FUTABA SKYSPORT-6H User manual

Other FUTABA Remote Control manuals

FUTABA

FUTABA 8J User manual

FUTABA

FUTABA 3PM-2.4GHZ User manual

FUTABA

FUTABA 3VCS User manual

FUTABA

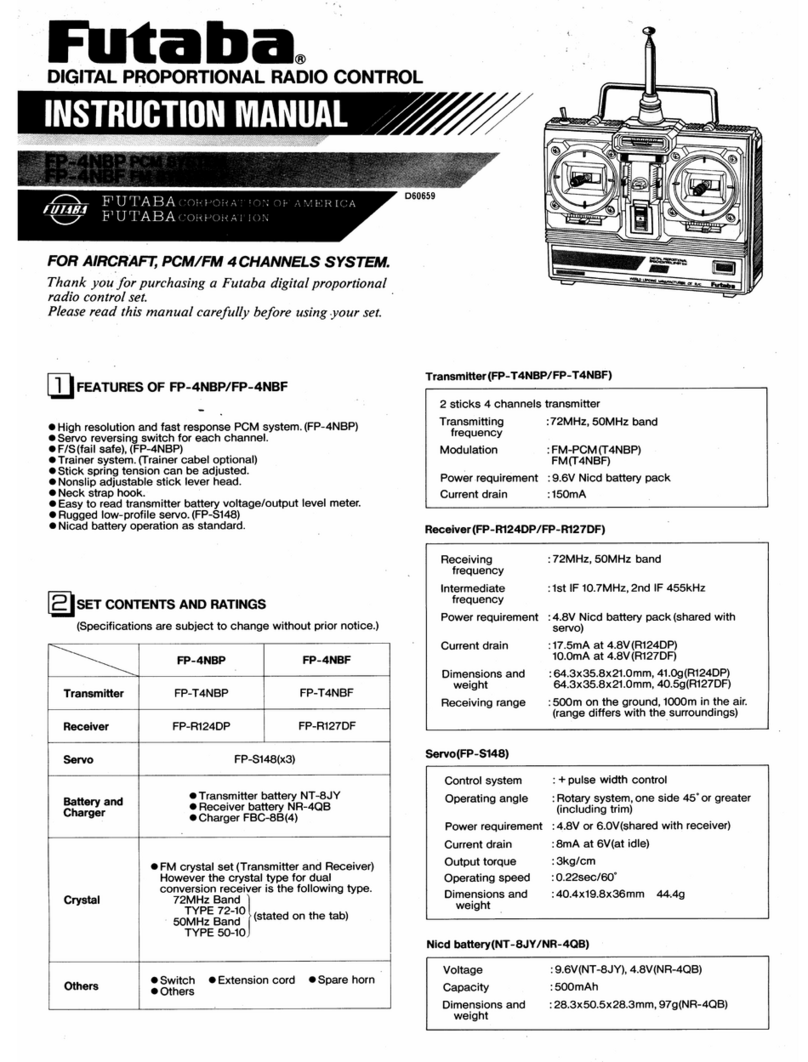

FUTABA FP-2PD User manual

FUTABA

FUTABA T10PX How to use

FUTABA

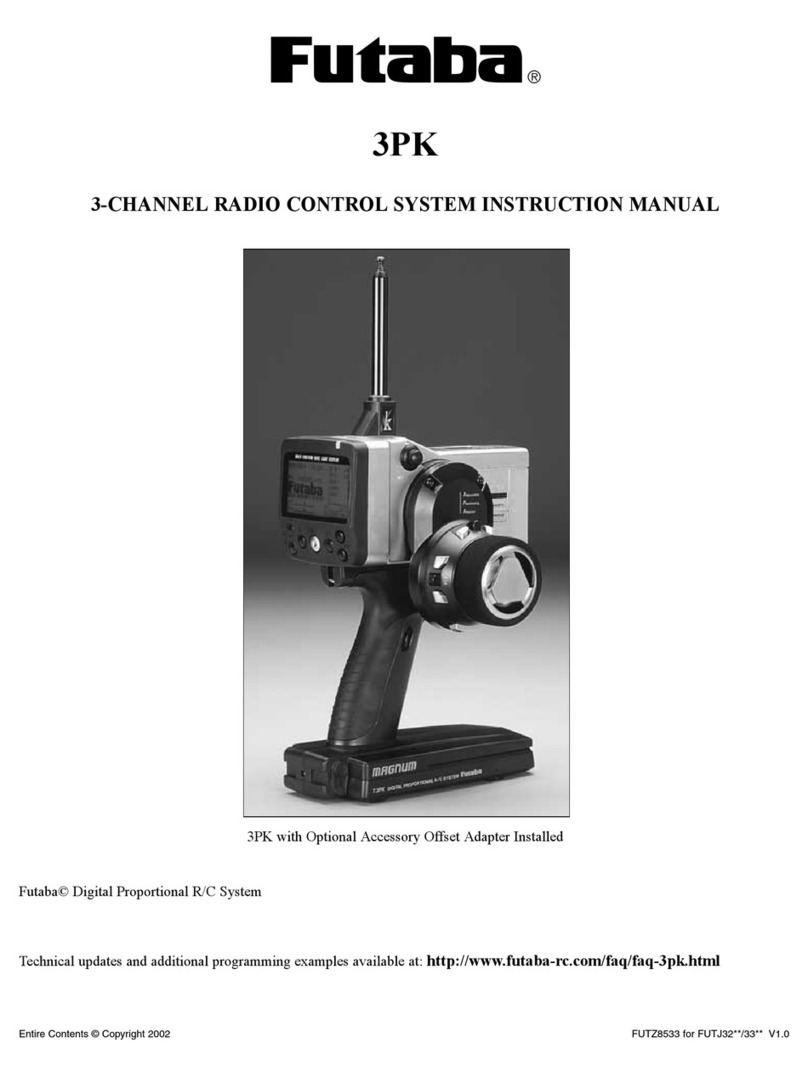

FUTABA Magnum 3PK Super User manual

FUTABA

FUTABA 12Z Series User manual

FUTABA

FUTABA 8FG User manual

FUTABA

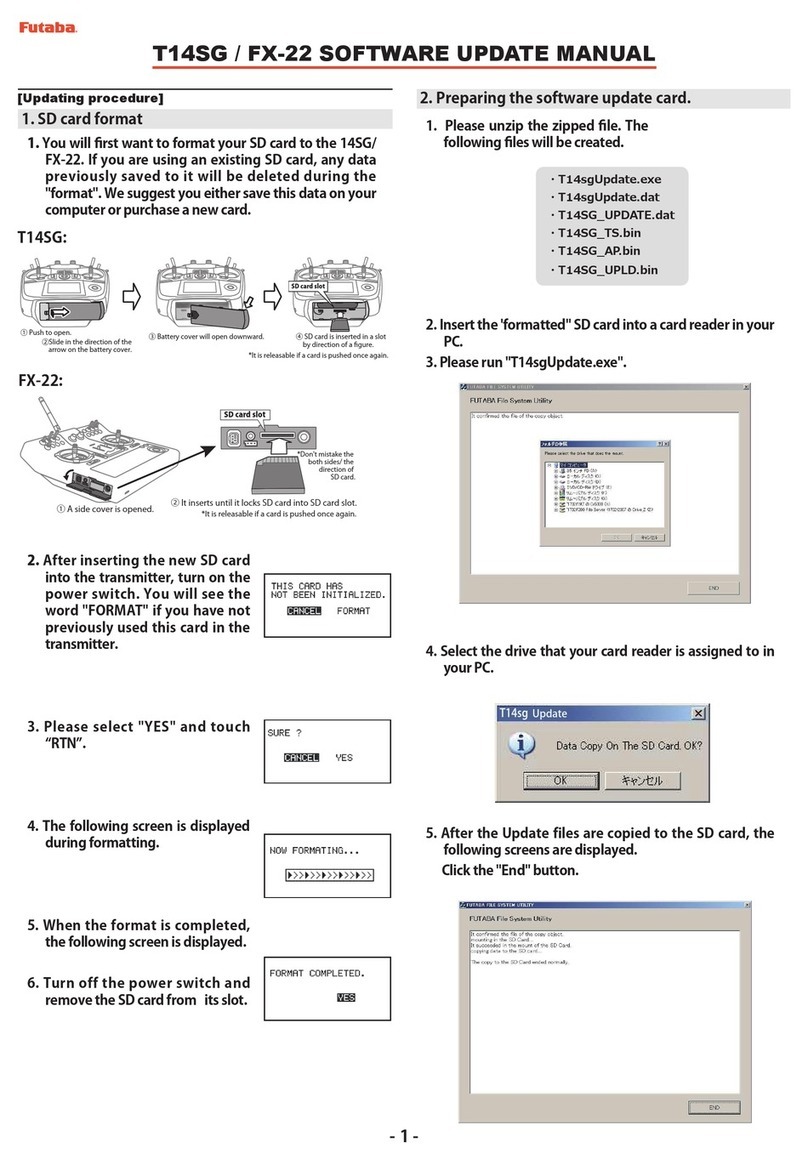

FUTABA 14SG User manual

FUTABA

FUTABA 2PL-2.4GHZ User manual

FUTABA

FUTABA FX-36 User manual

FUTABA

FUTABA FASSTest-2.4GHz T16SZ Series User manual

FUTABA

FUTABA 4YF-2.4GHZ User manual

FUTABA

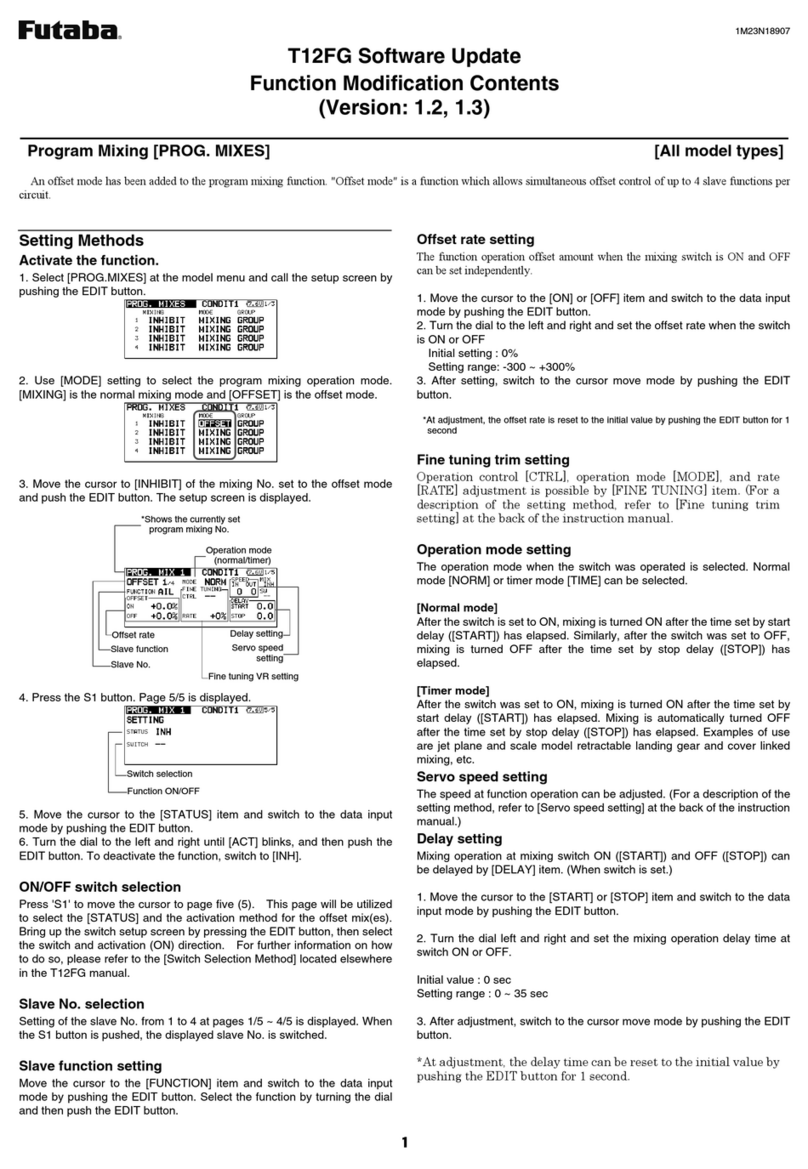

FUTABA T12FG Technical manual

FUTABA

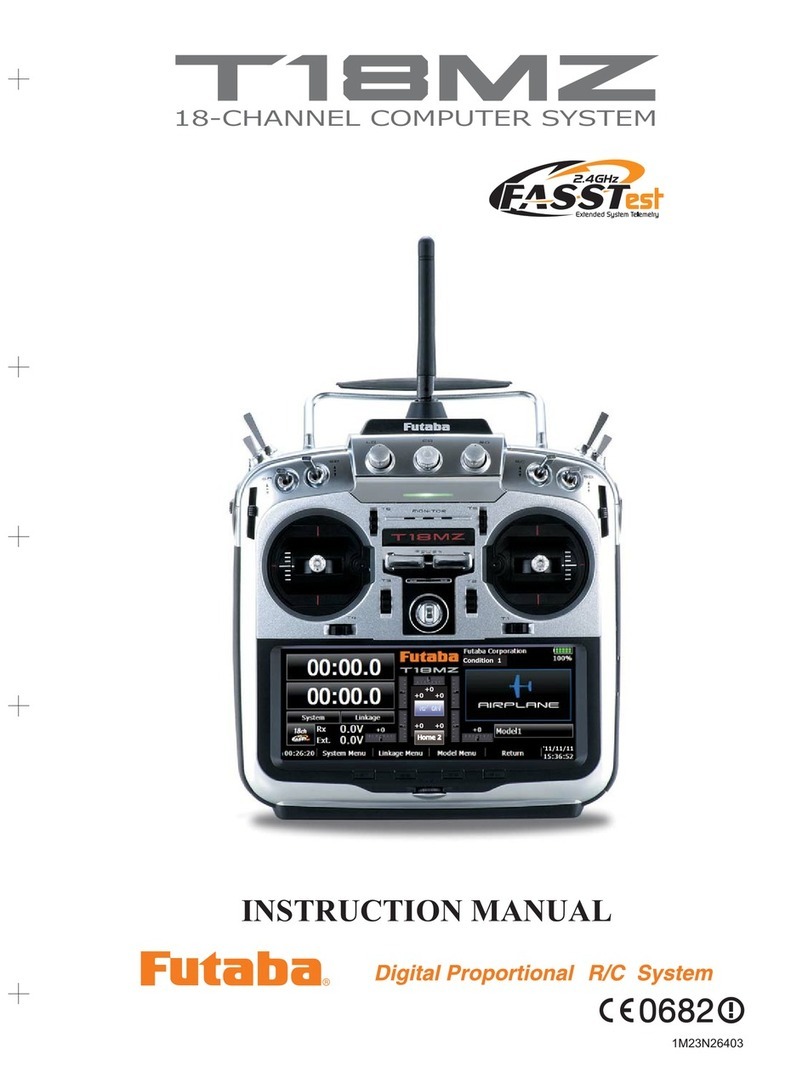

FUTABA T18MZ User manual

FUTABA

FUTABA T8FG User manual

FUTABA

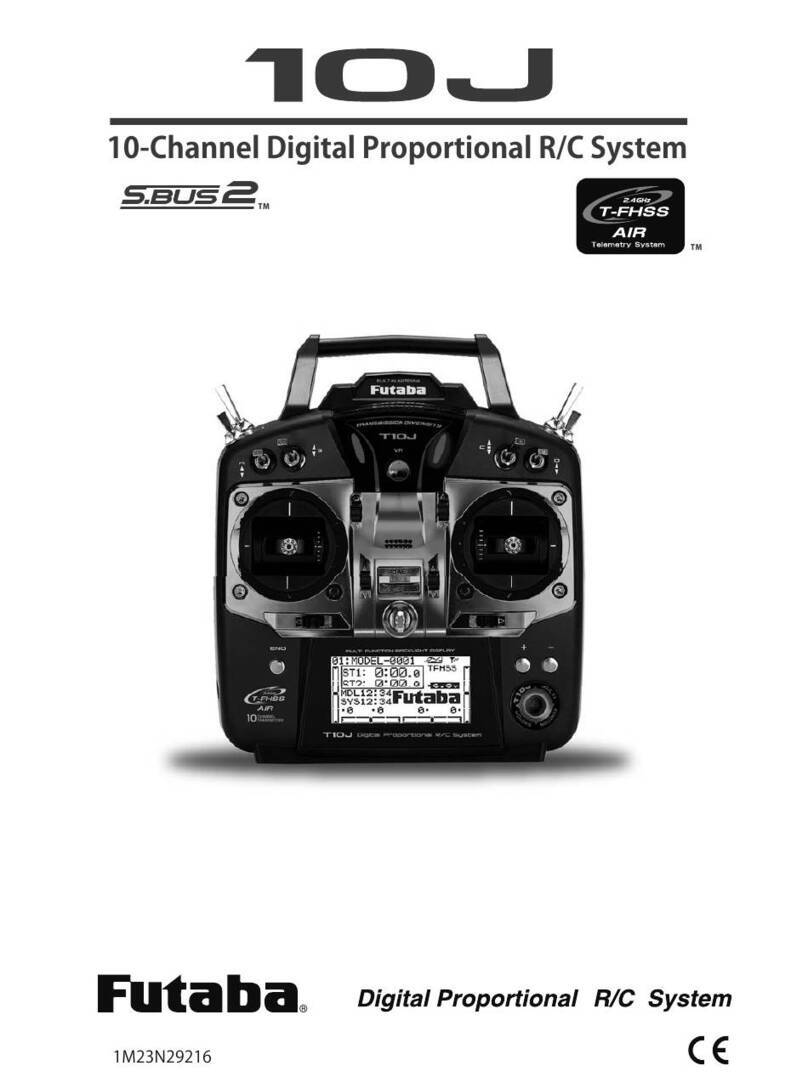

FUTABA S.BUS2 10J User manual

FUTABA

FUTABA 4EXA User manual

FUTABA

FUTABA FASST User manual

FUTABA

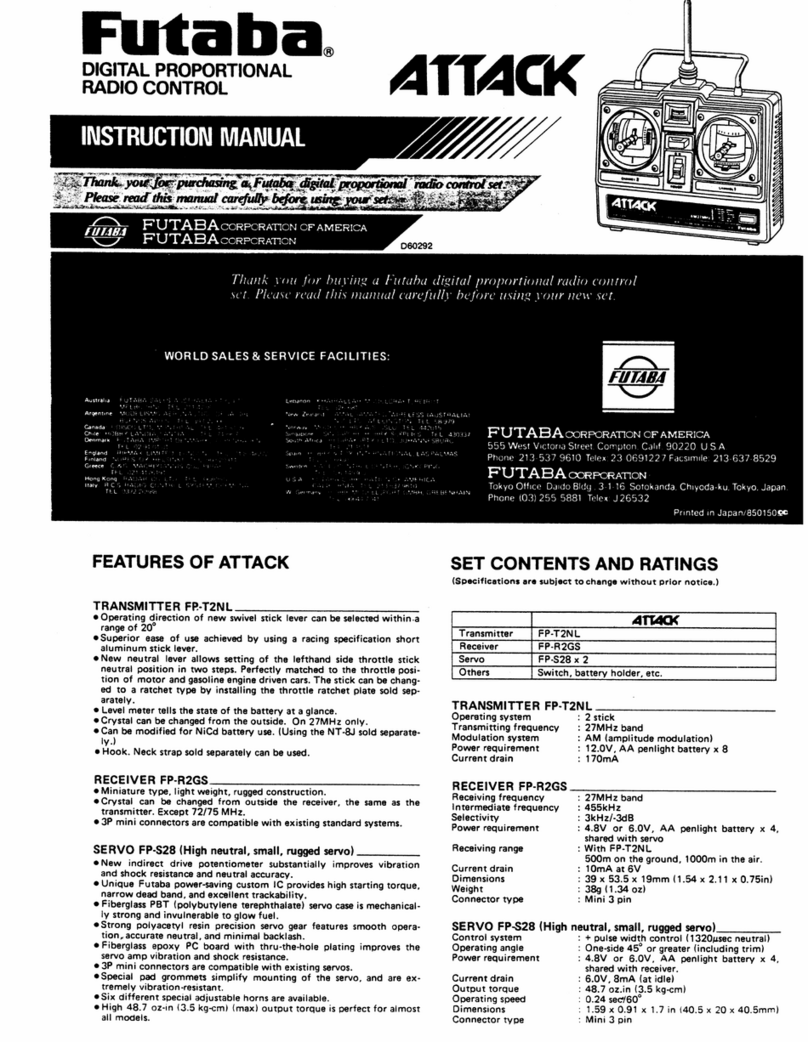

FUTABA Attack FP-R2GS User manual