Ver.08

MT-512Ri LOG

DIGITAL CONTROLLER FOR COOLING WITH

NATURAL DEFROST THROUGH COMPRESSOR

SHUTDOWN AND INTERNAL DATALOGGER

MT512LOGV08-02T-11157

1. DESCRIPTION

2. APPLICATIONS

3. TECHNICAL SPECIFICATION

The is a temperature controller and indicator, with a joined cyclical timer. Controls

cooling and defrost through compressor shutdowns. It also has an internal datalogger and a serial

output for communication with the SITRAD .

Product complies with CE (European Union) and UL Inc. (United States and Canada).

• Counters

• Cooled chambers

MT-512Ri LOG 115 or 230 Vac ±10%(50/60 Hz)

MT-512RiL LOG 12 or 24 Vac/dc

-50 to 75.0ºC / -58 to 167°F

NO 16(8)A/250Vac 1HP

NC 8A/250Vac

71 x 28 x 71mm

MT-512Ri LOG

®

- Power supply:

- Control temperature:

- Load current:

- Dimensions:

4. CONFIGURATIONS

4.1 - control temperature adjust (SETPOINT)

- Press for 2 seconds until appears and then release the key.

The set control temperature will appear.

- Use the and keys in order to change the value and, when ready, press to record.

- Operating temperature:

- Operating humidity:

0 to 50 ºC / 32 to 122°F

10 to 90% RH (without condensation)

SET

SET

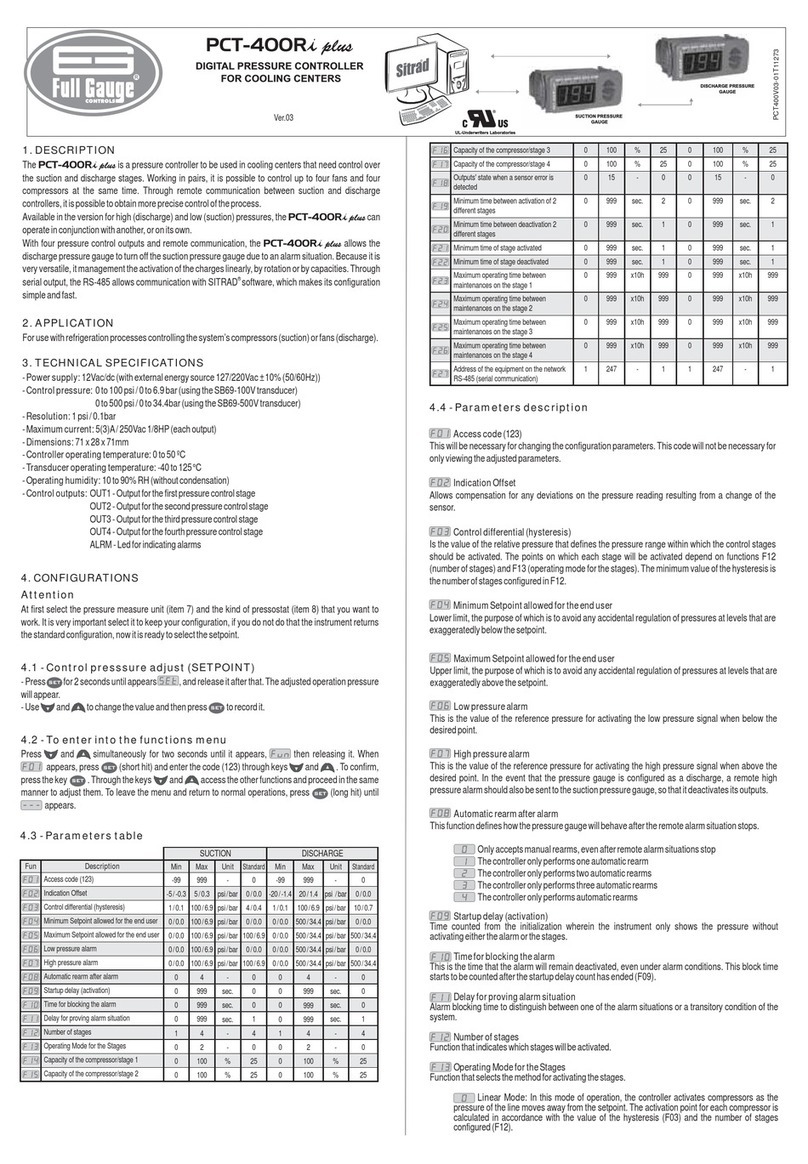

4.2 - Parameters table

Description

Fun

Datalogger operation mode

Indication offset

Minimum setpoint allowed for the end user

Maximum setpoint allowed for the end user

Control differential (hysteresis)

Delay to turn the cooling output on

Cooling time

Defrosting time

Initial state up on energizing the instrument

Indication of the temperature locked during defrost

Delay on the activation of the instrument

Datalogger sampling interval

Variation of the temperature to force data recording

Variation of the output force data recording

Memory overwriting

Address of the instrument on the network RS-485

Additional time at the end of the first cycle

Min Max Unit Default

0

-5.0 / -9

-50 / -58

-50 / -58

0.1 / 1

0

1

0

0 - cooling

0 - no

0

0

1

0 / 0

0

001

0 - no

2

5.0 / 9

75.0 / 167

75.0 / 167

20.0 / 40

999

999

999

1 - defrost

1 - yes

240

240

999

10.0 / 17

1

247

1 - yes

-

°C / °F

sec.

min.

min.

-

-

min.

min.

sec

-

-

-

°C / °F

°C / °F

°C / °F

°C / °F

2

0 / 0

-50.0 / -58

75.0 / 167

1.0 / 2

20

240

30

0

0

30

0 / 0

0

1

0 - cooling

0 - no

1 - yes

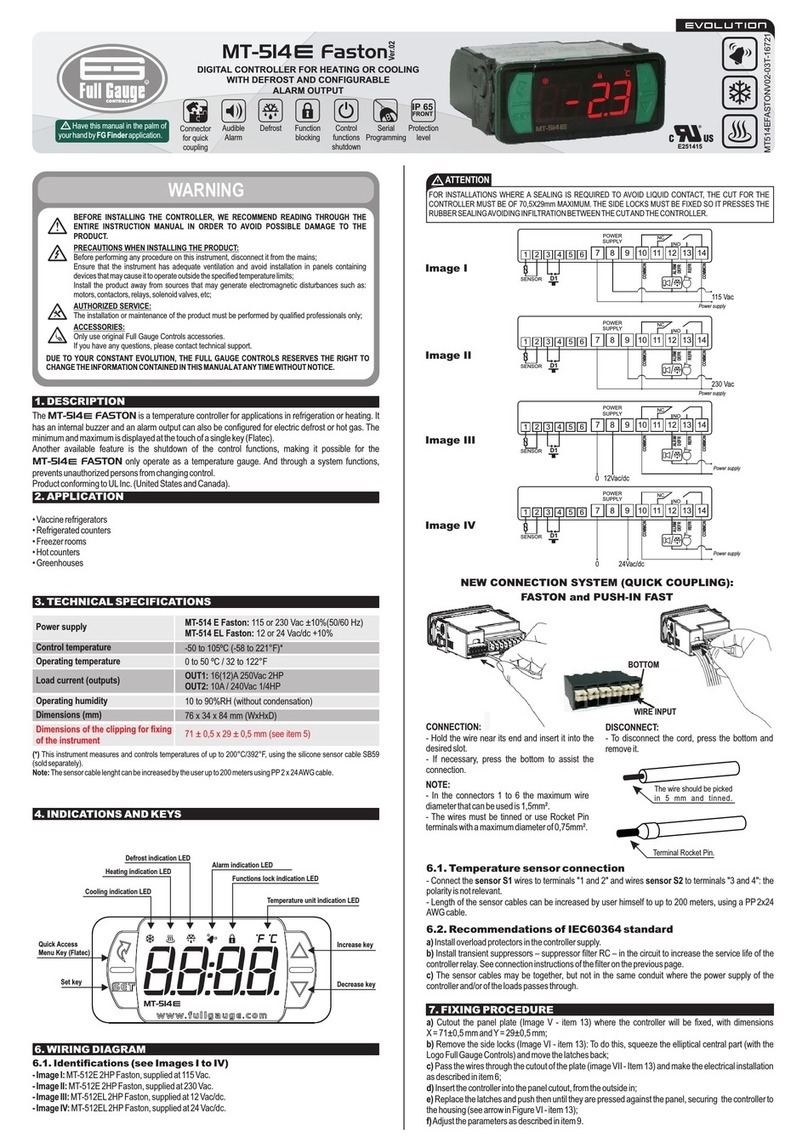

8. WIRING DIAGRAN

Note: The length of the sensor cable may be increased by the user up to 200 meters, using a 2 x 24AWG

cable. For immersion in water, use thermometric well.

Power

supply

Load

COMMON

NO

NC

12345678910 11 12

REFRIG

0

72 mm

29 mm

Serial communication

RS-485

Load

supply Dimension of the clipping for

setting of the instrument

in panel

7 - 8

7 - 9

115V

230V

12V

24V

115 V~

(12 V~)

230 V~

(24 V~)

MT-512Ri LOG MT-512RiL LOG

Sensor

To the terminal of

the distribution box

Above the current specified

use contactor

A

B

A B

RS-485 Network

RS-485 Serial Interface

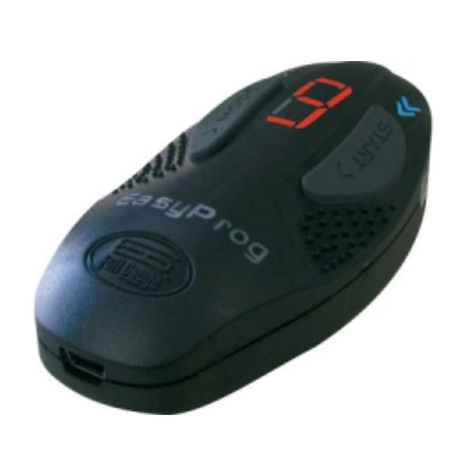

®

Device used to establish the

connection Full Gauge Controls’

instruments with the Sitrad .

Instrument

RS-485 Network

External

mesh

®

Integrating Controllers, RS-485 Serial Interface and Computer

A

B

PUMP AUX1

AUX2

MICROSOLII plus

AA

B B

AB

OUT1OUT2

OUT3

PCT-400R plus

OUT4 ALMR

AA

B B

AB

AA

B B

AB

A

BA

B

AA

B B

AB

Serial interface

RS-485

Full Gauge

MOD 64

AA

B B

AB

terminal

grounded

Distribution Box

Used to connect more than one instrument to the Interface.The wire's connections must

be made in agreement with the following rules: terminal of the instrument connects to

the terminal of the distribution box, that must be connected with the terminal of the

Interface. Repeat the action for terminals and , being the cable shield.

A

A A

B

The terminal of distribution box must be connected to the respective terminals of

each instrument.

4.3 - Parameters Alteration

5. FUNCTIONS WITH FACILITATED ACCESS

5.1 - Maximum and minimum temperature logs

-Access function “F01” by simultaneously pressing keys and for 2 seconds.

When the message appears release the keys and wait for the indication. When the

indication appears on the display press the key and use and to enter the access code

(123) When ready press the button to confirm.

- Use keys and to access the desired function.

- After selecting the function, press (press once quickly) to view the value configured for that

function.

- Use the and keys to change the value and, when ready, press to memorize the

configured value and return to the function menu.

- To exit the menu and return to the normal operation (temperature indication), press (hold it in)

until appears.

Press the key. The minimum and maximum temperatures registered will appear.

To restart the logs you just have to keep the key pressed during the viewing of the minimum

and maximum temperatures until to be displayed.

Note:

SET

SET

SET

SET

SET

5.3 - Clearing datalogger memory:

Press the and keys for 4 seconds to display . The display shows . If you

don't want to clear the memory press . To clear the memory press until is displayed and

press to confirm and exit the function.

SET

SET

SET

5.2 - Manual datalogger activation

ou can turn the internal recording ON or OFF by pressing

for seconds The message is displayed followed by the message (datalogger )

and (datalogger ). If the parameter F15 is configured with the values or the

messages or will be displayed accordingly.

Y temperature data (datalogger) or

10 .

5.4 - Viewing current date and time:

You can press the key shortly to view the date and time set in the controller. The display shows the

current day, month, year, hours and minutes, in this order:

Ex: 03/17/2006 12h43min

SET

Hours

Day

Month

Year

5.5 - Manual defrost:

6. SIGNALLING

7. SELECTION OF THE UNIT (Cº / Fº)

- To change from “cooling” to “defrost” or vice-versa, irrespective of the programming, hold key in

for four seconds, until or appears in the display.

To visualize the status and the elapsed time, press .

Initial delay Refrigeration Defrosting

- Cooling output on

- Performing natural defrost

- Sensor disconnected or temperature out of the specified range.

In order to define the unit that the instrument will operate in, enter function “F01” with the access code

“231” and confirm with the key. Press the key and the indication will appear. Press

to choose between or and confirm.After selecting the unit the message will

appear, and the instrument will return to the function “F01”. Every time that the unit is changed, the

parameters should be reconfigured, since they assume the “standard” values.

REFRIG

DEFROST

SET

SET