9

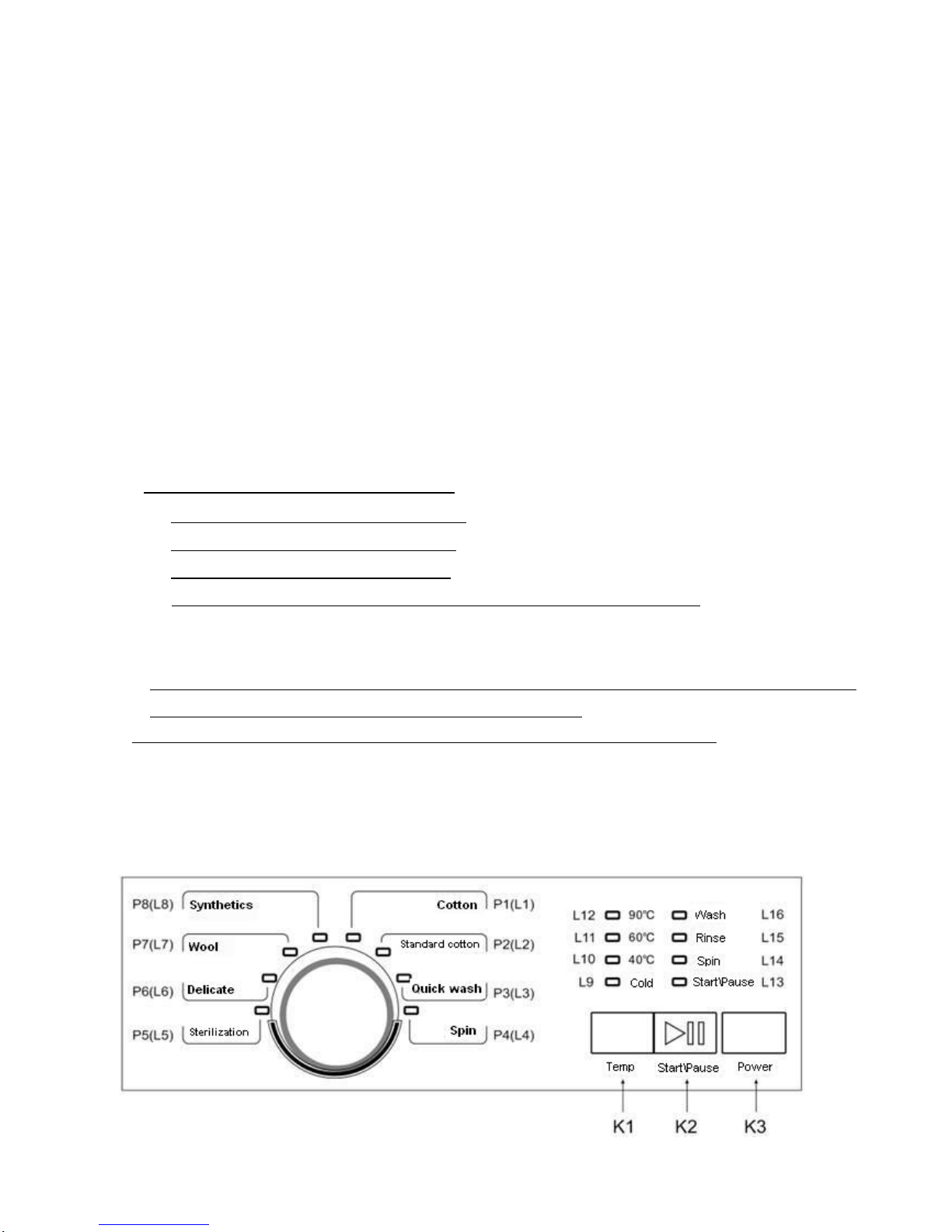

Attention:1、●—indicate the light is off;◎—indicate the light is flicking

2、when the error occurs,all LED light are flickering except indicator light on the control panel. Those indicator

lights can judge what kind of error by washing ,rinsing and drycleaning

5.2 Self-Examine Mode

Press【K1】 + 【K2】button simutaneously,after electricity ,the buzzzer will beep three times which

demonstrate the machinehas entered into the special option mode。The interface displays:the

indicator light of program option knob displays the position of current program knob,while”start\

pause”indicator light flickering at the frequency of 1Hz

Turn the progrm knob at the position of P7,press button[start\pause],the progrm enters into factory

mode to measure.All LED indicator lights flicker 3 second , then the machine starts to conduct the

following detection automaticly:

Prewashing valve detection:inflow 5 second,delay 1second;

1) Main washing detection:inflow 5 second,delay 1second

2) Soften valve detection:inflow 5 second,delay 1second

3) Heater valve detection: inflow 5 second,delay 1second

4) Heating detection:judge water level above the heating water level or not.If not,keep on addind

water to heating water level,then start to heat 5 s

5) Motor rotation direction test; the rotation rate :50 rpm,reversal time:5s

6)Outer cylinder leakage test;to judge if the water level lie in the 1 washing water,if not ,replenish to

1 washing water rotation rate (250rpm),posititive rotation 20s

7)Row of dewatering test :firstly ,drain water to the 0 water level of empty tube 10s

◆During the measurement,check the error warning,if happens in present process,the machine will

alarm at once and stop executive program

◆turn off the power and exit the mode