223

To ensure safe use, observe the following precautions.

Precautions During Flight

• Do not fly or turn on simultaneously with

another radio on the same frequency.

Interference will cause

a crash. Use of the

same frequency will

cause interference

even if the modulation

method (AM, FM,

PCM) is different.

• Do not fly on rainy or

windy days, or at night.

Water will penetrate into the

transmitter (Tx) and cause

faulty operation, or loss of

control, and cause a crash.

Do not fly in the following places:

• Near other R/C flying fields (within about

2.5 miles [4km]).

• Near people on the ground, or objects in

the air.

• Near homes, schools, hospitals, or other

places where there are a lot of people.

• Near high tension lines, high structures,

or communication facilities. Radiowave

interference and obstructions may cause a crash. A

crash caused by trouble in the R/C set, or the model

itself, may cause death or property damage.

Other Precautions

• Do not fly when you are tired, sick, or

intoxicated. Fatigue, illness, or intoxication will

cause a loss of concentration or normal judgment

and result in operation errors and a crash.

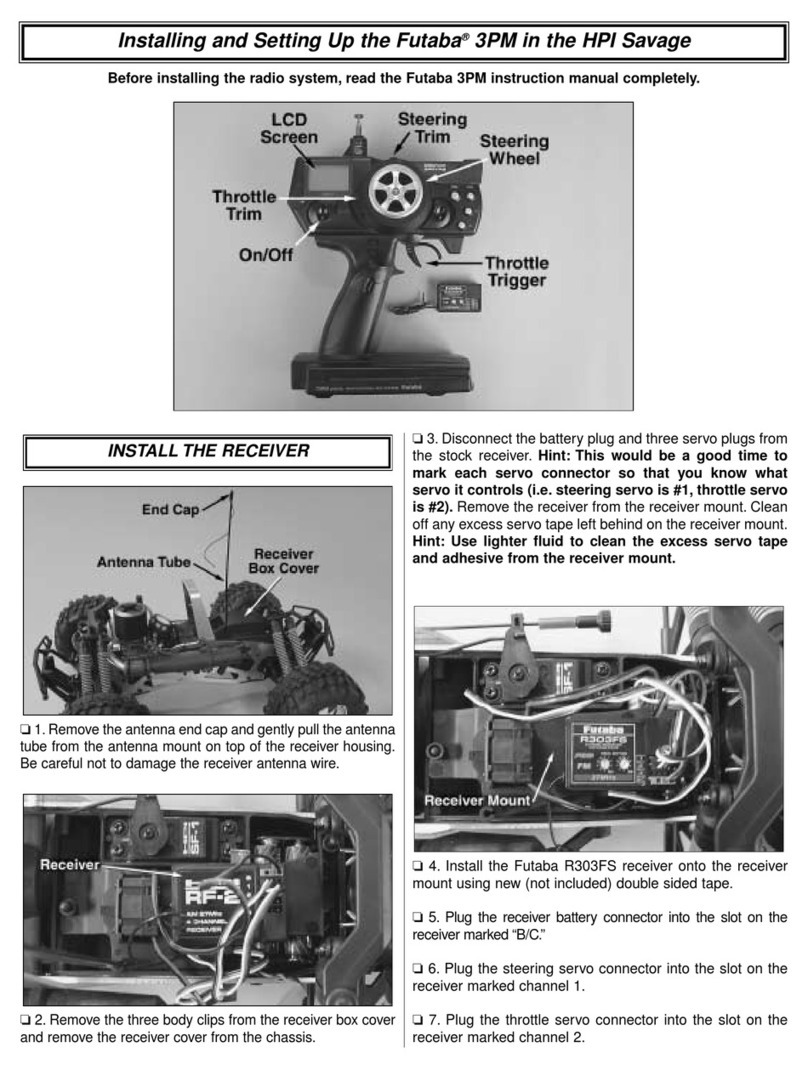

• Extend the antenna to its full

length. If the antenna is shortened,

the effective range of the radio signal

will be shorter.

• Check that the transmitter (Tx) antenna is

not loose. If the transmitter antenna comes off

during use, control will be lost and the model

will crash.

• Always test the R/C set before use. Any

abnormality in the R/C set, or model, may cause a

crash. Before starting the engine, check that the

direction of operation of each servo matches the

operation of its control stick. If a servo does not move

in the proper direction, or operation is abnormal, do

not fly the plane.

• When placing the transmitter (Tx) on the

ground during flight preparations, be sure

that the wind cannot knock it over. If it is

knocked over, the throttle stick may be pushed to full

throttle, the engine will speed up and may create a

very dangerous situation.

• When adjusting the R/C set, always stop

the engine. If the engine suddenly goes to full

throttle, it may cause an injury.

• Do not get fuel, oil, etc. on plastic parts.

The plastic may melt, discolor, become brittle and fail

to function.

• Always use Genuine Futaba transmitters,

receivers, servos, ESCs, NiCd batteries,

and other optional parts. Futaba is not

responsible for damage, etc. caused by the use of

parts other than Genuine Futaba parts. Use the parts

described in the instruction manual and catalogs.

NiCd Battery Charging Precautions

Always charge the NiCd batteries before

each flight. If the battery goes dead during flight, the

plane may crash or fly away.

Charge the R/C NiCd battery with the

standard charger, or fast field charger (sold

separately). Overcharging may cause burns, fire,

injury, blindness, etc. due to overheating, breakage,

electrolyte leakage, etc.

Do not short the NiCd battery connector

terminals. Shorting the terminals will cause sparking

and overheating and result in burns or fire.

Do not drop or apply strong shock to NiCd

battery. The battery may short out and cause

overheating or breakage and electrolyte leakage,

resulting in burns or damage from chemical contents.

SAFETY INFORMATION

Problem Possible causes Solution

Short range

Collapsed or loose Tx antenna...........Fully extend the antenna and make sure it is

securely attached

Interference.........................................Check frequencies in area and

check Rx installation

Rx antenna poorly routed ...................Reroute antenna away from other wiring

Severed Rx antenna ...........................Send to Futaba service center for new antenna

Tx or Rx battery not fully charged ......Fully charge batteries prior to use

Rx or Tx out of tune............................Send to Futaba service center for retuning

Crash damage ....................................Send to Futaba service center for inspection and repair

Faulty Rx or Tx crystal ........................Install new crystal and perform range check

Sluggish servo response

Low Tx or Rx batteries........................Fully charge batteries prior to use, may need cycling

(you must remove the batteries from the TX to cycle,

and this requires opening the Tx case.)

Binding servos causing

excess battery drain............................Check pushrods and free binding

Too many servos.................................Use fewer servos if possible, or use a higher capacity

battery pack

Tx meter low

Tx batteries are discharged ................Fully charge batteries prior to use

Tx meter above red zone

but servos do not function

Rx batteries are discharged................Fully charge batteries prior to use

No power to receiver...........................Move Rx switch harness to “ON” position

Switch harness incorrect ....................Make sure all leads are in the proper positions

Reversing switch stuck in-between

positions..............................................Move switch fully to one side or the other

Interference or servos glitching

Another Tx is on your channel............Turn off immediately and do not operate your system

until other user is finished

Outside interference............................Check local R/C club to learn of dangerous frequencies

in your area

Engine or motor electrical noise .........Reroute antenna or servo leads as far away from

engine or motor as possible

One glitching servo

Malfunctioning servo...........................Replace servo

Other interference...............................Check quality and installation of servo lead or extension

Servo movement not as expected

Mix accidentally activated ...................Check all mix dip switches

Servos connected incorrectly..............Check all servo connections

Interference.........................................See above

Too much/Too little throw ....................Check AST and D/R settings and switches

TROUBLESHOOTING GUIDE