The fan-delay cycle starts after draining. The refrigeration output (REFR) is active, therefore the

ambient temperature is high, but the fan is actived only after the temperature in evaporator is less than

the adjusted value. This process is necessary to remove the heat that still exists in the evaporator

because of defrost, preventing to transfer this heat to the ambient.

For security, if the temperature in the evaporator does not reach the adjusted value in F19 or sensor S2

is detached, the fan-delay will happen on the adjusted time in this function.

During the refrigeration cycle, the fan activation may depends on the compressor status.

"0" = The fan is actived only while the compressor is active. This alternative, in some cases, allows great

economy of electric energy.

"1" = The fan is kept on during all refrigeration cycle.

It has for purpose the cycle of evaporator ventilation until the ambient temperature approaches the

desired temperature in the refrigerating installation project, preventing high temperatures and

pressures that can damage the compressor. If the temperature in evaporator exceed the adjusted value,

the fan is turned off and turned on again with a fixed hysteresis of 2°C below this value.

F19 - Evaporator temperature (S2) for fan return after draining (fan-delay)

F20 - Maximum time of fan return after draining (fan-delay)

F21 - Fan on with compressor off

F22 - Fan stopped for high temperature in evaporator

5. OPERATION

5.1 - Parameters visualization

a)

b)

c)

d

e)

a)

b)

c) 5.1-b 5.1-c

d)

e)

Press at the same time and for 2 seconds until appear , releasing them after that.

Soon, appears .

Use and to access the desired function.

After selecting the function, press (short touch) to visualize the configured value.

) Press again (short touch) to return the functions menu.

To reset the menu and return to normal operation (temperature indication), press until appear

.

Access the function F01 by pressing at the same time and for 2 seconds until appear ,

releasing then after that. Soon will appear , and then press (short touch).

Use and to enter the access code (123), and then press .

Select the desired function and visualize the configured value (see itens and ).

Use and to change the value and then press to record the configured value and return

to the functions menu.

To reset the menu and return to normal operation (temperature indication), press until appear

.

5.2 - Parameters configuration

SET

SET

SET

SET

SET

SET

SET

5.3 - Process stage, elapsed time and evaporator temperature (S2)

Press . The stage of the process will appear, the elapsed time (in minutes) and evaporator

temperature (S2).

In case of detached sensor or temperature out specified range will appear .

Process stages: Initial delay (delay to start the control)

Fan-delay (delay to fan return)

Refrigeration

Defrost

Draining

FAN-DELAY REFRIGERATION DEFROST DRAINING

Indication released

F20 F14 F18F08

Indication locked (if enabled in F17)

5.4 - Manual defrost

To do a manual defrost, regardless of the programming, keep pressed for 4 seconds, until appears the

indication .

If the instrument is in defrost and you want to finish it, follow the above instructions, until appears the

indication .

5.5 - How to determine the end defrost by temperature

a)

b)

c)

d)

e)

f)

g)

h)

Adjust the follow functions with maximum values:

- Refrigeration time (F08 = 999 min)

- Evaporator temperature for end defrost (F13 = 75.0 ºC)

- Maximum duration of defrost (F14 = 90 min)

Wait until an ice layer to be created on the evaporator

Do a manual defrost, pressing for 4 seconds, until appear .

Observe the melting process.

Wait until melt all ice layer on the evaporator to consider the defrost finished.

Check the evaporator temperature read by the sensor S2 at this moment, pressing the key (see item 5.3)

and copy this value to the function F13 - Evaporator temperature (S2) for end defrost.

As security, adjust again the function F14 - that depends of the defrost type.

Now adjust the function F08 -

Maximum duration of defrost,

Exemple: Electrical defrost (resistance) =45 minutes as maximum

Defrost for by hot gas = 20 minutes as maximum

Refrigeration time with the desired value.

5.6 - Indicators and alarms

5.7 - Minimum and maximum temperatures register

The leds indicate the control outputs status:

: Compressor or solenoid of liquid gas

: Evaporator fans

: Defrost (heating)

In normal operation, indicates the ambient temperature (sensor S1)

The indication stays blinking when the ambient temperature (S1) reaches the adjusted value in F07.

Always that defrost ends for time and not for temperaure, a point located in the right down side of display will

blink until the next defrost indicating that:

- The interval between defrosts is too high.

- There are burned resistances.

- The hot gas is not circulating.

- There is an inoperative fan or the adjusted time is too short for the maximum duration of defrost.

If during the refrigeration sensor S1 or sensor S2 will be detached or outside the specified temperature range,

the indication will appear for S1 or for S2 and the compressor will assume the configurated

status in F11, for security.

Invalid configuration parameters

- In this situation the outputs are turned off.

- Check which parameters have invalid data and correct them to return to normal operation.

Press , soon appears and the minimum and maximum temperatures of S1 sensor (ambient

temperature). After soon appears and the minimum and maximum temperatures of S2 sensor

(evaporator).

REFR

FANS

DEFR

TC-900Ri

Note: To reset the registers keep pressed the key during the visualization of the minimum and

maximum temperatures until to be showed.

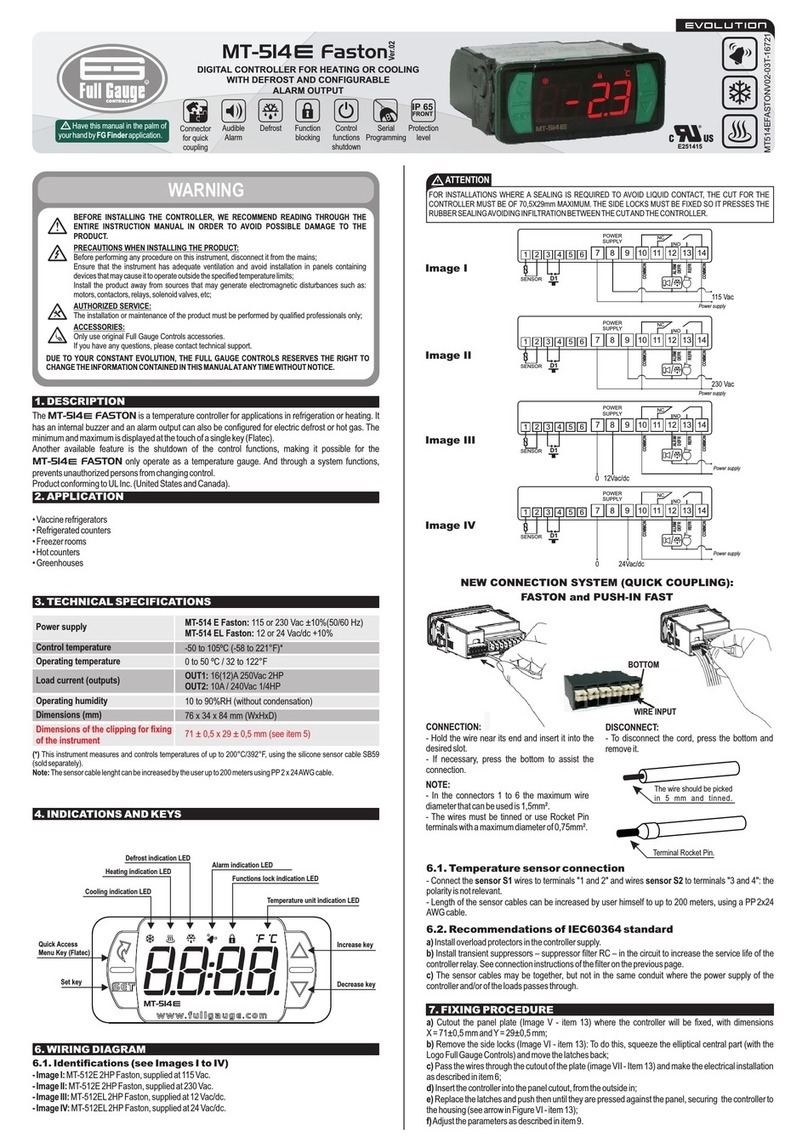

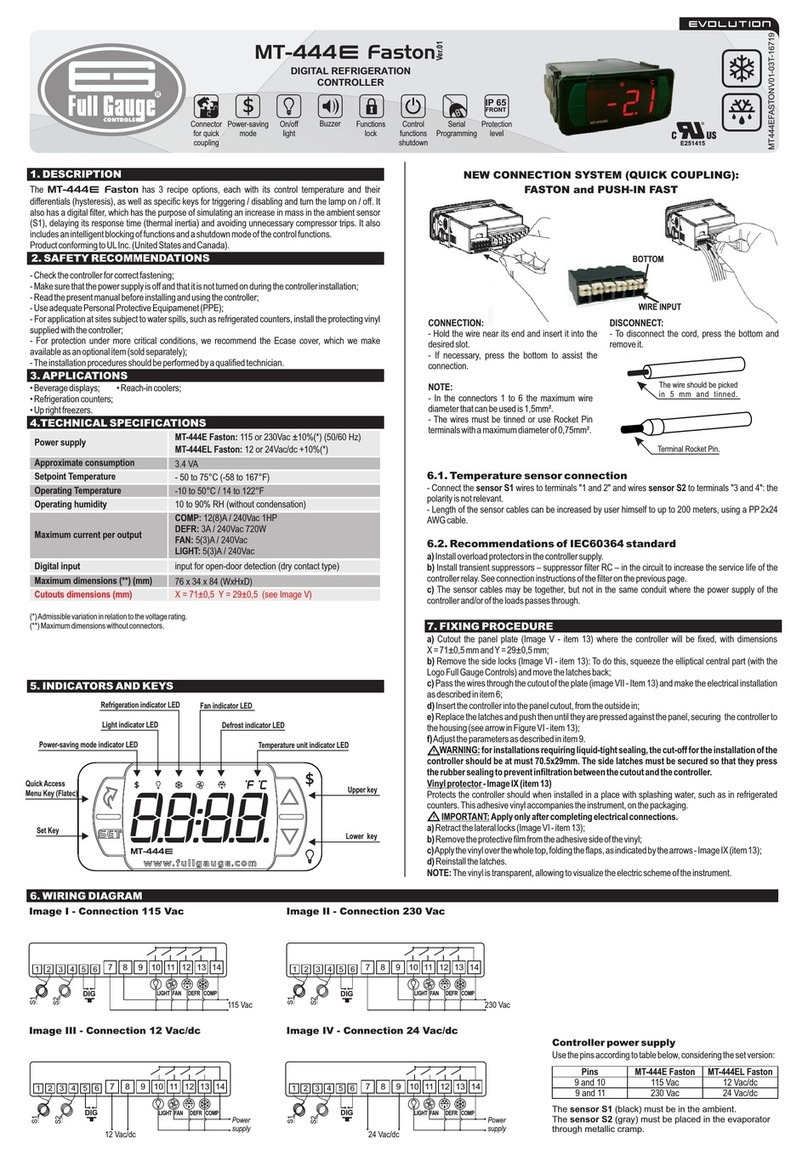

- The sensor S1 (black) must be in the ambient.

- The sensor S2 (gray) must be placed in the evaporator through metallic cramp.

Power

supply

0115V

(12V )

230V

(24V )

REFR

DEFR

FANS

Loads

supply

COMMON

Over the specifield current

use a contactor.

Sensor

(black)

1

Sensor

(gray)

2

45678910 11 12

321 21

6-7

6-8

115V

230V

12V

24V

TC-900Ri TC-900RiL

72 mm

Dimension of the clipping

for setting of the instrument

in panel

29 mm

6. ELECTRICAL CONNECTIONS

IMPORTANT

1:

2:

3:

According to the chapters from the IEC60364 standard:

Install on power supply

Sensor cables and computer signals can be together, however not at the same place where power

supply and load wires pass for

Install suppresor of transient in parallel to loads to increase the usefull life of the relays

protectors against over voltage

For more information contact our application eng. department through e-mail

or dial +55 51 3475.3308.support@ fullgauge.com

Contact suppresor connection diagram

Suppresor

A1

A2

A1 e A2 are the

contactor coils.

Diagram for suppresor installation

for direct drive load inputs

Load

Suppresor

For direct activation the maximum

specified current should be taken

into consideration.

Note: The sensor cable lenght can be increased by the user until 200 meters using2x24AWGcable.

PROTECTIVE VINYL:

This adhesive vinyl (included inside the packing) protects the instruments against

water drippings, as in commercial refrigerators, for example. Do the application after

finishing the electrical connections.

Remove the protective paper

and apply the vinyl on the entire

superior part of the device,

folding the flaps as indicated by

the arrows.