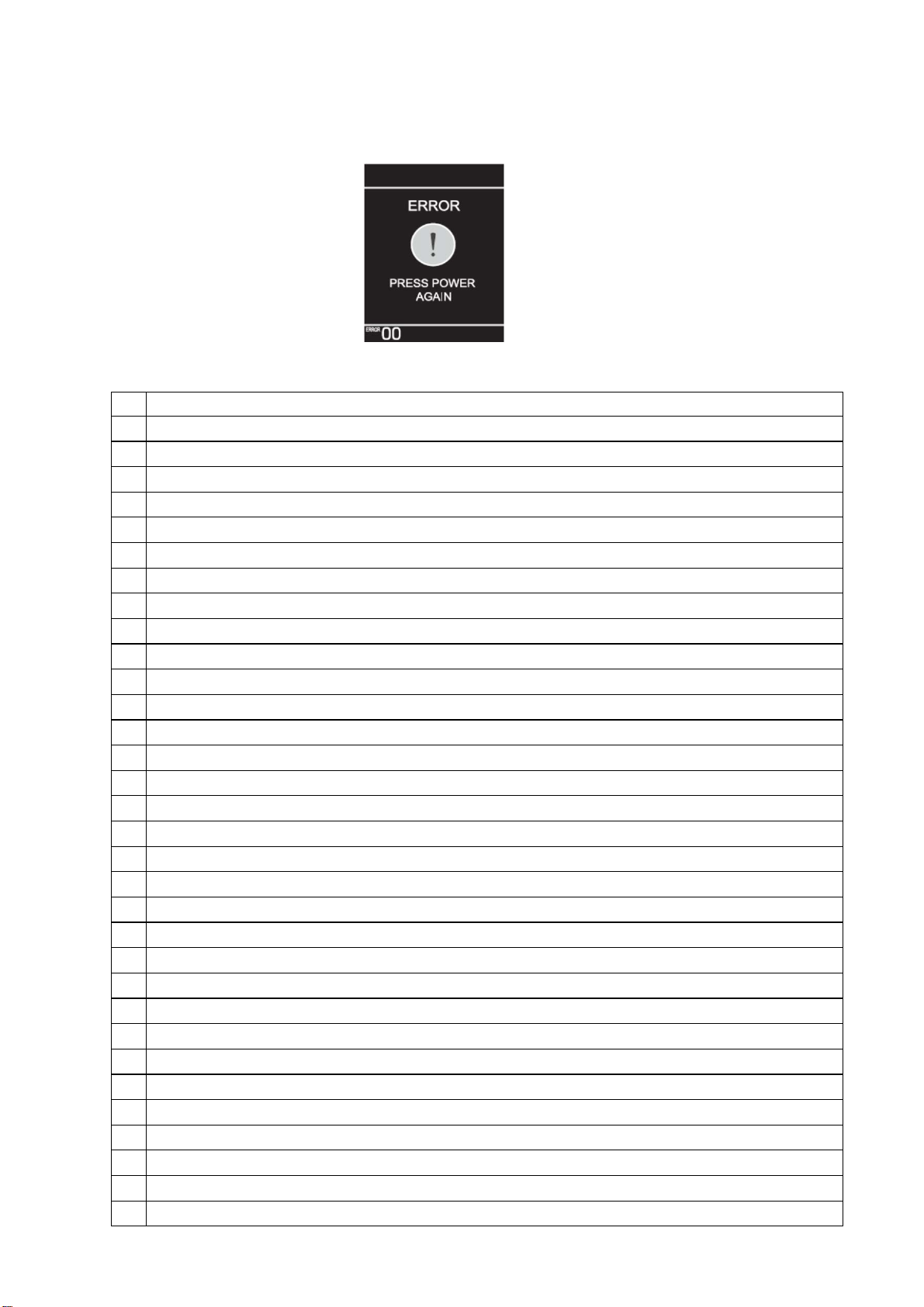

7. Safety precaution

When an error occurs, turn off air massage, mechanic massage, reclining, footrest, footrest Expansion and contraction, air movement, heater.

Error mode could be released by turning the power off.

Details of error are discribed on chart 7-1

Erro

2

3

4

5

6

8

9

10

11

14

18

19

20

21

22

23

24

25

26

27

28

29

30

40

41

42

43

44

45

46

60

61

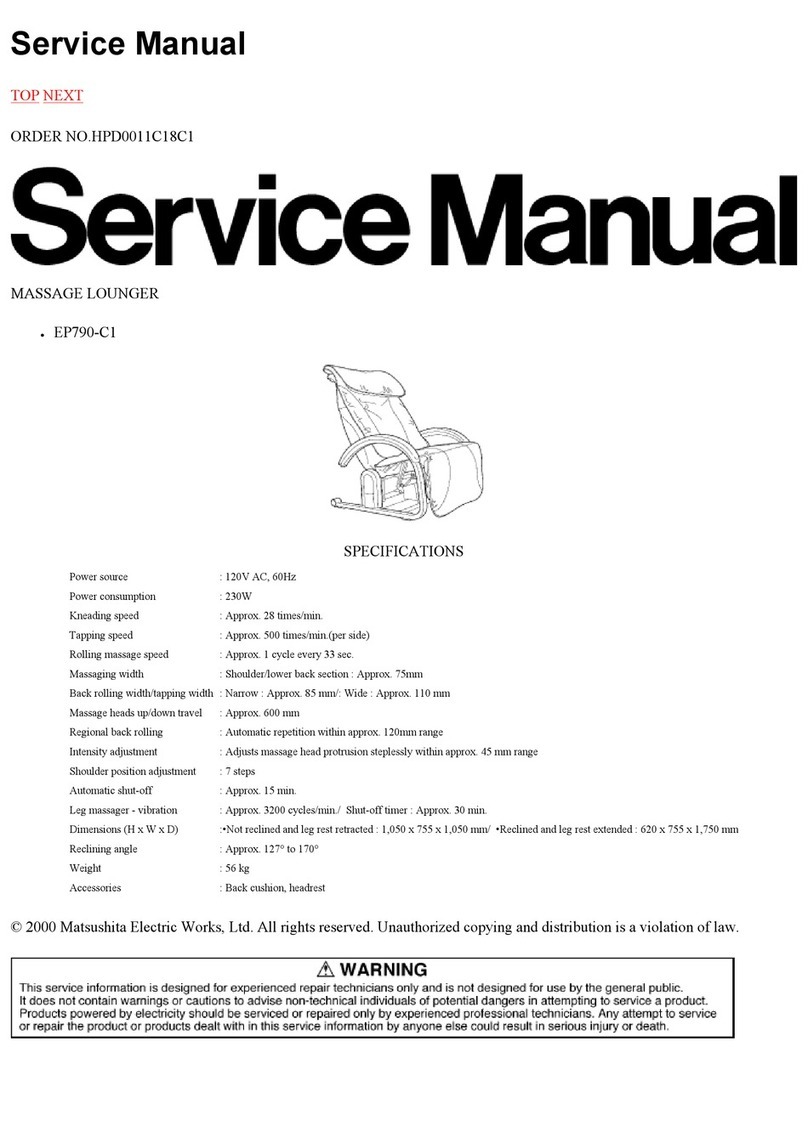

Connector comes off, continuous detection for 0.5 second.

Error contents

Limit sensor signal is not on for more than 42 seconds during moving up.

Lower limit stop sensor signal is not on for more than 42 seconds during moving down.

In case elevation pulse is not entered for more than 3 seconds during elevating operation.

Malfunction of weak position sensor(weak signal is not off for more than 6 seconds during moving to "strong"direction)

Malfunction of weak position sensor(weak signal is not off for more than 6 seconds during moving to "weak"direction)

In case Strong/Weak pulse is not entered for more than 1 second during strength operation.

In case 「Wide」position pulse is not entered for more than 2 seconds during kneading operation.

In case Knead pulse is not entered for more than 2 seconds during kneading operation.

Equipment error(from the main board)

Equipment error(from remote control)

Continuous detection of the overcurrent for ottoman expansion and contraction motor for more than 0.3 second during ottoman expansion and contraction operation.

Tapping motor lock signal is continuously on for 2 seconds.

In case reclining pulse is not entered for more than 2 seconds during reclining operation.

In case ottoman pulse is not entered for more than 2 seconds during ottoman operation.

In case reclining limit signal is not entered for more than 30 seconds during reclining up operation.

In case reclining limit signal is not entered for more than 30 seconds during reclining down operation.

In case ottoman limit signal is not entered for more than 30 seconds during ottoman up operation.

Remote control : It does not have communication processing for 1 second in a row.

Main circuit board : power outlet 24V become below 20V after 0.5 second pass from power on with 24V.

Main circuit board : power outlet 24V become below 12V for 0.1 second in a row.

Chart 7.1 : Error display

Chart 7-1 : Error contents

Main circuit board : CRC does not match for 1 second in a row.

Main circuit board : header does not match for 1 second in a row.

Main circuit board : remote control is in busy state for 1 second in a row.

Main circuit board : It does not receive a data from remote control for 1 second in a row.

Remote control : CRC does not match for 1 second in a row.

Remote control : header does not match for 1 second in a row.

In case ottoman limit signal is not entered for more than 30 seconds during ottoman down operation.

Actuator connector comes off, continuous detection for 0.5 second.

In case ottoman expansion and contraction pulse is not entered for more than 2 seconds during ottoman expansion and contraction operation.

In case limit signal is not entered for more than 15 seconds during ottoman expansion operation.

In case limit signal is not entered for more than 15 seconds during ottoman contraction operation.