1

SCANNER UNIT

Mounting Considerations,

Precautions

• The scanner unit is generally installed ei-

ther on top of the wheelhouse or on the ra-

dar mast on a suitable platform. Locate the

scannerunit wherethere is agood all-round

view. Any obstruction will cause shadow

and blind sectors.Amast for instance, with

adiameter considerably lessthan the width

ofthe radiator,will causeonly a small blind

sector, but a horizontal spreader or

crosstrees in the same horizontal plane as

the scanner unit would be a much more

serious obstruction; you would need to

place the scanner unit well above or below

it.

• Itis rarelypossible toplace thescanner unit

where a completely clear view in all direc-

tions is available. Thus, you should deter-

minethe angularwidth andrelative bearing

of any shadow sectors for their influence

on the radar at the first opportunity after

fitting.

• If you have a radio direction finder on your

boat, locate its scanner clear of the scan-

ner unit to prevent interference to the di-

rection finder. A separation of more than

two meters is recommended.

• To lessen the chance of picking up electri-

calinterference, avoidwhere possible rout-

ing the signal cable near other onboard

electrical equipment. Also avoid running

the cable in parallel with power cables.

• A magnetic compass will be affected if

placed too close to the scanner unit. Ob-

serve the following compass safe distances

to prevent deviation of a magnetic com-

pass: Standard compass, 1.00 m, Steering

compass, 0.75 m.

• Do not paint the radiator aperture, to en-

sure proper emission of the radar waves.

• When this radar is to be installed on larger

vessels, consider the following points:

• The signal cable run between the scan-

ner and the display comes in lengths of

10 m (standard), 15 m, 20 m and 30 m.

Whatever length is used it must be un-

broken; namely, no splicing allowed.

• Deposits and fumes from a funnel or

other exhaust vent can adversely affect

the aerial performance and hot gases

may distort the radiator portion. The

scannerunit mustnot bemounted where

the temperature is more than 70°C.

Mounting Methods

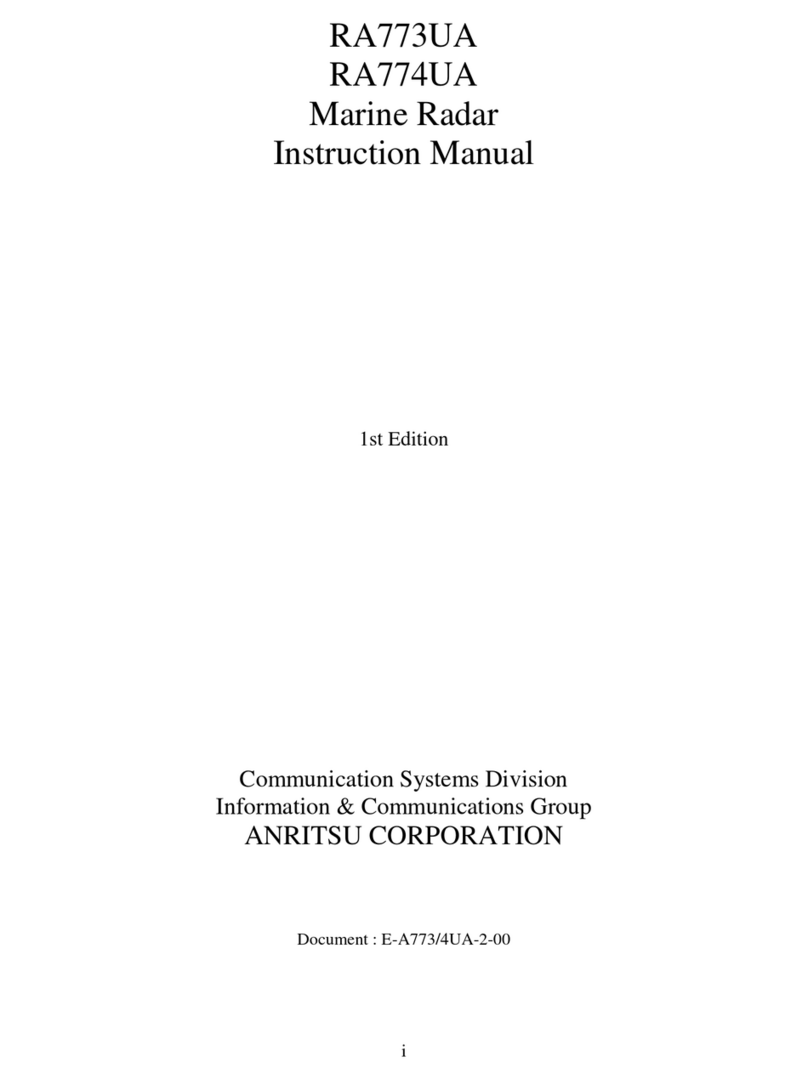

Asshown in thefigure below, the scanner unit

may be installed on the bridge, on a common

mast or on a dedicated mast.

(a) On bridge (b) Common mast (c) Dedicated mast

Figure 1 Scanner unit mounting methods

Fixing Holes in Mounting

Platform

Referring to the outline drawing on page D-

1, drill five holes in the mounting platform:

four holes of 15 mm diameter for fixing the

scanner unit and one hole of 25-30 mm diam-

eter for the signal cable.