DIGITAL PRESSURE CONTROLLER

FOR COOLING CENTERS

PCT-400Ri plus

DISCHARGE PRESSURE

GAUGE

SUCTION PRESSURE

GAUGE

UL-Underwriters Laboratories

1.DESCRIPTION

The isapressurecontrollerto be usedin cooling centersthat need controlover

the suction and discharge stages. Working in pairs, it is possible to control up to four fans and four

compressors at the same time. Through remote communication between suction and discharge

controllers,itispossibletoobtainmoreprecisecontroloftheprocess.

Availableintheversionforhigh(discharge)andlow(suction)pressures,the can

operateinconjunctionwithanother,oronitsown.

With four pressure control outputs and remote communication, the allows the

dischargepressuregaugetoturnoffthesuctionpressuregaugeduetoanalarmsituation.Becauseitis

veryversatile,itmanagementtheactivationofthechargeslinearly,byrotationorbycapacities.Through

serialoutput,theRS-485allows communicationwith software,whichmakesits configuration

simpleandfast.

PCT-400Ri plus

PCT-400Ri plus

PCT-400Ri plus

SITRAD

Forusewithrefrigerationprocessescontrollingthesystem’scompressors(suction)orfans(discharge).

®

2.APPLICATION

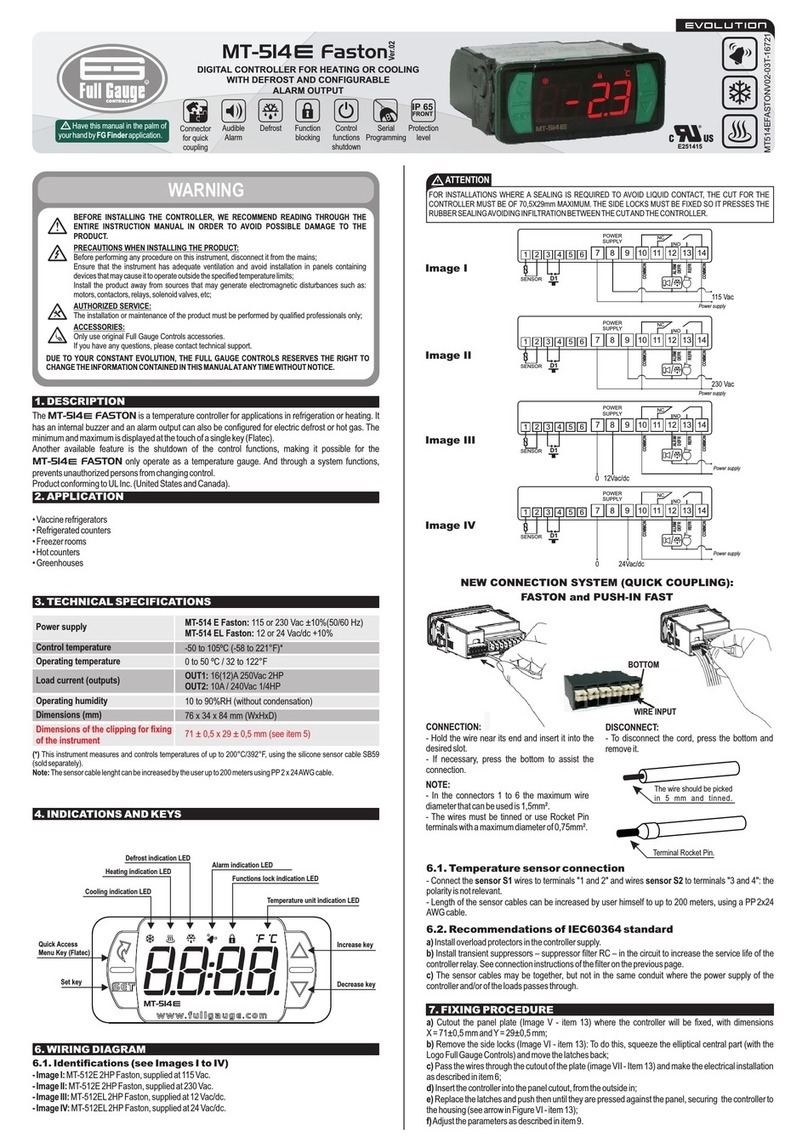

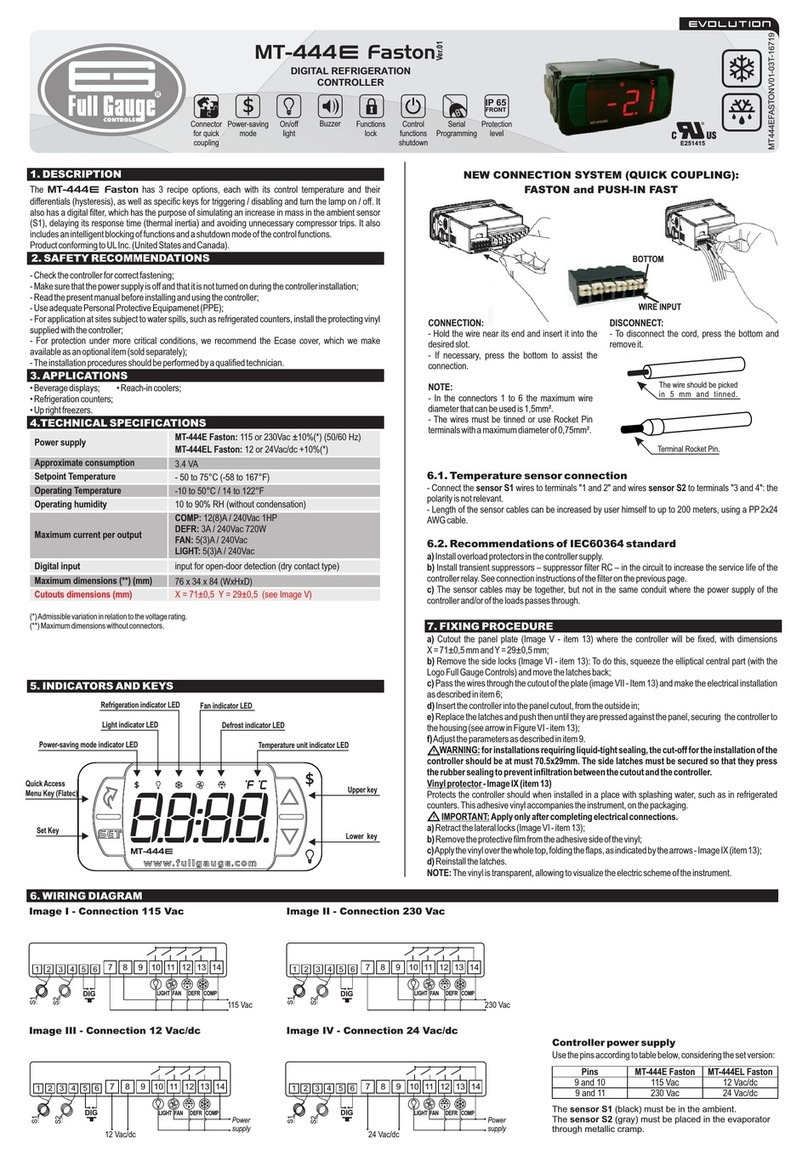

3.TECHNICALSPECIFICATIONS

-Powersupply:

-Controlpressure:

-Resolution:

-Maximumcurrent:

-Dimensions:

-Controlleroperatingtemperature:

-Transduceroperatingtemperature:

-Operatinghumidity:

-Controloutputs:

12Vac/dc(withexternalenergysource127/220Vac±10%(50/60Hz))

0to100psi/0to6.9bar(usingtheSB69-100Vtransducer)

0to500psi/0to34.4bar(usingtheSB69-500Vtransducer)

1psi/0.1bar

5(3)A/250Vac1/8HP(eachoutput)

71x28x71mm 0to50ºC

-40to125°C

10to90%RH(withoutcondensation)

OUT1-Outputforthefirstpressurecontrolstage

OUT2-Outputforthesecondpressurecontrolstage

OUT3-Outputforthethirdpressurecontrolstage

OUT4-Outputforthefourthpressurecontrolstage

ALRM-Ledforindicatingalarms

4.CONFIGURATIONS

Attention

At first select the pressure measure unit (item 7) and the kind of pressostat (item 8) that you want to

work.Itisveryimportantselectittokeepyourconfiguration,ifyoudonotdothat theinstrumentreturns

thestandardconfiguration,nowitisreadytoselectthesetpoint.

4.1-Control presssureadjust(SETPOINT)

4.2-Toenterintothefunctionsmenu

-Press for2secondsuntilappears ,andreleaseitafterthat.Theadjustedoperationpressure

willappear.

-Use and tochangethevalueandthenpress torecordit.

Press and simultaneously for two seconds until it appears, then releasing it. When

appears,press (shorthit)andenterthecode(123)throughkeys and .Toconfirm,

pressthekey .Throughthekeys and accesstheotherfunctionsandproceedinthesame

manner to adjust them. To leave the menu and return to normal operations, press (long hit) until

appears.

SET

SET

SET

SET

SET

4.3-Parameters table

Description Min Max Unit

SUCTION

Fun Min Max

DISCHARGE

Access code (123)

Indication Offset

Control differential (hysteresis)

Minimum Setpoint allowed for the end user

Maximum Setpoint allowed for the end user

Low pressure alarm

High pressure alarm

Automatic rearm after alarm

Startup delay (activation)

Time for blocking the alarm

Delay for proving alarm situation

Number of stages

Operating Mode for the Stages

Capacity of the compressor/stage 1

Capacity of the compressor/stage 2

-99

-5/-0.3

1/0.1

0/0.0

0

0

0

0

/0.0

/0.0

0/0.0

0

0

1

0

0

0

999

5/0.3

100/6.9

100/6.9

100/6.9

100/6.9

100/6.9

4

999

999

999

4

2

100

100

-

psi/bar

psi/bar

psi/bar

psi/bar

psi/bar

psi/bar

-

sec.

sec.

sec.

-

-

%

%

-99

-20/-1.4

1/0.1

0/0.0

0/0.0

0/0.0

0/0.0

0

0

0

0

1

0

0

0

999

20/1.4

100/6.9

500/34.4

500/34.4

500/34.4

500/34.4

4

999

999

999

4

2

100

100

Unit

-

psi /bar

psi/bar

psi/bar

psi/bar

psi/bar

psi/bar

-

sec.

sec.

sec.

-

-

%

%

0

0/0.0

10/0.7

0/0.0

500/34.4

0/0.0

500/34.4

0

0

0

1

4

0

25

25

Standard Standard

0

0/0.0

4/0.4

0/0.0

100/6.9

0/0.0

100/6.9

0

0

0

1

4

0

25

25

Capacity of the compressor/stage 3

Capacity of the compressor/stage 4

Outputs' state when a sensor error is

detected

Minimum time between activation of 2

different stages

Minimum time between deactivation 2

different stages

Minimum time of stage activated

Minimum time of stage deactivated

Maximum operating time between

maintenances on the stage 1

Maximum operating time between

maintenances on the stage 2

Maximum operating time between

maintenances on the stage 3

Maximum operating time between

maintenances on the stage 4

Address of the equipment on the network

RS-485 (serial communication)

0

0

0

0

0

0

0

0

0

0

0

1

100

100

15

999

999

999

999

999

999

999

999

247

%

%

-

sec.

sec.

sec.

sec.

x10h

x10h

x10h

x10h

-

25

25

0

2

1

1

1

999

999

999

999

1

0

0

0

0

0

0

0

0

0

0

0

1

100

100

15

999

999

999

999

999

999

999

999

247

%

%

-

sec.

sec.

sec.

sec.

x10h

x10h

x10h

x10h

-

25

25

0

2

1

1

1

999

999

999

999

1

4.4-Parameters description

Accesscode(123)

IndicationOffset

Controldifferential(hysteresis)

MinimumSetpointallowedfortheenduser

Thiswillbenecessaryforchangingtheconfigurationparameters.Thiscodewillnotbenecessaryfor

onlyviewingtheadjustedparameters.

Allows compensation for any deviations on the pressure reading resulting from a change of the

sensor.

Isthe value of therelative pressure that definesthe pressure range withinwhich the control stages

should be activated. The points on which each stage will be activated depend on functions F12

(numberofstages)andF13(operatingmodeforthestages).Theminimumvalueofthehysteresisis

thenumberofstagesconfiguredinF12.

Lowerlimit,thepurpose ofwhichistoavoidanyaccidentalregulationofpressuresatlevelsthatare

exaggeratedlybelowthesetpoint.

MaximumSetpointallowedfortheenduser

Lowpressurealarm

Highpressurealarm

Automaticrearmafteralarm

Upperlimit,the purposeofwhichistoavoidanyaccidental regulationofpressures atlevelsthatare

exaggeratedlyabovethesetpoint.

This is the value of the reference pressure for activating the low pressure signal when below the

desiredpoint.

This is the value of the reference pressure for activating the high pressure signal when above the

desired point. In the event that the pressure gauge is configured as a discharge, a remote high

pressurealarmshouldalsobesenttothesuctionpressuregauge,sothatitdeactivatesitsoutputs.

Thisfunctiondefineshowthepressuregaugewillbehaveaftertheremotealarmsituationstops.

Onlyacceptsmanualrearms,evenafterremotealarmsituationsstop

Thecontrolleronlyperformsoneautomaticrearm

Thecontrolleronlyperformstwoautomaticrearms

Thecontrolleronlyperformsthreeautomaticrearms

Thecontrolleronlyperformsautomaticrearms

Startupdelay(activation)

Timeforblockingthealarm

Delayforprovingalarmsituation

Numberofstages

OperatingModefortheStages

Linear Mode:

Time counted from the initialization wherein the instrument only shows the pressure without

activatingeitherthealarmorthestages.

Thisis the timethatthe alarm willremain deactivated, evenunderalarm conditions.This block time

startstobecountedafterthestartupdelaycounthasended(F09).

Alarmblockingtimeto distinguish between one of the alarm situations oratransitorycondition of the

system.

Functionthatindicateswhichstageswillbeactivated.

Functionthatselectsthemethodforactivatingthestages.

In this mode of operation, the controller activates compressors as the

pressureof theline movesaway fromthe setpoint.Theactivationpointforeachcompressoris

calculated in accordance with the value of the hysteresis (F03) and the number of stages

configured(F12).

Ver.03

PCT400V03-01T11273