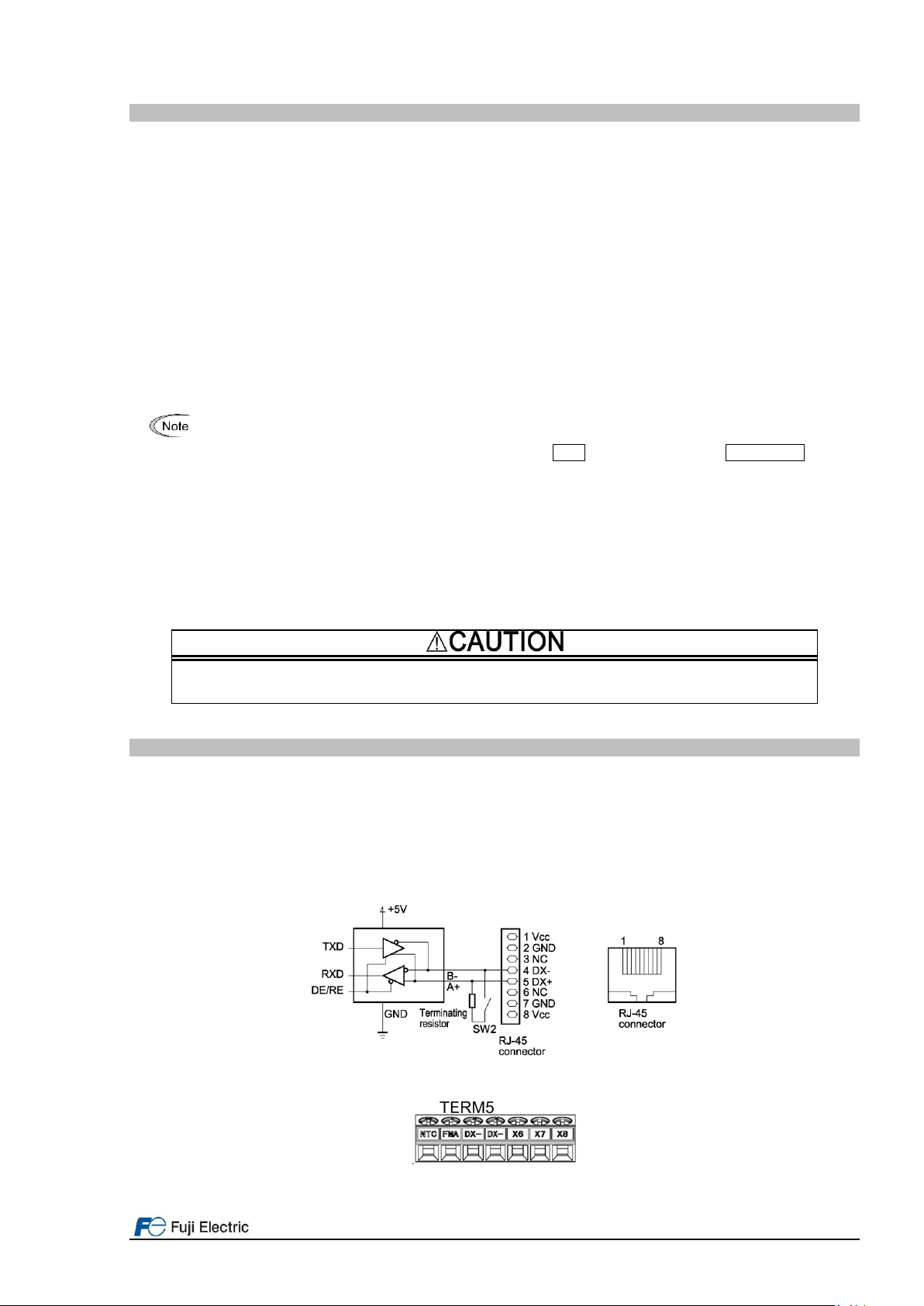

1.1 RS485 bus terminals.....................................................................................................4

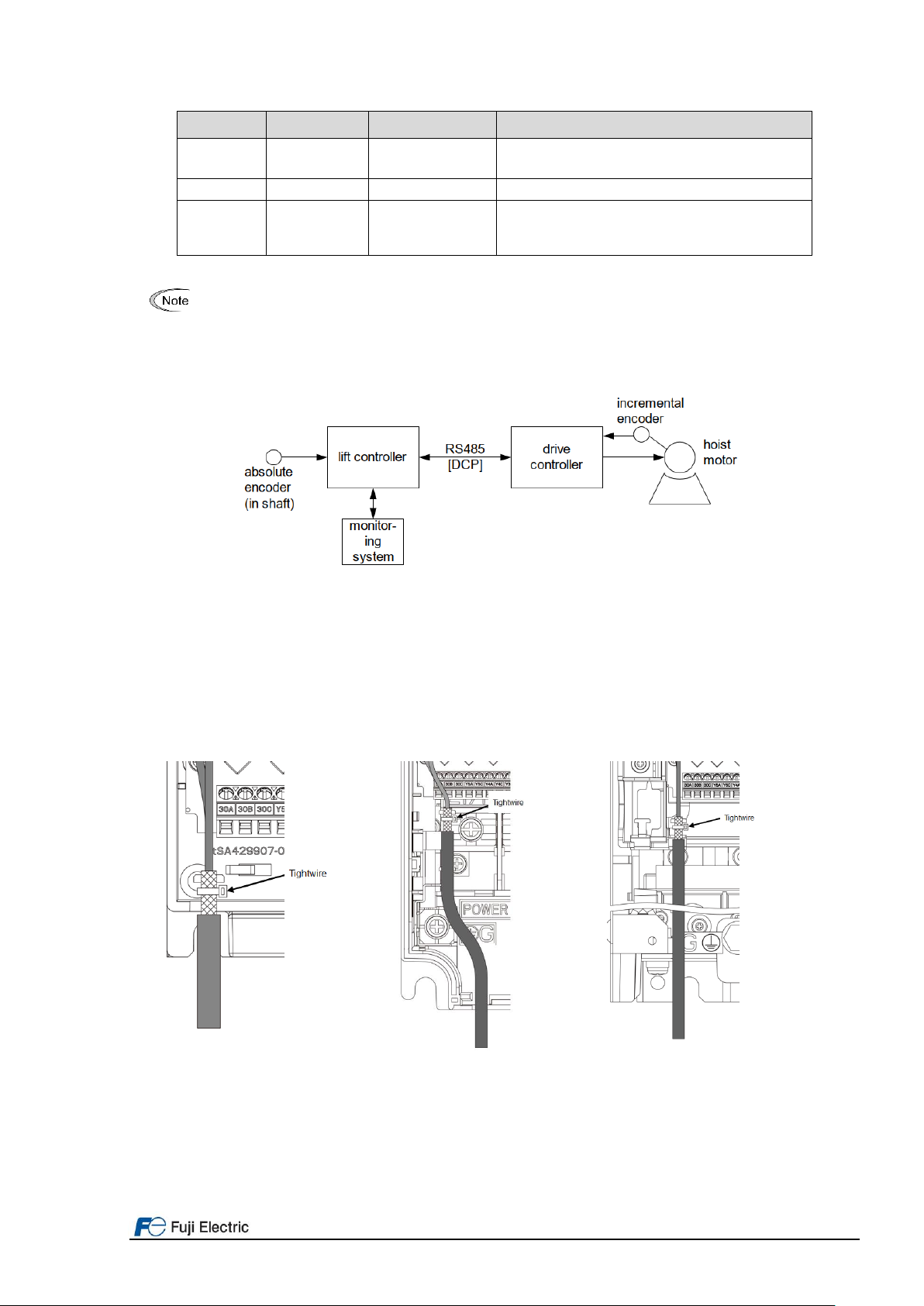

1.2 Shield connection..........................................................................................................5

1.3 Terminal resistor............................................................................................................6

2. Remote display ....................................................................................................................6

2.1 Remote display keys .....................................................................................................6

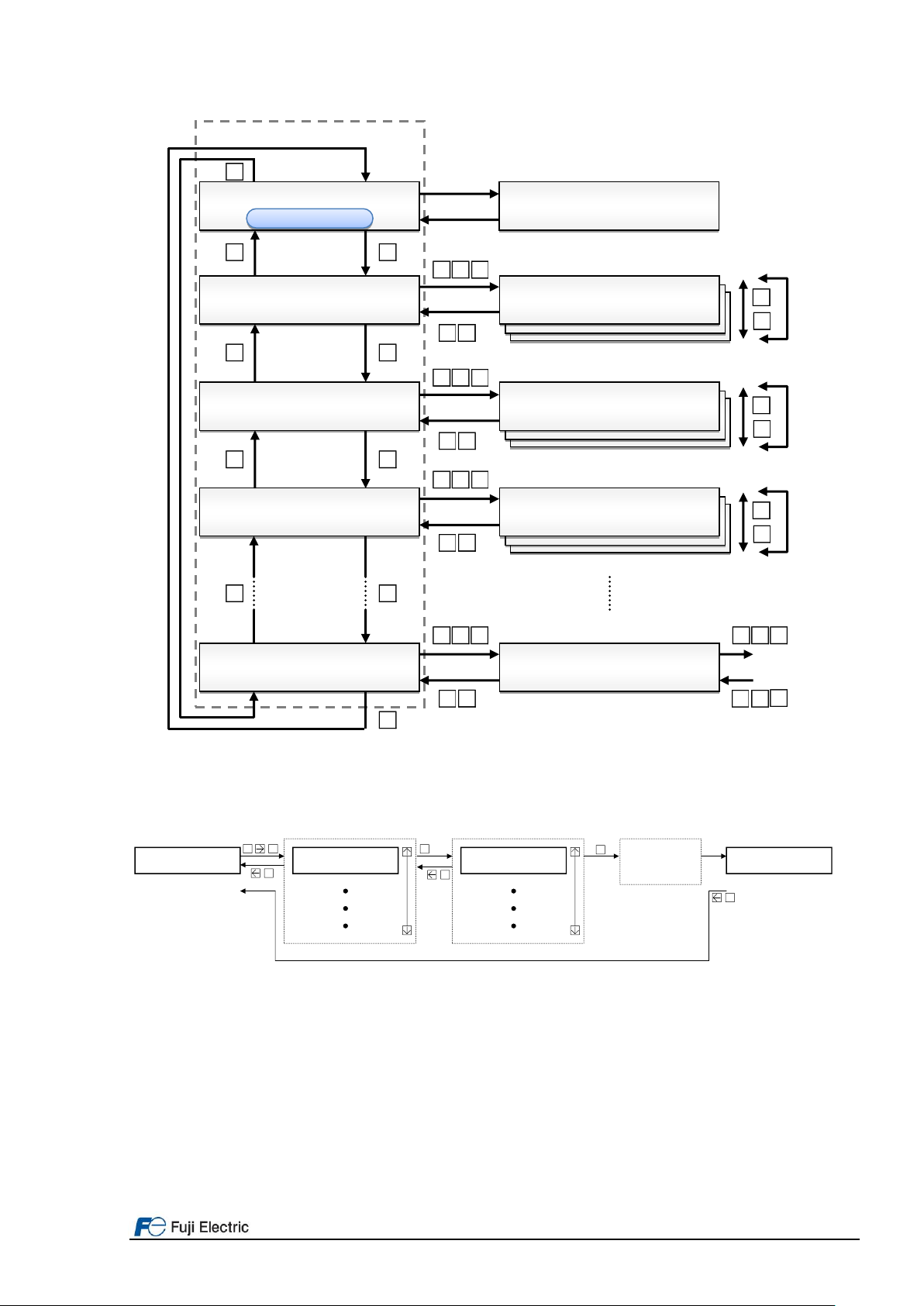

2.2 Remote display menus..................................................................................................7

3. Basic setting.......................................................................................................................10

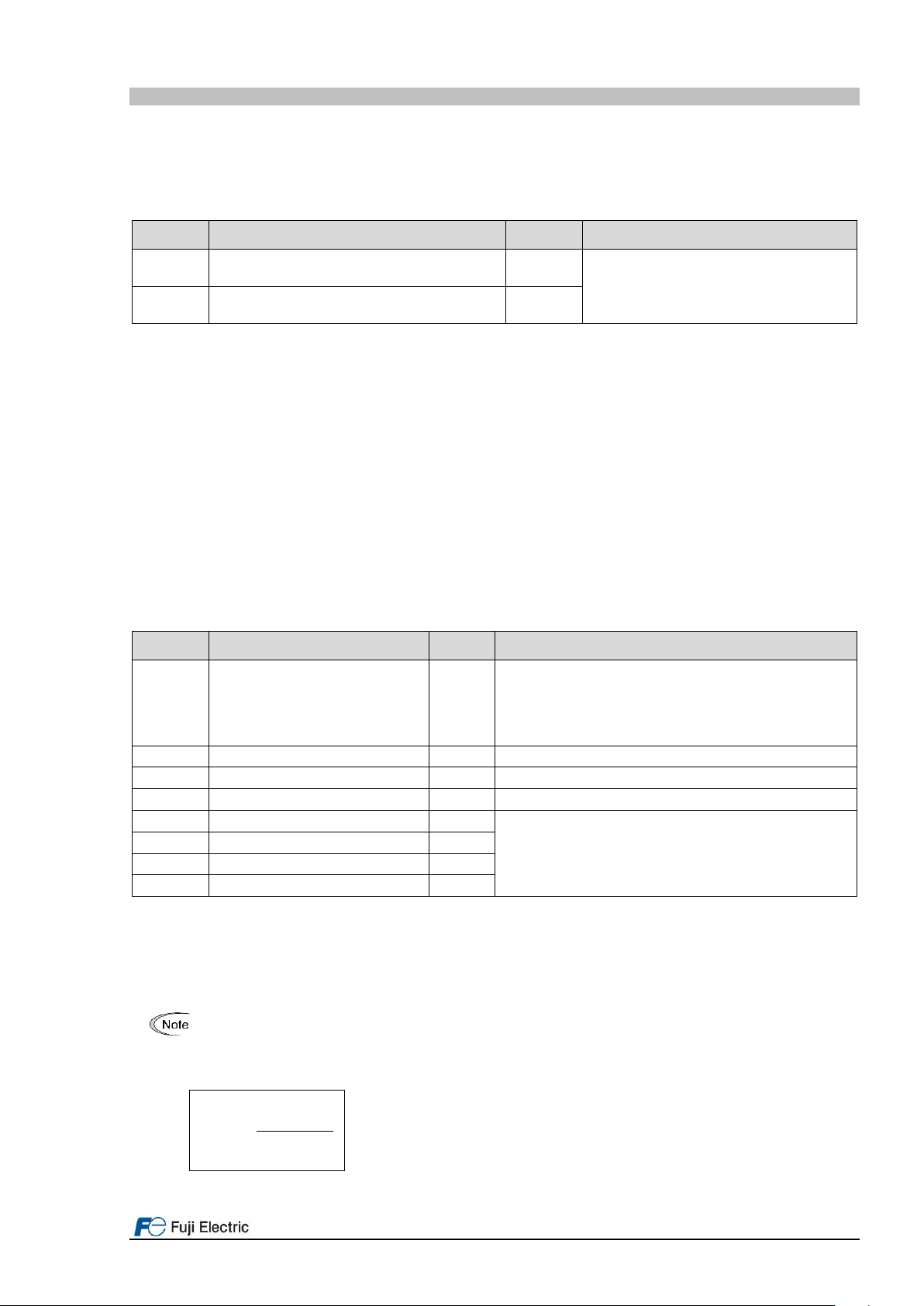

3.1 DCP bus setting ..........................................................................................................10

3.2 Lift / motor basic setting...............................................................................................10

3.3 Lift speeds...................................................................................................................11

4. Start-up..............................................................................................................................12

5. Lift speed profile settings....................................................................................................13

5.1 DCP 3 (Lift controller without absolute sensor system)................................................13

5.2 DCP 4 (Lift controller with absolute sensor system).....................................................14

6. Signals timing diagram in DCP...........................................................................................15

6.1 DCP 3 (Speed mode)..................................................................................................15

6.2 DCP 4 (Remaining distance mode) .............................................................................16

7. Travel optimization (Remaining distance mode).................................................................17