▲

▲

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

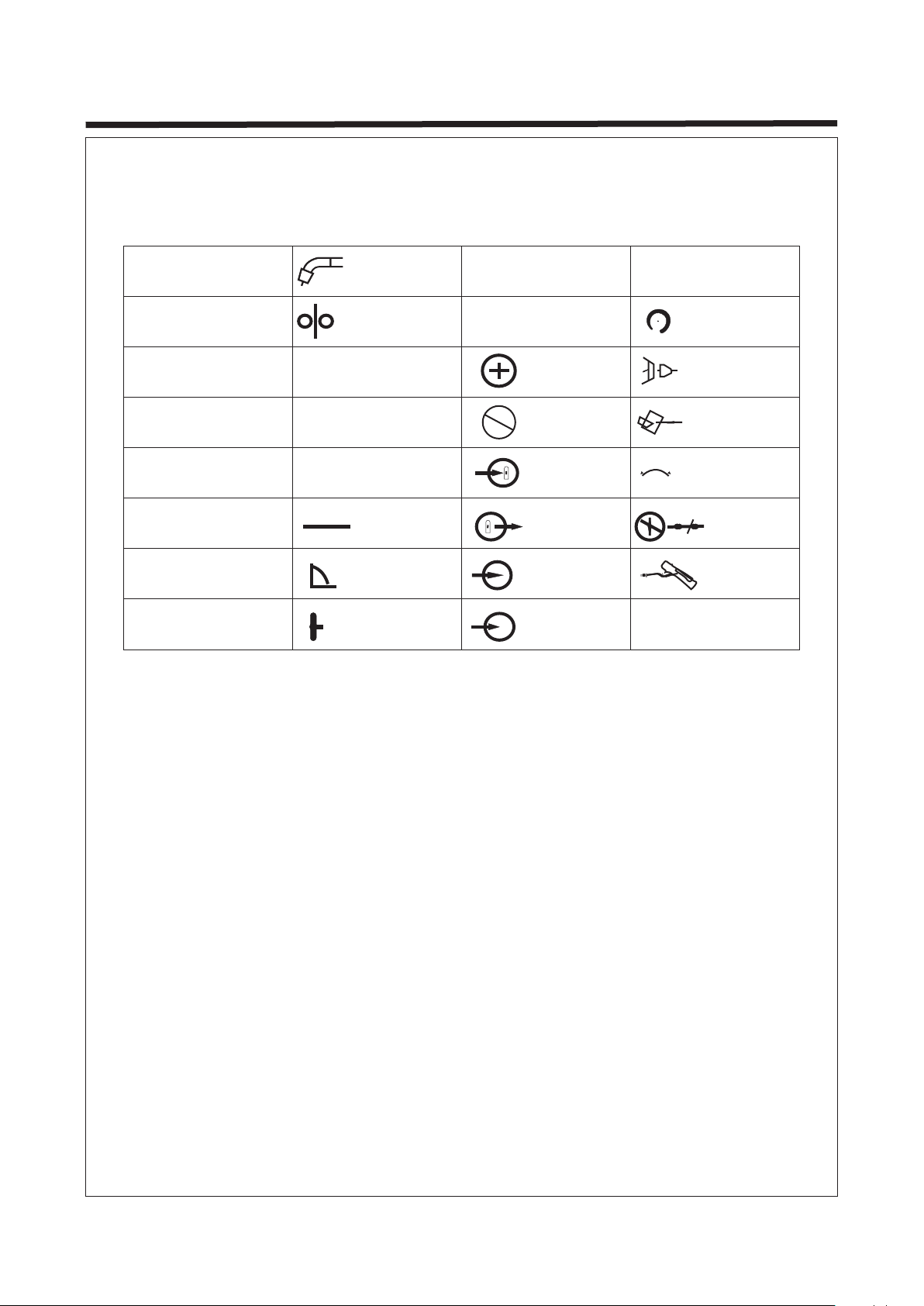

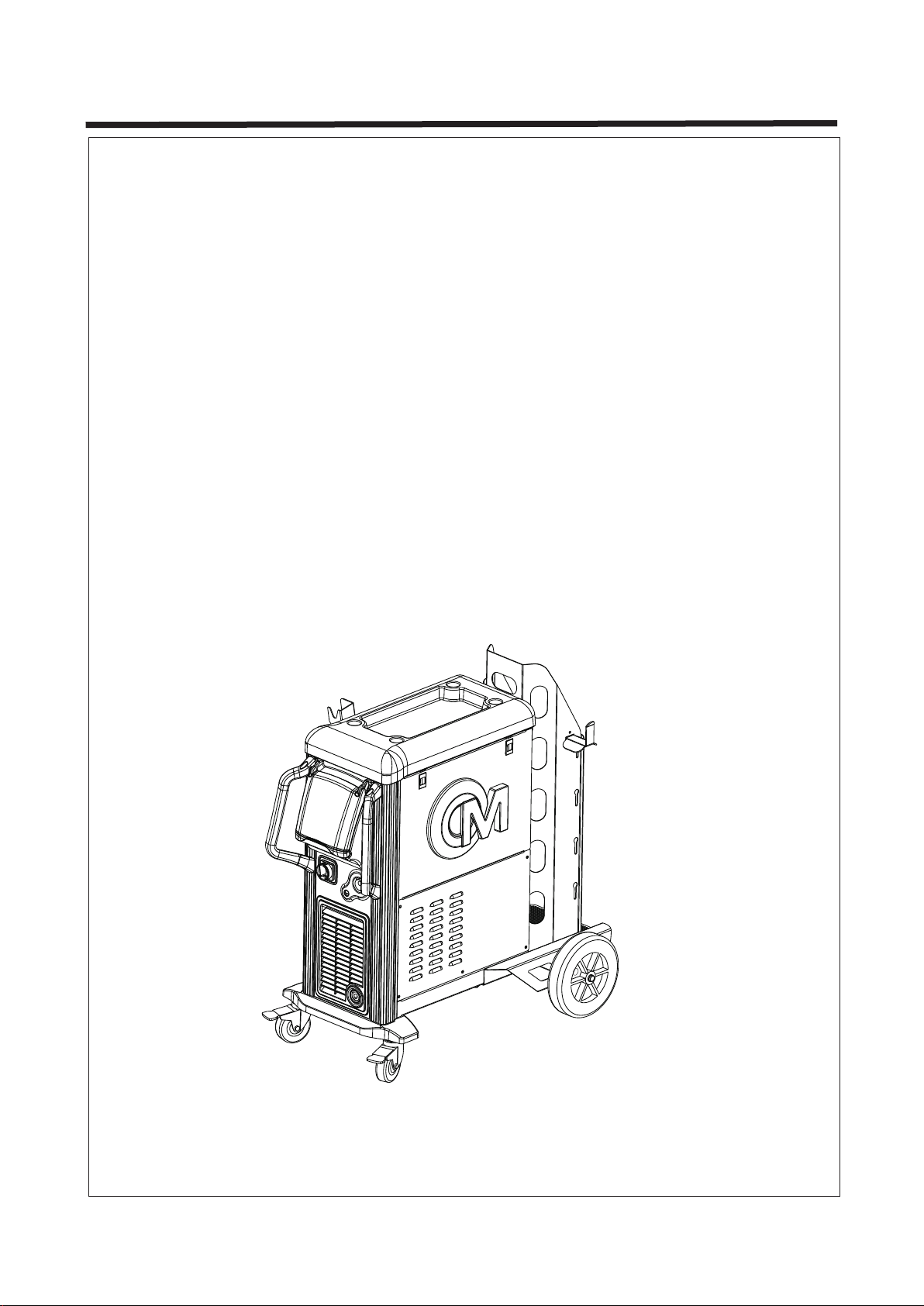

Preface

Please read this instruction manual carefully before using and the equipment and refer to it as

needed to ensure the continued safe operation of the equipment.

This instruction manual should be read completely before attempting to use or service the equipment.

Failure to follow the instructions in this manual could result in property damage, severe personal injury, or

death.

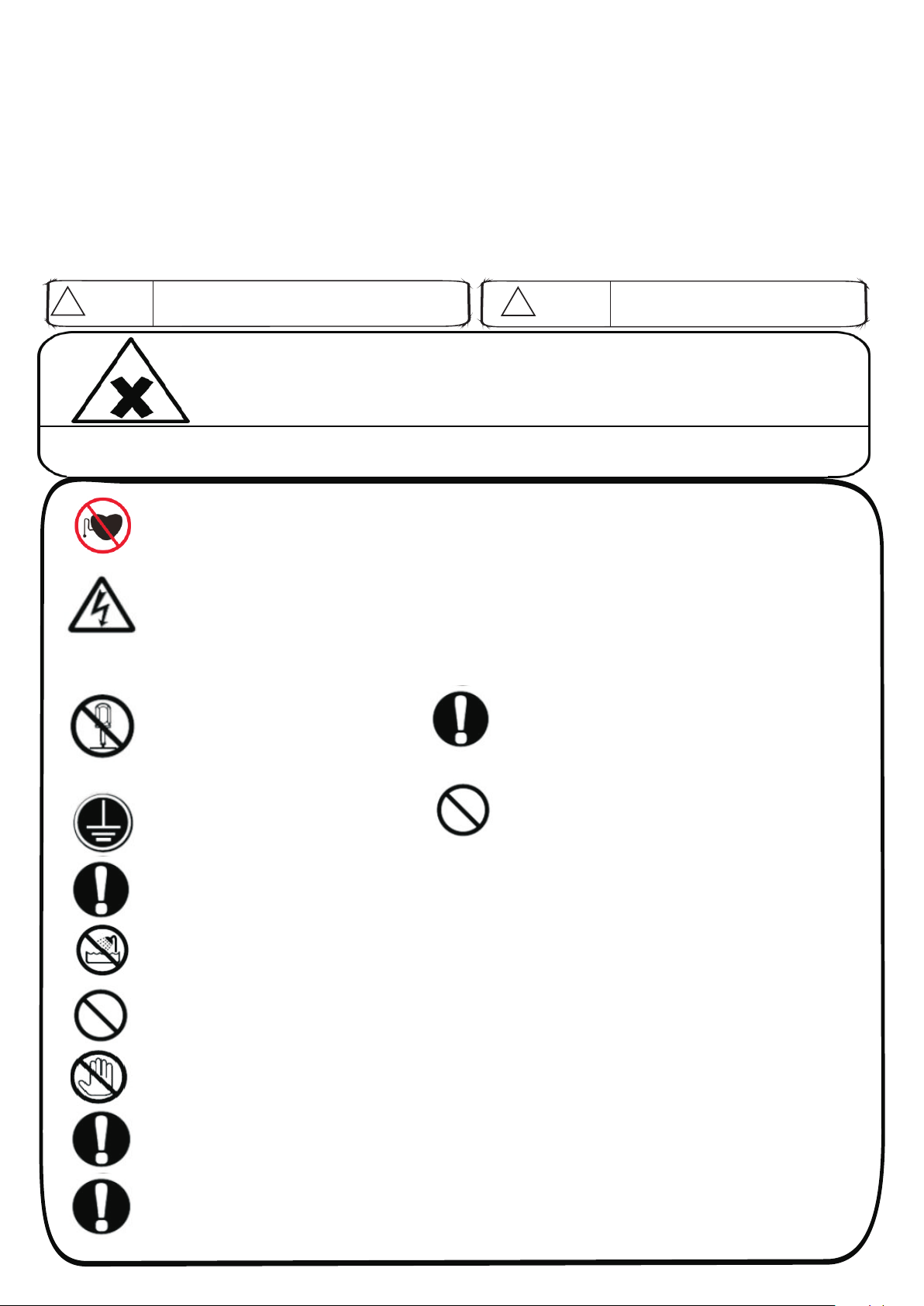

The followingwarningsand importantnotices are used in the instructionmanual:

!WARNING

Improper use of this equipment can cause

personal injury or property property damage

操作错误时。有可能会造成人体死亡或重伤的危险

DANGER

Improper use of this equipment can cause serious or fatal injury

.

Magnetic fields can affect pacemakers. Pacemaker wearers keep away from the equipment.

Wearers should consult their doctor before going near equipment operations.

Do not touch any live electrical parts. Wear dry, hole-free insulating gloves and body

protection. The input power circuit and machine internal circuit are live with high voltage

when power is on. Touching live electrical parts can cause fatal shocks or severe burns. High

voltage exists in the power supply socket. Never touch the conductor terminals with bare

hand.

Input power installation must meet national standard. All electrical connections must be

made by a qualified electrician. Insulated gloves and shoes must be worn when connecting

input power or maintaining equipment.

Never disassemble, repair, alter or

rebuild the equipment without approval

from the manufacturer. There is a risk

for electrical shock and fire.

Electric shock can kill. Properly ground

this equipment according to its user

manual and national standard.

Make sure the supply cable is up to national standard or

local code.Use only the right gauge of electrical

wire/cable.There is a risk of fire or electrical shock if

overload building wiring-be sure power supply system is

properly sized,rated and protected to handle this unit.

Replace power cord/wire/cable immediately-bare wiring can kill.

Do not step on, twist or pull the power cord..

Frequently inspect input power cord and regularly clean the unit to

remove dust and dirt.Any worn or damaged power cord or internal

components in heavy dust may cause electrical shock, short

circuit or fire.

In the event of abnormal, operation must be immediately stopped. If smoke, smell or abnormal noise is produced by the

unit, disconnect the power cord immediately and contact your local dealer. Do not use it until the problem is fixed.

Do not operate or place the device near water or in wet locations. Risk for electrical shock or damage to the device.

Do not operate the equipment in potential hazardous areas : chemicals, oil, gas and mining, or the worksites

where power supply system is in poor condition.

Use only well-maintained device. Inspect and maintain the device for safety every 12 months, including

cleaning and removing dust. Repair or replace damaged parts/cables at once.

Follow the installation and operation instruction to ensure user safety and proper equipment

performance. It is the responsibility of the owner to ensure that the equipment has been installed and

operated as specified in the instructions provided. The manufacturer takes no responsibility for any loss

or damage suffered as a result of using the equipment incorrectly or improperly.

XImproper use of this equipment

can cause serious or fatal injury

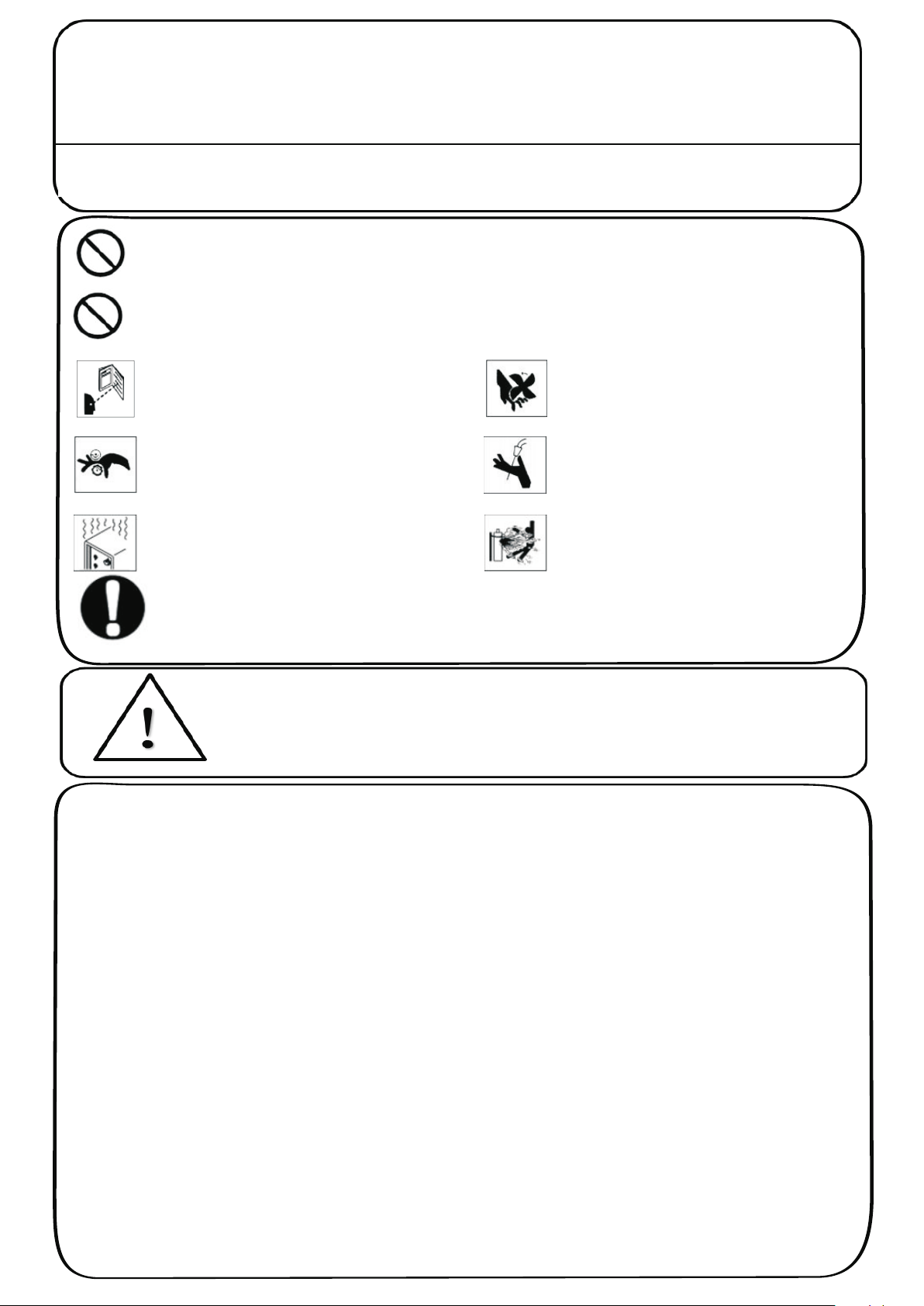

◆

◆

◆Hot parts can cause severe burns.Do not touch workpieces or metallic parts of torch with bare hands during or after

welding.Allow cooling period and use a proper tools or wear welding gloves to handle hot parts to prevent burns.